Product Design for Energy: An Inverted Pyramid Approach 245

advertisement

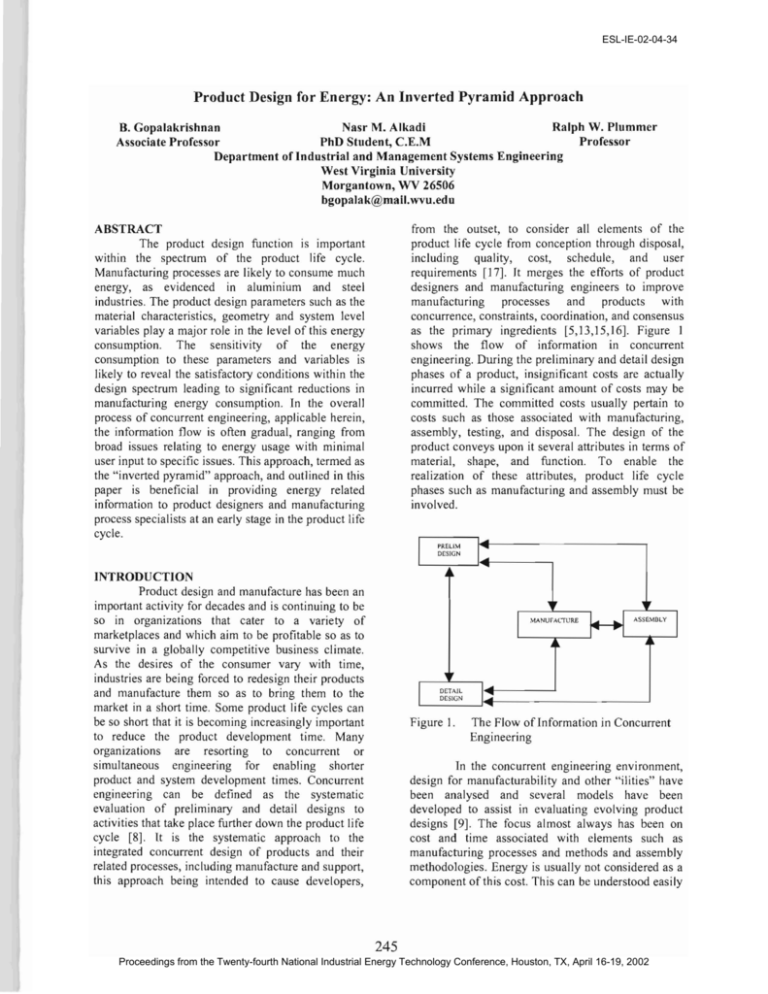

ESL-IE-02-04-34 Product Design for Energy: An Inverted Pyramid Approach Ralph W. Plummer B. Gopalakrishnan Nasr M. Alkadi Professor Associate Professor PhD Student, C.E.M Department of Industrial and Management Systems Engineering West Virginia University Morgantown, WV 26506 bgopalak@mall.wvu.edu from the outset, to consider all elements of the product life cycle from conception through disposal, including quality, cost, schedule, and user requirements [17]. Jt merges the efforts of product designers and manufacturing engineers to improve manufacturing processes and products with concurrence, constraints, coordination, and consensus as the primary ingredients [5,13,15,16]. Figure I shows the flow of information in concurrent engineering. During the preliminary and detail design phases of a product, insignificant costs are actually incurred while a significant amount of costs may be committed. The committed costs usually pertain to costs such as those associated with manufacturing, assembly, testing, and disposal. The design of the product conveys upon it several attributes in terms of material, shape, and function. To enable the realization of these attributes, product life cycle phases such as manufacturing and assembly must be involved. ABSTRACT The product design function is important within the spectrum of the product life cycle. Manufacturing processes are likely to consume much energy, as evidenced in aluminium and steel industries. The product design parameters such as the material characteristics, geometry and system level variables playa major role in the level of this energy consumption. The sensitivity of the energy consumption to these parameters and variables is likely to reveal the satisfactory conditions within the design spectrum leading to significant reductions in manufacturing energy consumption. In the overall process of concurrent engineering, applicable herein, the information flow is often gradual, ranging from broad issues relating to energy usage with minimal user input to specific issues. This approach, termed as the "inverted pyramid" approach, and outlined in this paper is beneficial in providing energy related information to product designers and manufacturing process specialists at an early stage in the product life cycle. INTRODUCTION Product design and manufacture has been an important activity for decades and is continuing to be so in organizations that cater to a variety of marketplaces and which aim to be profitable so as to survive in a globally competitive business climate. As the desires of the consumer vary with time, industries are being forced to redesign their products and manufacture them so as to bring them to the market in a short time. Some product life cycles can be so short that it is becoming increasingly important to reduce the product development time. Many organizations are resorting to concurrent or simultaneous engineering for enabling shorter product and system development times. Concurrent engineering can be defined as the systematic evaluation of preliminary and detail designs to activities that take place further down the product life cycle [8]. It is the systematic approach to the integrated concurrent design of products and their related processes, including manufacture and support, this approach being intended to cause developers, Figure I. The Flow of Information in Concurrent Engineering In the concurrent engineering environment, design for manufacturability and other "ilities" have been analysed and several models have been developed to assist in evaluating evolving product designs [9]. The focus almost always has been on cost and time associated with elements such as manufacturing processes and methods and assembly methodologies. Energy is usually not considered as a component of this cost. This can be understood easily 245 Proceedings from the Twenty-fourth National Industrial Energy Technology Conference, Houston, TX, April 16-19, 2002 ESL-IE-02-04-34 from the fact that the cost referred to herein is a function of product development time, "ease" of manufacture, and product quality. These three items have been important elements as criteria in the concurrent engineering process. Energy may not have an important role to play in any of these criteria. It is important that energy be a player in the concurrent engineering scenario. In the light of increasing energy costs, manufacturing processes must be evaluated on the basis of energy in order to derive meaningful conclusions regarding process feasibility. energy consumption during the design of a heat exchanger network. It was found that from the process design, demand for utilities could be estimated. Then, the utility system is designed based on the process design and the energy-integrated process design can be introduced at this stage to seek the design that requires minimum energy, and the corresponding levels at which the utility should enter the process can also be detennined [14]. Diana 1., Bauer has developed an integrated model of the