IE 366

Chapter 25

Time Study

Supplementary Material from:

Groover, M.P. (2007). Work Systems and the Methods, Measurement, and Management of Work,

Upper Saddle River, NJ: Pearson Prentice Hall, pp. 319 - 360.

1

IE 366

Time Study

●

Also known as

–

–

●

Involves

–

–

–

●

–

–

●

direct, continuous observation of a task

using a time measurement instrument

to record time taken to complete task.

Allowances made for

–

●

Direct Time Study

Stopwatch Time Study

personal needs

fatigue

unavoidable delays

Dates back to 1883

Inextricably connected with origins and early history of IE

2

IE 366

Direct Time Study Procedure

1.Define and Document Standard Method

2.Divide Task Into Work Elements

3.Time Work Elements

4.Rate Worker’s Performance

5.Apply Allowances

3

Define and Document

Standard Method

●

●

●

IE 366

Goal: “one best method”

Seek worker’s advice, if appropriate

Elements of Document

–

–

–

–

–

–

–

Procedure (steps, actions, work elements, hand/body

motions)

Tools, equipment

Machine settings (e.g., feeds, speeds)

Workplace layout

Frequency of irregular elements

Working conditions

Setup

4

Reasons For Thorough

Documentation

●

●

●

●

IE 366

Batch production (likely to be repeated)

Methods improvement by operator

Disputes about method (too tight?)

Data for standard data system

5

Divide Task Into Work

Elements

●

●

IE 366

Series of motion activities logically grouped because

of unified purpose.

Guidelines

–

Each work element should consist of a logical group of

motion elements.

●

–

Beginning point of one element should be end of previous.

●

–

No time gap between elements.

Each element should have readily identifiable end point.

●

–

e.g., reach, grasp, move, place

i.e., easily detected, no ambiguity

Work elements should not be too long.

●

< “several” min

6

Divide Task Into Work

Elements

●

IE 366

Guidelines (continued)

–

Work elements should not be too short.

●

–

Irregular elements should be identified & distinguished.

●

–

i.e., not every cycle

Manual elements should be separated from machine

elements.

●

–

> 3 sec

generally constant values

Internal elements should be separated from external

elements.

●

i.e., performed by operator during machine cycle

7

“Irregular” and “Foreign”

Elements

●

●

●

IE 366

Elements that occur routinely, but not every cycle – should be

included: irregular elements (Groover)

Elements that the observer didn’t anticipate –probably should

be included: irregular elements (Konz & Johnson)

Elements that are not normal work – should not be included:

foreign elements (Konz & Johnson)

8

IE 366

Time Work Elements

●

Collect data on time study form (on clipboard).

9

IE 366

Time Work Elements (2)

●

Collect data on time study form (on clipboard).

10

IE 366

Time Work Elements (3)

●

Use stopwatch calibrated in 0.01 minutes:

–

Snapback method

●

●

●

●

Start watch at beginning of every element.

“Snap” watch back to zero at end of element.

Record time.

Advantages

–

–

–

Element variations easily observable

No subtraction

Continuous method

●

●

●

●

Start watch at beginning of observation (or beginning of each

cycle)

Record elapsed time at end of each element.

Let it run …

Advantages

–

–

–

Not so much manipulation of stopwatch

Elements not so easily omitted

Regular/irregular elements more readily distinguished (?)

11

IE 366

Rate Worker’s Performance

●

●

Standard performance = 100%

Rate

–

–

●

●

Individual elements

Or entire work cycle

Most difficult & controversial step in time study

Requires analyst’s judgment

12

IE 366

Apply Allowance

Pure Manual Work

Work Element

a

b

c

d*

Obs. Time

0.56 min

0.25 min

0.50 min

1.10 min

Perf. Rating

100%

80%

110%

100%

* irregular element performed every 5 cycles

PFD Allowance = 15%

13

IE 366

Apply Allowance

Pure Manual Work

Work Element

a

b

c

d*

Obs. Time

0.56 min

0.25 min

0.50 min

1.10 min

Perf. Rating

100%

80%

110%

100%

* irregular element performed every 5 cycles

PFD Allowance = 15%

Normal Time:

NT = 0.56(1.00) + 0.25(0.80) + 0.50(1.10) + 1.10(1.00)/5

= 0.56 + 0.20 + 0.55 + 0.22 = 1.53 min

Standard Time:

ST = 1.53(1 +0.15) = 1.76 min

14

IE 366

Apply Allowance

Task Including Machine Cycle

Work Element

a

b

c

d*

Obs. Time

0.22 min

0.65 min

0.47 min

0.75 min

Perf. Rating

100%

80%

100%

100%

(idle)

m

1.56 min

(idle)

