2501 Dallas Street

Aurora, Colorado 80010

USA

Telephone 303.340.5200

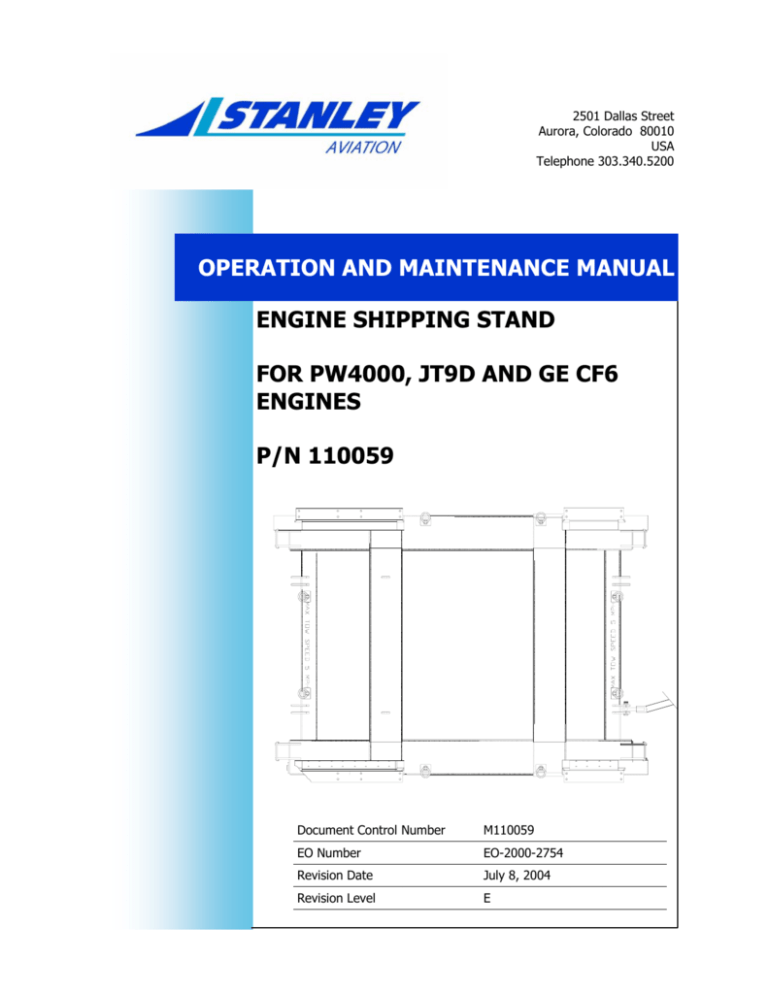

OPERATION AND MAINTENANCE MANUAL

ENGINE SHIPPING STAND

FOR PW4000, JT9D AND GE CF6

ENGINES

P/N 110059

Document Control Number

M110059

EO Number

EO-2000-2754

Revision Date

July 8, 2004

Revision Level

E

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

RECORD OF REVISIONS

EO#

REVISION

LEVEL

DATE

BY

-/NC-C

NO RECORD

2000-2552

D

MARCH 1, 1999

P. Castricone

2000-2754

E

JULY 8, 2004

P. Nemani

HIGHLIGHTS OF REVISIONS

Revision -/NC-C

No record of changes

Revision D

No record of changes

Revision E

Brought to current format, updating IPL w/latest ACAD drawings

2

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Table of Contents

Record of Revisions................................................................................................................ pg. 2

Table of Contents.................................................................................................................... pg. 3

Description ............................................................................................................................. pg. 4

Safety Considerations ............................................................................................................ pg. 5

Specifications and Capabilities ............................................................................................... pg. 5

Operation ............................................................................................................................... pg. 6

Shipping .................................................................................................................................. pg. 6

Storage ................................................................................................................................... pg. 6

Cleaning.................................................................................................................................. pg. 6

Inspection ............................................................................................................................... pg. 7

Minor repairs .......................................................................................................................... pg. 8

Major repairs .......................................................................................................................... pg. 8

Illustrated Parts List .............................................................................................................. pg. 9

110059-501,Top View ................................................................................................ pg. 10

110059-501, Port Side View ...................................................................................... pg. 11

110059-501, End View .............................................................................................. pg. 12

All rights reserved. No part of this handbook may be reproduced or transmitted in any form or by any means,

electronic or mechanical, including photocopying, recording, or by any information storage and retrieval

system, without written permission from Stanley Aviation Corporation.