grinding process. The model evaluated the energy utilization and waste mass flux for different surface and process specifications [3]. Epstein, 1., Gary and Ambs, Lawrence, have developed a technique for estimating the energy end-use utilizing an interactive computer model. The developed model served as a tool for industrial managers to gain an understanding of the relative magnitudes of energy consumption in different use categories and assists in prioritising the energy saving measures [6]. In conclusion, it can be said that the concepts related to "Design for Energy" have not been thoroughly explored in the literature. RELEVANT LITERATURE Drexel University, under a contract with the U.S. Department of Energy, initiated a program to develop a detailed database of industrial energy utilization. This database consists of typical process configurations and energy and material balances for 108 industrial processes representing 60 four-digit Standard Industrial Classification (SIC) industries. The outcome of this study was the development of energy and mass balances On a per unit basis (e.g. per pound product, per pound input) for each of the unit operations that comprise the 108 industrial processes [4]. Luis G., and Hyman, B. have developed a general approach for combining end-uses and process steps into calibrated energy consumption models of manufacturing processes using the Manufacturing Energy Consumption Survey (MECS). The main objective was to build complete, fully documented, end-use models for pulp, paper, and paperboard mills that are consistent with the 1991 MECS data and to depict the energy flows between inputs and end-uses in a manner that clarifies the energy-use patterns underlying the data [7]. Anders Martensson has investigated the impact of information technology on energy efficiency using steel-reheating furnace as an example to pursue this implication. The model evaluated the effect of process changes during the 12­ year period. Changes in furnace efficiency were detected and attempts were made to correlate these changes with known measures. It was found that energy use was lower than expected, with differences up to 17%. The deviations were found to be statistically significant on a 95% level [12]. Tracy Reed has developed a general method for estimating the physical energy-intensity of manufacturing a product. The approach was demonstrated for the electric intensity of pulp, paper, and paperboard. They found that relative physical electric intensity of products could be quite different from the relative economic electric intensities for the industries that produce those products [10]. A. E. Saeed has studied the effect of process integration on the reduction of ENERGY SENSITIVE DESIGN ATTRIBUTES The product design parameters that are most sensitive to energy requirements are the material properties and product geometry. Production volume also influences energy considerations. Material hardness and microstructure often have a large impact on the type of manufacturing processes that can be successfully applied. Machining in general less energy intensive than casting or forming, as it is mainly electrical energy that is being expended in motor operations. Casting processes require metal melting, an energy intensive process using either gas or electrically fired furnaces. The forming processes also require considerable electrical energy for the large sized motors that operate the die movements. Some materials such as aluminium and cast iron lend themselves to casting more easily than machining on account of their properties. Greater the hardness of the material more difficult it may be to machine. The product geometry may be critical in terms of machining time. More intricate the product geometry, more will be the complexity of the machining process and the tool movements, thus leading to increased energy requirements in terms of increased machining time. Casting a product possessing complex geometrical features may result in postoperative machining, thus leading to increased overall energy consumption. The same principle applies to formed products. Low production volumes can be targeted by machining operations in batches while large 246 Proceedings from the Twenty-fourth National Industrial Energy Technology Conference, Houston, TX, April 16-19, 2002 ESL-IE-02-04-34 THE OPERAnON OF THE DES production volumes often necessitate the use of casting or forming processes. The production rate required thus has a significant effect on the chosen manufacturing process strategy. Operations management personnel focus much on the production volumes required to meet customer demand fluctuations and are interested in having the manufacturing process infrastructure be flexible enough to support the mission and objectives of the organization. Hence, whether it is casting, machining, or forming processes, energy requirements are definitely related to the properties of the material, the product's geometry, and required production volumes. The nature of the operation of the DES is important. From analysing the systems diagram shown on figure 2, it is apparent that there may not be a consistent and complete amount of information emanating from the preliminary and the detail design functions as well as from the manu facturing function. This is because these functions are still evolving in terms of their accomplishment of their functionality at the early stages in the product development cycle. In the concurrent engineering framework, the interactions between product development phases are often iterative and are usually subject to a constant flow of constantly modified data. How should the DES operate in such a scenario? The DES must be able to: l. Incorporate, acquire and process incomplete information. 