profile

Drive & Control

Pedigree Ovens expands business

with Veronica cartoner

Challenge:

Help Pedigree Ovens meet

growing demand for producing

and packaging pet “treats” with a

flexible, high-throughput cartoning

machine able to package both

conventional and gable-top cartons

Rexroth Solution:

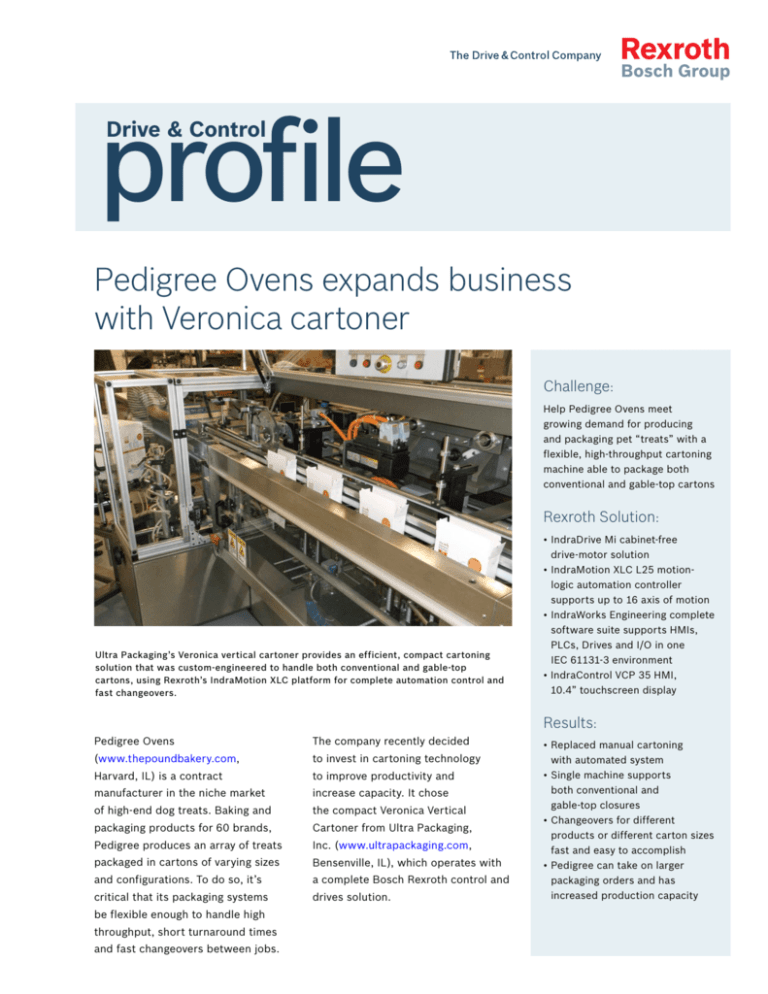

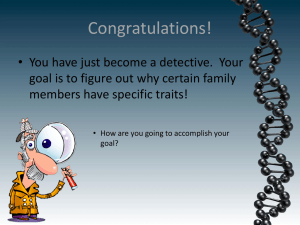

Ultra Packaging’s Veronica vertical cartoner provides an efficient, compact cartoning

solution that was custom-engineered to handle both conventional and gable-top

cartons, using Rexroth’s IndraMotion XLC platform for complete automation control and

fast changeovers.

•IndraDrive Mi cabinet-free

drive-motor solution

•IndraMotion XLC L25 motionlogic automation controller

supports up to 16 axis of motion

•IndraWorks Engineering complete

software suite supports HMIs,

PLCs, Drives and I/O in one

IEC 61131-3 environment

•IndraControl VCP 35 HMI,

10.4” touchscreen display

Results:

Pedigree Ovens

The company recently decided

(www.thepoundbakery.com,

to invest in cartoning technology

Harvard, IL) is a contract

to improve productivity and

manufacturer in the niche market

increase capacity. It chose

of high-end dog treats. Baking and

the compact Veronica Vertical

packaging products for 60 brands,

Cartoner from Ultra Packaging,

Pedigree produces an array of treats

Inc. (www.ultrapackaging.com,

packaged in cartons of varying sizes

Bensenville, IL), which operates with

and configurations. To do so, it’s

a complete Bosch Rexroth control and

critical that its packaging systems

drives solution.

be flexible enough to handle high

throughput, short turnaround times

and fast changeovers between jobs.

•Replaced manual cartoning

with automated system

•Single machine supports

both conventional and

gable-top closures

•Changeovers for different

products or different carton sizes

fast and easy to accomplish

•Pedigree can take on larger

packaging orders and has

increased production capacity

Operating at maximum capacity

The market for specialty pet treats

is competitive, with retail shelf

space at a premium. Manufacturers

need to find ways to stand out from

the competition, and eye-catching

packaging is an important and

successful technique.

