Spacer Fabrics Utilized in Active Wear

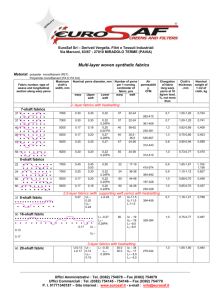

advertisement

Spacer Fabrics Utilized in Active Wear TT553-Formation and Structure of Woven and Knitted Fabrics Spring 2009 Dr. Seyam 04/15/2009 Jennifer Woodson Introduction Currently, spacer fabrics, also referred to as 3D fabrics, are being utilized in a myriad of applications varying from mattresses to seat cushions to automotive applications to activewear to extreme sporting apparel to intimate wear. Spacer fabrics have several attributes that make them ideal for a variety of uses including strength, insulation, breathability, and durability. In this paper the utilization of spacer fabrics in activewear will be investigated and discussed. Currently, research in this area is limited; therefore recommendations will be made in regard to where future research can be conducted throughout this paper. What are Spacer Fabrics Spacer fabrics (Figure 1) are knitted fabrics that have two, usually warp-knitted, faces and a pile, of varying thickness, between the two faces. Although spacer fabrics are more commonly found as warp knits they can also be produced as weft knits. Each face, and the spacer section, of spacer fabrics are knit from different yarns (Reisfeld, 2002). A method of production, which has been greatly utilized in the upholstery and automotive markets, is to cut down the middle of the spacer portion (across the width) of a spacer fabric; this is how many common pile fabrics, such as velvet, are produced. It was not until the 1980s that spacer fabrics began to receive recognition for their superior properties, and thus expanded into other markets, such as athletic apparel and outerwear (Reisfeld, 2002). Figure 1: Spacer fabrics of varying thicknesses Source: Fisher, G. (2003). Knitters establish technical niches. Knitting International, 110(1304), 34. Why are Spacer Fabrics Important Spacer fabrics are currently being used to replace such fabrics as polyurethane, neoprene, and other foam type products that are generally laminated, and utilized in end products that require flexible or bulky type characteristics in order to achieve the desirable outcomes. Spacer fabrics have properties such as breathability and thermal regulation that are far superior to that of foam and foam type products. The end uses generally require that these materials are able to withstand the test of time in regard to constant compression (Anand, 2003). Examples of Woodson Page 2 instances where these textiles are utilized include, but are not limited to, seat cushions, mattresses, geotextiles, bras, activewear, and outerwear. The foams used in these applications are usually flammable, and are considered to be rather uncomfortable due to the lack of breathability. Foams also tend to degrade and deform over time with continued use, and cannot withstand continuous home laundering. In contrast, spacer fabrics are recyclable, which makes them much more environmentally friendly than foam. Spacer fabrics also breathe well, have lower moisture absorption, and have superior compression and recovery properties to that of foams, and can withstand continued home launderings. Types of Spacer Fabrics: Construction 3-D spacer fabrics that are constructed with a warp knitting machine have two fabric faces that are produced separately, and are usually about 0.4mm to 1 mm thick. The two faces are joined via the spacer yarns which, with machine adjustments, can join the two faces directly or create a space of varying width ranging typically from 1mm to 15mm thick, though significantly larger thicknesses (i.e. 60mm) are possible (Anand, 2003). The two faces can be constructed differently, for example one side having a rib structure, or the two faces can have the same structure. Also, the face fabrics can have different elasticity ratings, can have a solid or net structure, and can have different textures than one another. Channels can be formed between the faces for the insertion of tubes, wires, or heating elements depending on the application. In regard to fibers, any fiber type can be utilized to produce spacer fabrics, though it will be the end use that dictates what fiber is necessary. A yarn utilized in the spacer area that is of a higher count will provide more stability to the fabric, whereas a fabric that utilizes yarns of a finer count will be more pliable, but less stable (Spacer fabrics for medical applications, 1998). Theoretically, the front face, back face, and pile yarns can all be composed of different fibers/ yarns. Monofilament yarns can offer greater fabric stability or stiffness, although this attribute may not be necessary or desired is some applications. When looking at the knitting machinery (Figures 2 & 3), guide bars 1 and 2 utilize the front needle bar and produce one face of the fabric. Guide bars 5 and 6 utilize the back needle and produce the other