Industrialization of Additive Manufacturing

advertisement

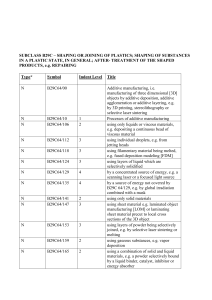

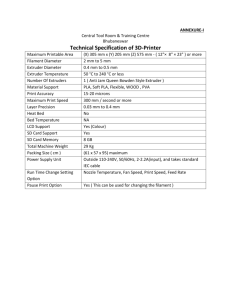

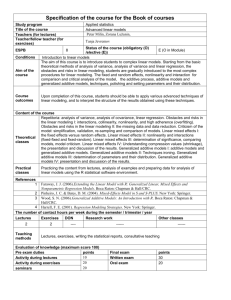

The industrialization of Additive Manufacturing Olivier Jay, Head of section Additive Manufacturing Tel: +45 7220 1713 oja@dti.dk STATUS An independent, non-profit institution Approved as a technological service institute by the Danish Ministry of Science, Technology and Innovation. OBJECTIVE The objective of the Danish Technological Institute is to address the needs of the industrial sector and society as a whole through the development and dissemination of technological innovation. KNOWLEDGE PROCESSES AT DTI Knowledge development Develops new knowledge through R&D activities – national as well as international Knowledge application Knowledge application takes place through general technological services, e.g. laboratory tests, testing, calibration and certification Knowledge transfer In interaction with and supplying advisory services to private and public market players, e.g. consultancy, education and operator tasks THE INSTITUTE COVERS A SIGNIFICANT NUMBER OF SMALL AND MEDIUM SIZED ENTERPRISES IN 2010 82% Delivery of services to 14,895 companies of which 9,449 were Danish. Share of companies, in total 9,449 Share of revenue, in total EUR 37.4 million 43% 38% 19% 12% 6% 0-49 50-199 200+ Number of employees in companies (customers) Additive Manufacturing AM RPT (Rapid Prototyping Technologies), ALM (Additive layer manufacturing) RM (Rapid manufacturing) AF (Additive fabrication) DDM (Direct digital manufacturing) SFF (Solid freeform fabrication) LM (Layered manufacturing). …. AM is the application of layer manufacturing techniques for the fabrication of functional longterm models or enduse products. The physical inputs into the RP systems are the materials, CAD model and laser. By using different RP technologies, final net shape metallic parts can be fabricated. It is a one-step process in which tooling is eliminated thereby reducing production time and cost. 3D Printed Violin Additive Manufacturing – The next industrial revolution Technologies Stereolithography (SLA) Selective Laser Sintering (SLS) Fused Deposition Modelling (FDM) 3D Printing (3DP) Metal Technologies (SLM, DMLS) 26,4% Compound annual growth rate for 1988–2011 Electron Beam Melting (EBM®) Principle of the SLM Process x-y Scanner Laser Laser Beam Levelling System Inert Gas F-Theta Optic Metal Powder Part Laser Beam Part Powder Retractable Platform Long tail Volume Product lifetime Time to market Response of the market Personalization Design Price Product Variety EPO's European Inventor Award 2012 goes to outstanding inventors from Germany, France, Denmark and Australia Industry: Widex (Denmark), for their invention of a computer-aided method to manufacture individually-fitted hearing-aid devices; http://www.youtube.com/watch?v=Dw82KSzvkAs&feature=player_embedded Customization Who is the developer ? Ramp up The beauty of Rapid Manufacturing. ”The RM technology has given us a bigger creative designing space, because we are no longer limited by a particular geometric shape. We do not produce tools, which means that the production process is reduced to a few weeks where it before took between 4 to 6 months. The time factor means that we can now try out our ideas, and it gives us an enormous amount of freedom” Leif Johannsen, Chief Officer of Acoustics and Technology Qphase density for a scan velocity of 23 cm/s 100 90 Relative density (%) 80 70 21/01 test cubes 22/01 test cubes 60 50 40 0 50 100 150 Laser power (W) 200 250 Sustainable Pumps and the world's electricity consumption Today pumps account for no less than 10% of the world's electricity consumption. Two third of all pumps use up to 60% too much energy [2]. If every business switched to a high efficiency pump system there could be global savings of 4% of the total electricity consumption- comparable with the residential electricity consumption of 1 billion people Parts with complex internal channels Demonstrator part: crossing manifold a manifold to let 2 hydraulic lines cross each other in limited space 230x230x54 mm 20,15 Kg Conventional manifold design 18 dp Conventional 16 dp AM - SLM pressure loss in/out [bar] 14 12 10 8 6 5,516 4 2 1,733 0 0,421 1,506 0,95 Kg -2 30 50 70 90 110 130 150 170 190 210 230 250 270 flow [l/min] 80x80x50mm Adri Overbeeke Economy and Environment Education Design RM Quality control Production Finish www.rm-platform.com Thank you for your attention Olivier Jay Telephone: +45 72 20 17 13 olivier.jay@teknologisk.dk www.garpa.org