3

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 1 - DESCRIPTION

This manual provides maintenance instructions and a parts list for the Stanley Aviation Engine Shipping

Stand, part numbers 110059-501, -507, -509, 601, -606, -701, and -801. This particular model facilitates air

and truck shipping of all Pratt & Whitney JT9D and 4000 engines and General Electric CF6 engines. The

stand has a 90” center-to-center rail system and ships on a standard 96” x 125” pallet.

The Engine Shipping Stand is generally used in conjunction with an engine cradle when transporting any aircraft engine. Although a cradle is designed for engine-specific applications, only the Shipping Stand is discussed in detail herein. See the appropriate Stanley Operation and Maintenance Manual for engine cradle

operation and service instructions and parts lists.

The primary difference between the different versions of the 110059 Shipping Stand is the rail size. All operations discussed herein apply to all versions of the Stanley Aviation 110059 Engine Shipping Stand.

For additional information on this or other aviation ground support applications, contact a Customer Service

Representative at the following address:

S T A N L E Y

A V I A T I O N C O R P O R A T I O N

2501 Dallas Street

Aurora, Colorado 80010 USA

303-340-5200

Fax 303-360-8965

GSE@stanleyaviation.com

4

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 2 - SAFETY CONSIDERATIONS

•

This equipment is heavy and has moving parts. Whenever such a combination exists, there is the potential for serious injury. Work carefully at all times.

•

Be alert and pay attention when using this equipment. Careless use, or a casual attitude during operation, may lead to an accident.

•

Keep your feet clear of the Shipping Stand during all operations.

•

Keep your hands clear of all pinch points on the Shipping Stand.

•

Pay attention to all warnings that are stenciled on the Shipping Stand. They are there for your safety. Do

not ignore or violate them.

•

Walk around the Shipping Stand; don't climb over it.

•

Never crawl under a Shipping Stand that is loaded.

Section 3 - SPECIFICATIONS AND CAPABILITIES

3.1

Applications

This Shipping Stand is designed specifically for transportation, ground handling, and bootstrapping of

all Pratt & Whitney JT9D and 4000 engines, as well as General Electric CF6 engines.

3.2

Dimensions

Length: -601, -606, -701 and -701 configurations are 178” (452 cm), excluding the towbar. All other

configurations are 173” (439 cm)

Width: 94” (239 cm)

Height: –509 and –701 configurations are 37” (94 cm). All other configurations are 38” (97 cm).

3.3

Capacities

The Stand is designed to hold the weight of the cradle and the compatible engines.

5

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 4 - OPERATION

For operational characteristics of the Stand-Cradle combination, i.e., for installation and removal of the engine, refer to the Cradle’s Operation and Maintenance Manual and the bootstrapping instructions provided by

the aircraft or engine manufacturer.

Section 5 - SHIPPING

The Shipping Stand may be shipped by any preferred method without special preparation. Position the Stand

casters in the normal towing position. Ground clearance is approximately 7.5” with the system empty, and

6.4” with the system loaded. The –509 and -701 configurations have approximately 1” of additional ground

clearance.

Section 6 - STORAGE

The Shipping Stand requires no special storage treatment, as it has been suitably protected from normal environmental deterioration. For long-term storage, the unit should be stored in a humidity-controlled environment.

Section 7 - CLEANING

7.1

Clean entire assembly with a mild detergent solution followed by a clear water rinse.

7.2

Dry all parts using a clean cloth or low pressure compressed air.

NOTE

DO NOT USE COMPRESSED AIR TO DRY AREAS NEAR

BEARINGS, GEARS, OR OTHER MOVING PARTS.