face fabric. Guide bars 3 and 4 carry the spacer yarn which knits, with both needles, on both faces of the fabric. It is the distance between the two needle bars that will determine the thickness of the final fabric (Roye, Gries, 2006; Anand, 2003). Woodson Page 3 Figure 2: Schematic view of warp knitted spacer Figure 3: Structure of warp knitted spacer fabrics fabric Source: Roye, A. (2004). Spacer fabrics for thin Source: Anand, S. C. (2003). Proceedings walled concrete elements. from ISTEK 2003: Recent advances in knitting technology and knitted structures for technical textiles applications. Spacer fabrics can also be produced on a circular double jersey machine or on a flat machine that is controlled electronically so as to produce weft knitted spacer fabrics (Figure 4). Producing fabric on the circular knitting machine allows for short runs to be economically produced, which is ideal for fashion items (Kunde, 2004). Fabrics produced in this way tend to be denser, and thus heavier, than warp knitted spacer fabrics. In regard to appearance, spacer fabrics can be constructed in a many ways with varying fibers being utilized; different elongation and stretch properties, and even different patterns can be produced on the face fabric with the use of a piezo jacquard mechanism (Karl Mayer machines). This mechanism will allow for the production of jacquard patterns on the face sides of spacer fabrics (Figure 5 a & b) (Anand, 2003). Woodson Page 4 Figure 4: Weft knitted spacer fabric Source: Anand, S. Spacers—at the technical frontier. (2003). Knitting International, 110(1305), 39 Figure 5 a & b: Jacquard face spacer fabrics Source a: http://www.anhuisilk.cn/sandwich.htm Source b: http://www.inteletex.com/FeatureDetail.asp?NewsId=3417 . Woodson Page 5 According to Anand (Anand, 2003), “an ideal ‘dynamic’ or ‘responsive’ fabric is a combination of a) the right combination of fibers; b) using the right fabric structure; and c) using the right chemicals or finishes on the fabric.” Spacer fabrics are ideal for activewear in that they excel in their breathability, wicking, and insulation capabilities (Figure 6). Spacer fabrics will not degrade in any way during home laundering, and exhibit the ability to release soil easily during laundering, and detergents can be easily rinsed off. These characteristics are ideal for the average consumer’s lifestyle as there are no special laundering requirements. Figure 6: Flow of air and moisture through a spacer fabric Source: Breathing room. (2002). Retrieved from http://www.inteletex.com/FeatureDetail.asp?PubID=27&NewsId=191. Fiber selection is very important when determining the comfort level of the wearer, and optimizing the beneficial properties noted above. For example, if cellulosic fibers, which are hydrophilic, are utilized in the face of the fabric touching the skin, the fibers will hold moisture and will not wick it away quickly, heat transport will then be inhibited, thus leaving the wearer damp and uncomfortable. As spacer fabrics have endless options in regard to potential fiber usage, one option is to use a synthetic fiber on the face side touching the skin, this will aid in pulling moisture away from the skin. A fiber that conducts moisture can act as a diffuser and thus be used as the pile, and a natural fiber can be utilized as the face not touching the skin, which will help bring the moisture to the surface of the fabric and allow it to evaporate (Önal, 2004). This fiber configuration will help maintain the body’s microclimate whilst the wearer is physically active and exerting energy. While fiber selection is important, how the fibers are actually utilized is another important consideration. Research at the University of Leeds found that by hydroentangling a thin layer of wool on one side of a spacer fabric, the thermal conductivity of the fabric is reduced and the thermal resistance is increased (Mao & Russell, 2007). This novel fiber configuration would keep the wearer warmer by blocking the small holes in the face of the knit fabric. Blocking these apertures may inhibit the inherent breathability characteristics of spacer fabrics, and thus may deter one from purchasing a garment made from the fabric. Further research in regard to comfort and breathability is necessary to determine the perceived consumer value of such a fabric. Woodson Page 6 Exploring Spacer Fabrics in Activewear Spacer fabrics can be utilized in a variety of athletic activities such as SCUBA diving, skiing, and snowboarding. Found in jackets, shoes, and protective accessories such as helmets and knee pads, spacer fabrics offer thermal insulation, impact protection, and breathability in the application in which they are utilized. Sports and other activities where spacer fabrics may be useful include: skiing, snowboarding, SCUBA diving, surfing, angling, cricket, cycling, hockey, rugby, trekking, equestrian, roller/ ice skating, and paddle sports (i.e. Kayaking, Whitewater Rafting). This is by no means an exhaustive list, as there are many other activities where spacer fabrics can be utilized. Desirable Properties in Activewear The comfort of a garment is not just determined by how it feels while being worn (sensorial comfort), but psychological comfort—or thermophysiological comfort. This is the thermoregulation and moisture management provided by the garment/ fabric which aims to keep the body’s temperature and moisture output, as close as possible to the normal level regardless of the person’s current physical activity or the current weather conditions. How the garment actually fits on the body must also be considered in order to determine overall garment comfort. While each segment of the active apparel industry has different needs or requirements in regard to comfort, several of the most important factors, that should be considered when determining garment comfort for athletic apparel, include: Waterproof / water resistant, breathability, moisture wicking, windproof, odor control, warmth / insulation, light weight, fashionable, tactile qualities, abrasion resistance, anti-static, protection, versatility, non-constrictive/ freedom of movement/ does not inhibit vision, and durability. Spacer Fabric Properties that Correspond to Desirable Properties in Activewear The Need for Spacer Fabrics in Activewear When a person is exerting energy during physical activity, it is important that the microclimate, the climate around the person’s body, stay constant. Spacer fabrics, in the pile portion of the fabric, have the inherent ability to trap and hold air, and therefore insulate the body. This, along with the ability to wick away moisture, maintains the body’s microclimate, and thus keeps the person dry and comfortable. There are many outdoor/ active apparel manufacturers who still employ the layering concept in order to achieve all the desirable properties in active apparel. According to Canadian Apparel Magazine (Building performance into outdoor wear, 2002) the outermost layer should protect the wearer from environmental elements such as wind, rain, or snow, the middle layer should provide the wearer with warmth, and the innermost layer should have an insulating factor and have the capabilities to wick moisture away from the skin; it is also noted that all layers should be breathable and should have wicking capabilities in order to provide the most comfort to the wearer (Building performance into outdoor wear, 2002). Three layers of outerwear could create a bulky, cumbersome outfit. Spacer fabrics can accomplish all of these desirable characteristics in one garment, instead of three. Woodson Page 7 The thermal insulation properties of both warp and weft knit spacer fabrics are excellent when being considered for activewear. A lower density in the pile yarns of the spacer fabrics will yield a higher thermal resistance which is ideal for activewear fabrics as it will keep the wearer warm (Pause, 2002). Warp knitted spacer fabrics tend to have a higher thermal insulation value than weft knitted spacer fabrics regardless to whether the fabric is wet or dry, an important feature for those who may utilize this fabric in the snow. Warp knitted spacer fabrics also have a higher thermal absorptivity value than weft knitted spacer fabrics, and thus the warp knitted will be warmer to touch than weft knitted (Anand, 2003). Yip and Ng found that warp knit spacer fabrics have a lower thermal conductivity rating than the weft knit fabric, which means the excess heat from the body would not be as quickly transferred if a warp knit spacer fabric is being utilized than if a weft knit fabric is to be utilized (Yip & Ng, 2008). Spacer fabrics that have a rib construction, and are flocked during the finishing process, have shown to provide better insulation, and better heat and moisture transference, both of which will help maintain the body’s microclimate (Krel, et al., 2005). The ribs of the face fabrics are what actually aid in the movement of heat and moisture; the channels created by ribbed fabric faces thus are better suited to control the microclimate and keep the wearer cool and dry. In regard to the water vapor permeability properties of spacer fabrics, weft knitted spacer fabrics have been found to have better evaporative heat loss properties and water vapor permeability properties than warp knitted spacer fabrics, thus making the weft knit more comfortable when worn close to the skin of a person who is exerting energy and perspiring (Anand, 2003). When choosing a fiber type to aid in microclimate regulation, viscose can absorb the perspiration of the wearer “and delay the moment at which the air in the spacer zone becomes saturated with moisture” (Machova, Hoffmann, & Cherif, 2007). This means that a person who is perspiring