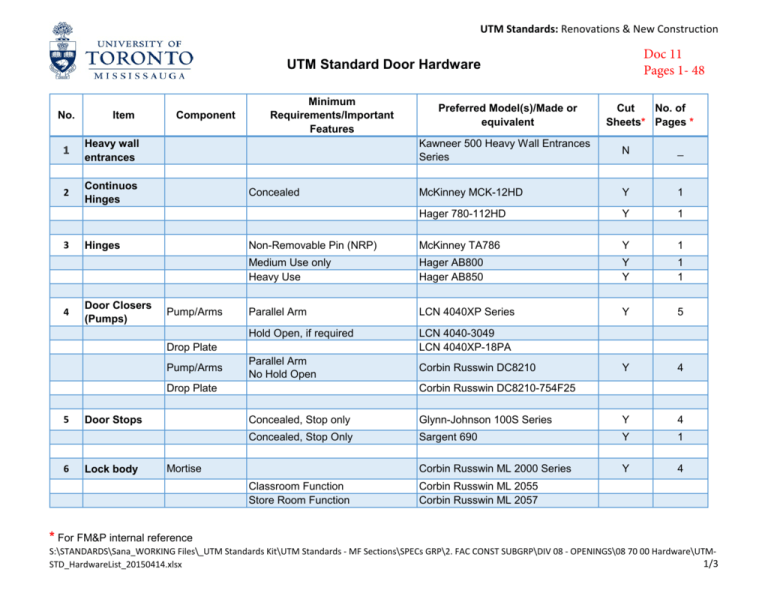

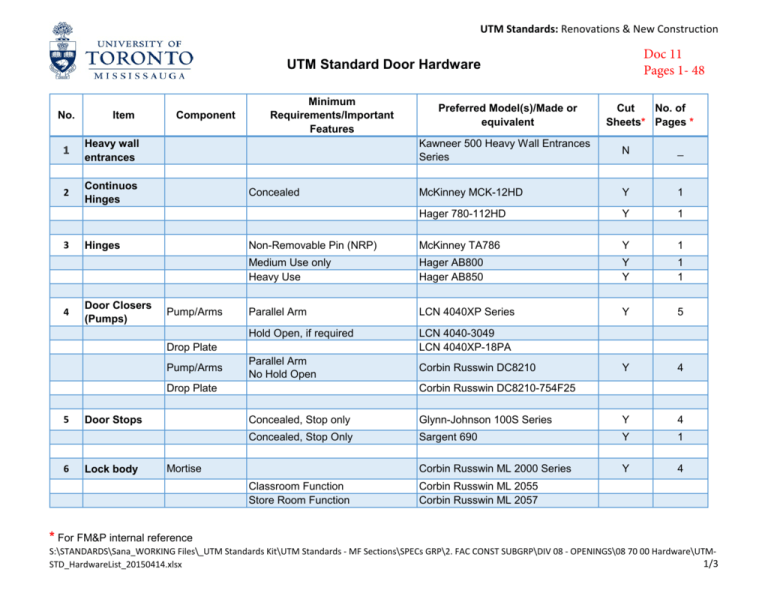

UTM Standards: Renovations & New Construction

Doc 11

Pages 1- 48

UTM Standard Door Hardware

No.

Item

1

Heavy wall

entrances

2

Continuos

Hinges

3

4

Component

Pump/Arms

_

McKinney MCK-12HD

Y

1

Hager 780-112HD

Y

1

Non-Removable Pin (NRP)

McKinney TA786

Y

1

Medium Use only

Heavy Use

Hager AB800

Hager AB850

Y

Y

1

1

Parallel Arm

LCN 4040XP Series

Y

5

Hold Open, if required

LCN 4040-3049

LCN 4040XP-18PA

Y

4

Parallel Arm

No Hold Open

Drop Plate

5

6

Door Stops

Lock body

Corbin Russwin DC8210

Corbin Russwin DC8210-754F25

Concealed, Stop only

Glynn-Johnson 100S Series

Y

4

Concealed, Stop Only

Sargent 690

Y

1

Corbin Russwin ML 2000 Series

Y

4

Mortise

Classroom Function

Store Room Function

* For FM&P internal reference

Cut

No. of

Sheets* Pages *

N

Drop Plate

Pump/Arms

Preferred Model(s)/Made or

equivalent

Kawneer 500 Heavy Wall Entrances

Series

Concealed

Hinges

Door Closers

(Pumps)

Minimum

Requirements/Important

Features

Corbin Russwin ML 2055

Corbin Russwin ML 2057

S:\STANDARDS\Sana_WORKING Files\_UTM Standards Kit\UTM Standards - MF Sections\SPECs GRP\2. FAC CONST SUBGRP\DIV 08 - OPENINGS\08 70 00 Hardware\UTM1/3

STD_HardwareList_20150414.xlsx

UTM Standards: Renovations & New Construction

UTM Standard Door Hardware

No.

Item

Minimum

Requirements/Important

Features

Entrance/Office Function

Privacy Function

Corbin Russwin ML 2051

Corbin Russwin ML 2030

Lever

ADA/AODA compliant

Corbin Russwin LWA

Finish

BMHA 626 Satin Chromium Plated

(US 26D)

Component

7

Kick Plate

18 guage min/ C32 finish tape

8

Push Button

ADA/AODA compliant /

4 1/2" square

9

Push Bar

(Panic Bar)

Rim Consealed

Rim

Lever

Mortise

Lever

Finish

10

Door Operator

* For FM&P internal reference

Preferred Model(s)/Made or

equivalent

Cut

No. of

Sheets* Pages *

N

_

Camden CM45/2 or CM46/4

Y

2

Corbin Russwin ED 5000 series

Y

11

Y

2

Y

2

Corbin Russwin ED 5860

Corbin Russwin ED 5200

Corbin Russwin Lustra L9

Corbin Russwin ED 5600L

Corbin Russwin Lustra L9M

US26D Satin Chromium Plated

(626)

Preferred Feature: Ability to detect

& handle high winds (under heavy Besam SW200i

wind load)

Horton 7100

S:\STANDARDS\Sana_WORKING Files\_UTM Standards Kit\UTM Standards - MF Sections\SPECs GRP\2. FAC CONST SUBGRP\DIV 08 - OPENINGS\08 70 00 Hardware\UTM2/3

STD_HardwareList_20150414.xlsx

UTM Standards: Renovations & New Construction

UTM Standard Door Hardware

No.

Item

Component

Minimum

Requirements/Important

Features

11

Keying

By Owner

12

Mullion

Key Removable Mullions

Electric Strike

Solenoid to be at the back of unit

(Follow I&ITS Access Control

Specs)

Retrofits only

13

14

Card Reader

Preferred Model(s)/Made or

equivalent

Medico system

Cut

No. of

Sheets* Pages *

N

_

N

_

RCI F2164

Y

2

HES 9600 series

Y

2

(Follow I&ITS Access Control

Specs)

Important Note: Changes to Access Control System may result in revising the hard ware components affected. Please

ensure to review the list in conjunction with the latest Access Control System Standards.

* For FM&P internal reference

S:\STANDARDS\Sana_WORKING Files\_UTM Standards Kit\UTM Standards - MF Sections\SPECs GRP\2. FAC CONST SUBGRP\DIV 08 - OPENINGS\08 70 00 Hardware\UTM3/3

STD_HardwareList_20150414.xlsx

UTM Standards: Renovations & New Construction

UTM Standard Door Hardware

Appendix:

Preferred Door

Hardware Cut Sheets

S:\STANDARDS\Sana_WORKING Files\_UTM Standards Kit\UTM Standards - MF Sections\SPECs GRP\2. FAC CONST SUBGRP\DIV 08 - OPENINGS

\08 70 00 Hardware\

Preferred model.

1-800-346-7707

www.mckinneyhinge.com

Recommended for new construction and renovations including new door and frame, new door

with existing frame or existing door with new frame. Designed for use on retrofit applications

and allows for adjustment in order to properly align the lock edge of the door to the frame.

• Designed for use with doors that are standard 13 ⁄4"

up to 21 ⁄4" thick

LISTED

Door Hinges

• Extruded 6063-T6 aluminum alloy/temper with

pinless assembly

• S pecial hinge reinforcements are not required.

Hollow metal door and frame manufacturers’

standard is acceptable. Removal of hinge

reinforcements in the door and frame is not advised

MCK-12HD

• S tandard Fasteners are #12-24x7⁄16" FHUC,

Type C, thread-forming screws. Wood screws

available on request

• Available in custom lengths (specify handing and

length in inches) and custom finishes (consult factory

for availability)

Standard Application

• Hinges are guaranteed for the life of the opening

• The Molex connectors or electrically modified hinges

are guaranteed for five years

Finishes

Code

Description

CL

Clear anodized aluminum

BZ

Dark anodized aluminum

G

Gold anodized finish

Options:

BL

Black anodized finish

Code

Description

HT

Hospital Tip

FP

Fire Pins

MM

Magnetic Monitoring

PT

Power Transfer Prep

(cut out only) for Adams

Rite, Securitron, Yale,

PEMKO, Dorma &

Centurion*

EPT

Power Transfer Prep

(cut out only) for

Von Duprin, Securitron, &

PEMKO*

LPT

Securitron, Adams Rite,

PEMKO*

Door

Size

Hinge

Length

# of

Bearings

Door

Weight

6' 8"

79"

26

520 lbs

7' 0"

83"

27

540 lbs

7' 2"

85"

27

540 lbs

8' 0"

95"

31

620 lbs

10' 0"

120"

39

780 lbs

full mortise-edge hung flush door continuous gear hinges

MCK-12HD Series Full Mortise Short Leaf Flush

Refer to catalog pages EH-6 for

additional information on our

electrical options.