6

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 8 - INSPECTION

To ensure efficient and reliable operation, the Stanley Shipping Stand must be maintained through regular

preventive maintenance practices. These practices include inspection, cleaning, and lubrication. All preventive maintenance must be performed at least once every six months. The manufacturer recommends more

frequent maintenance under conditions of heavy service or extreme weather. Replace any parts that do not

meet inspection standards.

Routine inspection should include the following items:

8.1

Clean the Stand per Section 7.

8.2

Inspect all parts for dirt and signs of wear or damage.

8.3

Inspect all structural members for distortion, breaks, cracks, or other signs of damage.

8.4

Jack up the Stand, place blocks or safety stands under it, and inspect the casters:

•

Check for free-running operation and proper treadwear.

•

Check the caster bearings for excessive play or binding. The wheels should spin freely, and

there should by no lateral or axial movement.

•

Check the aft casters for brake actuation and release. Adjust as necessary.

8.5

Inspect load-bearing surfaces and the threads of all bolts for small cuts, scoring, distortion, elongation, or other signs of wear or damage.

8.6

Inspect all bolted parts for looseness and tighten as necessary.

8.7

Inspect the paint and plating for cuts or chips and repair as required per Section 9.2

7

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 9 - MINOR REPAIRS

9.1

Replace any parts that do not meet inspection requirements and cannot be repaired in the field.

9.2

Minor corrosion and other surface blemishes may be removed using crocus cloth and phosphate ester resistant paint. Unpainted parts may be protected with a thin coating of light oil.

CAUTION

DO NOT paint plated surfaces or aircraft-attaching hardware.

Section 10 - MAJOR REPAIRS

No major repair is possible in the field. This unit must be returned to the manufacturer for overhaul,

proof load testing and recertification following any major damage.

8

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 11 - ILLUSTRATED PARTS LIST

11.1

How to use this Parts List

Turn to the Assembly Figure and identify the part by location and appearance. Note the Item Number assigned to the illustrated part. Locate the Item Number in the appropriate parts list. The line

entry for that Item Number provides the, Part Number, Description, and Quantity required Per Assembly.

11.2

Units Per Assembly

Quantities specified in the Units Per Assembly column are the total number of each part required for

the indicated assembly, if the part is included in a higher-level assembly. The total quantity required

is a product of the quantities indicated at each level, up to the Top Assembly.

11.3

How to order Replacement Parts

Replacement parts and/or spare parts listed in this manual may be ordered by specifying the Top

Assembly Part Number, the Subassembly Part Number (if any), the Item Number, Description, and

the Quantity Required.

Example:

TOP ASSEMBLY

SUBASSEMBLY

P/N 215030-1 TOWBAR ASSEMBLY

ITEM 20, ADAPTER KIT

Item number

Part number

Description

Quantity Req’d/

Units Per Assembly

4

101715-75

washer

2

In the above example, there are two washers per adapter kit, and one adapter kit per towbar, so to replace

all washers on the adapter kit bolt, a quantity of 2 is specified.

Replacement and/or spare parts may be ordered from:

S T A N L E Y

A V I A T I O N C O R P O R A T I O N

2501 Dallas Street

Aurora, Colorado 80010 USA

303-340-5200

Fax 303-360-8965

GSE@stanleyaviation.com

9

9

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

S P/N 110059

Section 11 – ILLUSTRATED PARTS LIST (cont’d)

10

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

S P/N 110059

Section 11 - ILLUSTRATED PARTS LIST (cont’d)

11

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 11 – ILLUSTRATED PARTS LIST (cont’d)

S P/N 110059

12

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 11 – ILLUSTRATED PARTS LIST (cont’d)

