F3D Crew Training

advertisement

FRANKE FROZEN FRY DISPENSER

F3D / F3DN / F3D3

TRAINING MANUAL

SECTION 1

F3D SERIES BASICS

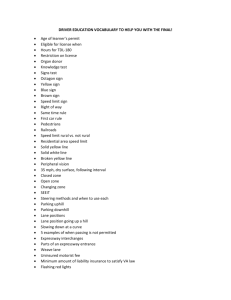

TABLE OF CONTENTS

INTRODUCTION

→Table

→

of Contents

SECTION 2

MECHANICS

F3D SERIES BASICS

→F3D

→

Design Challenge

→Model

→

Identification

→F3D

→

Unit Specifications

→F3Dn

→

and F3D3 Unit Specifications

→F3D

→

Series Installation Guidelines & Potential Issues

→F3D

→

Series Typical Unit Operation Sequence

→Operator

→

PM - Basic Care & Cleaning

→Section

→

1 The Basics QUICK QUIZ

2

4

5

6

7

8

8

9

10

CONTROLS

→F3D

→

Control Panel Function Guide

→F3Dn

→

Control Panel Function Guide

→F3D3

→

control Panel Function Guide

15

16

17

REFRIGERATION

→F3D

→

Series Refrigeration Basic Operator PM

18

TROUBLESHOOTING

→F3D

→

Control Panel Function Guide

→F3Dn

→

Control Panel Function Guide

→F3D3

→

Control Panel Function Guide

→F3D3

→

Error Message Guide

19

20

21

22

F3D3 TESTING ACCESS FOR CUSTOMER

→F3D3

→

Motor Test Procedure →F3D3

→

Display Panel LED Light Test

→F3D3

→

Load Cell Calibration

23

24

26

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

SECTION 4

REFRIGERATION

SECTION 3

CONTROLS

MECHANICS

→Basic

→

Fry Basket Fill Sequence

11

→F3D

→

Series Mechanical Systems: Hopper/Rotor/Doors12

→F3D

→

Series Mechanical : Weighing System

13

→Section

→

2 Mechanics QUICK QUIZ

14

2

INTRODUCTION

Table of Contents

3

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

SECTION 4

REFRIGERATION

SECTION 3

CONTROLS

SECTION 2

MECHANICS

SECTION 1

F3D SERIES BASICS

1.0 F3D Series Basics

SECTION 1

F3D SERIES BASICS

1.1 Frozen French Fries Dispensers – The Design Challenge

To optimize quality and ensure batch-to-batch cooking consistency,

French fries must be kept uniformly frozen until they are lowered

into the fryer. Baskets loaded with frozen fries should not be staged

or kept at ambient room temperature for even a few minutes. They

thaw quickly and can clump together.

SECTION 2

MECHANICS

French fry cut potatoes vary in length, are fragile (even in their

frozen state) and represent a challenge for dispensing into fry

baskets without damaging or breaking an unacceptable percentage

of whole fries.

SECTION 3

CONTROLS

The popularity of French fries and the high production volumes

necessary to meet drive-through and in-store order volume require

a simple and fast way to fill fry baskets with frozen product, without

unacceptable damage. The ebb and flow of daily fries production

requires a dispensing system that can quickly change batch size

(dispense-volume) to match order requirements.

F3D Series Freezer/Dispensers Meet the Challenge

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

SECTION 4

REFRIGERATION

All F3D Series Models provide:

1. Two parallel and redundant fries storage and dispensing lanes

2. A well insulated freezer compartment with a simple, yet efficient

modular condenser package

3. Very precise load cell-based batch weighing systems

4. Simple touchpad lane controls for operation and basic

troubleshooting

5. Easy access to condenser/filter for basic preventive maintenance

6. Space for extra (empty) fries basket storage

7. Caster mounting for easy movement and rear/side service access

4

F3D SERIES BASICS

F3D Design Challenge

1.2 Three Generations of Fries Dispenser – Model Identification

SECTION 1

F3D SERIES BASICS

There are currently three generations of F3D Series dispensers in use and in the field. The F3D is the

original version with a bottom mounted compressor package. The second generation F3Dn or “narrow”

model was developed to reduce the unit width for tight kitchen layouts. The F3D3 or third generation model

incorporates more sophisticated controls with a display that allows easier, from-the-front operational

settings, calibration and diagnostic system access.

SECTION 2

MECHANICS

All three generations share basic cold wall refrigeration technology, fries hopper design and much of the

automation assembly that releases, weighs and dispenses frozen fries. However, the narrow profile of

second and third generation models has changed some mechanical systems and on-going improvement of

control technology and user interface makes each model unique.

We have color-coded sections to help you quickly identify and use the relevant information and

instructions. Purple color bars are used for universal [all models] information and blue-green-red, as

follows:

F3Dn Models (Gen-2)

F3D3 Models (Gen-3)

SECTION 4

REFRIGERATION

SECTION 3

CONTROLS

F3D Models (Gen-1)

Differentiating Features:

Differentiating Features:

Different Features:

F3D Lane Control Panels

F3Dn Lane Control Panels

F3D3 Lane Control Panels

· Narrow: 28” [711 mm]

· Tall: 77.75” [1975 mm]

· Top-mounted refrigeration

· Top-front condenser air in take

· Lane controls above door:

SECTION 5

TROUBLESHOOTING

· Narrower: 27.5” {698 mm]

· Taller: 77.375 [1965 mm]

· Top-mounted refrigeration

· Top-right condenser air in take·

Lane controls above door:

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

· Wider: 29.5” [750 mm]

· Shorter: 69” high [1753 mm]

· Bottom-mounted refrigeration

· Bottom-front condenser access

· Top-mounted lane controls:

F3D SERIES BASICS

Model Identification

5

SECTION 1

F3D SERIES BASICS

1.3 Unit Specifications

Key electric and refrigerant specifications are included on the unit Data Plate/Sticker found on:

Right-rear on F3Dn Models

Front panel behind air

filter on F3D3 Models

SECTION 2

MECHANICS

Left side on F3D Models

Complete Model Specifications follow:

1.3.1 Model F3D Unit Specifications

Model Variations:

F3D 120V

Fries Capacity:*

Up to 60 lbs. or 27 kg.

Dispensing Rate*:

Up to 700 basket loads per hour

Dispense Accuracy*:

Plus/minus 10% by weight

Fry Basket Storage*:

7 total, 2 in dispense areas, 5 in side storage rack

Refrigeration/Type:*

Self-contained, cold wall construction, using R-404A Refrigerant

Agency Listings:

CULUS & NSF

CE

Unit Width [No Rack]:

Unit Width [w/Rack]:

29.5”

35.375”

750 mm

899 mm

Unit Depth [frt-to-bk]:

Unit Height

Prod. Loading Height

Minimum Door Swing

33.5”

69”

56.5”

30”

851 mm

1753 mm

1435 mm

763 mm

Shipping Weight:

530 lbs.