* PT, EPT, LPT Location Form must

accompany your order

Copyright © 2012, McKinney Products Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of McKinney Products Company is prohibited.

CG-7

PRODUCT SPECIFICATIONS

For more information visit www.hagerco.com

Preferred model.

780-112HD

Heavy Duty

Concealed Leaf Hinge

Application:

- Lead lined model for hospital x-ray room doors with double row of screws

to straddle lead (specify "LL")

- Frame and door leaf alignment ribs for proper hinge and door location

PRODUCT SPECIFICATIONS

CLEARANCE:

- 5/16" (8 mm) hinge side

- Plus standard lockside clearance

WARRANTY:

- All Roton products have a lifetime warranty. When ordering electric Roton, the

electric portion of the hinge has a one-year warranty.

FASTENERS:

- #12-24 X 11/16" Flat Head Self-Drill Screws

MATERIAL:

- Aluminum 6063-T6

LENGTH OPTIONS:

- Standard and Custom

ELECTRIC

MODIFICATIONS:

- Power Transfer Preparation (EPT 2) or (EPT 10)

- Exposed Electric Contacts (E)

- Exposed Electric Switches (E1S)

- Electric Through-Wire (ETW)

- Electric Monitoring (EMN)

- Electric Through-Wire and Monitoring (ETM)

- Removable Electric Through-Wire (RETW)

DOOR REINFORCEMENT:

- None required to 200 lbs. Heavier weight use 16-gauge channel.

FRAME REINFORCEMENT:

- None required to 200 lbs. Heavier weight use 16-gauge channel.

FIRE RATING:

- Up to 3 hr. metal and 90 min. wood composite (with studs)

PRODUCT SIZE OPTIONS

LENGTH (INCHES)

LENGTH (CM)

HOLE COUNT (DOOR)

HOLE COUNT (JAMB)

79

200.7

15

15

83

210.8

19

19

85

215.9

19

19

95

241.3

19

19

119

302.3

21

21

Preferred model.

FULL MORTISE BEARING HINGES

1-800-346-7707

www.mckinneyhinge.com

Three Knuckle Heavy Weight Series

Recommended for use on high frequency and/or heavy wood or metal doors in

schools, hospitals or other public buildings where heavy traffic is experienced.

• Heavy weight hinges should be used on all extra heavy

doors or those exposed to high frequency use

TA386

TA786

• Use for the common flush door/frame/wall application

• Beveled Edge - where doors are beveled on hinge side specify TA5386 or TA5786

• For available finishes see page 29

No.

ANSI Cross Reference

Base Material

Weight

TA386

A5111

Stainless

STD

TA386

A2111

Brass

STD

TA786

A8111

Steel

STD

Application

Specifications

Inches

mm

Gauge

No. of

Holes

4 ⁄2" x 4"

114.3 x 101.6

.180

4 1⁄2" x 4 1⁄2"

114.3 x 114.3

5" x 4 1⁄2"

Machine

Wood

8

1

⁄2 x 12-24

11⁄4 x 12

.180

8

1

⁄2 x 12-24

11⁄4 x 12

127 x 114.3

.190

8

1

⁄2 x 12-24

11⁄4 x 12

5" x 5"*

127 x 127

.190

8

1

⁄2 x 12-24

11⁄4 x 12

6" x 5"*

152.4 x 127

.203

10

1

⁄2 x 1⁄4 -20

11⁄2 x 14

6" x 6"*

152.4 x 152.4

.203

10

1

⁄2 x 1⁄4 -20

11⁄2 x 14

1

* Not available in Brass Base material

FM-6

Fasteners

Updated April 2014

Options:

Code

Description

NRP

Non-Removable Pin

ET

Exposed Tip

RC

Round Corner - 1⁄4"

radius furnished unless

specified otherwise

HT

Hospital Tip

SSF

Safety Stud Feature

QC

ElectroLynx ® Hinge - 2,

4, 6, 8, 10 or 12 wire

available

CC

Concealed Circuit - 2,

4, 6, 8, 10 or 12 wire

available

CC-18

Concealed Circuit - 2, 4,

6, 8 or 10 wire available

(2-18AWG wires and

the remainder 28AWG

wires)

MM

Magnetic Monitoring

Copyright © 2012, 2014, McKinney Products Company, an ASSA ABLOY Group company. All rights reserved.

Reproduction in whole or in part without the express written permission of McKinney Products Company is prohibited.

PRODUCT SPECIFICATIONS

For more information visit www.hagerco.com

Preferred model.

AB800

Three Knuckle

Concealed Anti-Friction Bearing

Standard Weight

Application:

- ANSI A2112 (Brass)

- ANSI A5112 (Stainless Steel)

- Non-rising removable pin with flush pin and plug

- For use with medium weight doors or doors requiring medium frequency

service

Electric Modifications:

- EMN (Electric Monitor Only)

- ETW (Electric Through-Wire Only)

- ETM (Electric Through-Wire with Monitoring)

- Quick Connect

PRODUCT SPECIFICATIONS

MATERIALS:

- Stainless Steel with Stainless Steel pin

- Brass with Stainless Steel pin

NOTE:

- Available with SecureCoat Lifetime finish. (Specify US3SC when ordering)

FINISHES:

- US3SC, US3, US10, US10B, US26, US26D, US32D

PRODUCT SIZE OPTIONS

HINGE SIZE

(INCHES)

HINGE SIZE

(MM)

GAUGE OF

METAL

HOLE

COUNT

SCREW SIZE

(MACHINE)

SCREW SIZE

(WOOD)

3 1/2 x 3 1/2

89 x 89

0.119

6

1/2 x 10-24

1x9

4x4

102 x 102

0.129

8

1/2 x 12-24

1 1/4 x 12

4 1/2 x 4

114 x 102

0.134

8

1/2 x 12-24

1 1/4 x 12

4 1/2 x 4 1/2

114 x 114

0.134

8

1/2 x 12-24

1 1/4 x 12

5x4

127 x 102

0.145

8

1/2 x 12-24

1 1/4 x 12

5 x 4 1/2

127 x 114

0.145

8

1/2 x 12-24

1 1/4 x 12

5x5

127 x 127

0.145

8

1/2 x 12-24

1 1/4 x 12

PRODUCT SPECIFICATIONS

For more information visit www.hagerco.com

Preferred model.

AB850

Three Knuckle

Concealed Anti-Friction Bearing

Heavy Weight

Application:

- ANSI A2111 (Brass)

- ANSI A5111 (Stainless Steel)

- Non-rising removable pin with flush pin and plug.

- For use on heavy weight doors or doors requiring high frequency service

Electric Modifications:

- EMN (Electric Monitor Only)

- ETW (Electric Through-Wire Only)

- ETM (Electric Through-Wire with Monitoring)

- Quick Connect

PRODUCT SPECIFICATIONS

MATERIAL:

- Brass with Stainless Steel pin

- Stainless Steel with Stainless Steel pin

FINISHES:

- US3SC, US3, US10, US10B, US26, US26D, US32D

NOTE:

- Available with SecureCoat Lifetime finish. (Specify US3SC when ordering)

PRODUCT SIZE OPTIONS

HINGE SIZE

(INCHES)

HINGE SIZE

(MM)

GAUGE OF

METAL

HOLE

COUNT

SCREW SIZE

(MACHINE)

SCREW SIZE

(WOOD)

4 1/2 x 4 1/2

114 x 114

0.180

8

1/2 x 12-24

1 1/4 x 12

5x5

127 x 127

0.190

8

1/2 x 12-24

1 1/4 x 12

6 x 4 1/2

152 x 114

0.203

10

1/2 x 1/4-20

1 1/2 x 14

6x5

152 x 127

0.203

10

1/2 x 1/4-20

1 1/2 x 14

6x6

152 x 152

0.203

10

1/2 x 1/4-20

1 1/2 x 14

5 x 4 1/2

127 x 124

0.190

8

1/2 x 12-24

Preferred model.

The 4040XP is LCN’s

CLOSER MOUNTS

*HINGE (PULL) SIDE

TOP JAMB (PUSH SIDE)

PARALLEL ARM (PUSH SIDE)

most durable and flexible

heavy duty closer designed for

institutional and other demanding

high traffic applications.

Cast Iron

n Forged Steel Arm

n Double Heat Treated Steel Pinion

n All Weather Fluid

n Non-Handed

n LCN Patented Green Dial

n Peel-n-Stick Templates for Fast and

Accurate Installation

n UL & cUL Listed

n 3/4˝ Journal Diameter Pinion

n Full Compliment Bearing

n

*HINGE (pull) side mount shown

n

Standard 4040XP Series closer shipped with regular arm, standard plastic cover,

and self reaming and tapping screws.

n

Non-sized cylinder is adjustable for interior doors to 5’0” and exterior doors

to 4’0”.

n

Closer mounts hinge side, top jamb, and parallel arm on either right or left

swinging doors.

n

Closers to meet ADA requirements.

n

Standard or optional custom powder coat finish.

n

Optional plated finish on cover, arm, and fasteners.

n

Optional SRI primer for installations in corrosive conditions. (Available with

powder coat finishes only.)

n

UL and cUL listed for self-closing doors without hold-open.

n

Tested and certified under ANSI Standard A156.4, grade one.

D

ZE

ND

SI

AC

HA

N-

N-

NO

NO

AS

TI

C

ET

AL

M

120°

AVAILABLE

NOT AVAILABLE

**ARM FUNCTION

CYLINDER

CE

S

DE SIB

LA

I

YE LIT

Y

AV D AC

TIO

B*

**

N*

**

*

RE

GU

L

ST AR

AN (DO

DA UB

HO RD LE)

LD (SIN

G

FU OPE LE)

N

SI

BL

ED E L

IN

A/

HE K

CU DA

SH

/

SC HCU

US SH

H

DO /SH

UB CU

LE SH

EG

RE

SS

COVER

ED

FINISH

PL

HI

NG

E

TO (PU

LL

P

)S

J

ID

TO AM

E

B

P

JA (PU

M

L

PA

L

RA B (P )

US

LL

ST EL

H

OP AR )

FA M

CE

PO

W

D

PL ER C

AT

O

ED AT

MOUNTING

The 4040XP Series includes the

LCN® "Green Dial"

Spring Force Indicator

Closer available with less than 5.0 lbs. opening force on 36˝ door.

