Bond Energy and Physical Properties

advertisement

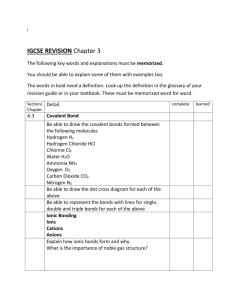

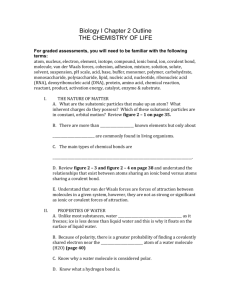

Material Science I Ceramic Materials Chapter 3: Bond Energy and Properties F. Filser & L.J. Gauckler ETH-Zürich, Departement Materials frank.filser@mat.ethz.ch HS 2007 Ceramics: Bond Energy and Properties, Chap 3 1 Material Science I Goal of this Chapter is … to develop semiquantitative relationships between • the properties of a ceramic material and • the depth and shape of the energy well Ceramics: Bond Energy and Properties, Chap 3 2 Material Science I The Bond Energy and the Physical Properties • Bond forces / energy between ions or atoms composing a solid determine a lot of its physical properties Hence we can use the bond energy as a means to predict physical properties Examples: melting temperature, modulus of elasticity, strength, hardness • • • • This prediction works in a lot of cases but not in all. Refinement is required for crystallized solids, i.e. effect of Madelung, and for solids made up of mixed ionicconvalent bondings. Ceramics: Bond Energy and Properties, Chap 3 3 Material Science I Contents • potential well & bond energy for ionic bonding, the equilibrium distance • bond force as a function of the inter-ionic distance, max. force, inflexion point. • melting temperature and hardness for ionic bonded compounds • limitation of the prediction by potential well (example of MgO / Al2O3) -> introduction of covalency (of an ionic bond) • thermal expansion explained with the potential well • elastic modulus • theoretic strength of compounds Ceramics: Bond Energy and Properties, Chap 3 4 Material Science I The Bond Energy for Ionic Type of Bonding Enet Eatt Erep z1 z2 e 2 Eatt r 4 0 r repelling Sum E repulsion attracting - Ion’s Distance r0 + E attraction r0 = equilibrium distance B Erep r n r z1 z2 e 2 B Enet r n 4 0 r r Potential Ebond Ceramics: Bond Energy and Properties, Chap 3 z1 z2 e2 1 1 4 0 r0 n 5 Material Science I Potential and Force as Function of Inter-Ionic Distance 150 40 20 50 0 0 x2 -50 Force [nN] Potential [eV] 100 -20 x1 -100 x1 x2 -40 -150 0 100 200 300 400 500 600 Inter-Ionic Distance r [pm] z1 z2 e2 B Enet r n 4 0 r r Ceramics: Bond Energy and Properties, Chap 3 700 800 0 100 200 300 400 500 600 700 800 Inter-Ionic Distance r [pm] Fnet r dEnet r dr 8 Material Science I Comparison of Potential – Inter-Ionic Distance Curves for NaCl, MgO, LiF 40 • MgO potential well is much deeper than for LiF and NaCl (ca 4x deeper) NaCl LiF MgO • LiF potential well is a bit deeper than for NaCl. Potential [eV] 20 r0 • Same crystal structure (Rocksalt) 0 • Inter-Ionic Equilibrium Distances - NaCl r0=283 pm - LiF r0= 209 pm - MgO r0=212 pm -20 Ebond -40 0 0.5 1 1.5 2 z1 z2 e2 1 1 4 0 r0 n 2.5 3 3.5 Relative Inter-Ionic Distance r/r0 [-] Ceramics: Bond Energy and Properties, Chap 3 4 • Valencies are different 9 Material Science I The Melting Temperature The Bond strength Ebond -> depends strongly on the valency and the ionic radii/distance (lattice distance). • The bond strength Ebond of ionic bonded compounds is directly proportional the multiplication of its ionic charges z1 and z2 and inverse proportional the equilibrium ionic distance r0. • The higher the valency the stronger the bond strength. • The compounds MgO, NaCl and LiF crystallize in same lattice (fcc lattice), and ionic character of the bond is prevailing (>60 %). MgO NaCl LiF Crystal Structure 2852°C 801°C 848°C Rocksalt Ceramics: Bond Energy and Properties, Chap 3 10 Material Science I Melting Temperature of some Compounds Ionic Distance [Å] z1=+1, z2=-1 inter-ionic distance increasing due to anion radius increasing Melting Temperature [°C] NaF 2.31 988 NaCl 2.81 801 NaBr 2.98 755 NaI 3.23 651 MgO 2.1 2800 CaO 2.4 2580 SrO 2.57 Comparable BaO 2.76 !!! LiF 2.01 824 NaF 2.311 988 KF 2.67 846 RbF 2.82 775 melting temperature decreasing z1=+2, z2=-2 inter-ionic distance increasing due to cation radius increasing 2430 decrease 1923 melting temperature decreasing !!! z1=+1, z2=-1 inter-ionic distance increasing due to cation