(idle)

Mach. Time

PFD Allowance = 15%

Machine Allowance = 20%

* irregular element performed every 15 cycles

15

IE 366

Apply Allowance

Task Including Machine Cycle

Work Element

a

b

c

d*

Obs. Time

0.22 min

0.65 min

0.47 min

0.75 min

Perf. Rating

100%

80%

100%

100%

(idle)

m

1.56 min

(idle)

(idle)

Mach. Time

PFD Allowance = 15%

Machine Allowance = 20%

* irregular element performed every 15 cycles

Normal Time:

NT = 0.22(1.00) + Max{0.65(0.80), 1.56} + 0.47(1.00) + 0.75(1.00)/15

= 0.22 + 1.56 + 0.47 + 0.05 = 2.30 min

Standard Time:

ST = (0.22 +0.47 + 0.05)(1 + 0.15)

+ Max{0.52(1 + 0.15), 1.56(1 + 0.20)}

= 0.85 + 1.87 = 2.72 min

16

IE 366

Number of Cycles To Be

Timed

Let X be a random variable, time of one work element in a task.

Time several cycles to estimate true mean:

close estimate

low estimate

high estimate

1-α

1-α

α/2

α/2

1-α

α/2

α/2

α/2

x

x

α/2

x

μX

Overall, P(μx lies within x + zα/2 [σ/√nc ]) = 1 – α

where nc = number of cycles timed

But σ unknown, so take preliminary sample of ns observations and use

s=

∑(x-x)2

ns-1

17

Number of Cycles To Be

Timed (2)

IE 366

P(μ lies within x + tα/2 [s/√nc ]) = 1 – α

Interval size = x + kx

where k = proportion of sample mean

(e.g., if k = 10%, interval size = x + 0.10 x)

kx = tα/2 [s/√nc ] (remember, s is an estimate of σ based on preliminary sample of ns)

So, rearranging,

nc = (tα/2s / kx)2

18

Number of Cycles To Be

Timed: Example

●

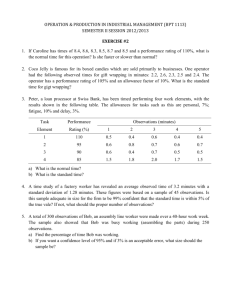

From preliminary study, engineer has collected n s=10 samples on one work

element

–

–

●

IE 366

x = 0.40 min

s = 0.07 (an estimate of σ based on preliminary sample of ns=10)

How many cycles should be timed to ensure actual element time is + 10%

of the sample mean, with 95% confidence?

–

df = (ns – 1) = 10 – 1 = 9

–

α = 0.05, α/2 = 0.025

tα/2 = t0.025 = 2.262

Number of cycles = nc = (tα/2s / kx)2 = [2.262(0.07) / 0.10(0.40)]2

–

–

= 15.7 ≈ 16 cycles

●

If 16 observed cycles yields

–

x = 0.45 min

P(μx lies within x + kx) = P(μx lies within 0.45 + 0.10(0.45))

= P(μx lies within [0.405, 0.495]) = 95%

19

IE 366

Performance Rating

●

●

●

Also called performance leveling.

Performance relative to engineer’s concept of “standard” performance.

Most common method based on speed or pace: speed rating.

–

–

–

> 100% means faster than standard pace

engineer must use judgment

must consider

●

●

●

Standards

–

●

●

●

degree of difficulty of work element

worker’s pace relative to standard

Walk 3 mi/hr on flat, level ground, no load, 27-in steps.

Problem: few work situations lend themselves to such precise measurement.

However, many situations in which experts judge (e.g., gymnastics, dog shows)

Solutions

–

–

Experience (including feedback)

Training (e.g., using training films)

20

IE 366

Performance Rating (2)

●

Pace depends on worker’s

–

–

–

–

●

So, select skilled worker

–

–

●

skill

experience

exertion level

attitude toward time study

familiar with job

Accepts time study as necessary management tool

Characteristics of good performance rating system

–

–

–

–

–

–

–

consistency among tasks (one task to another)

consistency among engineers

easily understood

related to standard performance (well-defined concept)

machine-paced elements rated at 100% (no worker control of machine)

rating recorded during observation, not after

worker notification

21

IE 366

Time Study Issue

●

●

●

Why is time study important to the

organization?

What are some worker concerns?

How can they be resolved?

22

Time Study Equipment:

Mechanical Stopwatch 1

IE 366

23

Time Study Equipment:

Mechanical Stopwatch 2

IE 366

24

IE 366

www.stopwatchesusa.com

25

Time Study Results

IE 366

(from text)

26