** Maximum opening/hold-open point with standard template.

*** Advanced Variable Backcheck.

**** Delayed Action Closer incorporates standard 4041 Delay Cylinder.

37

120°

180° 110° 110°

PHONE 877-671-7011

FAX 800-248-1460

www.allegion.com/us

2/14

FEATURES

4040XP SERIES

MOUNTING DETAILS

4040XP SERIES

PARALLEL ARM (PUSH SIDE)

MOUNTING

Optional mounting requires PA SHOE,

4040XP-62PA for regular or HOLD-OPEN

arms. Add prefix "P" to closer description

(eg. P4040XP). P4040XP closer includes

4040XP-201 FIFTH HOLE SPACER to support

PA SHOE.

MAXIMUM OPENING

180° opening/hold-open points with all

except CUSH arms.

110° opening/hold-open with CUSH arms.

Options

n 4041 Delayed action cylinder*.

n Hold-open, EDA, HEDA, CUSH,

HCUSH, SPRING CUSH or

SPRING HCUSH arm.

n Metal cover.

Special Templates

Customized installation templates

or products may be available

to solve unusual applications.

Contact LCN Product Support

for assistance.

n

Butt Hinges should not exceed 5” (127 mm) in width.

n

Auxiliary Stop is recommended at hold-open point, where the door cannot

swing 180°, or where CUSH-N-STOP arm is not used.

n

Clearance for 4040XP-62PA shoe is 4” (102 mm) from door face.

EDA shoe projects 5-1/2” (140 mm) from door face.

CUSH shoe projects 6” (152 mm) from door face.

n

Top Rail less than 5-3/8” (137 mm) measured from the stop requires PLATE,

4040XP-18PA. Plate requires 2” (51 mm) minimum from the stop.

n

Head Frame flush or rabetted requires PA SHOE ADAPTER, 4040XP-419.

n

Stop Width minimum 1” (25 mm). CUSH arm requires

minimum 1-1/2” (38 mm).

n

Blade Stop clearance requires 1/2˝ (13mm) BLADE STOP SPACER,

4040XP-61.

n

*Delayed Action Incorporates standard 4041 cylinder, without XP

cylinder. Delays closing from 120° to 70°. Delay time adjustable up to

approximately 1 minute.

40

PHONE 877-671-7011

FAX 800-248-1460

www.allegion.com/us

2/14

4040XP SERIES EDA MOUNT

Mounting details are the same

as 4040XP Series REGULAR or

HOLD-OPEN except as listed below.

4040XP Series closers ordered with

EDA or CUSH arms include 4040XP201 FIFTH HOLE SPACER to support

the shoe.

MAXIMUM OPENING

EDA arm can be templated for

points at: 110°,

A = 6-3/8” (162 mm)

B = 7-3/4” (197 mm)

or 180°.

A = 2-7/8” (73 mm)

B = 4-1/4” (108 mm)

Hold-open points up to maximum opening

with HEDA arm.

4040XP SERIES CUSH MOUNT

CUSH arms can be templated for

opening/hold-open point at:

85°,

A = 7-15/16” (202 mm)

B = 9-1/8” (232 mm)

90°,

A = 7-3/16” (183 mm)

B = 8-1/2” (216 mm)

100°,

A = 6-1/16” (154 mm)

B = 7-1/4” (184 mm)

or 110°.

A = 5-1/16” (129 mm)

B = 6-3/8” (162 mm)

Spring Cush dead stop points are

approximately 5˚ more than templated stop

point. Hold open at templated stop points.

n

Clearance for 4040XP-62EDA is 5-1/2” (140 mm) from door face. 6” (152 mm)

for CUSH.

n

Head Frame flush or rabetted requires CUSH FLUSH PANEL ADAPTER,

4040XP-419.

n

CUSH ARM requires SHOE SUPPORT, 4040XP-30 for fifth screw anchorage for

narrow frames.

n

*Delayed Action Incorporates standard 4041 cylinder, without XP cylinder.

Delays closing from maximum opening to ; 115˚ with 180˚ template, 95˚ with 110˚

template, 85˚ with 100˚ template, 75˚ with 90˚ template. Delay time adjustable up

to approximately 1 minute.

41

PHONE 877-671-7011

FAX 800-248-1460

www.allegion.com/us

2/14

MOUNTING DETAILS

4040XP SERIES

ACCESSORIES

4040XP SERIES

CYLINDERS

4041-3071 DEL

4040XP-3071

72

72MC

79LR

62PA

CYLINDER, 4040XP-3071

Heavy duty, non-handed cast iron cylinder assembly.

CYLINDER, 4041-3071 DEL

Cylinder used for delayed action options.

COVERS

COVER, 4040XP-72

Standard, non-handed plastic cover.

METAL COVER, 4040XP-72MC

Optional, handed cover. Required for plated finishes and custom

powder coat finishes.

ARMS

REGULAR ARM, 4040XP-3077

Non-handed arm mounts pull side or top jamb with shallow reveal.

P4041 closer includes PA SHOE, 4040XP-62PA required for parallel

arm mounting.

PA SHOE, 4040XP-62PA

Required for parallel arm mounting.

LONG ARM, 4040XP-3077L

Optional non-handed arm includes LONG ROD AND SHOE, 4040XP-79LR

for top jamb mount.

EXTRA LONG ARM, 4040XP-3077ELR

Optional non-handed arm includes EXTRA LONG ROD AND SHOE,

4040XP-79ELR for top jamb mount with deep reveal.

HOLD-OPEN ARM, 4040XP-3049

Optional, non-handed arm mounts pull side or top jamb with

shallow reveal, hold-open adjustable shoe. 4040XP closer includes

4040XP-62PA shoe required for parallel arm mounting.

LONG HOLD-OPEN ARM, 4040XP-3049L

Optional non-handed arm includes LONG HEAD AND TUBE,

4040XP-3048L for top jamb mount.

EXTRA DUTY ARM, 4040XP-3077EDA

Non-handed parallel arm features forged, solid steel main and forearm for

potentially abusive installations.

HOLD-OPEN EXTRA DUTY ARM, 4040XP-3049EDA

Handed parallel arm features forged, solid steel main and forearm for

potentially abusive installations. Hold-open function is adjusted at

the shoe.

EXTRA DUTY ARM WITH 62G, 4040XP-3077EDA/62G

Non-handed parallel arm features forged, solid steel main and forearm for

potentially abusive installations. 62G shoe provides additional blade

stop clearance.

HOLD-OPEN EXTRA DUTY ARM WITH 62G, 4040XP-3049EDA/62G

Handed parallel arm features forged, solid steel main and forearm for

potentially abusive installations. 62G shoe provides additional blade stop

clearance. Hold-open function is adjusted at the shoe.

42

3077

79ELR

3048L

3049

3049EDA

3077EDA

3049EDA/62G

3077EDA/62G

PHONE 877-671-7011

FAX 800-248-1460

www.allegion.com/us

2/14

ARMS CONT.

ACCESSORIES

4040XP SERIES

3077CNS

CUSH-N-STOP® ARM, 4040XP-3077CNS

Optional, non-handed parallel arm features solid forged steel main arm

and forearm with stop in soffit shoe.

HCUSH ARM, 4040XP-3049CNS

Provides hold-open function with templated stop/hold-open points.

Handle controls hold-open function.

3049CNS

SPRING CUSH ARM, 4040XP-3077SCNS

Optional, non-handed parallel arm for abusive applications features solid

forged steel main arm and forearm with spring loaded stop in the

soffit shoe.

3077SCNS

SPRING HCUSH ARM, 4040XP-3049SCNS

Optional, non-handed parallel arm for abusive applications features solid

forged steel main arm and forearm with spring loaded stop in the soffit

shoe. Handle controls hold-open function.

3049SCNS

INSTALLATION ACCESSORIES

PLATE, 4040XP-18

Required for hinge side mount where top rail is less than

3-3/4” (95 mm). Plate requires minimum 2” (51 mm) minimum top rail.

PLATE, 4040XP-18G

Locates top jamb mounted closer flush with top of head frame face in

flush ceiling condition. Plate requires 1-3/4” (44 mm) minimum

head frame.

18

18G

18TJ

PLATE, 4040XP-18TJ

Centers top jamb mounted closer vertically on head frame where face is

less than 3-1/2” (89 mm). Plate requires 1-3/4” (44 mm) minimum

head frame.

18PA

PLATE, 4040XP-18PA

Required for parallel arm mounting where top rail is less than 5-1/2” (140

mm), measured from the stop. Plate requires 2” (51 mm) minimum

top rail.

43

PHONE 877-671-7011

FAX 800-248-1460

www.allegion.com/us

2/14

Mountings and Applications

DC8000

Preferred model.

Regular Arm Mounting DC8200 Series

Parallel Arm Mounting DC8210 Series

Most common mounting, providing the greatest closing

efficiency. Closer is mounted on the pull side, with the arm

almost perpendicular to the face of the door. Arm bracket is

attached to the door frame.

Allows inside application of closer on out-swinging doors. Closer

is mounted on the push side, with the arm almost parallel to the

face of the door. Arm does not project from the opening.

Top Jamb Mounting DC8220 Series

Closer is mounted on the frame on the push side, with the arm

perpendicular to the face of the door. Arm bracket is mounted

on the door. Minimum 1-3/4" (44mm) top jamb required.

