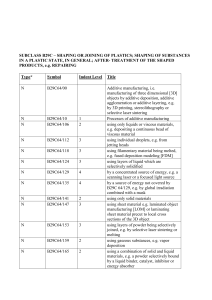

ADDITIVE/SUBTRACTIVE MANUFACTURING RESEARCH

advertisement