24

24

24

24

24

24

24

20

102515-200 BOLT

18

18

18

18

18

18

18

19

102801-1

TIE DOWN RING

2

2

2

2

2

2

2

18

150096-3

FILLER

2

2

2

2

2

2

2

17

150096-1

FILLER

4

4

4

4

4

4

4

16

102489-2

DRIVE SCREW

1

1

1

1

1

1

1

15

102001-1

NAME PLATE

120

120

120

120

120

120

120

14

103109-50 LOCK WASHER

96

96

96

96

96

96

96

13

-

-

-

2

-

2

-

9

112602-1

ALUMINUM RAIL

-

2

-

-

-

-

-

8

112601-1

ALUMINUM RAIL

2

-

-

-

2

-

2

7

112603-1

ALUMINUM RAIL

12

12

12

12

12

12

12

6

2

2

2

2

2

2

2

5

150086-1

AFT LOWER MT

1

1

1

1

1

1

1

4

150093-1

AFT UPPER MT LEFT

1

1

1

1

1

1

1

3

150092-1

FWD UPPER MT LEFT

2

2

2

2

2

2

2

2

150081-1

FWD LOWER MT

1

1

1

1

1

1

1

1

150300-1

BASE WELDMENT

101895-125 BOLT

110407-104 SHOCK MT

110059

-501

-507

-509

-601

-606

QUANTITY REQUIRED

-701

-801

ITEM

NO.

PART NO.

STANDARD ASSEMBLY

DESCRIPTION

13

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 11 – ILLUSTRATED PARTS LIST (cont’d)

6

6

6

6

6

6

6

41

102892-1

-

-

(4)

-

-

(4)

-

40

110059-40 SPACER

2

2

2

2

2

2

-

38

101872-100 CASTLE NUT

2

2

2

2

2

2

-

37

1

1

1

1

1

1

-

36

16

16

16

16

16

16

-

35

101897-250 BOLT

32

32

32

32

32

32

-

34

101715-62 FLAT WASHER

16

16

16

16

16

16

-

33

101876-62 LOCK NUT

4

4

4

4

4

4

-

32

101899-725 BOLT

4

4

4

4

4

4

-

31

101876-88 CASTLE NUT

4

4

4

4

4

4

-

30

101715-88 FLAT WASHER

4

4

4

4

4

4

-

29

110120-14-6 T-HANDLE PIN

2

2

2

2

2

2

-

28

103846-4

CASTER W/ BRAKE

2

2

2

2

2

2

-

27

103846-3

CASTER W/O BRAKE

4

4

(4)

4

4

(4)

-

26

110100-2

CASTER CARRIER

2

2

2

2

2

2

2

25

110397-41 AFT RAIL PLATE

2

2

2

2

2

2

2

24

110397-40 FWD RAIL PLATE

-501

-507

-509

-601

-606

-701

-801

ITEM

NO.

QUANTITY REQUIRED

SAFETY PIN

101905-450D BOLT

110087-1

PART NO.

TOW BAR

DESCRIPTION

14

STANLEY AVIATION CORPORATION

Operation and Maintenance Manual

ENGINE SHIPPING STAND P/N 110059

Section 11 – ILLUSTRATED PARTS LIST (cont’d)

2

2

2

2

2

2

2

69

150082-7

SPACER

2

2

2

2

2

2

2

68

150082-5

SPACER

-

-

4

-

-

4

-

67

110100-27 CASTER CARRIER

8

8

8

8

8

8

8

66

110100-5

BRACKET

1

1

1

1

1

1

1

58

150093-2

AFT UPPER MT RIGHT

1

1

1

1

1

1

1

57

150092-2

FWD UPPER MT RIGHT

-

-

(16)

-

-

(16)

-

50

-

-

1

-

-

-

-

49

-

-

2

-

-

-

-

48

-

-

2

-

-

-

-

46

112605-1

4

4

4

4

4

4

4

45

100059-27 SPRING PIN

4

4

4

4

4

4

4

44

100048-15 SPRING

4

4

4

4

4

4

4

43

112604-1

6

6

6

6

6

6

6

42

101809-09 LANYARD

-501

-507

-509

-601

-606

-701

-801

ITEM

NO.

QUANTITY REQUIRED

101897-350 BOLT

111551-1

BUMPER

104036-125 BOLT

PART NO.

ALUMINUM RAIL

STOP PIN

DESCRIPTION

15