heavily, or has varying perspiration levels with high peaks, will remain drier for a longer period of time, and have a more level microclimate, if wearing a garment utilizing spacer fabrics with a viscose inserted weft yarn. An inserted weft yarn, that is hydrophobic, will maintain the body’s microclimate more effectively than an inserted weft yarn that is hydrophilic because the hydrophilic yarn will hold the moisture and inhibit it from being transported away from the body (Machova, Hoffmann, & Cherif, 2006). Air permeability is another important factor that should be taken into account when choosing fabrics for activewear. In this regard, weft knitted spacer fabrics have significantly better air permeability ratings, and are thus more able to resist air penetration, than the warp knit fabric (Yip & Ng, 2008). Although, it should be noted that the density of the fabric, regardless of whether it is a warp knit or a weft knit will have a substantial impact on the air permeability and thermal regulation properties. A spacer fabric that is quite dense will have a higher thermal conductivity value, but a low air permeability value; therefore end use must be taken into consideration to find an optimum density for the fabric. In regard to breathability, moisture wicking, and insulation of spacer fabrics, research at the Institute for Textile and Clothing Technology at the Hohenstein Institutes was conducted in regard to the insertion of a hydrophilic weft yarn on the face of the spacer fabric that is closest to the body, and its effect on the body’s microclimate. Using a spacer fabric made of polyester (PES), monofilament for the pile and multifilament for the faces, and various inserted weft yarns, which accounted for about 5% of the total fabric, in the face of the fabric closest to the body, which also had a ribbed construction Machova, Hoffmann, and Cherif found that the inserted Woodson Page 8 weft yarns increased the density of the fabric, and thus lowered the air permeability. It was also found that viscose weft yarns increase heat transport by 14.2% when compared to spacer fabrics without inserted weft yarns. The inserted weft yarn, while increasing the thermal insulation properties of the fabric, also can increase the dimension stability of the fabric (Reisfeld, 2002). Another, not commonly realized, important factor of spacer fabrics for certain types of activewear is compressibility. Many outdoor activities of athletes are seasonal (i.e. skiing), therefore during the off-season it is likely that the garments are stored away in containers, or other means, where they under a heavy load. During the in season, these garments are packed in suitcases for traveling. The athlete or outdoor enthusiast expects the garments to not be distorted in any way when they are removed from storage, as they should be ready to be utilized for the new season. Spacer fabrics are very resilient and will resist and recover from pressure that may be applied on them (Figure 7), thus deformation is not a problem in apparel made using spacer fabrics and this may increase the life of the garment. Compression properties of spacer fabrics are highly reliant on the how thick the actual fabric is and how the spacer yarns are oriented within the fabric. The actual compression resistance can be controlled via the machinery and the fibers/ yarns being utilized (Anand, 2003). When spacer yarns are positioned in a “V” shape between the two fabric faces, the final fabric will have better compression resilience than if the spacer yarns are perpendicular to the fabric faces (Yip & Ng, 2008). When the angle of the spacer yarns are set at a larger angle, θ (all other variables constant), they are better able to resist compression than fabrics with spacer yarns set at a smaller angle (Figure 8).The actual angle of the spacer yarn in the fabric can be calculated with the following formula (Yip & Ng, 2008): Where: L= thickness of spacer fabric W= segment width Since the compression capabilities of a spacer fabric are largely determined by the structure of the spacer area, when considering the compression properties of spacer fabrics that utilize a monofilament as the spacer yarn will have slightly better compression and recovery capabilities than those that utilize multifilament spacer yarns (Yip & Ng, 2008). Yip and Ng (Yip & Ng, 2008) found the bending rigidity of the fabric to be dependent on how the fabric is constructed. For example, warp knitted fabrics have better bending rigidity in the warp direction and vice versa. Fabric density will also affect the bending rigidity of the final fabric (Yip & Ng, 2008). The ability for a spacer fabric to stretch is directly related to how the fabric is constructed, either as a warp knit or a weft knit. Therefore, the ability of the fabric to stretch will depend on how well the warp or weft knit face fabrics stretch, and