240 kg

Unit Weight:

475 lbs.

215 kg

Max. Loaded Weight:

547 lbs

248 kg

Voltage [VAC]

120 VAC

230 VAC

Phase [PH]

1-phase

1-phase

Cycles [Hz]

60 Hz

50 hz

Amperage [AMP]

9 AMP

5.5 AMP

Watts

1100

1300

Power Cord Provided

8-foot

2.44 meter

Plug Provided

Straight Blade

Pin & Sleeve

18000744

18000744

Max. Room Temp.

82° F

27° C

Max. Room Humidity

Min. Side Clearance**

60%

none

60%

none

Min. Rear Clearance

4”

102 mm

SECTION 3

CONTROLS

Key Performance Specifications

SECTION 4

REFRIGERATION

Key Dimensions & Weights

SECTION 5

TROUBLESHOOTING

Electric/Utility Requirements

F3D 230V

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

Available Options

Wire Hopper Rack

Requirements

6

F3D SERIES BASICS

F3D Unit Specifications

1.3.2 Model F3Dn Unit Specifications

120V/60Hz

F3D SERIES BASICS

27° C

60%

none

153 mm [Top]

none

230V/50Hz & 60Hz

SECTION 4

REFRIGERATION

Up to 60lbs. or 27 kg.

Up to 700 basket loads per hour

Plus/minus 10% by weight of large load

8 total: 2 in, 2 adjacent to & 4 below lane dispense areas

Self-contained, cold wall construction, using R-404A

Refrigerant

CETLUS & NSF

CE, GS & NSF

Agency Listings:

Key Dimensions & Weights

Unit Width:

28”

Unit Depth [front-to-back]:

30.75”

Unit Height:

77.75”

Product Loading Height:

57.5”

Minimum Door Swing:

+29”

Shipping Weight:

530 lbs.

Unit Weight:

475 lbs.

Max. Loaded Weight:

547 lbs

Electric/Utility Requirements

Voltage [VAC]

120 VAC

Phase [PH]

1-phase

Cycles [Hz]

60 Hz

Amperage [AMP]

10 AMP

Watts

1200

Power Cord Provided

10-foot

Plug Provided

Straight Blade

Available Options

Hash Brown Rack

18001528

Side Basket Storage Kit**

K502565

Operating Conditions & Installation Requirements

Max. Room Temp.

82° F

Max. Room Humidity

60%

Min. Left Side Clearance

none

Min. Right Side Clearance

none

Min. Rear Clearance

none

* All models, unless otherwise noted

230 VAC

1-phase

50 Hz & 60 Hz

5.4 AMP

1300

3-meter

Pin & Sleeve

** Stores 5 additional empty fry baskets

1.3.3 Model F3D3 Unit Specifications

Product Model:

Key Performance Specifications

Fries Capacity:*

Dispensing Rate*:

Dispense Accuracy*:

Fry Basket Storage*:

Refrigeration/Type:*

SECTION 2

MECHANICS

698 mm

781 mm

1965 mm

1461 mm

+736 mm

240 kg

215 kg

248 kg

SECTION 3

CONTROLS

27.5”

30.75”

77.375”

57.5”

+29”

530 lbs.

475 lbs.

547 lbs

SECTION 1

F3D SERIES BASICS

Up to 60 lbs. or 27 kg.

Up to 700 basket loads per hour

Plus/minus 10% by weight of large load

8 total: 2 in, 2 adjacent to & 4 below lane dispense areas

Self-contained, cold wall construction, using R-404A

Refrigerant

CULUS & NSF

CE & GS

CE

120 VAC

1-phase

60 Hz

9 AMP

1100

10-foot

Straight Blade

Available Options

Hash Brown Rack

18001528

18001528

Side Basket Storage Kit**

K502565

K502565

Operating Conditions & Installation Requirements

Max. Room Temp.

82° F

Max. Room Humidity

60%

Min. Left Side Clearance

none

Min. Right Side Clearance

6” [at top]

Min. Rear Clearance

none

* All models, unless otherwise noted

230/50Hz & 60Hz

711 mm

781 mm

1975 mm

1461 mm

+736 mm

240 kg

215 kg

248 kg

SECTION 5

TROUBLESHOOTING

Agency Listings:

Key Dimensions & Weights

Unit Width:

Unit Depth [front-to-back]:

Unit Height:

Prodoct Loading Height:

Minimum Door Swing:

Shipping Weight:

Unit Weight:

Max. Loaded Weight:

Elertric/Utility Requirements

Voltage [VAC]

Phase [PH]

Cycles [Hz]

Amperage [AMP]

Watts

Power Cord Provided

Plug Provided

120V/60Hz

230 VAC

1-phase

50 Hz & 60Hz

5.5 AMP

1300

3-meter

Pin & Sleeve

18001528

K502565

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

Model Variations:

Key Performance Specifications

Fries Capacity:*

Dispensing Rate*:

Dispense Accuracy*:

Fry Basket Storage*:

Refrigeration/Type:*

27° C

60%

none

none

none

** Stores five additional empty fry baskets

F3Dn and F3D3 Unit Specifications

7

1.4 F3D Series Installation Guidelines & Potential Issues

SECTION 1

F3D SERIES BASICS

Like most commercial kitchen equipment, the F3D Series of Frozen French Fries Dispensers must

be properly positioned and installed to operate effectively, avoid premature component failures and

unnecessary downtime.

A Good Installation will include:

SECTION 2

MECHANICS

1. A flat floor that allows the unit to be rolled out for required maintenance or service;

2. A nearby wall or chase-mounted electric outlet providing power per data plate and

unit specifications [See Section 1.3];

3. Ambient room temperatures that is below 82° F [27° C]; and

4. A maximum room humidity of 60%.

A Problematic Installation may include:

SECTION 3

CONTROLS

1. Temperature or humidity levels that exceed

Operating Conditions Requirements;

2. Exposure to high pressure steam or water spray

cleaning;

3. Installation under a ventilation hood and/or

exposure to grease-laden vapors that can drip

into or be drawn into controls or the condenser

compartment;

4. Installation and operation outdoors or any area

not protected from weather or corrosive salt air.

F3Dn improperly installed under

a Type I exhaust hood.