Accommodates reveals up to 3-1/4" (83mm).

Track Mounting DC8230 Series

Closer is door mounted on the pull side; arm is connected to

a frame-mounted track. Maximum degree of opening is 100°.

Maximum closing power is size 4.

Track Mounting DC8240 Series

Closer is mounted on push side of door; arm is connected to

a stop-mounted track. Maximum degree of opening is 100°.

Maximum closing power is size 4.

DC8000.6

45528-8/14

Parallel Arm Mounting

DC8000

To obtain extra closing force add 3" (76 mm) to dimensions marked (*).

NOTE: This will limit degree of door opening to 110°.

Mounting holes for Quik-Install™ bracket are spaced 1" (25mm) x 10" (254mm).

Arm Function

Minimum Top Rail

Non-Hold Open

5-1/4" (133)

Hold Open

Door Width Inches (cm)

Interior

Exterior

28" (71)

—

30" (76)

—

36" (91)

30" (76)

42" (107)

36" (91)

48" (122)

42" (107)

54" (137)

48" (122)

Model Numbers

Multi-Sized Closer

Non-Hold Open

Hold Open

DC8210

DC8210 x A1

Standard arm closers are tri-packed.

Consult factory if door weight exceeds 250lbs.

DC8000.8

45528-8/14

Arm Options

DC8000

688F95

(Non-Hold Open)

Regular Arm

•

•

•

•

Used with Regular Arm mounting (pull side) and Top Jamb mounting (push side)

Available in painted or plated finishes

Non-hold open arm standard on the DC8200 closers

Hold open arm optional, specify closer x A1*

688F77

(Hold Open)

597F52

(Non-Hold Open)

Heavy-Duty Regular Arm

688F95 x 188F41

(Non-Hold Open)

Parallel Arm

•

•

•

•

•

•

•

•

•

•

•

Recommended for high-use, high-abuse environments

Tamper-resistant, solid forged steel riveted arm

Mounted on pull side

Not available in plated finishes

Optional on DC8200 closers, specify closer x A10

Mounted on push side

Available in painted or plated finishes

Non-hold open arm – combines regular arm with parallel arm mounting bracket

Hold open arm – combines regular hold-open arm with parallel arm mounting bracket

Non-hold open arm standard – order DC8210 series

Hold open arm optional, specify closer x A1*

688F77 x 509F49

(Hold Open)

Specify finish when ordering arms. *Not allowed by code on fire doors.

DC8000.17

45528-8/14

Covers and Plates

DC8000

754F84

Full ABS Plastic Cover

• Standard on all DC8000 series door closers

• Completely covers closer body

• Non-handed

• Dimensions: 11-7/8" (302mm) x 4-3/16" (106mm) x 2-1/8" (54mm) deep

• Available in painted finishes only

754F19

Full PVC Cover

•

•

•

•

Completely covers closer body

Non-handed

Dimensions: 11-7/8" (302mm) x 4-3/16" (106mm) x 2-1/8" (54mm) deep

Available in painted finishes only

Full Metal Cover

• For use in high-abuse applications

• Specify hand; not field reversible

• Available in painted and plated finishes

• Dimensions: 11-7/8" (302mm) x

4-1/4" (108mm) x 2-1/8" (54mm) deep

Drop Plate

Permits parallel arm or top jamb

mounting on door when top rail is too

narrow to install closer in the regular

manner. Mini­mum 2" (51mm) top rail

required. To order separately, specify

Part No. x Finish.

754F36

Retrofit Plate

For installation of Corbin Russwin DC8200

closers where doors & frames have been

prepared for the DC6200 closers. To order

with closers specify Closer x Quick Code.

Part Numbers

RH/LHR

LH/RHR

754F22

754F23

Closer Series

Drop Plate

DC8200

754F20

DC8200 (with concealed holder)

754F24

DC8210

754F25

DC8220

754F24

DC8230

754F20

DC8240

754F25

To Replace

DC6000 Model

Part

Number

Quick

Code

Regular Arm

754F36

M101G

Parallel Arm or

Top Jamb

754F46

M101H

DC8000.23

45528-8/14

Preferred model.

100 Series Concealed Overhead Door Holders/Stops

Materials and Finishes:

In Heavy Gauge Brass or 300 Series Stainless Steel, these models

offer the broadest range of finishes in the industry, complementing

any design and offering the highest resistance to corrosion.

Available in the following finishes:

100 Series Heavy-Duty

Glynn-Johnson offers a complete line of overhead door holders and

stops, accommodating virtually all openings with solutions for even

the most complex door control problems. These concealed holders

and stops provide the most attractive and reliable heavy-duty door

control available.

Glynn-Johnson 100 series holders and stops provide the most reliable and versatile concealed overhead door control. They are

designed for installation on virtually all types of doors mounted on

conventional type butt hinges, pivots, continuous hinges, swing

clear hinges and numerous other specialty hinges. When used in

conjunction with many surface-applied door closers, 100 series

holders and stops provide the most effective control for entrance

doors and vestibule doors of all types, as well as heavy or often

used interior doors. Templates provided allow for variable mounting

positions, ranging from 85° - 110° of opening.

Five Models:

• 100H Series Hold-Open Model

• 100HP Series Internal Hold-Open Model

• 100F Series Friction Hold-Open Model

• 100S Series Stop-Only Model

• 100SE Series Special Stop-Only Model

Six Sizes:

• Each model comes in six sizes.

• Simple

• Standardized

Three Options:

• ADJ—Adjustable Jamb Bracket

• CJ—Jamb Bracket for use with LCN5030 Closer

• SOC—Pin-in-Socket Security Screw Package

Unmatched Convenience:

• Non-handed

• Improved Compatibility with Door Closers

• Single/Double-Acting Doors

• Interior/Exterior Applications

• Reduced Door Prep

• Durable

• Improved Corrosion Resistance

• Function Conversion Kits are Available.

18

Finishes

US3

US4

US10

US10B

US32

US32D

SP4

SP10

SP28

SP313

SPBLK

Description

Polished Brass

Satin Brass

Satin Bronze

Oil Rubbed Bronze

Polished Stainless Steel

Satin Stainless Steel

Powder Coat Brass

Powder Coat Bronze

Powder Coat Aluminum

Powder Coat Dark Bronze

Powder Coat Black

Models

These models provide a wide range of optional features, and are

ideal for use on entrance and vestibule doors, large doors, doors

opened frequently, or doors subject to abuse. These models are also

furnished with an offset-style jamb bracket.

Designed for heavy-duty applications, 100 series models will

provide long-lasting protection to doors, frames, hinges, related

hardware and surrounding walls or obstructions.

100H Series Hold-Open

(Suffix H) The Hold-Open function should be used where it

is desired to hold a door open at a predetermined position for

short or long periods of time, permitting an unobstructed

traffic flow through the opening.

These models are both selective and adjustable, featuring the

most reliable Hold-Open mechanism available. They feature

a control knob which protrudes from the face of the door and

turns the Hold-Open function on or off. Set in the inactive

position, the unit acts as a stop and shock absorber. The tension

on the Hold-Open mechanism can be adjusted using an allen

wrench to offset air currents or other exterior conditions. The

Hold-Open tension adjustment is located in the bottom of the

track in the top of the door.

100HP Series Internal Hold-Open

These models provide a Hold-Open unit with the Hold-Open

mechanism built into the channel, thus reducing the door prep.

The 100HP have a preset Hold-Open force that is not adjustable.

The Hold-Open feature is not selectable in these units, so the doors

are always held open.

100F Series Friction Hold-Open

(Suffix F) Friction Hold-Open models provide an alternative

holding method, ideal for heavy patient room doors, closet

doors or similar applications where multiple Hold-Open

positions are desired. The friction tension is adjusted using

an allen wrench and an open end wrench. The friction tension

adjustment is located on the top of the slider in the channel.

100S Series Stop-Only

(Suffix S) When the Hold-Open function is not required, the

Stop-Only function provides the same effective door control

minus the Hold-Open feature. The Stop-Only model may be

used on fire doors.

100SE Series Special Stop-Only

(Suffix SE) When Stop-Only models are used in conjunction with

single point Hold-Open electronic door closers, they may be ordered

without the shock-absorbing mechanism. Used as an auxiliary stop

with these closers, they will prolong the life of the closer. The stop

location is adjusted using an allen wrench on the stop block located

in the channel.

Note: Caution should be used when using this option in other applications,

as the elimination of the shock-absorbing spring can put added stress on door

and frame if used improperly.

Application Information

UL Classification

The 100 series Stop-Only models are classified by Underwriters

Laboratories (UL) as Miscellaneous Fire Door Accessories. This

classification applies to use on either Hollow Metal Fire Doors or

Wood Fire Doors. Where Wood Door manufacturer’s listing allows

for the cutout required for installation, concealed overhead stops

may be used on those wood fire doors. These units may be used on

doors of any rating. As a reminder, the Miscellaneous Fire Door

Accessories (GVUX) section is defined by UL as: “Miscellaneous

fire door accessories are intended in the individual Listings. The

accessories have been investigated to determine that when installed

in accordance with the manufacturer’s instructions, the accessories

do not adversely affect the fire rating of the fire door and/or fire

door frames.”

Dead Stop Templating:

If a wall or similar obstruction is in place at 110° or less opening

angle (i.e. doors that open back-to-back), Dead Stop Templating

should be used. This includes all Hold-Open, Friction and

Stop-Only models, except when the “SE” Option is used. The

Dead Stop position is reached when the shock-absorbing spring

is fully compressed, the initial degree of opening will be 5° to 7°

less than the Dead Stop opening.

Example: If the holder is templated to 100° Dead Stop, the door will hold open

somewhere between 93° and 95°, but no further than 100°.