radius increasing melting temperature decreasing The melting temperature increases as the ionic distance decreases within the lattice. The melting temperature increases for increasing valency given about same ionic distance Ceramics: Bond Energy and Properties, Chap 3 11 Material Science I Hardness as function of the inter-ionic distance and the ionic charge Compound Ionic Distance [Å ] Hardness [Mohs] BeO 1.65 9 MgO 2.3 6.5 CaO 2.4 4.5 SrO 2.57 3.5 BaO 2.76 3.3 +F Na NaF 2.01 3.2 2+O2Mg MgO 2.3 6.5 3+N3ScN Sc 2.67 7-8 4+C4TiC Ti 2.82 8-9 z1=+2, z2=-2 inter-ionic distance increasing due to cation radius increasing valency of ions increasing & despite inter-ionic distance increasing hardness decreasing hardness increasing The hardness increases with decreasing ionic distance, assuming constant ionic charges. The hardness increases for increasing valency, despite ! increasing ionic distance. Ceramics: Bond Energy and Properties, Chap 3 12 Material Science I The Melting Temperature of Al2O3 and MgO Al2O3: 2054 °C MgO: 2852 °C } Presumption: MgO has the lower melting temperature. Why? Criteria of Analysis: • Ionic Distance • Valency • Bond Energy • Lattice Energy Ceramics: Bond Energy and Properties, Chap 3 13 Material Science I The Melting Temperature of Al2O3 and MgO Al2O3: 2054 °C MgO: 2852 °C } Presumption: MgO has the lower melting temperature. Why? Criteria of Analysis: • Ionic Distance -> r0Al2O3 = 193.5 pm, r0MgO = 212 pm • Valency -> (z1 x z2)Al2O3= -6, (z1 x z2)MgO= -4 • Bond Energy E • Lattice Energy E Al2O3 bond Al2O3 Lattice MgO E bond 1.64 MgO E Lattice 23.54 The analysis based on the potential well of an ionic bonded solid is often good and correct, however not all the time!!! Ceramics: Bond Energy and Properties, Chap 3 14 Material Science I The Melting Temperature of Al2O3 and MgO Al2O3: 2054 °C MgO: 2852 °C } We need other and better criteria !!! Further Criterium of Analysis: -> Type of Bond: amount of covalency in the bonds for Al2O3 is higher than for MgO. A measure for covalency is, for example, the difference in electronegativity of the ions. DENAl2O3 = 1.83, DENMgO = 2.13 Ceramics: Bond Energy and Properties, Chap 3 15 Material Science I The Covalent Character of a Bond TiO2 idealized Rutile Tm = 1857°C CdI2 layer structure Tm = 387°C CO2 molecule lattice Tm = -57°C MX2 stoichiom., DEN = 1.9 MX2 stoichiom., DEN = 0.97 MX2 stoichiom., DEN = 0.89 Tm = melting temp. • The covalent character of a bond increases from the left to right. • The network structure of the bonds changes: from a 3D structure of TiO2 (Rutile), to a layered structure of CdI2, to a molecule lattice of CO2. The melting temperature decrease in this direction, too. Ceramics: Bond Energy and Properties, Chap 3 16 Material Science I What issues influence the amount of covalency in an ionic bond? MgO vs Al2O3 • Polarizing power of the cation fAl3+ = 60 1/nm; fMg2+ = 31 1/nm • Polarizibility of the anion aeO2- equal for both cases • Elektron configuration of the cation no d-electrons in both cases ideal pair of ions (no polarization) Ceramics: Bond Energy and Properties, Chap 3 polarized pair of ions high amount of polarizing sufficient to form a covalent bond 17 Material Science I The Thermal Expansion Coefficient 1 l l0 T p Potential Energy a rmin r0 rmax max X ionic distance r maximum potential energy energy level of the thermal vibration = mean ion density (location) for increasing temperature Ceramics: Bond Energy and Properties, Chap 3 18 Material Science I Thermal Expansion of Chosen Ceramic Materials • Metals possess a higher thermal expansion than ceramic materials • a is a function of the temperature • The higher T the higher a • Loosely packed, non-dense structures (higher amount of bond covalency) may have very small a changement of angle of the the bonds Temperature °C Ceramics: Bond Energy and Properties, Chap 3 19 Material Science I Thermal Expansion Coefficient in case of phase transformation Cristobalit Cristobalite Ceramics: Bond Energy and Properties, Chap 3 Quarz Quartz • a is a function of temp. • Quartz shows one transformation temperature. Q. is a single crystal - the other materials are polycrystals. • a of b-quartz has a negative slope, i.e. increasing temp. leads to smaller a(see also ZrO2) • Quartz has a lower a than cristobalite because quartz bonding can change angles, and cristobalite bond angles are already more straight • SiO2 vit. : bond angles change in all spatial directions. 