SECTION 4

REFRIGERATION

1.5 F3D Series Typical Unit Operation Sequence

To operate a F3D Series Frozen French Fries Dispenser:

SECTION 5

TROUBLESHOOTING

Assuming the unit is off and empty, you would:

1. Turn ON the main Power Switch. [It is just left of left Lane Control Panel. You should hear the

compressor come on within 2 minutes.]

2. Close the compartment door and allow compressor to draw down freezer temperature to the target/

normal of 0° to -10° F or -18 to -23° C.

3. Open the freezer compartment door and fill one or both white plastic hoppers with frozen fries. [It

will take 1-2 bags to raise fries level above the Low Product Sensor.]

For F3D Models

For F3Dn Models

For F3D3 Models

4. To dispense a load, turn on the Lane Power:

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

Press & hold LANE ON/OFF

touchpad

Press & hold LANE POWER

touchpad

Press International ON/Off

symbol for 4 seconds

MANUAL LED will come on

All LED lights and display come

on [Display will show filling

progress as a growing horizontal

bar.]

5. Wait for READY indicator:

Three LOAD READY LEDs will

come on

8

F3D SERIES BASICS

F3D Series Installation Guidelines & Potential Issues

F3D Series Typical Unit Operation Sequence

LARGE is default. Press LOAD

SIZE button to change

SMALL is default. Press LOAD

SIZE button to change

SMALL is default. Press left

action button 5 under word”

‘Small’ to change.

In AUTO Mode: Insert basket

into filling lane. Fries will

automatically dispense.

In MANUAL mode: Insert basket

then PRESS FOR MANUAL

DISPENSE button.

Place empty basket in filling lane

& push against bump-bar switch.

7. Dispense fries:

Insert basket in filling lane. If

LOAD READY light is on, fries will

automatically dispense.

SECTION 1

F3D SERIES BASICS

[NOTE: LOAD READY LEDs or word ‘Ready’ must be on.]

SECTION 2

MECHANICS

6. Set batch load size:

8. Remove loaded basket and transfer immediately to fryer.

8 For User Interface/Operator Control Panels – go to Section 3.2

8 For F3D3 Error Codes – go to Section 5.1

SECTION 3

CONTROLS

1.6 Operator PM – Basic Care & Cleaning

All F3D Series Fries Dispensers require base level cleaning and preventive maintenance to operate

effectively, extend equipment life and minimize downtime. All models should receive the following

preventive maintenance performed by designated crew or maintenance personal on the following

schedule (per McD PMM Pages):

SECTION 4

REFRIGERATION

· Daily* – Defrost Freezer, Clean Interior, Exterior & all removable parts.

· Monthly – Wash Condenser Coil Filter

· Quarterly – Clean Condenser Coil

* In 24-hour stores it must be shut down for two hours during a slow time.

Location & Access to Condenser Coil/Filter:

For F3D Models

Access panel on upper-right

side, facing freezer

For F3D3 Models

Access panel is above controls

on front of unit

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

Access panel is below filling

lanes

For F3Dn Models

F3D SERIES BASICS

Operator PM - Basic Care & Cleaning

9

Franke F3D-Series STM - Section 1 The Basics QUICK QUIZ

SECTION 1

F3D SERIES BASICS

[Quiz Key: Multiple Choice: circle the single best answer; True or False: circle one;

Fill-in-the-blank(s): write in brief answer(s)]

1) The original F3D Models had the condenser unit mounted below the basket-fill

lanes, in the unit base. True False (circle one)

SECTION 2

MECHANICS

2) The FD3n (Gen-2) Models are:

a) Narrower than the original F3D Model

b) Taller than the original F3D Model

c) Have a top-mounted condensing unit

d) All of the above

3) The F3D3 Models’ Control Panels & Microprocessor Chips are:

a) Located on the back of the unit

b) Are mounted behind the Lane Operator/User Interface Panels

c) Are mounted in the freezer compartment to dissipate heat

d) Have two PIC Chips on each board

e) b) and d) above

SECTION 3

CONTROLS

4) F3Dn Models have both MANUAL and AUTOMATIC dispense modes.

True False (circle one)

5) All F3D-Series Models have cold wall evaporator construction. True

one)

False (circle

6) All F3D-Series Models use ___________ refrigerant. (provide refrigerant type)

SECTION 4

REFRIGERATION

7) All F3D-Series Models MUST be installed under a Type I ventilation hood. True

False (circle one)

SECTION 5

TROUBLESHOOTING

8) The normal or target freezer temperature for all F3D-Series units is:

a) 0° to -10° F or -18 to -23° C

b) 32° to 0° F or 0 to -18° C

c) Absolute zero, give or take a few degrees

d) -10° to -40° F or -23 to -40° C

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

9) Which F3D-Series Model has a bump-bar switch to activate the basket fill cycle?

a) The original F3D Models

b) The second generation F3Dn Models

c) The third generation F3D3 Models

d) All of the above

10)All F3D-Series Models are designed to require NO Operator/Crew preventive

maintenance (PM): True False (circle one)

11) List the basic Preventive Maintenance requirements for all F3D-Series Model:

Daily: ___________________________________________________

Monthly: ________________________________________________

Quarterly: _______________________________________________

10

F3D SERIES BASICS

Section 1 The Basics QUICK QUIZ

2.0 F3D Series Mechanical Systems

SECTION 1

F3D SERIES BASICS

F3D Series dispenser mechanical systems were designed to quickly and accurately dispense a measured

amount of frozen French fries from a hopper located in the freezer, into an empty fryer basket positioned

in the loading area, with minimum damage to those delicate frozen fries. Two redundant and identical

dispensing lanes are provided, with matching electric, control and mechanical systems.

We will begin our review of the mechanical systems with the basic Fry-Basket-Fill-Sequence.

2.1 Basic Fry Basket Fill Sequence:

SECTION 2

MECHANICS

[Assumes Hopper is loaded, unit power is ON, Lane power is ON and LOAD READY LEDs are on (F3D &

F3DN models) or seven “load ready” LEDs are on in the basket icon (F3D3 models):

SECTION 4

REFRIGERATION

SECTION 3

CONTROLS

1. [F3D]: Position fry basket in loading lane

[F3Dn in AUTO]: Position fry basket in loading lane

[F3Dn in MANUAL]: Position fry basket in loading lane and press MANUAL DISPENSE

[F3D3] Position fry basket in loading lane and press it against rear bumper-bar switch

2. Basket present sensor or switch will signal and activate a dispense cycle

3. Door Open Motor will open the two Product Doors (gates), allowing the pre-measured fries load

from the previous fill cycle to drop into waiting fryer basket.

