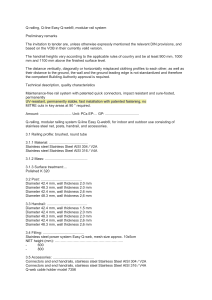

steel work nozzles

advertisement