Note: Do not use dead-stop templating on the 100SE Series since there is no

shock-absorbing spring.

Environmental Considerations:

Environmental factors should always be considered when

specifying overhead holders and stops. Doors that are positioned

on a building’s exterior or subject to corrosive conditions should

be equipped with a holder constructed primarily of stainless steel

or brass materials. For interior applications, steel is acceptable,

though brass substrates generally provide a more attractive

architectural-grade finish.

Options

Suffix ADJ (Adjustable Jamb Bracket):

An additional option on the 100 series is the adjustable jamb bracket,

which allows the degree of Hold-Open or Stop angle to be adjusted

after installation. Suffix “ADJ” is available in all functions, but only

in sizes 3, 4, 5 & 6. ADJ jamb bracket requires additional frame prep.

The ADJ option cannot be added to an existing unit, it must be

factory ordered.

Suffix CJ (Closer Jamb Bracket):

Provides a special jamb bracket needed for 100 series units used with

LCN5030 closers. These special jamb brackets are handed, so handing

will need to be specified when ordering the “CJ” option, CJLH for

a left hand door and CJRH for a right hand door. The CJ option

cannot be added to an existing unit, it must be factory ordered.

Suffix SOC (Pin-in-Socket Security Screw Package):

A screw package with pin-in-socket screws for mounting the jamb

bracket to the frame is provided instead of the standard screw package.

19

100 Series Concealed Overhead Door Holders/Stops

1/4"

3/4"

2"

1"

1-1/4"

1"

1-1/4"

4-1/4"

3/4"

1-1/4"

1/4"

1/4"

1"

3/8"

2-3/8"

5-1/2"

3-1/2"

12"

1/2"

1-1/4"

3/8"

100 Series Sizing Chart

BUTTS/OFFSET PIVOTS

SIZE

1

2

3

4

5

6

DOOR

OPENING

18"–23"

23-1/16"–27"

27-1/16"–33"

33-1/16"–39"

39-1/16"–45"

45-1/16"–54"

STOP

ONLY

101S*

102S*

103S

104S

105S

106S

HOLD

OPEN FRICTION

101H*

101F*

102H*

102F*

103H

103F

104H

104F

105H

105F

106H

106F

CENTER HUNG

DOOR

OPENING

--------33-1/16"–39"

39-1/16"–45"

45-1/16"–51"

51-1/16"–59"

STOP

ONLY

-------103S

104S

105S

106S

HOLD

OPEN FRICTION

--------------103H

103F

104H

104F

105H

105F

106H

106F

Note: This chart illustrates the most common types of hinging and door opening sizes.

For unusual door details, contact Glynn-Johnson for availability.

*These sizes are not available for use with offset pivots. Also not available with the ADJ option.

The template information on this page is for reference only and is not intended to serve as an installation template.

For complete dimensional information, refer to Glynn-Johnson template book.

20

BHMA/ANSI, A156.8 & FED. Spec. Cross Reference

G-J Model

BHMA*

FED. Spec.

101-106 H

C01511

1160

101-106 S

C01541

---101-106 F

C01531

---* First numeral (0) designates optional material.

To specify:

Brass material, change 0 to 1 (i.e. C11511)

Stainless Steel material, change 0 to 5 (i.e. C51511)

BHMA

All 100 series models are designed for heavy-duty

applications and far exceed BHMA cycle test and

force test requirements for Grade 1 holders and stops.

How to Order

10

___

4

___

H

___

–

US26D

______

–

ADJ

____

Overhead Series:

10

Size

1

2

3

4

5

6

(Door Opening Using Butts or Offset Pivots:

(18"–23")

(23-1/16"–27")

(27-1/16" –33")

(33-1/16"–39")

(39-1/16"–45")

(45-1/16"–54")

Function:

H

HP

F

S

SE

Hold-Open

Internal Hold-Open

Friction Hold-Open

Stop-Only

Special Stop-Only

Finishes:

US3

US4

US10

US10B

US32

US32D

SP4

SP10

SP28

SP313

SPBLK

Polished Brass

Satin Brass

Satin Bronze

Oil Rubbed Bronze

Polished Stainless Steel

Satin Stainless Steel

Powder Coat Brass

Powder Coat Bronze

Powder Coat Aluminum

Powder Coat Dark Bronze

Powder Coat Black

Options:

ADJ

CJLH

CJRH

SOC

Adjustable Jamb Bracket

Special Jamb Bracket for LCN 5030 Closer, LH Door

Special Jamb Bracket for LCN 5030 Closer, RH Door

Pin-in-Socket Security Screws

21

690 Series Heavy Duty Overhead

Concealed Mount

Preferred model.

Holders & Stops

Interior or Exterior – High Traffic Doors

690 Series

Concealed Application

690 Series

• Concealed application for exterior and

interior single or double acting doors

• Two types to choose from:

– “H” Holder; Stops and Holds

doors open

– “S” Stop; Stops door only

• B

oth series can be mounted to stop the door at any angle from 85° – 110°

• Non-handed (Reversible)

ANSI/BHMA A156.8 Grade 1

690H Series BHMA Certified to CO1511

690 S Series BHMA Certified to CO1541

697H shown

Specifications

For DoorsExterior and interior doors from 24" – 60" wide*.

For doors 1-3/8" – 1-3/4" thick standard, Available for doors up

to 3-1/4" thick, use 31- option and specify thickness

Hold-Open Feature

• Convenient knob provides simple

“on-off” control of hold-open feature

Finishes

• Adjustable release tension

FastenersWood screws and machine screws provided

Accessories

Options

31- Doors 2" – 3-1/4" thick, specify door thickness

• Standard screw packs

36- Torx Security machine screws. 8 required

690H Series

690S Series

CPC-Clear Powder Coat

SG-MicroShield® – antimicrobial silver-based finish

21-2263 x finish

21-2267 x finish

03, 04, 9, 10, 10B, 10BE, 10BL, 15, 20D, 26, 26D, EN, EB, ED, EP

and EAB

and specify thickness

How to Order

Specify options, number, letter designation, finish and door thickness as required.

Example: 31-CPC-697H x 03 x 2" door

Sizing Chart

Actual

Width of Door

Stop with

Hold-open

Stop

Only

24" – 32-1/2"

697H

697S

32-5/8" – 39-1/8"

698H

698S

39-1/4" and over

699H

699S

* When using vertical rod exit devices and/or surface/flush bolts, use caution in choosing the proper size to ensure compatibility

351-P10 shown with 697S

on a single acting door

1-800-727-5477 • www.sargentlock.com

5

Reproduction in whole or in part without the express written permission of Sargent Manufacturing Company is prohibited.

• S

ARGENT 690 Series stops are UL10B & 10C

classified by Underwriter Laboratories as

Miscellaneous Fire Door Accessories

90124:J 04/28/14Copyright © 2003, 2007, 2009-2014, Sargent Manufacturing Company, an ASSA ABLOY Group company. All rights reserved.

UL Classified

Features

ML2000

Preferred model.

Finishes

ANSI/BHMA605(US3)

HS

Bright Brass

ANSI/BHMA606(US4)

HS

Satin Brass

ANSI/BHMA611(US9)

HS

Bright Bronze

ANSI/BHMA612(US10)

HS

Satin Bronze

ANSI/BHMA613(US10B)

HS

Oxidized Bronze, oil rubbed

613E (US10BE)

Dark Oxidized Satin Bronze - Equivalent

613L

Dark Oxidized Satin Bronze, Clear Coated

ANSI/BHMA618(US14)

BrightNickelPlated

ANSI/BHMA619(US15)

HS

SatinNickelPlated

ANSI/BHMA625(US26)

HS

BrightChromiumPlated

ANSI/BHMA626(US26D)

HS

SatinChromiumPlated

626C

SatinChromiumPlatedwithMicroShield®

ANSI/BHMA629(US32)

VR

Bright Stainless Steel

ANSI/BHMA630(US32D)

VR

Satin Stainless Steel

630C

HS

Satin Stainless Steel with MicroShield®

ANSI/BHMA722

Armored front conceals lock

mounting screws and onepiece heavy- gauge steel front

Black Oxidized Bronze, oil rubbed

Deadbolt at 1"

throw will project

further than

latchboltat3/4"

throw

Patentedlatchtail

enables easy

handing changes

(Patent#6,349,982)

1" throw,

one-piece

deadbolt

meets

security

Grade 1

Heavy-gauge

internal parts provide

security, reliability,

and durability

HS

Indicates ML2000HS (High Security) availability.

VR

Indicates ML2000VR (Vandal Resistant) availability.

Heavy-duty

3/4" throw

latchbolt with

stainless steel

insert provides

positive secure

latching

ML2000.4

45300-11/14

Functions

ML2000

Outside

Series/Function

Inside

A01

ML2022

A01

HS

VR

HS

VR

HSS

A01

(Hotel Cylinder)

ML2029

VR

A01

(Hotel Cylinder)

ANSI No.

ML2029HS

Store Door

F14

Entrance or

Storeroom

F21

•

•

•

•

F15

• Latchboltbygripinsideandbyguestkeyormasterkeyoutside.

• Outsidegripalwaysrigid.

• Deadboltbythumbturngripinsideorbyemergencykeyoutside.

• Insidegripsimultaneouslyretractslatchboltanddeadbolt.

• Emergencykeyshutsoutallotherkeys.

• Auxiliarylatchdeadlockslatchbolt.

Note: Indicator shows deadbolt position only

—

• Latchboltbygripinsideandbyguestkeyormasterkeyoutside.

• Outsidegripalwaysrigid.

• Emergencykeythrowsdeadbolt,shuttingoutallotherkeysand

preventing exit from inside.

• Auxiliarylatchdeadlockslatchbolt.

