Powder Metallurgy routes as a versatile method to process on

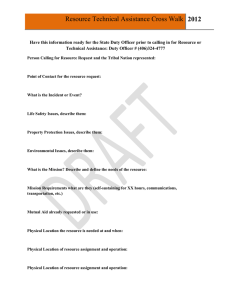

advertisement

Powder Metallurgy routes as a versatile method to process on demand advanced microstructures G. Dirras, D. Tingaud Université Paris 13, Sorbonne Paris Cité Institut Galilée, Laboratoire des Sciences des Procédés et des Matériaux (LSPM), CNRS, UPR 3407 99 avenue JB Clément – 93430 Villetaneuse Because of more and more demanding and complex performances for structural materials, they need to be studied under various loading conditions and environments. To this end efforts should be put on the control and development of adequate microstructures. Indeed, despite the fact that the properties of these materials seem to be optimized for most current applications, the low availability (in some cases) in the Earth crust in addition to geo-strategic interests and issues related to environment sustainability, require new approaches to optimize properties of already existing materials. Conventional material developments have emphasized grain refinement and homogenization. However, “nano- and homo-” materials do not usually satisfy the need to be both strong and ductile, which are of course rather contradictory characteristics. Through the use of one of powder metallurgy processes we have designed multimodal and/or multi-structured pure or metallic alloys such as Ni, NiW and titaniumbased (Ti, Ti-6-4) as an attempt to overcome that antinomy. In addition to conventional testing methods, solicitations under extreme conditions such as high velocity impact loadings have been carried out. The underlying deformation mechanisms will be presented and discussed.