A Case Study in Successful Product Line Development

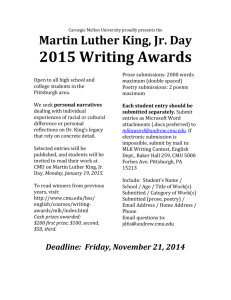

advertisement