brochure

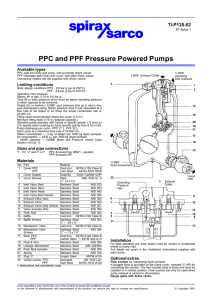

advertisement

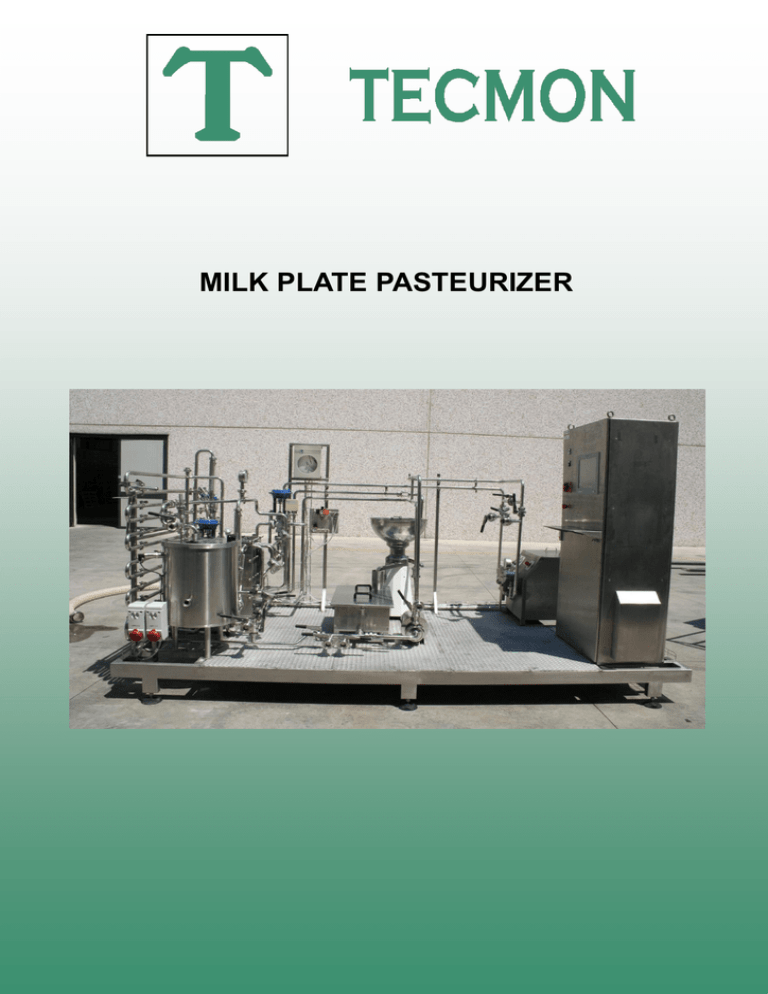

MILK PLATE PASTEURIZER MILK PLATE PASTEURIZER Milk pasteurizer for instance the following thermal cycle 4-75-4 or other, in relation with the product to handle. The plant will be composed as follow: *Buffer tank for milk made in AISI 304 stainless steel, with the following characteristics: - AISI 304 stainless steel tank, with glazed and pickled inside and outside surface - Pickled, flattened, grounded and spotted welding - Conical bottom with total exhaust valve - Plate cover with CIP (cleaning in place) devices. - Total discharging piping, manufactured in stainless steel - Glass level rod, with stainless steel protection. - level sensor to stop /start the pump -three legs supporting structure manufactured in stainless steel *Milk centrifugal pump with sanitary close impeller manufactured in stainless steel AISI 304, connection DN 25. *Plate pasteurizer designed for the treatment milk. Thermal cycle 475-4°C or different if it is necessary. The pasteurization section is composed of an heating section from 4°C to 50°C using product in counter flow, a pasteurisation section from 50 to 75 with hot water at 90°C, a precooling product section from 75 to 30°C with product in counterflow (heating recovery system) and a cooling section from 30 to 4°C with ice cold water at +2°C. The exchanger is composed of: -plates in stainless steel AISI 316 and nitrile alimentary rubber joints -intermediate plates in stainless steel AISI 304 -frame in stainless steel AISI 304 with closing lateral tie rod -pipe connections for various fluids in stainless steel -thermal holding system with multiple pipes. The pipes are connected in serial with detachable turns and mounted on a supporting frame in stainless steel. - hot water at 90°C adjustable group formed by an heat exchanger pump, an expansion tank pipes automatic temperature control - steam group formed by a manual valve, pneumatic valve, steam filter and condensate discarging group -chilled water at +2°C adjustable group formed by a pneumatic valve, pipes, and manual valve and chiller -Instruments to record the pasteurising and the exit temperature -System to adjust the thermal fluid temperatures -3 ways valve to divert the product in case of low temperature -Necessary electro pneumatical transducers -PT 100 probes for temperature measurements - Air reducing equipment for compressed air *Electrical control board including: electronic temperature regulator with PID control, main circuit breaker, work/ wash selector switch, pump selector switches TECMON S.R.L. VIA LEONARDO DA VINCI, 11/B 20060 CASSINA DE’ PECCHI (MI) TEL. +39 0295299106 FAX +39 0295299315 E-MAIL : tecmon@tin.it E-MAIL : info@tecmon.it http:// www.tecmon.it P.IVA 00791710965 COD.FISC. 04821200153 CAP. SOC. € 83.000,00 INT. VERS. ISCR. TRIB. DI MONZA REG. SOC. 17929 C.C.I.A.A. MONZA E BRIANZA 1041916