Company Profile - Acme Engineering Products

advertisement

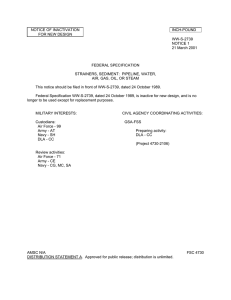

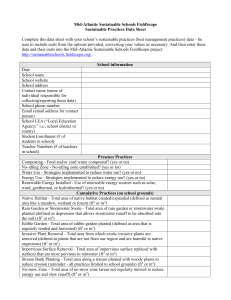

ACME – Company Profile Acme Engineering is a manufacturing company with three product lines: 1) Gas Detectors, 2) Heating Systems, and 3) Automatic Strainers. Acme possesses a wide range of custom products to meet any industrial or commercial need. The company was founded as a manufacturer's representative firm in 1956 and began large-scale production of its own Heating, Ventilation and Air Conditioning (HVAC) equipment in 1963. Our gas detection line was launched in the early 1970’s and we have been manufacturing automatic strainers since the mid 1980’s. Automatic Scraper Strainers • The ACRS Automatic Strainer is a motorized unit designed for the continuous removal of suspended solids from intake, process and wastewater flows. • Cleaning is accomplished by a spring-loaded blade and brush system managed by a fully automatic control system. Strainer Components SCRAPER MECHANISM BRUSH MOTOR ASSEMBLY BLADE VESSEL & CONTROL PANEL DPT BLOWDOWN ACTUATOR SCREEN Modes of Operation Manual Operation • When in manual operation, selector switches control the motor and blowdown operation. Automatic Operation • When in automatic operation, timers within the control panel regulate strainer operations in conjunction with differential pressure override. Relays start and stop the motor & valve. New FRP Strainers Advantages in using FRP Strainers (i) More cost effective than an all metal construction (ii) Extremely resistant to corrosive environments (iii) High impact solids resistance (iv) High-strength and high-performance design (v) Versatile and enduring construction Industrial Applications Applications for ACRS strainer include: • Process & Power Industry • Pulp & Paper • Wastewater Treatment • Metal and Mining Industries • Oil Refineries • Seawater Filtration • Cooling Systems • Chemical Processes Projects in the Middle East •2x6”, CS painted, 500micron •7x24”, FRP body, 2mm slot •2x10”, CS painted, 500micron •Monel Internals and scraper mechanism, common control panel for 7 strainers, touch screen interface, PVC vents and vales. •Rubber lined vessels, skid mounted with common control panel, Monel internals. •Strainers used for sea water cooling system at pump house. Ras Laffan Industrial City -QATAR- •Used for sea water cooling at 1200MW power plant Hadjret en Nouss -ALGERIA•1x4”, CS painted, 75micron •2x12”, FRP body, replacement vessels Skikda -ALGERIA- •1x6”, CS painted, 75micron •Designed for seawater filtration at the Skikda cogeneration plant •1x8”, CS painted, 75micron, •Special coated internals for resistance against salt water •Used for straining cooling water at several pump houses •Oversized vessels to support higher flow rate United Gulf Construction -KUWAIT-