Wire Gauge Explained?

The term wire gauge refers to the thickness of a wire. Wire gauge can be used to determine electrical resistance

and the current handling capability of the wire. There are two major standards for describing wire gauge, Metric Wire

Gauge (MWG) and American Wire Gauge (AWG). B&S is another commonly used measure of wire gauge, B&S means

Brown & Sharpe and B&S is equal to AWG.

Metric Wire Gauge is used outside of the US. Metric Wire Gauge is quoted using its cross sectional area in mm² to

describe the wire thickness.

American Wire Gauge is most commonly used in the US. The AWG is determined via the cross sectional area of the

conductor, the same as MWG however AWG is described using a list of gauge numbers. AWG gauge numbers work in

the opposite direction to MWG descrpitions, with the smallest numbers representing the largest diameter wires.

B&S is commonly used for thicker wires in Australia. B&S follows the same gauge descriptions as AWG and is simply

another way of explaining the wire gauge. AWG = B&S.

AWG/B&S - Small gauge number for large wire cross sectional area - smaller the gauge/larger the wire.

MWG - Small gauge number for small wire cross section area, described in mm² - smaller the gauge/smaller the wire.

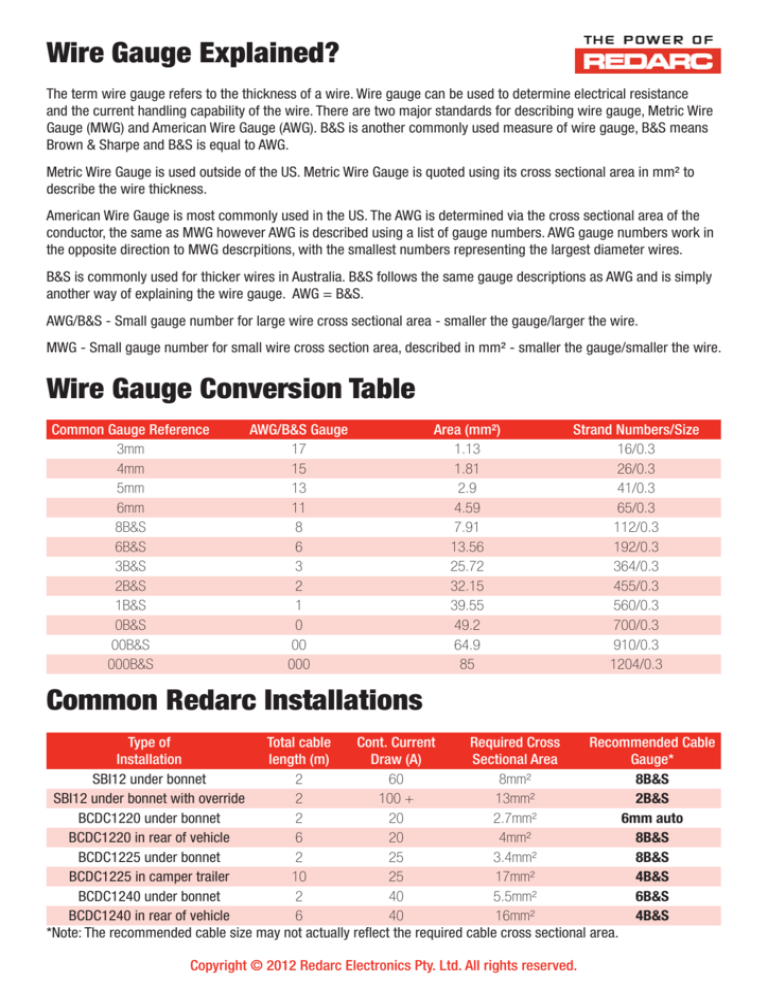

Wire Gauge Conversion Table

Common Gauge Reference

3mm

4mm

5mm

6mm

8B&S

6B&S

3B&S

2B&S

1B&S

0B&S

00B&S

000B&S

AWG/B&S Gauge

17

15

13

11

8

6

3

2

1

0

00

000

Area (mm²)

