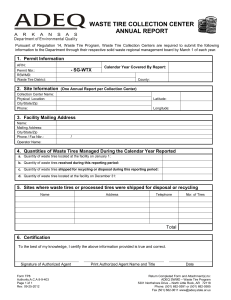

annual report 2014

advertisement