Note: Indicator shows deadbolt position only

F19

• Latchboltbygripeithersideunlessoutsidegriplockedbythumbturn

•Deadboltbythumbturngripinsideorbyemergencyreleasetool

outside.

• Insidegripsimultaneouslyretractslatchboltanddeadboltand unlocks outside grip.

• NotavailablewithM19SorM19SN

F30

•Latchboltbykeyeitherside.

•Bothgripsalwaysrigid.

•Auxiliarylatchdeadlockslatchbolt.

Note: This function does not allow free egress and can pose a life

safety hazard in event of an emergency. Installation should be in

accordance with approved codes only.

F09

• Latchboltbygripeitherside,unlessoutsidegripislockedbykey

from inside.

• Latchboltbykeyoutsidewhenoutsidegripislocked.

• Auxiliarylatchdeadlockslatchbolt.

• Insidegripalwaysfree.

Entrance

or

Apartment

F08

F10

• L atchbolt*bykeyoutsideorbygripeitherside,unlessoutsidegrip

is locked by toggle-action stop.

• Deadboltbykeyoutsideorbythumbturngripinside.

• Insidegripfreewhendeadboltisretracted.

• Non-panicrelease.

• Nosimultaneousdeadboltandlatchretraction

Note: Indicator shows deadbolt position only

Half

Dummy

Trim

—

• Gripactsaspullonly;nooperation.

Hotel or

Motel

Hotel or

Motel

HS

ML2030

R

HS

A01

ML2032

A01

HS

A01

VR

VR

HSS

ML2042

A02

HS

A01

VR

HSS

ML2048

HS

VR

ML2050

Indicates Indicator

option is available

Indicates Indicator

option is available

ML2000.6

Function Description

•

•

•

•

HSS

ML2024

A01

Type

Privacy

Bedroom or

Bathroom

Institution or

Utility

Entrance

orPublic

Restroom

Latchboltbygrip*eithersidewhendeadboltisretracted.

Deadboltbykeyeitherside.

Non-panicrelease.

Nosimultaneousdeadboltandlatchretraction

Latchboltbygrip*eithersidewhendeadboltisretracted.

Deadboltbykeyoutsideorbythumbturngripinside.

Non-panicrelease.

Nosimultaneousdeadboltandlatchretraction

* When lever handles are furnished, both outside and inside are locked when deadbolt is projected.

HS Indicates function availability in ML2000HS.

VR Indicates function available in Vandal Resistant Trim.

HSS

Indicates function available in Anti-Harm Trim.

Indicates rigid grip.

45300-11/14

Functions

ML2000

Outside

Inside

ML2051

A01

A02

Series/Function

HS

A02

VR

HSS

ML2052

Type

ANSI No.

Function Description

F04

• Latchboltbykeywhenoutsidegriplockedbytoggleaction

stop.

• Latchboltbygripeitherside,unlessoutsidegripislockedby

toggle-action stop.

• Auxiliarylatchdeadlockslatchbolt.

• Insidegripalwaysfree.

F32

• Latchboltbygripeitherside,unlessoutsidegripislockedby

key either side.

• Latchboltbykeywhenoutsidegriplocked.

• Auxiliarylatchdeadlockslatchbolt.

• Insidegripalwaysfree.

• Outside grip remains locked unless unlocked by key either side.

Note: Not available with indicator, specify ML2002.

Entrance

or Office

Classroom

Intruder

HSS

A02

ML2053

—

• Latchboltbygripeitherside,unlessoutsidegripislockedor

unlocked by key or thumbturn.

• Unlockedbykeyorthumbturn.

• Outsidegriplockedorunlockedbykeyorthumbturn.

• Latchboltbykeywhenoutsidegriplocked.

• Auxiliarylatchdeadlockslatchbolt.

• Insidegripalwaysfree.

F04

•

•

•

•

•

F05

• Latchboltbygripeitherside,unlessoutsidegripislockedby

key outside

• Latchboltbykeywhenoutsidegriplocked

• Auxiliarylatchdeadlockslatchbolt

• Insidegripalwaysfree

• Outsidegripremainslockedunlessunlockedbykey

Note: Not available with indicator, specify ML2003

Classroom

Holdback

F06

• L atchboltbygripeitherside,unlessoutsidegripislockedor

unlocked by key.

• Latchboltbykeyoutsidewhenoutsidegripislocked.

• Latchboltcanbeheldinaretractedpositionbykey,or

released by key.

• Auxiliarylatchdeadlockslatchbolt.

• Insidegripalwaysfree.

Note: Not approved for use on U.L. fire listed applications.

Storeroom

or Closet

F07

•

•

•

•

—

• Latchboltbygripeitherside,unlessoutsidegripislocked.

• Outsidegriplockedorunlockedbykeyorthumbturn.

• Latchboltretractedbykeyoutsidewhenoutsidegripis

locked.

• Latchboltcanbeheldinaretractedpositionbykeyor

thumbturn, or released by key or thumbturn.

• Auxiliarylatchdeadlockslatchbolt.

• Insidegripalwaysfree.

Note: Not approved for use on U.L. fire listed applications.

Entrance

or Office

HSS

ML2054

A01

HSS

A02

ML2055

HS

VR

HSS

A01

ML2057

HS

A02

VR

Indicates rigid grip.

HSS

ML2058

HSS

Classroom

HSS

ML2056

A02

Entrance

or Office

Entrance or Office

Holdback

Latchboltbygripeitherside,unlessoutsidegripislocked.

Outsidegriplockedorunlockedbythumbturn.

Latchboltbykeywhenoutsidegriplocked.

Auxiliarylatchdeadlockslatchbolt.

Insidegripalwaysfree.

Latchboltbygripinsideorbykeyoutside.

Outsidegripalwaysrigid.

Auxiliarylatchdeadlockslatchbolt.

Insidegripalwaysfree.

HS Indicates function availability in ML2000HS.

VR Indicates function available in Vandal Resistant Trim.

HSS

Indicates function available in Anti-Harm Trim.

ML2000.7

45300-11/14

Trim Designs

ML2000 and ML20900 ECL

Lustra

Complies with codes requiring lever to return to

within 1/2" (13mm) of door face. Brass, bronze or

stainless steel.

LWA

Lever: Wrought

Rose: Wrought

LWB

Lever: Wrought

Rose: Cast

2-1/4

(57)

LWA

LSA

2-1/2*

(64)

Lever: Cast

Rose: Wrought

5-1/8

(130)

LSB

Lever: Cast

Rose: Cast

LWF

Lever: Wrought

Rose: Cast

LSF

Lever: Cast

Rose: Cast

2-7/8

(73)

LWF

5-1/8

(130)

2-1/2*

(64)

Dimensions:

inches

millimeters

*Dimension from face of door, not surface of rose or escutcheon.

ML2000.14

45300-11/14

DOOR ACTIVATION

DEVICES

Preferred model.

PUSH/EXIT SWITCHES

• VARIOUS LOGOS & MESSAGES

• DURABLE STAINLESS STEEL OR SOLID

BRASS CONSTRUCTION

• ARCHITECTURAL FINISHES

DE SCRIP TION

Camden Door Controls CM-45/46 Series all-active switches are heavy-duty,

ADA-compliant door controls. The 4 1/2” square faceplates are stainless steel or

solid brass, and the assemblies are designed for easy installation.

Both series mount to standard single gang or double gang electrical boxes. CM-45

series is sold as a complete assembly, which is mounted to the in-wall box (or

surface box) using Allen screws and a hex key (included with the switch). Access to

the mounting screws is through small holes in the front of the faceplate. This

provides for tamper resistance, while maintaining an attractive overall appearance.

CM-45/3

CM-46 series is sold as a two part assembly. The rear assembly is mounted to the

in-wall box (or surface box). The front faceplate is then screwed to the rear

assembly using either standard or snake-eye security screws (included with kit). This

configuration allows for fast and easy installation by all trades.

The SPDT (and optional DPDT) switches are UL/CSA approved, and rated 15 amps @

30 VDC. The push switches are offered with different logos, and in various

architectural finishes. Weather resistant, and water tight configurations are also

available.

APPLI C ATION

CM-46/4

Camden all-active switches are designed for areas where an easy-to-activate, high

visibility switch is desired. Ideal for high-traffic areas, hospitals, wheelchair access,

seniors’ residences, etc. They can be surface or flush mounted.

Camden all-active switches are designed to control electric strikes, electromagnetic

locks and automatic doors. They may also be used for shunting, bypassing alarms,

request to exit, timed functions, and many other applications.

The switches are made for high frequency usage, in both indoor and outdoor

environments. Camden switches are versatile, and can be supplied in various

configurations and finishes, to suit any commercial, industrial, or residential

application.

5502 Timberlea Blvd. Mississauga, ON Canada L4W 2T7 • Toll Free: 1 877 226-3369 (CAMDEN9)

Tel: (905) 366-3377 • Fax: (905) 366-3378 • E-mail: info@camdencontrols.com • www.camdencontrols.com

PUSH BUTTONS

• MEETS ADA REQUIREMENTS

MOUNTING OPTIONS

• UL/CSA APPROVED SWITCH,

RATED 15 AMPS @ 30V DC

RF CONTROLS

• ALL-ACTIVE DESIGN REQUIRES MINIMAL

ACTUATION FORCE

HANDS-FREE SWITCHES

• FLUSH MOUNT OR SURFACE MOUNT

SPECIAL PURPOSE SWITCHES

CM-45/2

• LARGE, EASY TO OPERATE SWITCHES

KEYPADS

FE ATURE S

ACCESSORIES

4 1/2” SQUARE ALL-ACTIVE SWITCHES

KEY SWITCHES

CM-45/46

41/2” SQUARE ALL-ACTIVE SWITCHES

A R C HIT ECT S /ENGIN E E RS SPECIFI C ATIONS

¾”

(19mm)

The switches to be used throughout the complex shall be Camden Door Controls

CM-45 or CM-46 series all-active switches.