While some of Pedigree’s clients use

conventional folded top cartons,

others request a gable-top closure for

improved shelf appeal. In addition,

Pedigree supports multiple package

dimensions, ranging from 4 to

10.5 inches high, 3 to 9 inches wide

and .75 to 3.5 inches deep.

With approximately 60 clients— each

with multiple treat types or flavors

and up to five packaging variations—

Pedigree’s success depends on its

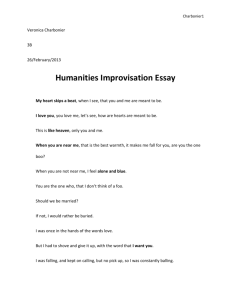

Pedigree Ovens recently installed the Veronica cartoner from Ultra Packaging, automating

the cartoning process for pet treats and helping the company increase throughput and

grow its capacity to handle contract packaging projects.

ability to meet all client requests.

Until recently, the company used a

paperboard blanks and efficiently

PLCopen standard IEC 61131-3. For

manual cartoning process to fulfil

transports, closes and glues

the Veronica, it provides synchronized

customers’ needs. Once treats were

the cartons.

motion control on each axis as well as

bagged, a conveyor brought the filled

logic programming and features a wide

bags to manual stations where they

It is engineered to be a cost-effective

range of open interfaces, including

were inserted into erected boxes. The

solution for growing companies that

Sercos III, PROFINET and EtherNet/IP.

boxes were then manually sealed with

need fast changeovers and flexibility;

glue guns.

key to the Veronica’s versatility is its

Rexroth’s IndraDrive Mi cabinet-free

advanced control and drives platform

drive/motor system drives each axis.

from Bosch Rexroth.

With drive electronics integrated

“When we were smaller, we were able

to do everything manually,” said Kurt

into the motor housing, servo units

Stricker, owner of Pedigree Ovens.

“Rexroth components help make the

can be housed on the machine itself;

“But when we started getting larger

Veronica as powerful and as versatile

this helps make the Veronica a very

requests, only to turn them down

as it is,” said Bob Stockus, owner

compact and modular machine

because we didn’t have the cartoning,

of Ultra Packaging. “With Rexroth’s

that can be easily fit into tight

we knew it was time to expand our

components, the Veronica is user-

factory workspaces.

limited capacity.”

friendly and can be adapted for each

Automating the cartoning process

user’s needs, while staying within

The integrated motors and drives

a budget.”

offer additional benefits like reduced

Eager to boost throughput and enable

space and cooling requirements in

expansion without adding significantly

The Veronica uses the IndraMotion

the control cabinet. This system also

to costs, Pedigree researched

XLC motion logic controller, Bosch

reduces the machine’s component

several machines and selected Ultra

Rexroth’s premiere platform

cost; a single cable for power

Packaging’s Veronica cartoner. The

for motion, robotic, logic and

and communication runs from the

Veronica is a user-friendly seven-axis

hydraulic control applications, that

power supply, and each IndraDrive

cartoner that erects cartons from flat

is programmed according to the

erected, the bottom sealed and the

product inserted, the Veronica must

create gussets on the sides. The

machine has a mechanism that moves

up and down on either side of the

box to push the sides in. Then the

machine applies the glue and folds the

flap over the top to create a gable-top

closure resembling a milk carton.