the stretchability of the fiber/ yarn type, as multifilament yarns will be able to stretch more than monofilament yarns (Yip & Ng, 2008). Woodson Page 9 Figure 7: Compression of spacer fabrics Source: Anand, S. C. (2003). Proceedings from ISTEK 2003: Recent advances in knitting technology and knitted structures for technical textiles applications. Warp Knit Θ=52.33° Weft Knit Θ=79.49° Weft Knit Θ=78.07° Weft Knit Θ=63.43° Weft Knit Θ=61.08° Figure 8: Various spacer fabric construction, fiber/ yarn types, and views Source: Yip, J., & Ng, S. (2008). Study of three-dimensional spacer fabrics: Physical and mechanical properties. Journal of Materials Processing Technology, 206(1-3), 359. Woodson Page 10 Comparing Conventional Activewear Fabrics to Spacer Fabrics A study conducted by Anand (Anand, 2003), using 100% polyester yarns in both warp and weft knitted spacer fabric samples, provides insight into the different properties of warp knit spacer fabrics and weft knit spacer fabrics (actual values in Appendix I). The warp knitted and weft knitted spacer fabrics were found to have significantly better tenacity, breaking extension, and initial modulus than current technical fabrics used today. Although the weft knitted fabrics will not lose as much heat as the warp knitted fabrics, they are not as well able to absorb and wick away moisture as the warp knitted spacer fabrics. This could be due partly to warp knitted spacer fabrics having more bulk than weft knitted spacer fabrics. This aspect is very important in regard to comfort of the wearer, as it will affect the how well the body’s microclimate is maintained, and is thus directly related to wearer comfort. Figure 9 provides a concise comparison of the properties of warp and weft knitted spacer fabrics. When compared to Sportwool™, a fabric utilized in athletic uniforms, spacer fabrics have notable superior qualities in regard to thermal insulation, thermal absorptivity, and moisture wicking. The Sportwool™ fabric performed better than the spacer fabrics in regard to evaporative heat loss and water vapor permeability, these are two very important properties to consider when taking comfort into account. The Sportwool™, will allow a wearer to feel cooler and drier than either of the spacer fabrics, when participating in high energy sports, such as soccer, where the wearer will likely perspire a great deal. All three fabrics had similar moisture absorption properties. Figure 9 provides a comparison of all three fabrics (warp knitted, weft knitted, and Sportwool™). Property Superior Fabric Superior Fabric (Warp or Weft knit) (Warp Knit, Weft Knit, or Sportwool™) Thermal Insulation Warp Warp or Weft Thermal Absorptivity Warp Warp or Weft Evaporative Heat Loss Weft Sportwool™ Water Vapor Permeability Weft Sportwool™ Moisture Absorption Warp All Are Similar Moisture Wicking Warp Warp Figure 9: Comparison of the properties of warp and weft knitted spacer fabrics When compared to fleece, which is commonly used as a base insulation layer, spacer fabrics have significantly better wicking capabilities, a vital property when considering a garment for activewear (Schubert, Umbach, Bartels, 2004, Spink, 2003). When taking into account the various humidities that an athlete may encounter during regular activity, the spacer fabrics will perform better (keeping the wearer cooler or warmer and drier) than the currently employed three layer system which utilizes fleece as a thermal insulating layer (Spink, 2003). In regard to thermal insulation, the fleece performed better than a spacer fabric of the same weight (Schubert, Umbach, Bartels, 2004). Woodson Page 11 Current Uses of Spacer Fabrics in Activewear Spacer fabrics are currently being utilized in many applications associated with sports and other physically exerting activities. Gloves, elbow pads, and knee pads, for any activity that requires them, utilize spacer fabrics to act as shock absorbers should the wearer fall or incur another type of impact. By absorbing the impact, the person is less likely to incur serious injuries such as broken, or fractured, bones. Gloves, and other apparel and accessories for sports have been developed to allow for full wrist movement, yet are rigid enough on one side to be able to sustain an impact. Also, since spacer fabrics have superior breathability and thermal insulation properties the gloves and other apparel will be comfortable to wear, regardless of the activity (Fun with winter sports and innovative warp-knitted fabrics, 2003). Spacer fabrics can also be incorporated into specific areas of a garment or accessory. For example, helmets can incorporate spacer fabrics in the critical zones including the ear, neck, and crown areas thus practically eliminating potential injuries in the case of an accident (Fun with winter sports and innovative warp-knitted fabrics, 2003). With conventional diving suits (SCUBA diving), which are made from neoprene, the mobility of the diver can be inhibited, and the protection from cold water temperatures is limited (Spacer fabrics for diving suits, 1998). When a new diving suit, constructed from a warp knitted spacer fabric, was utilized by test divers (Appendix III), the temperature regulation, as noted by the test subjects was superior to that of conventional neoprene; this was especially true for long dives, to great depths. This is due to the spacer fabric having an area where air can move freely and thus keep the wearer warmer for a longer period of time. The new suit is about one fifth less dense, and only one fifth the weight of the neoprene suits (Spacer fabrics for diving suits, 1998). Dow Corning Corporation® recently developed an “Active Protection System” (APS) that is replacing the current hard surfaced protection accessories and apparel with a spacer fabric that has been infused with a dilatant silicone. This not only makes the fabric softer and more flexible, but also turns the spacer fabric into “body armor” (Rodie, 2006). Upon impact, the silicone, which is normally quite flexible, becomes instantly hard and the energy from the impact is dispersed into the surrounding spacer yarns (Figure 10) (Rodie, 2006). Multiple layers of the APS fabric will increase the protection of the wearer, and can be strategically placed in the garment, such as on the back and shoulders (Figure 11). The fabric, which has been originally formulated with motorcycle riders as the ultimate consumer, could definitely be carried into other sports, such as skiing, soccer, and football, where high impact collisions are a real possibility. Snowboarders, for example, may fall or slide down the side of a mountain during an accident, and could incur friction burns, and other, more serious injuries (Anon, 1995). It is in such an instance, protective clothing that also offers warmth and moisture wicking, such as the APS described, is necessary. Having all of the above noted characteristics of spacer fabrics, this new form of protection will also have a longer lifespan than traditional, hard body-armor. It also has simple laundering needs, which makes it more attractive to potential consumers. The APS fabric system exceeds European standards and significantly better in regard to absorbing impact than tradition hard-shell protective accessories (Dow Corning, 2007, Budden, 2006). Woodson Page 12 Figure 10: Schematic of how the APS fabric absorbs impact Figure 11: Cross-section of APS fabric Source: Dow Corning. (2007). Superior defense and comfort for high-performance apparel and accessories NEW Dow Corning® active protection system. Figure 12: Example of how multiple layers of APS fabric can be strategically placed in a garment to provide ultimate protection. Source: Dow Corning. (2007). Superior defense and comfort for high-performance apparel and accessories NEW Dow Corning® active protection system. Woodson Page 13 Potential Uses of Spacer Fabrics Layering is considered to be “a key element” for one who is attempting to dress comfortably and appropriately for sports that involve snow such as skiing or snowboarding (Performance apparel for skiing and snowboarding, 2005). Layering is utilized so that as the wearer can adjust to changes in the weather, or his/her level of physical exertion. “An efficient layering system consists of three elements: a base layer for moisture management, a middle layer for warmth and insulation, and an outer layer for weather protection” (Performance apparel for skiing and snowboarding, 2005). With the use of spacer fabrics, these layers can be effectively eliminated, or at least minimized providing the wearer with more range of movement due to the decrease in bulk. Currently, jackets utilized for winter sports can be designated as having a hard shell or a soft shell. Hard shell jackets are designed to protect the wearer from the elements encountered during sporting (i.e. wind, water) while also having a breathability factor. Soft shell jackets are designed to be comfortable by wicking moisture away from the wearer’s body and provide insulation. The soft shell jackets are generally made from fleece while a hard shell could be made from materials such as Gore-Tex. (Performance apparel for skiing and snowboarding, 2005). Again, spacer fabrics can provide the protection from both the elements and impact, which would eliminate the need for hard or soft shell jackets. Ski pants and gloves are generally designed to be both waterproof and breathable on the outside with an inside layer that provides moisture wicking and insulation. Those who participate in winter sports may or may not utilize a base layer with their ski/ snowboarding pants (Performance apparel for skiing and snowboarding, 2005). A spacer fabric can completely eliminate the need for the different layers. Abrasion