½”

(13mm)

The switches shall be easy-to-activate, ADA compliant, 4 1/2” square. Switches shall

be all-active, whereby pressing any part of the faceplate will activate the device.

Faceplates shall be constructed of 18-gauge stainless steel or solid brass. Switches

shall use plastic spacers and rubber dampers for noise reduction. Switches shall be

rated at a minimum of 15 amps @ 30V DC.

OR DERING IN FOR MATION

All CM-45/46 series all-active switches are complete ready-to-install assemblies.

CM-45 series are supplied with stainless steel Allen screws and an Allen wrench

for mounting. CM-46 series are supplied with stainless steel tamperproof screws.

MODELMODEL DESCRIPTION

CM-45/46

4 1/2” 4 1/2”

SQ. CONCELED SQ. EXPOSED

SCREWSSCREWS

CM-45/1CM-46/1NO EMBOSSING

4 ½” (114mm)

3 ¾”

CM-45/2CM-46/2EMBOSSED WITH WHEELCHAIR LOGO IN BLUE

(95mm)

CM-45/2ALCM-46/2ALEMBOSSED WITH WHEELCHAIR LOGO IN BLUE AND LEFT ARROW

2”

(51mm)

CM-45/2ARCM-46/2AREMBOSSED WITH WHEELCHAIR LOGO IN BLUE AND

RIGHT ARROW

CM-45/3CM-46/3EMBOSSED WITH ‘PUSH TO OPEN‘ LOGO IN BLACK

3”

(76mm)

CM-45/3FCM-46/3FEMBOSSED WITH ‘POUSSEZ POUR OUVRIR‘ LOGO

IN BLACK

3 ¼”

(83mm)

CM-45/4CM-46/4EMBOSSED WITH WHEELCHAIR LOGO AND

‘PUSH TO OPEN‘ LOGOS IN BLUE

4 ½”

(114mm)

CM-45/4ALCM-46/4ALEMBOSSED WITH WHEELCHAIR LOGO AND

‘PUSH TO OPEN‘ LOGOS IN BLUE WITH LEFT ARROW

CM-45/4ARCM-46/4AREMBOSSED WITH WHEELCHAIR LOGO AND

‘PUSH TO OPEN‘ LOGOS IN BLUE RIGHT ARROW

CM-45/4FCM-46/4FEMBOSSED WITH WHEELCHAIR LOGO AND ‘POUSSEZ POUR OUVRIR‘ LOGOS IN BLUE

MOUNTING FOR

TYPICAL DOUBLE

GANG ELECTRICAL BOX

CM-45/8CM-46/8EMBOSSED WITH ‘PUSH TO LOCK‘ LOGO

CM-45/8DCM-46/8DEMBOSSED WITH ‘PUSH TO LOCK‘ DOOR LOGO

CM-45/8FCM-46/8FEMBOSSED WITH ‘POUSSEZ POUR VERROUILLER‘ LOGO

OPTIONS/FINISHES:

- DPADD DP TO PRODUCT # TO ORDER DPDT SWITCH INSTEAD OF SPST SWITCH

(USE SPECIAL MOUNTING PLATE/TEMPLATE)

- WRADD WR TO PRODUCT # FOR WEATHER RESISTANT BOOT

- WTADD WT TO PRODUCT # FOR BOOT AND WATER TIGHT COATING

- ALADD AL TO PRODUCT # FOR ARROW LEFT

- ARADD AR TO PRODUCT # FOR ARROW RIGHT

- ABADD AB TO PRODUCT # FOR ANTIQUE BRASS FINISH (US5/C5)

- PBADD PB TO PRODUCT # FOR POLISHED BRASS FINISH (US3/C3)

- SBADD SB TO PRODUCT # FOR SATIN BRASS FINISH (US4/C4)

- OBADD OB TO PRODUCT # FOR OIL RUB BRONZE FINISH (US10B/C10B)

5502 Timberlea Blvd. Mississauga, ON Canada L4W 2T7 • Toll Free: 1 877 226-3369 (CAMDEN9)

Tel: (905) 366-3377 • Fax: (905) 366-3378 • E-mail: info@camdencontrols.com • www.camdencontrols.com

LIT-SP-45&46

MOUNTING FOR

TYPICAL SINGLE

GANG ELECTRICAL BOX

CM-45/46

Preferred model.

ED5000 Series

Pushpad Exit Devices

Rim Features

ED5000

ED5200

ED5200A

ED5202

ED5202A

Panic-Listed Rim Exit Device

3-Hour Fire-Listed Rim Exit Device

Panic-Listed Listed Rim Double Cylinder Exit Device

3-Hour Fire-Listed Rim Double Cylinder Exit Device

Features

Handing

Standard device is non-handed.

Double Cylinder Device is Handed.

Lever trim is handed.

Bar Length

Easily field cut to size.

Standard: 36" (914mm) bar fits 30"- 36"

(762mm-914mm) door.

Optional: 24" (610mm) bar fits 24" (610mm)

door; specify W024.

Optional: 48" (1219mm) bar fits 36"-48"

(914mm-1219mm) door; specify W048.

Door Thickness

1-3/4" (44mm) standard.

Optional: 2" (51mm); specify D200.

Optional: 2-1/4" (57mm); specify D214.

Stile

Minimum width 4-1/2" (114mm).

Latchbolt

3/4" (19mm) throw, stainless steel pullmantype with stainless steel deadlocking latch.

Materials

Heavy-duty cold-forged steel chassis; heavygauge steel mechanisms, electroplated

for corrosion resistance; finished parts are

brass, bronze or stainless steel; stainless steel

springs; nylon bearings.

Projection

3-1/4" (83mm) active, 2-3/4" (70mm) dogged.

Dogging

Standard on panic devices; single-point 1/4

turn hex key dogging.

Optional: less dogging, specify M51.

Optional: cylinder dogging; specify M52.

Optional: electric dogging; specify M97.

Mechanical dogging not available on firerated devices.

Fasteners

Standard on panic devices: machine screws

and wood door fasteners. Standard on firerated devices: sex nuts and bolts. Optional

on panic devices: sex nuts and bolts for use

on wood, composite, or unreinforced metal

doors; specify M54. Optional wood screws for

use on approved fire-rated solid wood or wood

core doors. Specify M64.

Strike

Surface-mounted 3/8" (10mm) diameter roller

strike, complete with positive locking plate and

shims, assuring low friction relocking for a long,

trouble-free life.

California State Reference Code

This product has been approved by the

California State Fire Marshal pursuant to

section 13144.1 of the California Health and

Safety Code.

Functions and Trims

Through-bolted lever, knob, pull and

thumbpiece trims available with wide range

of functions; see Trims and Functions, pages

20-25.

NFPA

AllexitdevicescomplywithNFPA101Life

Safety Code. All fire-rated devices comply

withNFPA80FireDoorsandWindows.

Cylinders

Cylinder not included unless specified. See

Quick Codes, page 53.

Removable Mullion

See Mullions, page 48.

Shim Kit

Optional for mounting device over raised vision

light molding; specify M58.

Applications and Listings

See page 4.

Warranty

Five-year limited.

ADA

Exit devices, lever trims and pulls comply

with Americans with Disabilities Act.

Finishes

BHMA 605

BHMA 606

Bright Brass

Satin Brass

BHMA 611

Bright Bronze

BHMA 612

Satin Bronze

BHMA 613

613E

Oxidized Bronze, oil rubbed,

available lacquered

Dark Oxidized Satin Bronze

Equivalent

BHMA 618

BrightNickelPlated

Certification/Compliance

BHMA 619

SatinNickelPlated

ANSI

MeetsA156.3,Type1,Grade1.

Meets A117.1 Accessibility Code.

BHMA 625

Bright Chromium Plated

BHMA 626*

(Trim only)

Satin Chromium Plated

UL /cUL

All devices listed for safety as panic hardware;

devicescomplywithUL305standardsforpanic

hardware. Three-hour fire-rated devices listed

as fire exit hardware for A label and lesser class

4'x8'singleor8'x8'doubledoors;ULsymbol

on active case cover indicates listing.

626C

Satin Chromium Plated

with MicroShield®

BHMA 629

Bright Stainless Steel

BHMA 630

Satin Stainless Steel

Any retrofit or other field modification to a fire

rated opening can potentially impact the fire

rating of the opening, and Corbin Russwin,

Inc. makes no representations or warranties

concerning what such impact may be in any

specific situation. When retrofitting any portion

of an existing fire rated opening, or specifying

and installing a new fire-rated opening, please

consult with a code specialist or local code

official (Authority Having Jurisdiction) to ensure

compliance with all applicable codes and

Satin Stainless Steel

with MicroShield®

Black oxidized bronze,oil

BHMA 722

rubbed

*Contact factory for devices required in

BHMA 626

630C

ratings.

ED5000.8

45063-8/14

Rim Features

ED5000

ED5200 and ED5200A

Rim Exit Devices

Architecturally finished brass,

bronze or stainless steel

Wrought brass or

bronze rear cover

Heavy-duty chassis

Low profile; no pinch points —

closed on all sides

Single point, 1/4 turn hex key

dogging

(ED5200 Series Panic Devices)

3/4" (19mm) throw stainless

steel pullman-type latchbolt

with stainless steel auxiliary

deadlocking latch standard

ED5202(A) Rim

Double Cylinder

Exit Devices

ED5000.9

45063-8/14

Concealed Vertical Rod Features

ED5000

ED5860 Panic-Listed Concealed Vertical Rod Exit Device

ED5860B 1-1/2 Hour Fire-Listed Concealed Vertical Rod Exit Device

FOR USE WiTH METAL OR WOOD DOORS

Features

Handing

Device is handed but is easily field reversible.