4. Door-Open Sensor reverses the polarity of the Door-Open Motor, closing the two linked Product

Doors, then

5. Door Lift Motor lowers the Automation Assembly (contact pin) on to the Load Cell beam.

6. Load Cell weighs automation assembly and fries. Main Board controller nets out or tares empty

weight of Automation Assembly.

7. Drum Rotor Motor turns the multi-lobe Rotor in the bottom of Hopper, allowing frozen fries to

drop onto the loading doors at the base of Fill Bucket,and continues the fill cycle until weight

value for (Large, Medium or Small) load is reached.

8. When fill value (weight) is reached, Hopper drum/Rotor will stop and Door Lift Motor raises

Automation Assembly to seal freezer bottom and returns it to the ready position.

SECTION 5

TROUBLESHOOTING

The Lane is now ready to dispense another pre-measured load into an empty fry basket.

MECHANICS

F3Dn – stainless bucket is

filled inside freezer

A Load Cell is positioned

below the Lift Motor

Electric eye sensor & flag

reverse the Door Motor

Basic Fry Basket Fill Sequence

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

F3D3 – basket in fill lane

11

2.2 F3D Series Mechanical Systems: Hopper/Rotor/Doors

SECTION 1

F3D SERIES BASICSI

1. Fry Hoppers

· Slide onto center & side brackets

· Pull out for cleaning/inspection

· Can be filled with fries, in position

· Need to be aligned on brackets to

seat with freezer bottom

SECTION 2

MECHANICS

To adjust fry hopper alignment see:

8F3D SM Section 3.6

8F3Dn SM Section 3.6

8F3D3 SM Section 3.5

F3D3 Model shown

2. Hopper Rotor

SECTION 3

CONTROLS

· Drum Motor w/coupling turn

rotor

· Manual front handle can turn

rotor to engage motor drive

coupling

· Rotor must engage coupling to

seat Hopper & close freezer door

· Rubber baffle controls fry drop

F3D3 Model shown

SECTION 4

REFRIGERATION

3. Fill Buckets (Chutes)

For Rotor Replacement see:

8F3D SM Section 2.17

8F3Dn SM Section 2.20

8F3D3 SM Section 2.24

· F3D & F3Dn have metal chutes

· F3D3 has silicon rubber buckets

· Metal chutes seat on freezer

bottom, over doors

· Rubber buckets slide on one door

shaft & hinge up for cleaning

For Bucket Replacement see:

8F3D3 (Only) SM Section 2.9

F3D3 Model shown

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

4. Product Doors

· Pair of doors seal bottom of each

hopper. F3D & F3Dn doors are the

same, F3D3 doors are asymmetric

· Mount on door actuator shafts

· Replacement is similar for all

models:

F3D3 Model shown

12

MECHANICS

For Door Replacement see:

8F3D SM Section 2.6

8F3Dn SM Section 2.9

8F3D3 SM Section 2.9

F3D Series Mechanical Systems: Hopper/Rotor/Doors

2.3 F3D Series Mechanical: Weighing System

SECTION 1

F3D SERIES BASICS

The F3D Series uses a Load Cell and Main Control Board controller programming to measure the weight of

frozen fries dispensed into the bucket to meet McDonald’s (US or EU) standards for: Small, Medium and

Large batches. These different batch sizes allow stores to match batch size to demand during different dayparts.

Currently, McDonald’s nominal or average load sizes are:

SECTION 2

MECHANICS

F3D3 / F3Dn / F3D3

Load Size*

For Global Calibration except Europe (Large 625gm)

SMALL

.75 lb. [340 gm.]

MEDIUM

1.0 lb. [454 gm.]

LARGE

1.5 lb. [680 gm.]

NOTE: The first load dispensed is always the default size.(small)

The standard load sizes can be modified:

To change F3D Standard Load Sizes – See F3D SM Section 3.4

To change F3Dn Standard Load Sizes – See F3Dn SM Section 3.4

To change F3D3 Standard Load Sizes – See F3D3 SM Section D1

SECTION 3

CONTROLS

8

8

8

Checking the Load Cell gap

SECTION 4

REFRIGERATION

Some Load Cell Basics

Load Cells are commonly used in manufacturing to accurately weigh ingredients in batch and continuous

processing applications. The Franke F3D Series employs a small beam-type load cell to accurately measure a

portion of frozen fries, plus the Automation Assembly that is holding and dispensing that batch. It is mounted

just below the Door Lift Motor

Load cells generally have three components: a mechanical system, a strain gauge and an electric

amplification device. The mechanical system transfers force to the strain gauge (elastic foil), which is

connected to a wheatstone bridge that converts strain into electric output. This small electric output is

amplified and sent to the controller, which converts the electric output into a measurement of force, in this

case a weight factor.

To calibrate F3D Load Cells – See F3D SM Section 3.7

8

8

8

To replace a F3D Load Cell – See F3D SM Section 2.6

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

8

8

8

SECTION 5

TROUBLESHOOTING

Load Cell Calibration

The Load Cell (actually the software on the Main Broad

controller) must be calibrated so that it nets out the weight of the

Automation Assembly (including bucket & product doors) when

calculating the actual fries batch weight (Small, Medium or Large).

Load cells must also be calibrated when replacing the Load Cell,

Automation Assembly or Main Control Board.

To calibrate F3Dn Load Cells – See F3Dn SM Section 3.7

To calibrate F3D3 Load Cells – See F3D3 SM Section D3

F3Dn Main Board calibration

To replace a F3Dn Load Cell – See F3Dn SM Section 2.9

To replace a F3D3 Load Cell – See F3D3 SM Section 2.10

MECHANICS

F3D Series Mechanical : Weighing System

13

SECTION 3

CONTROLS

SECTION 2

MECHANICS

SECTION 1

F3D SERIES BASICSI

Franke F3D-Series STM - Section 2 Mechanics QUICK QUIZ

[Quiz Key: Multiple Choice: circle the single best answer; True or False: circle one; Fill-in-theblank(s): write in brief answer(s)]

1) When the basket in loading lane (or MANUAL FILL button on F3Dn) initiates a fill cycle, the

basket receives a load already measured into the lane bucket during the pervious fill cycle?

True False (circle one)

2) Lane Fry Hoppers must be removed to:

a) Add fries to the hopper

b) Clean the hopper

c) Inspect the fries bucket and lane doors

d) Position the optional hash browns rack

e) b) and c) above

3) In F3D3 Models, you can easily remove:

a) Both Hoppers

b) The insulated Freezer Bottom

c) The silicone rubber Fries Buckets

d) a) and b) above

4) F3D and F3Dn Model fries Buckets are tapered stainless steel and lift out, for easy cleaning.