2. Provide meaningful feedback in light of such information. 3. Incorporate, acquire and process information as it evolves and becomes "complete". SYSTEMS APPROACH Consider the system as shown in Figure 2. The preliminary and detail design functions generate product attributes that are being evaluated by the Design for Energy System (DES). The manufacturing process attributes are also being evaluated by the DES. The DES subjects the attributes to a rigorous evaluation and provides feedback to the design function on aspects that could be modified to cause a reduction in manufacturing energy consumption. The evaluations from the DES will be in terms of providing the amount of energy required to make a specific unit of the product. The specific unit could be in terms of individual units, pounds, tons etc. The system shown on figure I can be integrated into the regular concurrent engineering framework, hence providing an active energy based interface for dialogue between the design function and otl1er down the line functions in the spectrum of the product life cycle. As an example, consider someone who is interested in knowing how much energy would be needed to produce one pound of ice cream? This person may be interested in erecting a factory to produce the product and would be able to provide minimal information about the production infrastructure and requirements. Consider on the other hand someone who already owns a machine shop and is ready to introduce a new product into the market. Such a person may have information that is more detailed and complete and may be expecting energy information that is much more accurate. The third example relates to an evolving product design function at which stage a reasonably accurate estimate of energy requirements must be provided. In all the three examples described, it is clear that the design and manufacturing information is not at the same level of "completeness". Thus the DES must be able to deliver meaningful energy related advice in the face of incomplete information and/or evolving information. PRELIM DESIGN Figure 2. The Inverted Pyramid Approach The DES must be able to provide a broad range of information to the user using minimal input. On the other hand, the DES must also be able to provide focused detailed information to the user using comprehensive input data. The completeness of the data could vary and hence the level of information supplied by the DES must also vary. Consider the inverted pyramid shown in Figure 3. At the top of the pyramid lies the broad range of Design for Energy System Diagram 247 Proceedings from the Twenty-fourth National Industrial Energy Technology Conference, Houston, TX, April 16-19, 2002 ESL-IE-02-04-34 infonnation which are good estimates as provided by the DES while at the bottom of the inverted pyramid lies focused information that is not estimates but rather detailed and accurate. In between the top and bottom of the inverted pyramid lie varying levels of infonnation as supplied by the DES. interface for providing any desired input and data is necessary. When conclusions are being arrived at, the user is presented with the workings of an explanation-based subsystem that offers the reasoning behind any conclusion that has been reached. When the inference engine searches through the knowledge base, intennediate conclusions are often reached prior to the substantiation of the goals. Thus, in this light a working memory, or a database is necessary to hold the infonnation generated on an intennediate basis. Broad level of energy information ..- A~ ~, Working Memory KnDWiedge Base A. i t r r I Focused and detai led energy information Inference Engine I A~ ~Ir Figure 3. ... The Inverted Pyramid Methodology Contents Of The DES In order for the DES to be able to supply varying levels of infonnation to the user, its design must be robust enough to incorporate and process varying levels of input information. The basic design attributes of the DES include quantitative algorithms and expert systems for processing symbolic infonnation. Expert systems are suited well for processing incomplete information and are able to adapt well to uncertainty in data. Algorithms and associated databases on the other hand are well suited for accurate numerical computation and are used to model well known energy oriented information. An expert system can be defined to be an intelligent system composed of a knowledge base, an inference engine, a working memory, a user interface, and an explanation