Protective Strainers

advertisement

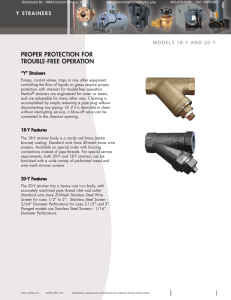

Protective Strainers Construction and Manifacturing Protective strainers are built in or welded into pipes so as to protect high-quality system parts, especially pumps, compressors and measuring devices from damage. Using protective strainers prevents processrelated waste, corrosion residues and other contaminants from penetrating into sensitive system parts. This ensures the longevity of your machines. The services provided by Voith Industrial Services with regard to protective strainers are comprehensive and supplement our broad portfolio of services in the area of on-site services and specifically in pipe construction. We ensure outstanding quality, short delivery times and a particular emphasis on implementing special customer requirements. Our Range of Services • • • • • Design and construction in collaboration with the customer Manufacturing in our workshops Documentation Non-destructive checking Installation/assembly In all activities, we observe the relevant specifications and regulations such as: • AD-2000 data sheet • ASME • DIN EN 13445 and DIN EN 13480 • DGRL 97/23/EC (within the European Union) • Customer specifications Strainer Models Screen Packs Strainer models differ in their design and thus in their implementable free screen surface. The screen surface and model are decisive for the dirt take-up capacity and pressure loss. The calculations of pressure loss are based on measurements of flow rates on test rigs. The structure of screen packs is similar in all models. A perforated plate is used as a support beam. The wire fabric is aligned towards the direction of flow. The machine width for the wire screen is chosen according to the critical particle size for the component to be protected. In order to achieve a longer service life for screen packs, in particular for protective strainers in front of gas turbines, we process the support beams (perforated plates) so that there are no welding seams in the perforated areas. Selection of the model is done in accordance with the following parameters: • Maximum permissible pressure loss • Space requirement • Strength requirement • Material requirement and material availability • Other customer requirements and specifications Material for Screen Packs • • Versions of Protective Strainers T-Y Corner or Strainer Basket Filters Strainer version with welded ends or flange connection in accordance with DIN or ANSI. The installation lengths are oriented toward DIN EN 558-1 and DIN 3202-2. The installation dimensions, nominal screen connection widths and required wall thicknesses are adapted to customer-specific conditions such as supported loads from the pipe calculation within the framework of structural possibilities. • Individual Customer Services • • • • Dome Filters Strainer version with single or double cone, with removable fabric upon request. Sealing surface: • B1/2 – C - D, EN1092-1 • RF - RTJ, ASME B16.5 Perforated plates: material 1.4571 Wire fabric: material 1.4401 Other materials on request • • • • • • Surface treatment in accordance with customer specifications Additional protective or drainage fabric Additional supports for differential pressure measurement, etc. Flange design according to customer specification Lifting eyes, pivoting mechanisms for blind flanges Shut-off device for emptying/ventilating Version with adjustable feet Materials according to customer specification within the framework of our authorizations Double jacket version (with heating jacket) Special designs Material for Protective Strainers In accordance with DIN or ASTM, the following materials are used: • Ferritic steel (P265GH, P235GH, 16Mo3, 12CrMo9 10, etc.) • Austenitic steel (1.4301, 1,4541, 1.4571, etc.) • Special materials (Hastelloy, Monel, Duplex, Titan, etc.) Voith Industrial Services GmbH Jahnstr. 25 63533 Mainhausen, Germany Tel. +49 6182 939-0 Fax +49 6182 939-105 EnPC-Services@voith.com www.voith.com/EnPC Contact Tel. Sales +49 6182 939-175 Tel. Headquarters +49 6182 939-0 Email EnPC-Services@voith.com