True False (circle one)

5) The insulated Freezer Bottom can NOT be installed backwards. True False (circle one)

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

SECTION 4

REFRIGERATION

6) All F3D-Series lane Product Door pairs are the same or symmetric. True False (circle one)

7) The orange rubber Baffle inside each lane Hopper:

a) Catches broken fries

b) Controls fry drop, helps reduce breakage

c) Pulls out of the Hopper for easy cleaning

d) b) and c) above

8) A Load Cell is used to: _____________________________________________

9) Tare weight is the weight of the Bucket, a full load of fries and Door Lift Slide Assembly. True

False (circle one)

10) The Load cell must be replaced when:

a) The Main Control Board is replaced

b) The Load Cell itself is replaced

c) The Automation Assembly or Door Lift Slide is replaced

d) None of the above

e) a), b) and c) above

11) The handle on the Hopper Rotor (protrudes through front of Hopper) is used to:

a) Remove any excess fries in the hopper

b) Initiate the Hopper CLEAN Cycle

c) Seat the Hopper/Rotor when returning the Hopper to the Freezer compartment.

d) Break up a frozen fries bridge.

12) When viewed from the front of the dispenser, the (Drum) Rotor inside the Hopper rotates:

a) Clockwise

b) Counter-clockwise

c) Both ways

d) Clockwise in the Northern Hemisphere, counter-clockwise in the Southern Hemisphere.

14

MECHANICS

Section 2 Mechanics QUICK QUIZ

3.0 F3D Series Controls

SECTION 1

F3D SERIES BASICS

The F3D Series lane operator control panels have been moved, reconfigured and updated to meet the

needs of users and to simplify troubleshooting and unit programming. F3D and F3Dn models have

touch pads and LED status/indicator lights. The F3D3 adds a text LCD display.

SECTION 2

MECHANICS

3.1 F3D Control Panel Function Guide:

-2-

-3-

-4-

-5-

SECTION 3

CONTROLS

-1-

Each lane overlay has the following touch-pad controls and LED indicator lights:

1. LANE ON/OFF – Turns the individual lane on and off. Press and Hold to activate or deactivate the

dispense lane. Do NOT turn lane ON until after the hopper is loaded with fries.

2. LOAD READY – Three green lights indicate that the lane is ready to dispense a load of fries.

SECTION 4

REFRIGERATION

3. LOAD SIZE – Indicates size of load of fries to be dispensed. Can only be changed when LOAD

READY lights are illuminated. The default is LARGE (Load Size). Pressing the LOAD SIZE touch-pad

changes it from: LARGE to MEDIUM to SMALL, then back to LARGE.

4. RESET LANE – A fault condition has occurred.

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

5. LOW PRODUCT – The fry level in the hopper is low and the hopper should be refilled.

Approximately 1 bag of fries remains. Unit will continue to dispense fries.

CONTROLS

F3D Control Panel Function Guide

15

3.2 F3Dn Control Panel Function Guide:

SECTION 2

MECHANICS

SECTION 1

F3D SERIES BASICS

The F3Dn Model added the choice of AUTO(matic) or MANUAL(ly) activated basket fill.

-1-

-2-

-3-

-4-

-5-

-6-

Each lane overlay has the following touch-pad controls and LED indicator lights:

1. LANE POWER – Turns individual lane on and off. Press and Hold to activate. Press again to change

to AUTO or MANUAL. Do NOT turn lane ON until after hopper is filled with fries.

SECTION 3

CONTROLS

2. PRESS FOR MANUAL DISPENSE – Press touch pad to dispense a single load of fries. LANE POWER

must be in MANUAL mode, the lights above MANUAL DISPENSE button and LOAD READY INDICATOR

illuminated and an empty fries basket in load position. (NOTE: In AUTO Mode, a load of fries is

dispensed automatically, if basket is present and activates basket-present sensor.)

3. LOAD READY – Indicates that lane is ready to dispense a load of fries.

SECTION 4

REFRIGERATION

4. LOAD SIZE – Indicates size of load of fries to be dispensed. Can only be changed when LOAD READY

lights are illuminated. The default is SMALL (Load Size). Pressing LOAD SIZE touch-pad changes it

from: SMALL to MEDIUM to LARGE, then back to SMALL.

5. RESET LANE – A fault condition has occurred:

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

6. LOW PRODUCT – Fry level in hopper is low and hopper should be refilled. Approximately 1 bag of

fries remains. Unit will continue to dispense fries.

16

CONTROLS

F3Dn Control Panel Function Guide

3.3 F3D3 Control Panel Function Guide:

3

4

5

6

SECTION 2

MECHANICS

2

SECTION 1

F3D SERIES BASICS

The F3D3 adds an LCD display for from-the-front programming and diagnostic capability.

7

SECTION 3

CONTROLS

1

Each lane control panel overlay has the following touch pads, indicator lights and LCD display:

SECTION 4

REFRIGERATION

1. Lane POWER Touch Pad (With green right & left LED Lights)

Press to turn individual lane ON or OFF:

§ Press and Hold touch pad for 4 seconds to turn on. Lights will stay on.

§ Press and Hold touch pad for 4 seconds to turn off. Lights will turn off.

NOTE: Do not turn ON until hopper is filled with fries.

2. Load READY Graphic (With 7 Green LED lights inside basket icon):

When lights are on, the lane is ready to dispense into a fry basket.

SECTION 5

TROUBLESHOOTING

3. Attention/Warning Graphic (With 3 LED Lights at corners):

This symbol communicates lane status:

§ No lights on – Unit status OK

§ Lights ON – Getting low on frozen fries in hopper, but unit will continue to dispense.

§ Lights Flashing – Error condition. See display (4) for error message & SM Section 1.4 or in

this STM Section 5.3 for Error Message Displays and corrective actions.

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

4. LCD Message Display Window

§ Displays current freezer operating temperature (in upper-right corner of left display)

§ Displays Error Messages (Err04, etc.) and possible causes and remedies

§ Displays unit Setup & Diagnostic Programs with possible actions or decision options.

5-7 Program Decision or Action Touch Pads

Three touch pads are evenly spaced under the Display Screen, which displays options: Inc

(increase) Dec (decrease) OK etc. Use the Action 5 touch pad under the option (Inc/Dec/OK)

to initiate that action.

