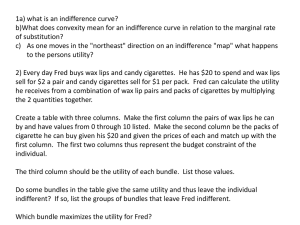

Part 40 Utility Workers - Alberta Jobs, Skills, Training and Labour

advertisement