The changeovers between

conventional and gable folds can

be done quickly, thanks to a special

sub-assembly Ultra Packaging added

to the Veronica for Pedigree. All the

components necessary for each type

of fold are grouped together on one

plate so the machine operator can

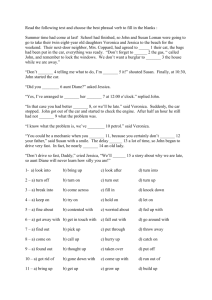

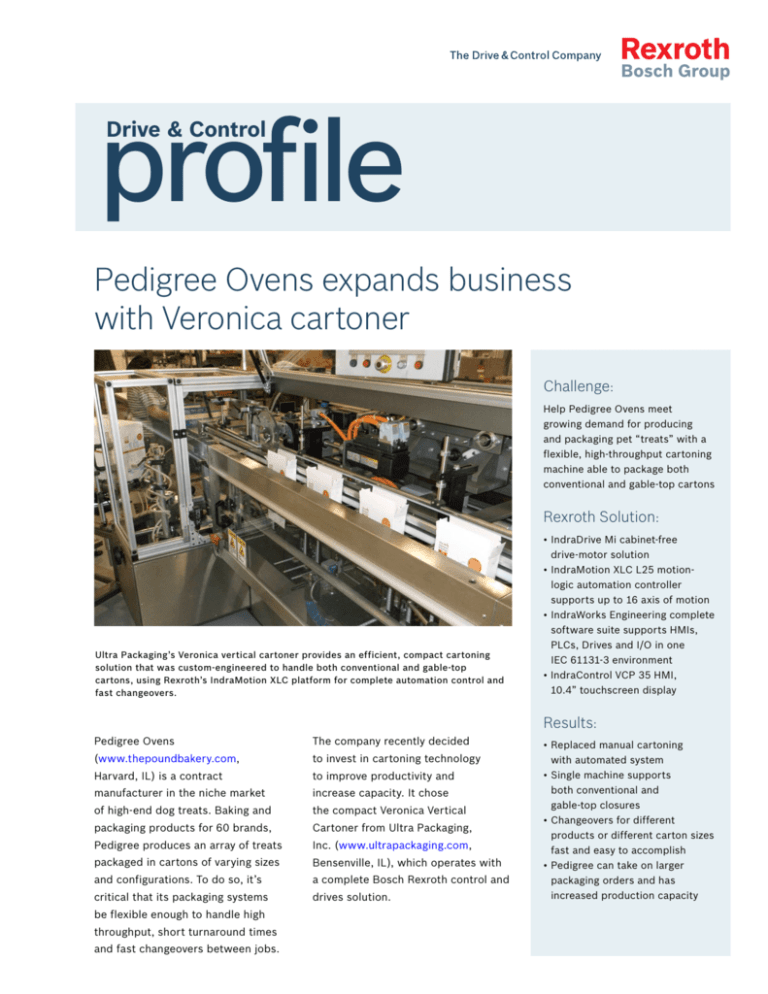

Multiple Rexroth IndraDrive Mi cabinet-free drive/motor units drive all the major axes on

the machine, including this portion of the machine which closes the carton top, shown

here closing a conventional carton.

change them all at once.

“Rexroth’s control and drives platform

provided essential programming

capabilities,” Stockus said. “Because

Mi is daisy-chained to the next for

then seals the filled box. For

the Rexroth IndraDrive Mi drive

significantly reduced cabling.

conventional closures, this is the

platform is extremely accurate

same process as sealing the bottom:

regarding the timing of the drives’

“Rexroth’s control and drives platform

The Veronica kicks a flap into place,

position, we were able to accomplish

gave us the flexibility we needed,”

applies glue and kicks the second flap

this and keep the changeover times to

Stricker said. “It was critical for our

into place.

a minimum.”

Gable-top closures require an

For Pedigree, this was an important

additional step. After the carton is

benefit of the Veronica. While most

dual fold capabilities.”

Veronica facilitates expansion

The Pedigree application is the first

that uses the Veronica for gable-fold

closures, but the cartoner proved

extremely well-suited for the job.

Once the pet treats are bagged,

they are transported to the cartoner

via a conveyor controlled with the

same IndraMotion XLC used for

the Veronica. The conveyor lifts the

products about six feet to reach

the Veronica.

The Veronica’s first step is to erect

each carton and seal the bottom.

The product is inserted at a manual

production station, and the Veronica

The IndraMotion XLC motion logic control system is the centerpiece of a complete

Rexroth machine control and drives solution, engineered for maximum efficiency and

compact space savings.

manufacturers would have two

“We were able to reduce labor and

“New opportunities are key as we

separate systems in place to handle

increase speed immediately, and

grow the company,” Stricker said.

two different folds, Pedigree can do

the return on investment was really

“We can definitely look at bigger jobs

everything with just one machine.

quick,” Stricker said. “A job that used

and larger customers, knowing that

With greater capacity for changeovers,

to take us three days can now be done

we can fill the orders.” He added that

the company now does up to

in an afternoon. It’s no comparison

Pedigree has recently added a new

three a day and 10 to 12 per week,

from before.”

customer worth several million dollars

enabling faster turnaround times and

greater flexibility.

a year in additional contract packaging

The Final Result

revenue — new business that’s a direct

The Veronica met all of Pedigree’s

result of adding the Veronica to

Overall, the automated cartoning

objectives and exceeded target

Pedigree’s production operations.

process is five to seven times faster,

production rates. The Rexroth

creating significant improvements in

XLC controller and IndraDrive Mi

“We pride ourselves in our flexibility,

throughput. Five to six people working

drive system provided the modular

in manufacturing and in packaging,”

together with the Veronica can

technology and intelligent automation

Stricker said. “That’s where the

package 40 to 60 bags per minute.

platform that enabled Ultra Packaging

Veronica’s really helped us. It’d be

And for easier jobs that simply require

to efficiently modify the Veronica to

hard to imagine getting all this work

repackaging into shelf-ready boxes,

integrate conventional and gable-top

done without the Veronica.”

the team can reach 60 to 70 bags

cartons on a single machine.

per minute.

Facebook “f ” Logo

CMYK / .ai

Facebook “f ” Logo

CMYK / .ai

www.facebook.com/BoschRexrothUS

twitter.com/BoschRexrothUS

www.youtube.com/BoschRexrothUS

©2015 Bosch Rexroth Corporation

Subject to change without notice.

Printed in USA.

ALL RIGHTS RESERVED

FORM bos3232/01.2015

Bosch Rexroth Corporation

14001 South Lakes Drive

Charlotte, NC 28273-6791

Telephone (800) 739-7684

www.boschrexroth-us.com