CONTROLS

F3D3 control Panel Function Guide

17

SECTION 1

F3D SERIES BASICS

4.0 F3D Series Refrigeration System – Basic Operator PM

SECTION 2

MECHANICS

Regular preventive maintenance is specified and required for proper performance and long term health

of F3D Series Freezers/Dispensers. Instructions for daily, monthly and quarterly PM are included in

F3D, F3Dn and F3D3 Operating Manuals and McDonald’s PMM (Preventive Maintenance Manuals)

provided at store level. All three F3D variants require:

1. Daily - freezer defrosting and cleaning of interior, exterior and removable components, including

the hoppers, freezer bottom and dispense lane racks and drip pans;

2. Monthly – removal and cleaning of the condenser coil filter; and

3. Quarterly – cleaning of the condenser coils with a soft brush or vacuum.

F3Dn Models

F3D3 Models

SECTION 3

CONTROLS

F3D Models

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

SECTION 4

REFRIGERATION

Check the condition of the freezer compartment, condenser filter and condenser coil to see if PM has

been performed. If not, defrost and clean unit before performing system diagnostics, replacement or

repair of components. Notify unit or shift manager of perceived problems with regular PM.

18

REFRIGERATION

F3D Series Refrigeration Basic Operator PM

SECTION 1

F3D SERIES BASICS

5.0 F3D Series Troubleshooting – Control Panel Function Guides

Each generation of F3D Series Freezer/Dispenser has added system troubleshooting and

diagnostic capabilities, making it faster and easier to identify problems and provide solutions.

Let’s begin with a review of the basic operator control panel functions, associated error indicator

lights or display messages [F3D3 only].

5.1 F3D Control Panel Function Guide

SECTION 3

CONTROLS

SECTION 2

MECHANICS

Note RESET LANE LED lights interpretation in red, below.

Each lane overlay has the following touch-pad controls and LED displays:

2.

SECTION 4

REFRIGERATION

1.

LANE ON/OFF – Turns the individual lane on and off. Press and Hold to activate. Do NOT turn

lane ON until after the hopper is loaded with fries.

LOAD READY – Three green lights indicate that the lane is ready to dispense a load of fries.

3.

LOAD SIZE – Indicates size of load of fries to be dispensed. Can only be changed when LOAD

READY lights are illuminated. The default is LARGE (Load Size). Pressing LOAD SIZE touch-pad cycles

from: LARGE to MEDIUM to SMALL, then back to LARGE.

RESET LANE – A fault condition has occurred.

SECTION 5

TROUBLESHOOTING

4.

•

Flashing lights – Time out error. The Hopper is either out of fries or a bridge has formed

preventing fries from feeding. Correct condition and press RESET LANE button to resume normal

operation.

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

•

Lights ON – Failure to tare error. Most likely a component assembly issue. Disassemble and

reassemble that lane per Operating Manual or Quick Reference Card instructions. Make sure all stray

fries are cleaned out. Then press RESET LANE button to resume normal operation.

5.

LOW PRODUCT – The fry level in the hopper is low and the hopper should be refilled.

Approximately 1 bag of fries remains. Unit will continue to dispense fries.

For any issues beyond the above, contact Franke Service Hotline 1-800-5 Franke (1-800-537-7563

Option 2)

TROUBLESHOOTING

F3D Control Panel Function Guide

19

5.2 F3Dn Control Panel Function Guide

SECTION 2

MECHANICS

SECTION 1

F3D SERIES BASICS

The F3Dn Operator Lane Control panel is similar to the F3D Model, with the addition of a MANUAL

DISPENSE Mode and fill initiation touch pad. Note RESET LANE LED lights interpretation in red, below.

-1-

-2-

-3-

-4-

-5-

-6-

Each lane overlay has the following touch-pad controls and LED displays:

SECTION 3

CONTROLS

1.

LANE POWER – Turns individual lane on and off. Press and Hold to activate. Press again to

change to AUTO or MANUAL. Do NOT turn lane ON until after hopper is filled with fries.

2.

PRESS FOR MANUAL DISPENSE – Press touch pad to dispense a single load of fries. LANE

POWER must be in MANUAL mode, the lights above MANUAL DISPENSE button and LOAD READY

INDICATOR illuminated and an empty fries basket in load position. (NOTE: In AUTO Mode, a load of fries

is dispensed automatically, if basket is present and activates basket-present sensor.)

SECTION 4

REFRIGERATION

3.

LOAD READY – Indicates that lane is ready to dispense a load of fries.

4.

LOAD SIZE – Indicates size of load of fries to be dispensed. Can only be changed when LOAD

READY lights are illuminated. The default is LARGE (Load Size). Pressing LOAD SIZE touch-pad cycles

from: SMALL to MEDIUM to LARGE, then back to SMALL.

5.

RESET LANE – A fault condition has occurred.

SECTION 5

TROUBLESHOOTING

•

Steady Flashing Lights – Time out error. Hopper is either out of fries or a bridge has formed

preventing fries from feeding. Correct condition and press RESET LANE touch pad to resume normal

operation.

•

Three Quick Flashing Lights – Drum/Rotor motor jam. Refrozen fries have stopped rotor from

turning. Clear frozen fries and press RESET LANE touch pad. .

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

•

Continuous Lights ON – Failure to tare error. Most likely an assembly issue. Disassemble and

reassemble lane per Operating Manual. Make sure all stray fries are cleaned out. Then press RESET

LANE touch pad to resume operation.

6.

LOW PRODUCT – Fry level in hopper is low and hopper should be refilled. Approximately 1 bag

of fries remains. Unit will continue to dispense fries.

For any issues beyond the above, contact Franke Service Hotline 1-800-5 Franke (1-800-537-7563

Option 2)

20

TROUBLESHOOTING

F3Dn Control Panel Function Guide

5.3 F3D3 Control Panel Guide

3

4

5

6

SECTION 2

MECHANICS

2

SECTION 1

F3D SERIES BASICS

The F3D3 was designed with the lane Main Control Boards front-mounted, just under the Operator Control

Panels. The diagnostics LCD display now can be seen though the Operator Control Panel; and diagnostics or

programming done using the three touch pads on that Operator Control Panel.

7

SECTION 3

CONTROLS

1

Each lane control panel overlay has the following touch pads, indicator lights and LCD display:

SECTION 4

REFRIGERATION

1. Lane POWER Touch Pad (With green right & left LED Lights)

Press to turn individual lane ON or OFF:

Press and Hold touch pad for 4 seconds to turn on. Lights will stay on.

Press and Hold touch pad for 4 seconds to turn off. Lights will turn off.

NOTE: Do not turn ON until hopper is filled with fries.

4. LCD Message Display Window

Displays current freezer operating temperature (in upper-right corner of left display)

Displays Error Messages (Err04, etc.)and possible causes and remedies

Displays unit Setup & Diagnostic Programs with possible actions or decision options.