resistance is also a coveted attribute for these items. Headwear for those participating in winter sports ranges from hats to actual helmets. A lightweight helmet that is both durable and comfortable is important. Many companies currently use down, or a down alternative, to provide the warmth necessary when participating in winter sports (Performance apparel for skiing and snowboarding, 2005). Down feathers utilized in commercial applications have no oil on them which encourages water absorption, therefore when the feathers become wet, they tend to stick together and their thermal insulation properties are greatly reduced—this would be a common occurrence for those participating in sports, as moisture from the body or from the outside environment will likely be encountered (Bonser & Dawson, 1999). Research from Gao, Yu, and Pan (Gao, Yu, & Pan, 2007) show down feathers to be superior insulators to polyester, wool, and cotton (Figure 13). Though, it should be noted that the research was conducted on virgin down, and thus the oils, which improve many of down feather’s properties, had not been removed. Down is, by far the bulkiest material at 349.65 cm3/ g (polyester had a bulk rating of 87.11cm3/g), and while it did have notable compression and recovery values (Figure14), the bulky physical aspect of down feathers must be taken into account (Gao, Yu, & Pan, 2007). Down alternatives, such as Primaloft®, which can provide insulation even when wet, do not provide insulation to the degree that spacer fabrics are able to. Further research making direct comparisons between down feathers utilized for mass market consumer products and spacer fabrics should be conducted. Factors such as compression, recovery, thermal regulation, comfort, degradation, and moisture regain should be considered. Woodson Page 14 Figure 13: Thermal conductivity of wool, down, cotton, and polyester Source: Gao, J., Yu, W., & Pan, N. (2007). Structures and properties of the goose down as a material for thermal insulation. Textile Research Journal, 77(8), 617. Figure 14: Compression (top) and recovery (bottom) characteristics of wool, down, cotton, and polyester. Source: Gao, J., Yu, W., & Pan, N. (2007). Structures and properties of the goose down as a material for thermal insulation. Textile Research Journal, 77(8), 617. Woodson Page 15 Conclusion Although spacer fabrics have many superior properties when compared to other fabrics for outdoor or athletic wear, they are moving into this particular market rather slowly. Spacer fabrics can, with just one layer, keep an athlete warm or cool, depending on the environment, and dry. Maintaining the body’s microclimate is of the utmost importance for any activewear garment, and while spacer fabrics may not always be the absolute best thermal insulators, as when compared to fleece, their overall ability to maintain the microclimate is superior to that of other fabrics. There is still a great deal of research that is necessary to further prove the superiority of spacer fabrics. Comparative research regarding comfort, cost, lifespan, durability, care, actual warmth, and deformation should be conducted. From the current research one can see that spacer fabrics are not only better for the environment, but also consumer friendly in regard to their easy care, decreased bulk, and potentially increased protection from environmental elements and accidents. Woodson Page 16 References Anand, S. C. (2003). Proceedings from ISTEK 2003: Recent advances in knitting technology and knitted structures for technical textiles applications. Anand, S. Spacers—at the technical frontier. (2003). Knitting International, 110(1305), 38-41. Anand, S. (2003). Technical overview. Knitting International, 110(1304), 49. Anon. (1995). Softer landings. Bonser, R.H.C, Dawson, C. (1999). The structural mechanical properties of down feathers and biomimicking natural insulation materials. Journal of Materials Science Letters, 18, 17691770. Breathing room. (2002). Retrieved from http://www.inteletex.com/FeatureDetail.asp?PubID=27&NewsId=191. Budden, G. (2006). Defense and comfort: new advancement in impact-protection textiles. Technical Textile Technology. Building performance into outdoor wear. (2002). Canadian Apparel, 26(2), 10. Dow Corning. (2007). Superior defense and comfort for high-performance apparel and accessories NEW Dow Corning® active protection system. Fisher, G. (2003). Knitters establish technical niches. Knitting International, 110(1304), 32-34. Fun with winter sports and innovative warp-knitted fabrics—two things that go together well. (2003). Kettenwirk Praxis, (1), 4. Gao, J., Yu, W., & Pan, N. (2007). Structures and properties of the goose down as a material for thermal insulation. Textile Research Journal, 77(8), 617. Greenwood, B. (2003). Up the creek with the right apparel. World Sports Activewear, 9(1), 46. Krel, V., Hoffmann, G., Offermann, P., Machova, K., & Hes, L. (2005). Spacer fabrics for sports clothing with improved comfort. Melliand Textilberichte, 86(5), E73. Kunde, K. (2004). Spacer fabrics - their application and future opportunities. Melliand International, 10(4), 284. Machova, K., Hoffmann, G., & Cherif, C. (2006). Micro-climate regulation of clothing systems with warp knitted spacer fabrics. Melliand Textilberichte Internat Textile Reports German Incl Yellow Engl Tra, 87(11-12) Woodson Page 17 Machova, K., Hoffmann, G., & Cherif, C. (2007). 