1.13

1.81

2.9

4.59

7.91

13.56

25.72

32.15

39.55

49.2

64.9

85

Strand Numbers/Size

16/0.3

26/0.3

41/0.3

65/0.3

112/0.3

192/0.3

364/0.3

455/0.3

560/0.3

700/0.3

910/0.3

1204/0.3

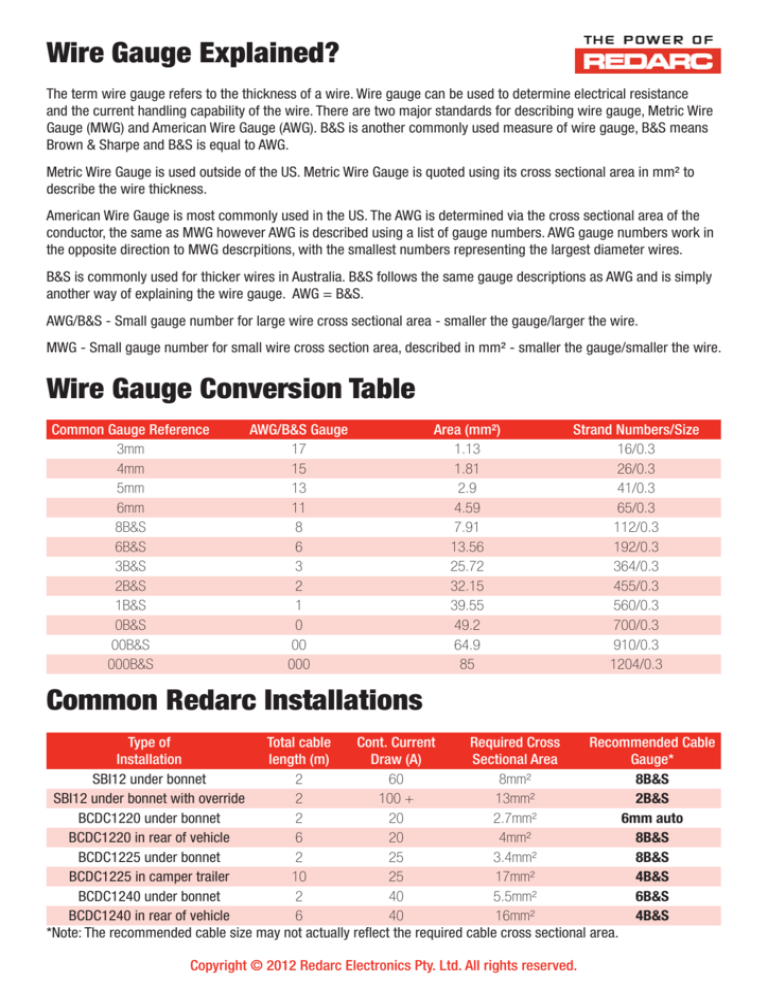

Common Redarc Installations

Type of

Total cable

Cont. Current

Required Cross

Recommended Cable

Installation

length (m)

Draw (A)

Sectional Area

Gauge*

SBI12 under bonnet

2

60

8mm²

8B&S

SBI12 under bonnet with override

2

100 +

13mm²

2B&S

BCDC1220 under bonnet

2

20

2.7mm²

6mm auto

BCDC1220 in rear of vehicle

6

20

4mm²

8B&S

BCDC1225 under bonnet

2

25

3.4mm²

8B&S

BCDC1225 in camper trailer

10

25

17mm²

4B&S

BCDC1240 under bonnet

2

40

5.5mm²

6B&S

BCDC1240 in rear of vehicle

6

40

16mm²

4B&S

*Note: The recommended cable size may not actually reflect the required cable cross sectional area.

Copyright © 2012 Redarc Electronics Pty. Ltd. All rights reserved.

Required Wire Gauge Chart

The below diagram will advise the minimum required wire gauge for a given cable length and the current draw or

wattage. Simply draw a line from the required cable length (meters or feet), to the required current draw or wattage

figure. Where the line passes through the gauge column will indicate the required wire gauge.

Watts

Amps

AWG/B&S

mm2

Ft

m

Amps

Watts

24V

AWG/B&S

mm2

Ft

m

12V

100

100

25

20

The example shows

a BCDC1220 install

with a total cable

length of 3 metres.

The chart suggests

a 4mm² cross

sectional area to

handle the 20A

maximum current

draw.

15

80

70

50

35

60

50

25

40

10

8

6

5

4

3

30

1

0.8

10

6

20

15

10

4

2.5

1.5

1

0.75

2

1.5

16

2/0

0

2

4

6

8

10

12

14

16

18

50

40

30

0.5

20

25

20

400

15

300

10

20

15

200

8

150

6

5

10

8

6

5

4

5

100

700

600

500

3

100

4

80

3

60

50

80

60

50

40

50

35

30

25

16

20

1.5

1

2

20

0.8

6

4

10

2.5

1.5

1

5

30

3

10

15

2

40

120

95

70

0.75

0.5

5/0

150

4/0

3/0

2/0 100

0

80

2

60

4

50

6

40

4000

8

800

10

12

14

16

18

20

3

30

3000

2000

1500

1000

600

20

15

500

400

300

10

8

200

6

150

5

Gauge chart supplied by Ashdown-Ingram

How to Calculate Voltage Drop or Cable Size

Cable Cross Section

T = Temperature of

l = Total

cable

Length of

wire (not shroud)

n = Number of

individual strands

of wire

A

I

d = Diameter

= Cross Sectional

Area

of wire

strands

= Current Draw

Vd= Voltage Drop

Cross Sectional Area (cable size)

A=

pd2 Gn

4

Voltage drop (at 25°C)

Vd = l G I G 0.017

A

Cross Sectional Area (cable size)

A = l G I G 0.017

Vd

Voltage drop (other temperatures)

Vd = lGIG0.017 G(1+0.004G(T-25))

A

Want an easier way to work out Voltage Drop or required Cable Size?

www.redarc.com.au/handy-hints/calculator/