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

3. Attention/Warning Graphic (With 3 LED Lights at corners):

This symbol communicates lane status:

No lights on – Unit status OK

Lights ON – Getting low on frozen fries in hopper, but unit will continue to dispense.

Lights Flashing – Error condition. See display (4.) for error message & SM Section 1.4.

SECTION 5

TROUBLESHOOTING

2. Load READY Basket Graphic (With 7 Green LED lights inside basket icon):

When lights are on, the lane is ready to dispense into a fry basket.

5-7 Program Decision or Action Touch Pads

Three touch pads are evenly spaced under the Display Screen, which displays options: Inc (increase) Dec

(decrease) OK etc. Use the Action touch pad under the option (Inc/Dec/OK) to initiate that action.

TROUBLESHOOTING

F3D3 Control Panel Function Guide

21

5.4 F3D3 Error Message Guide

SECTION 1

F3D SERIES BASICS

F3D3 Models have lane touch control panels that display

unit status and Error Messages. The following table lists

all Error Messages and the lane condition or action

required to correct the problem.

Error

Code

Error Description

Ready

Low Fry Level

Small

Low Product Warning

Add fries to hopper. If you

continue dispensing Err04(A)

Message appears.

01

Err01

Load Cell Error

Call for Service

Reset

Tare Time Out

Call for Service

02

Err02

No Bucket

Recheck Assembly

Reset

No Bucket

Check rubber dispense bucket

and loading doors.

Press Reset (bottom-right)

touchpad to reset.

03

Err03

Drum Stuck

Empty Hopper & Refill

Reset

Drum Torque Error in PrePulse Mode

Empty fries from Hopper and

refill.

Press Reset (bottom-right)

touchpad to reset.

04A

Err04

Hopper Empty

Add Fries

Reset

Fill Time Out (with Low

Product Warning ON*)

Add fries to hopper.

Press Reset (bottom-right)

touchpad to reset.

04B

Err04

Fry Bridge

Clear Fry Bridge

Reset

Fill Time Out (with Low

Product Warning OFF*)

Clear any fry bridge in hopper.

Press Reset (bottom-right)

touchpad to reset.

SECTION 3

CONTROLS

SECTION 2

MECHANICS

---*

SECTION 4

REFRIGERATION

Action Required

(Section No.s in F3D3 SM)

Actual Display Message

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

* When Hopper Level is below Low Product Sensor, display flashes “Low Fry Level” and three LEDs around

warning triangle illuminate.

22

05

Err05

Drum Stuck

Empty Hopper

Reset

Drum Torque Error in Pulse

Mode

Empty fries from Hopper. Test

rotation of drum.

Press Reset (bottom-right)

touchpad to reset.

06

Err06

Bucket Lift Error

Call for Service

Reset

Lift Torque Error

Call for Service

07

Err07

Doors Stuck

Clear Dispense Area

Reset

Door Torque Error in Forward

(Open) Direction

Clear Dispense Area.

Press Reset (bottom-right)

touchpad to reset.

08

Err08

Doors Stuck

Call for Service

Reset

Door Torque Error in Reverse

(Close) Direction

Call for Service.

Check door open motor for

obstruction.

TROUBLESHOOTING

F3D3 Error Message Guide

SECTION 1

F3D SERIES BASICS

6.0 F3D3 Testing Access for Customer

SECTION 2

MECHANICS

6.1 F3D3 Motor Test Procedure

NOTE: All programming is done using the three choice buttons () below the Lane Control Panel display.

SECTION 3

CONTROLS

1) Leave unit plugged in.

2) Turn Main Power Switch ON.

3) Lane power must be OFF. Display will be blank or show current freezer temperature, depending on the

lane.

From Standby condition use 3rd touchpad and enter: Special Mode Select

3-3-3-3. [Entry code]

Cust

Fact

Exit

Press touchpad 1 = Cust

Lev2 – Customer Access

Set Language ?

Prev

OK

Next

Press touchpad 3 = Next

Lev2 – Customer Access

Set Temp Control ?

Prev

OK

Next

Press touchpad 3 = Next

Lev2 – Customer Access

Calibrate ?

Prev

OK

Next

Press touchpad 3 = Next

Lev2 – Customer Access

Test Motors ?

OK

OK

Next

Press touchpad 2 = OK

Drum Mtr?

OK

Next

Press touchpad 1 = OK

Drum Trq = 0000

Peak = 0000

Run

Reset

Next

3

4

5

6

7

F3D3 TESTING ACCESS FOR CUSTOMER

F3D3 Motor Test Procedure

SECTION 4

REFRIGERATION

1

2

Resulting Display

SECTION 5

TROUBLESHOOTING

Action Required

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

Step

23

SECTION 1

F3D SERIES BASICS

8

9

10

SECTION 2

MECHANICS

11

12

SECTION 3

CONTROLS

13

Press 1 = Run [To energize drum motor] Maximum

(peak) torque is displayed…then

Press 2 = Reset [To zero display value]…then

Press 3 = Next [For next motor test]

Press touchpad 1 = OK [To run test]

Press 1 = Run [To energize lift motor]

Torque and load cell (LC) are displayed…then

Press 3 = Next [For next motor test]

Press touchpad 1 = OK [To run test]

Press 1 = Run [To energize door motor] Maximum

(peak) torque is displayed…then

Press 2 = Reset [To zero display value]…then

Press Next 3 = Exit

Press 1 = OK [to repeat tests] or

Press 2 = Exit

14

Press touchpad 2 = OK [To Exit]

To Replace Drum Rotor Motor…See Section 2.5

Lift Mtr?

OK

Trq = 0000

Run

Door Mtr?

OK

Next

LC = 00000

Next

Next

Door Trq = 0000

Peak = 0000

Run

Reset

Exit

Repeat Mtr Tests?

OK

Exit

Lev2 – Customer Access

Exit Lev2 ?

Prev

OK

Next

To Replace Door Lift Motor…See Section 2.7

To Replace Door [Open] Motor…See Section 2.8

SECTION 4

REFRIGERATION

6.2 F3D3 Display Panel LED Light Test

NOTE: Follow this LED Test Procedure before replacing the Lane Touch Pad Control Panel for a LED failure.

All programming is done using the three choice buttons labeled: 1, 2 and 3 above.

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

1) Leave unit plugged in.

2) Turn Main Power Switch ON.

3) Lane power must be OFF. Display will be blank or show current freezer temperature,

depending on the lane.