Lever trim is handed.

Bar length

Easily field cut to size.

Standard: 36" (914mm) bar fits 30"- 36"

(762mm-914mm) door.

Optional: 24" (610mm) bar fits 24" (610mm)

door; specify W024.

Optional: 48" (1219mm) bar fits 36"-48"

(914mm-1219mm) door; specify W048.

Door Thickness

1-3/4" (14mm) standard.

Optional: 2" (51mm); specify D200.

Optional: 2-1/4" (57mm); specify D214.

Stile

Minimum width 4-1/2" (114mm).

Door Height

Standard: top rod for 8' door.

Telescoping rod assembly to accommodate

various door heights.

Optional door heights up to 10' available; see

Quick Codes, page 55.

Latchbolt

Top: 3/4" (19mm) throw, stainless steel,

pullman-type with automatic deadlatching.

Bottom: 5/8" (16mm) throw deadbolt, held

retracted during door swing.

Vertical Rods

1/2" O.D. tubing, electroplated for corrosion

resistance.

Less Bottom Rod

Optional on ED5860 and ED5860B devices

only; specify M55.

Heat-Activated Door Bolt (Popper)

Standard with all fire-rated devices with M55

option (less bottom rod).

Materials

Heavy-duty cold-forged steel chassis; heavygauge steel mechanisms, electroplated

for corrosion resistance; finished parts are

brass, bronze or stainless steel; stainless steel

springs; nylon bearings.

Projection

3-1/4" (83mm) active, 2-3/4" (70mm)

dogged.

ED5000.16

Dogging

Standard on panic devices; single-point 1/4

turn hex key dogging.

Optional: less dogging, specify M51.

Optional: cylinder dogging, specify M52.

Optional: electric dogging; specify M97.

Mechanical dogging not available on firerated devices.

Fasteners

Standard on panic devices: machine screws

and wood door fasteners.

Standard on fire-rated devices: sex nuts and

bolts.

Optional on panic devices: sex nuts and bolts

for use on wood, composite, or unreinforced

metal doors; specify M54.

Optional wood screws for use on approved

fire-rated solid wood or wood core doors.

Specify M64.

Strike

Top: mortise. Bottom: flush mounted.

Optional strikes available; see Options and

Accessories, page 50.

Functions and Trims

Through-bolted lever, knob, pull and

thumbpiece trims available with wide

range of functions; see Trims and

Functions, pages 20-25.

Cylinders

Cylinder not included unless specified. See

Quick Codes, page 53.

Shim Kit

Optional for mounting device over raised

vision light molding; specify M58.

Applications and Listings

For use with metal or wood doors. See page 4.

Warranty

Five-year limited.

Certification/Compliance

ANSI

MeetsA156.3,Type7and8,Grade1.

Meets A117.1 Accessibility Code.

UL/cUL

All devices listed for safety as panic hardware;

devicescomplywithUL305standardsfor

panic hardware. 1-1/2 hour fire-rated devices

listed as fire exit hardware for B label and lesser

class8'x10'doubledoors;ULsymbolon

active case cover indicates listings.

Any retrofit or other field modification to a fire

rated opening can potentially impact the fire

rating of the opening, and Corbin Russwin,

Inc. makes no representations or warranties

concerning what such impact may be in any

specific situation. When retrofitting any portion

of an existing fire rated opening, or specifying

and installing a new fire-rated opening, please

consult with a code specialist or local code

official (Authority Having Jurisdiction) to ensure

compliance with all applicable codes and

ratings.

California State Reference Code

This product has been approved by the

California State Fire Marshal pursuant to section

13144.1 of the California Health and Safety

Code.

NFPA

AllexitdevicescomplywithNFPA101Life

Safety Code.

Allfire-rateddevicescomplywithNFPA80

Fire Doors and Windows.

ADA

Exit devices, lever trims and pulls comply with

Americans with Disabilities Act.

Finishes

BHMA 605

BHMA 606

Bright Brass

Satin Brass

BHMA 611

Bright Bronze

BHMA 612

Satin Bronze

BHMA 613

613E

BHMA 618

Oxidized Bronze, oil rubbed,

available lacquered

Dark Oxidized Satin Bronze

Equivalent

BrightNickelPlated

BHMA 619

SatinNickelPlated

BHMA 625

Bright Chromium Plated

BHMA 626*

(Trim only)

Satin Chromium Plated

626C

Satin Chromium Plated

with MicroShield®

BHMA 629

Bright Stainless Steel

BHMA 630

Satin Stainless Steel

Satin Stainless Steel

with MicroShield®

Black oxidized bronze,oil

BHMA 722

rubbed

*Contact factory for devices required in

BHMA 626

630C

45063-8/14

Concealed Vertical Rod Features

ED5000

ED5860 and ED5860B

Concealed Vertical

Rod Exit Devices

Heat-activated door bolt

(Popper) –Usedwhenbottom

rod is omitted from fire exit

devices (M55).

FOR USE WiTH METAL OR

WOOD DOORS

3/4" (19mm) throw deadlocking

stainless steel latchbolt

ED5860B

M55 (Less Bottom Rod)

Architecturally finished brass,

bronze or stainless steel

Wrought brass or

bronze rear cover

Low profile; no pinch points –

closed on all sides

Heavy-duty chassis

Single point 1/4 turn

hex key dogging

(ED5860 Series Panic Devices)

5/8" (16mm) throw

deadbolt

ED5000.17

45063-8/14

Heavy-Duty Trims & Functions

ED5000

Rim, SecureBolt®, Vertical Rod

Features:

•FreeWheelingvandal-resistantdesign

•Bevelededges

•Through-boltedtoexitdevice

•Flushcylinderwith6-pincylinderapplications

•5-yearlimitedwarranty

Trim/Function

Passage

AnSi no.

14

Dummy

AnSi no.

02

A910

A950

A9551

A9572

A9591

C910

C950

C9551

C9572

C9591

Dirke

D9

Lever: Cast

Escutcheon: Forged

Cylinder: Rim

Handed: Specify RHR

or LHR

D910

D950

D9551

D9572

D9591

Essex

E9

Lever: Cast

Escutcheon: Forged

Cylinder: Rim

E910

E950

E9551

E9572

E9591

Lustra

L9

Lever: Cast

Escutcheon: Forged

Cylinder: Rim

L910

L950

L9551

L9572

L9591

newport

n9

Lever: Cast

Escutcheon: Forged

Cylinder: Rim

N910

N950

N9551

N9572

N9591

Pull Trim Design

Armstrong

A9

Lever: Cast

Escutcheon: Forged

Cylinder: Rim

Citation

C9

Lever: Cast

Escutcheon: Forged

Cylinder: Rim

Classroom nightlatch Storeroom

AnSi no.

AnSi no.

AnSi no.

08

03

09

1. Classroom function trims can be converted to Storeroom function by a simple field adjustment.

2. Active lever, knob or thumbpiece trim recommended for use with surface or concealed vertical rod exit devices.

ED5000.20

45063-8/14

Mortise Features

ED5000

ED5600

ED5600A

ED5602L

ED5602AL

Panic-Listed Mortise Exit Device

3-Hour Fire-Listed Mortise Exit Device

Panic-Listed Listed Mortise Double Cylinder Exit Device

3-Hour Fire-Listed Mortise Double Cylinder Exit Device

Features

Handing

Device is non-handed.

Mortise lock body is handed, but field

reversible.

Lever trim may be handed.

Bar length

Easily field cut to size.

Standard: 36" (914mm) bar fits 30"- 36"

(762mm-914mm) door.

Optional: 24" (610mm) bar fits 24" (610mm)

door; specify W024.

Optional: 48" (1219mm) bar fits 36"-48"

(914mm-1219mm) door; specify W048.

Door Thickness

1-3/4" (44mm) standard.

Optional: 2" (51mm); specify D200.

Optional: 2-1/4" (57mm); specify D214.

Stile

Minimum width 4-1/2" (114mm).

Latchbolt

2-piece mechanical, 3/4" (19mm) throw,

stainless steel with auxiliary deadlocking

latch.

Materials

Heavy-duty cold-forged steel chassis; heavygauge steel mechanisms, electroplated

for corrosion resistance; finished parts are

brass, bronze or stainless steel; stainless steel

springs; nylon bearings.

Projection

3-1/4" (83mm) active, 2-3/4" (70mm)

dogged.

Dogging

Standard on panic devices; single-point 1/4

turn hex key dogging.

Optional: less dogging, specify M51.

Optional: cylinder dogging, specify M52.

Optional: electric dogging; specify M97.

Mechanical dogging not available on firerated devices.

Fasteners

Standard on panic devices: machine screws

and wood door fasteners.

Standard on fire-rated devices: sex nuts and

bolts.

Optional on panic devices: sex nuts and bolts

for use on wood, composite, or unreinforced

metal doors; specify M54.

Optional wood screws for use on approved

fire-rated solid wood or wood core doors.

Specify M64.

Any retrofit or other field modification to a fire

rated opening can potentially impact the fire

rating of the opening, and Corbin Russwin,

Inc. makes no representations or warranties

concerning what such impact may be in any

specific situation. When retrofitting any portion

of an existing fire rated opening, or specifying

and installing a new fire-rated opening, please

consult with a code specialist or local code

official (Authority Having Jurisdiction) to ensure

compliance with all applicable codes and

ratings.

Strike

Non-handed.ANSIcurvedlipstandard.

4-7/8" x 1-1/4" x 1-1/4" lip to center.

Optional strikes available; see Options and

Accessories, page 51.

California State Reference Code

This product has been approved by the

California State Fire Marshal pursuant to section

13144.1 of the California Health and Safety

Code.

Functions and Trims

Through-bolted lever, knob, pull and

thumbpiece trims available with wide range