based subsystem, capable of solving problems that are generally unstructured and difficult enough for human beings to solve easily [1,2,11,18]. Figure 4 shows the components of an expert system. The knowledge base within an expert system contains all the necessary infonnation represented in an appropriate manner and amenable for the employment of search procedures. The inference engine uses search techniques to wade through the knowledge base to arrive at conclusions. A user Figure 4. User Components of an Expert System Consider the DES architecture as shown in Figure 5. The user is supplying information to the DES that in tum is processed and provided back to the user. The user will then be able to modifY the infonnation and reinvoke the DES that can then fine­ tune the accuracy of the information provided earlier. One of the important facets of the DES architecture is the ability to perfonn sensitivity analysis. The user, whether from the preliminary and/or the detail design function or the manufacturing function, often has the desire to know ''what if' some of the data is varied within a range of values. Would the decision points still stay the same? For example, if the hardness of the material were varied from J 20 Bhn to 250 Bhn, how would the energy cost per pound to manufacture the product change? If the production volume were varied from 500 pieces per hour to 2000 pieces hour, how would the energy cost per unit manufactured change? The answers to these questions are important as the user must have the capability to exercise a variety of design and manufacturing options in order to successfully produce and market the products. 248 Proceedings from the Twenty-fourth National Industrial Energy Technology Conference, Houston, TX, April 16-19, 2002 ESL-IE-02-04-34 navigation procedures cannot happen without an effective database interface. The database is crucial for holding transient processed information that translates from one system to another. It is also required for being the repository for data so as to enable the generality of the associated knowledge based systems. Inverted Pyramid Figure 5. Let us consider the type of information processed and delivered by the DES. Say, the user is a businessperson considering the development of a manufacturing facility for producing product X. The user, along with the manufacturing specialist invokes the DES. It is required to manufacture 2,500 pieces of X per month using the machining process. The DES analyses this information at the highest level of the pyramid and provides a response that the amount of energy required to make each unit of X will be C MMBtu. The user then changes the information on the required production volume to vary from 2,500 to 5,500 per month and the DES responds with a graph showing the change in energy requirements to correspond to the change in production volume. The manufacturing specialist then wishes to consider heat-treating the product after machining and provides relevant information in terms of temperature gradients and time sensitive parameters. The DES analyses this information and provides the necessary energy requirements, functioning at a relatively lower level of the pyramid. At this stage, the manufacturing specialist may decide to enhance the information provided such as in terms of specific nature of the furnaces to be used, and detailed time temperature variance. Armed with more detailed information, the DES will be able to Refine its estimates arrived at previously. The design specialist now enters the dialogue and wishes to know if there would be any cbanges to energy requirements if the material changed from alloy A to alloy B. The design specialist is able to provide all relevant details on each alloy. The DES is now at a relatively middle range in level and is able to cater to the request of the designer. The DES will also be able to provide feedback to the designer on possible "redesign" options or identify key energy indices for the design so as to reduce energy consumption. Architecture of DES RESULTS OBTAINED The development of the DES is ongoing within the architectural scope defined in this paper. Preliminary research is being done to analyse the effect of varying design parameters on manufacturing energy consumption, especially in the machining and heat treating areas. In the machining area the experimental set-up has been determined to machine a variety of material of varying geometry and subsequent analysis of machine power consumption. The key variables under consideration are the material hardness, material removal rate, machining conditions including cutting speed, feed, and depth of cut to enable the required material removal rate, and raw material stock geometry. In the heat treating area, preliminary research with a reheating furnace of a major steel manufacturer has revealed interesting knowledge with respect to furnace energy consumption as pertaining to variance in work material properties and entry temperatures. SYSTEM OPERAnON How will the system operate when it has been completed? The system will have user-friendly features and incorporate the power of