24

F3D3 TESTING ACCESS FOR CUSTOMER

F3D3 Display Panel LED Light Test

4

5

6

7

8

9

10

11

SECTION 1

F3D SERIES BASICS

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

12

13

14

SECTION 2

MECHANICS

3

From Standby condition use 3rd touchpad and enter: Special Mode Select

3-3-3-3. [Entry code]

Cust Fact

Exit

Press touchpad 2 = Fact

Factory Access Menu

Lev1

Lev3 Exit

Press touchpad 2 = Lev3

Service Access Menu

Enter Password 0 _ _ _

Inc

OK

Exit

Press touchpad 2 = OK…then

Lev3 – Top Menu

Press touchpad: 2 then 2 then 1…then

Tests?

Press 2 = OK [to enter password code: 0001]

Prev OK Next

Press touchpad 2 = OK

Lev3 – Test Menu

Tests Motors ?

Prev OK Next

Press touchpad 3 = Next

Lev3 – Test Menu

Test LEDs ?

Prev OK Next

Press touchpad 2 = OK

LED Test

Select Below

On/Off Blink Exit

Press touchpad 1 = On/Off [To light LEDs] or

Lev3 – Top Menu

Press touchpad 2 = Blink [To flash LEDs] then

Test Menu Exit

Press touchpad 3 = Exit [To exit LED tests]

Prev OK Next

Press touchpad 2 = OK

Lev3 – Top Menu

Specials 1 ?

Prev OK Next

Press touchpad 3 = Next

Lev3 – Top Menu

Specials 2 ?

Prev OK Next

Press touchpad 3 = Next

Lev3 – Top Menu

Stats + Cal ?

Prev OK Next

Press touchpad 3 = Next

Press touchpad 3 = Next

Press touchpad 2 = OK [to Exit]

SECTION 3

CONTROLS

2

Resulting Display

SECTION 4

REFRIGERATION

1

Action Required

SECTION 5

TROUBLESHOOTING

Step

F3D3 TESTING ACCESS FOR CUSTOMER

25

6.3 F3D3 Load Cell Calibration

SECTION 1

F3D SERIES BASICS

Load Cell Calibration, like all F3D3 Model programming, is done

using the lane operator control panel, its display and the three (5)

choice buttons under that LCD display.

Leave unit plugged in.

Product hopper should be removed and any remaining fries

removed from rubber bucket

before proceeding.

3) Turn Main Power Switch ON.

4) Press Lane Power-ON touchpad and wait for display to show:

Ready.

SECTION 2

MECHANICS

1)

2)

Step

SECTION 5

TROUBLESHOOTING

SECTION 4

REFRIGERATION

SECTION 3

CONTROLS

5

6

From Standby condition press touchpads:

3-3-3-3. [Entry code]

Press touchpad 1 = Cust

7

Press touchpad 3 = Next

8

Press touchpad 3 = Next

9

Press touchpad 2 = OK

10

Press touchpad 1 = OK

11

Press touchpad 1 = OK

12

Add Large Weight = 1.5 lb / 680 gm to product

loading bucket... then

Press touchpad 1 = OK

13

Press 1 = Recal [if error occurs during Calibration

Procedure]…or

Press 2 = Accept

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

13A

26

Action Required

14

Press touchpad 3 = Next

15

Press touchpad 2 = OK [to Exit]

F3D3 TESTING ACCESS FOR CUSTOMER

Resulting Display

Special Mode Select

Cust

Fact

Exit

Lev2 – Customer Access

Set Language ?

Prev

OK

Next

Lev2 – Customer Access

Set Temp Control ?

Prev

OK

Next

Lev2 – Customer Access

Calibrate ?

Prev

OK

Next

Lev2 – Customer Access

Calibrate Now ?

OK

Exit

Lev2 – Customer Access Load

Cell = XXXX

All

Clear?

Lev2

– Customer Access

OK

Exit

Zero = XXXX

Lev2 – Customer Access

Preload = XXXX

Lev2 – Customer Access

Add Large Wt [Weight]

OK

Lev2 – Customer Access

Large = XXXX

Lev2 – Customer Access

Z = XXXX

C = XXXX

P = XXXX

Recal

Accept

[Returns to screen shown in Step

6 on page 1]

Lev2 – Customer Access

Accepted !!

Lev2 – Customer Access

Test Motors ?

Prev

OK

Next

Lev2 – Customer Access

Exit Lev2 ?

Prev

OK

Next

Shut… [appears briefly, then

display goes blank]

F3D3 Load Cell Calibration

SECTION 1

F3D SERIES BASICS

16) Remove calibration weight from the Product Loading Bucket.

17) Reinstall Product Hopper in freezer and fill it with 2 bags of frozen fries.

18) Power up the Lane being calibrated. Check LCD display to insure “Ready” is shown for Lane being refilled

with fries.

19) Dispense several loads from this lane at each size: Small, Medium and Large, to verify calibration

procedure has been completed successfully.

20) Refer to Section D1 for adjusting “Standard” load sizes, if this is required by operator preference.

SECTION 2

MECHANICS

NOTES & TIPS:

1. A US Calibration Weight [1.5 lb / 680 gm] is available

through Franke Technical Support Group. Order Part

Number 18002044.

SECTION 3

CONTROLS

2. If US Calibration Weight is not available, use six

frozen 4:1 hamburger patties. Place them in a

clean bag or on aluminum foil. IMPORTANT:

If hamburger patties are used, clean and sanitize

the Product Chute to avoid any chance of

cross contamination.

SECTION 6

F3D3 TESTING ACCESS FOR CUSTOMER

SECTION 5

TROUBLESHOOTING

SECTION 4

REFRIGERATION

TIP: If a calibrated 1.5 pound/680

gram weight is not available, use six

4:1 frozen hamburger patties. Clean

Product Chute after calibration.

F3D3 TESTING ACCESS FOR CUSTOMER

27

Franke Foodservice Systems, Inc.

800 Aviation Parkway

Smyrna, TN USA 37167

Tel: 1.615.462.4000

Toll Free: 1.888.4.FRANKE

Toll Free: 1.888.437.2653

email: fs-sales.us@franke.com

www.frankefs.com

© 2012 - Franke Foodservice Systems Inc.

This document is the confidential and proprietary property of Franke Foodservice Systems Inc, and shall not be

reproduced in any form of media without the expressed written permission of a Franke Foodservice Systems Inc

representative. Due to continuous product development, Franke Foodservice Systems reserves the right to make

changes in design and specification without prior notice.

All registered brands, logos and trademarks are trademarked to thier respective companies.

REV 12Jun2012•Franke Frozen Fry Dispenser F3D_ F3Dn_F3D3 2012•

Under license of NIRO-Plan AG, Switzerland. Printed in U.S.A.