Additional problems

advertisement

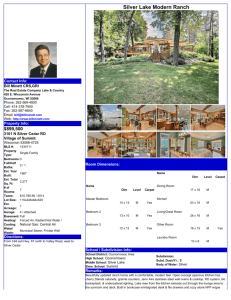

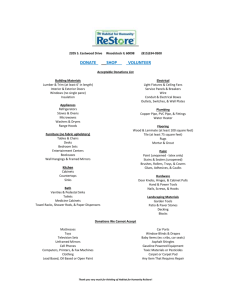

Ronco manufactures Bass-O-Matics. Their sales are subject to a downward sloping (linear) demand function: P(x) = 100 – x. The price that their product brings is a function of the quantity sold – or conversely – the quantity they can sell is a function of the price at which they sell the product. x = 100 – P(x). So if they set the price at $70 per unit, they can sell 30 units; if they set the price at $50 per unit, they can sell 50 units, and so forth. They are currently producing and selling at capacity, which is 35 units. Suppose they are approached by Bed, Bath, and Beyond with an order for 10 Bass-OMatics. Their variable costs are $10 per unit. What is the minimum price that they should consider for this order? Suppose that they can buy a new machine and increase capacity by 10 units. Ignoring the special order, how much should they be willing to pay to increase machine capacity from 35 to 45? Silver Lake Cabinets is approached by Ms. Jenny Zhang, a new customer, to fulfill a large one-time-only special order for a product similar to one offered to regular customers. The following per unit data apply for sales to regular customers: Direct materials Direct labor Variable manufacturing support Fixed manufacturing support Total manufacturing costs Markup (60%) Targeted selling price $100 125 60 75 360 216 $576 Silver Lake Cabinets has excess capacity. Ms. Zhang wants the cabinets in cherry rather than oak, so direct material costs will increase by $30 per unit. Required: a. b. For Silver Lake Cabinets, what is the minimum acceptable price of this onetime-only special order? Suppose that Silver Lake has capacity of 10,000 cabinets and is currently operating at 90% capacity. If the order is for 2,000 cabinets, what is the minimum acceptable price for the special order?