today's software systems working within the confines of the most suitable hardware system. The intent is to enable energy based information to be provided to a wide variety and spectrum of users, ranging from the knowledgeable process engineer to the non-technical operations management senior personnel. The DES will have the client-server interface designed with accuracy and user friendliness in mind. The user will be able to navigate within varying levels of the inverted pyramid and "zoom" in and expand on any information provided at any level of the pyramid. The use of algorithmic and expert systems programming will facilitate this aspect. The At this stage, the maintenance specialist enters the dialogue and wishes to know the specific methods that can be used to reduce energy consumption in machining processes that are essentially motor oriented. The DES scopes the possessed knowledge and is able to identify energy conservation opportunities such as the use of cogged belts, adjustable speed drives, and the use of energy 249 Proceedings from the Twenty-fourth National Industrial Energy Technology Conference, Houston, TX, April 16-19, 2002 ESL-IE-02-04-34 efficient motors. The maintenance specialist can driB down to an even lower level of the pyramid and obtain information on how exactly to implement such energy conservation opportunities and what the potential savings would be. Thus, the DES will be able to adapt and modify its operational procedures to cater to a varying audience interested in product and system development. Computer Model, Energy Engineering, Vol. 86, No. 2,1989. [7] Giraldo, Luis, and Hyman, Barry, Energy End­ Use Models for Pulp, Paper, and Paperboard Mills, Energy, Vol. 20, No. 10, pp 1005-1019, 1995. [8] Gopalakrishnan, 8., Product Design and Process Planning in Concurrent Engineering, International Society for Productivity Enhancement, 1996. [9] Huang, G.Q., Editor, Design for X, Concurrent Engineering Imperatives, Chapman and Hall, 1996. [10] Hyman, Barry, and Reed, Tracy, Energy Intensity of Manufacturing Processes, Energy, Vol 20, No.7, pp 593-606, 1995. [11] Kline, P., and Dolins, S., Designing Expert Systems, John Wiley, New York, 1990. [12] Martensson, A. The Impact ofInformation Technology on Energy Efficiency: An Evaluation Case Study of Steel-Reheating Furnaces, Energy, Vol. 19, No.7, pp 717-728,1994. [13] Nevins, J.L., Whitney, D.E., Concurrent Design of Products and Processes, McGraw Hill, New York, 1989. [14] Saeed, A.E., Blakemore, F.B., and Doulah, M.S. Effect of Process Integration on the Reduction of Fuel Consumption, Applied Energy, Vol. 54, No.4, pp 287-300, 1996 [15] Stauffer, R.N., Simultaneous Engineering: Beyond a Question of Mere Balance, Manufacturing Engineering, Vol. 108, pp. 35-37, 1992. [16] Stoll, H.W., Design for Manufacture, Manufacturing Engineering, 1988. [17] Winner, R.I., Pennel, J.P., Bertrand, H.E., and Slusarczuk, M.M.G., The Role of Concurrent Engineering in Weapons Systems Acquisition, Report R-338, Institute for Defense Analysis, 1988. [18] Yaghmai, N.S., and Maxin, J.A., "Expert Systems: A Tutorial", Journal of American Society ofInformation Science, Vol. 35, No.5, 1984. CONCLUSION There is definitely a need for the development of a system such as the DES to function in the concurrent engineering domain. The US Department of Energy (USDOE) has identified several industries including aluminium, steel, and metal casting to be energy intensive enough to be included in the Industries of the Future (IOF) program, thus focusing on manufacturing energy reductions at every stage. Systems such as the DES will go a long way in enabling such visions to be a reality as they place a capability in the hands of the industrial practitioner that was not available previously, namely the ability to evaluate the sensitivity of energy with respect to key design and manufacturing parameters. Performing the sensitivity analysis of energy requirements with respect to design and manufacturing parameters will enable energy savings across major industrial sectors as they facilitate the process within the scope of economic competitiveness and business profitability, two elements critical for survival in today's global markets. REFERENCES [I] Addis, T.R., "The Nature of Expert Systems, Colloquium on the Application of Knowledge Based Systems, IEE, United Kingdom, 1982. [2] Alpar, P., "Towards Structured Expert Systems Development", Expert Systems with Applications, Vol. 1, No. 1,1990. [3] Bauer, 1., Diana, Thurwachter, S., and Sheng, S. Paul, Integration of Environmental Factors in Surface Planning, Part I - Mass and Energy Modeling, Society of Manufacturing Engineers, 1998. [4] Brown, L. Harry, Hamel, B. Bernard, and Hedman, A., Bruce, Energy Analysis of 108 Industrial Processes, Fairmont Press, Inc., Lilburn, GA,1996 [5] Clausing, D., Concurrent Engineering, Proceedings of the ASME Winter Annual Meeting, San Francisco, 1989. [6] Gary, 1. Epstein, and Lawrence, Ambs, Energy End-Use Estimation Techniques With An Interactive 250 Proceedings from the Twenty-fourth National Industrial Energy Technology Conference, Houston, TX, April 16-19, 2002