3-D warp-knitted fabrics with inserted weft yarns improve comfort. Kettenwirk Praxis, (1), 32. Mao, N., & Russell, S. (2007). The thermal insulation properties of spacer fabrics with a mechanically integrated wool fiber surface. Textile Research Journal, 77(12), 914. Önal, L. (2004). Proceedings from International Istanbul Textile Congress: Structure and applications of 3D knitted spacer fabrics. Pause, B. (2002). Studies of the thermo-physiological comfort provided by knitted spacer fabrics. Melliand International, 8(1), 57. Performance apparel for skiing and snowboarding: Making a more comfortable and safer experience.(2005). Performance Apparel Markets, (15), 20. Reisfeld, A. (2002). Outer limits. Knit Americas, 64. Rodie, J. B. (2006). Protection on demand. Textile World, 156(4), 66-66. Retrieved from http://search.ebscohost.com.www.lib.ncsu.edu:2048/login.aspx?direct=true&db=tdh&AN=2 2066220&site=ehost-live&scope=site Roye, A. (2004). Spacer fabrics for thin walled concrete elements. Roye, A., & Gries, T. (2006). Spacer textiles in a resin coat – a textile tit-bit for specialists in FRC. Kettenwirk Praxis, (2), 21. Schubert, M., Umbach, K. & Bartels, V. (2004). Simple on the outside, functional on the inside – a clothing system with hidden depths. Kettenwirk Praxis, (4), 4. Simplex and ultrafine spacer fabrics.(1999). Kettenwirk Praxis, 33(2/99), 15. Spacer fabrics for diving suits. (1998). Kettenwirk Praxis, 32(4), 57. Spacer fabrics for medical applications.(1998). Kettenwirk Praxis, 32(4), 51. Spacer fabrics in clothing.(2006). Kettenwirk Praxis, (2), 7. Spink, A. (2003). Totally spaced out. World Sports Activewear, 9(1), 26. Weiser, M., Schmutzler, T., & Mohring, U. (2004). Spacer fabrics show their best side Kettenwirk Praxis, (4), 19. Yip, J., & Ng, S. (2008). Study of three-dimensional spacer fabrics:: Physical and mechanical properties. Journal of Materials Processing Technology, 206(1-3), 359. Woodson Page 18 Appendix Woodson Page 19 Appendix I: Comparison of Properties of Warp and Weft Knitted Spacer Material Comparison of Properties of Warp and Weft Knitted Spacer Material Yarn used: 100% polyester in both cases Dimensional Properties Warp Knitted Weft Knitted Spacer Fabric Spacer Fabric Area Density (g/ m-2) 417.2 431.8 Thickness (mm) 2.9 2 -3 Bulk Density (g/ cm ) 0.143 0.215 Tensile Properties Tenacity (Ntex-1) Course Direction Wale Direction 45° Direction Breaking Extension (%) Course Direction Wale Direction 45° Direction Modulus (Ntex-1) Course Direction Wale Direction 45° Direction 0.038 0.037 0.033 0.031 0.031 0.032 185.53 137.96 167.66 142.1 153.3 132.2 1.85 1.37 1.67 1.41 1.53 1.31 Comfort Properties Alambeta Thermal Resistance (W-1Km2)*10-3 Dry 63.42 38 Wet 0.5ml 24.9 15.1 Wet 1ml 23.8 10..2 Thermal Absorptivity (Wm-2S1/ 2K-1) Dry 82.08 98.56 Wet 0.5ml 246.6 460.3 Wet 1ml 269.66 633.3 Permatest 6.51 14.95 Water Vapor Permeability (%) 2 -1 0.124 0.0498 Resistance to Evaporate Heat Loss (m PaW ) 3.53 2.89 Absorption Wicking Course Direction 18.68 0.52 Wale Direction 28.3 0.36 Area 23.00 0.43 Source: Anand, S. C. (2003). Proceedings from ISTEK 2003: Recent advances in knitting technology and knitted structures for technical textiles applications. Woodson Page 20 Appendix II: Properties of Sportwool™ Manchester United Football (Soccer) Strip Properties of Sportwool™ Manchester United Football (Soccer) Strip Area Density (g/ m-2) 161.23 Thickness (mm) 0.64 -3 Bulk Density (g/ cm ) 0.252 Alambeta Thermal Resistance (W-1Km2)*10-3 Dry 24 Wet 0.5ml 10 -2 -1 Thermal Absorptivity (Wm S1/ 2K ) Dry 83 Wet 0.5ml 328 Permatest 36.5 Water Vapor Permeability (%) 2 -1 0.0155 Resistance to Evaporate Heat Loss (m PaW ) 3.59 Absorption Wicking Course Direction 3.64 Wale Direction 2.61 Area 3.08 Source: Anand, S. C. (2003). Proceedings from ISTEK 2003: Recent advances in knitting technology and knitted structures for technical textiles applications. Woodson Page 21 Appendix III: Details of Warp Knitted Spacer Submerser Diving Suit Fabric Type Fabric Thickness Weight Material Production Machine Gauge Fabric Manufacturer Suit Producer Warp knitted spacer fabric, elastic 3.5 mm 330 g/ m2 45% polyester, 36% elastane, 19% CoolMax® RD 6 N raschel machine, double bar E 18 Müller Textil Beluga Tauchsport Source: Spacer fabrics for diving suits. (1998). Kettenwirk Praxis, 32(4), 57. Woodson Page 22