20 Material Science I Anisotrope thermal Expansion Coefficients b-Eucryptite (LiAlSiO4) = Glass Ceramic cold kalt heiss hot Ceramics: Bond Energy and Properties, Chap 3 21 Material Science I Glass ceramics: Zerodur Astro Space: Mirrors of future x-ray satelites Micro lithography: Zerodur® components are used as movable elements in wafer-stepper and wafer-scanners. Metrology: Because of its very low thermal expansion and its long-term stability, components made of Zerodur® will show excellent precision in measurements instruments and metroloy. Mechanic: Excellent machinability of Zerodur® in combination with the modern high-tech manufacturing technologies enables complex shapes. Further Applications: Zerodur® has good transmission properties in visible and infrared spectrum and a very good optical homogeneity. Because of these properties Zerodur® is often used in optical systems. http://www.schott.com/optics_devices/german/products/zerodur/?c=mL Ceramics: Bond Energy and Properties, Chap 3 22 Material Science I Thermal Expansion and Melting Temperature of chosen chemical Elements Ceramics: Bond Energy and Properties, Chap 3 23 Material Science I Thermal Expansion and Melting Temperature of chosen chemical Elements 0 Potential [eV] -40 -80 -120 -160 -200 -240 0 100 200 300 400 500 600 700 800 Abstand [pm] Ceramics: Bond Energy and Properties, Chap 3 24 Material Science I Thermal Expansion and Melting Temperature of chosen chemical Elements 0 • The higher the melting temperature the deeper the potential well. Potential [eV] -40 -80 • The deeper the potential well the more symmetric it appears. -120 -160 • The more symmetric the less thermal expansion -200 -240 0 100 200 300 400 500 600 700 800 Abstand [pm] Ceramics: Bond Energy and Properties, Chap 3 25 Material Science I The Elastic Modulus of Materials 150 Fmax 100 20 50 r0 0 0 r0 Force [nN] Potential [eV] 40 Hook’s law rfail -50 Epot -20 -100 -40 -150 0 100 200 300 400 500 600 Ionic Distance r [pm] Enet z1 z2 e2 B n 4 0 r r Ceramics: Bond Energy and Properties, Chap 3 700 800 0 100 200 300 400 500 600 700 800 Ionic Distance r [pm] dEnet z1 z2 e2 n B Fnet n 1 2 dr 4 0 r r 26 Material Science I The Elastic Modulus of Materials 8 Kraft Fmax F 6 Force 4 F (r ) Enet / r Dx/Dy = elastic modulus, linear elastic portion of Hook’s law Kraft Force 2 0 z1 z2 e 2 4 0 r 2 nB r n1 -2 -4 -6 -8 -10 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 r00 Abstand Distance The force – inter-ionic distance curve. In the equilibrium point r0 a tangential line exists which in a first approximation describes good the linear elastic behaviour of a solid under tensile force. Ceramics: Bond Energy and Properties, Chap 3 27 Material Science I The Elastic Modulus of Materials E F S0 (r r0 ) F S0 r r r0 S0 E ro 1 F 1 2 Enet E 2 r0 r r r0 r0 r r r 0 This result is important: 1. the stiffness (elastic modulus) of a solid is directly related to the curvature of its potential – ionic distance curve. The curvature is inverse of the curvature radius. 2. compounds with stronger bonds have a higher elastic modulus (stiffness) than weak bonded compounds, and 3. compounds with a high melting temperature, i.e. ceramic materials, (deep potential well) are very stiff solids. Ceramics: Bond Energy and Properties, Chap 3 28 Material Science I The Elastic Modulus Ceramics: Bond Energy and Properties, Chap 3 29 Material Science I The Elastic Modulus Ceramics: Bond Energy and Properties, Chap 3 30 Material Science I Force-Distance-Curve Ceramics: Bond Energy and Properties, Chap 3 31 Material Science I The Theoretic Strength of Solids - simple approximation assuming that generally bonds in solids fail at 25% elongation, which calculates to 1.25 x r0. 2 Fmax 2 Fmax S0 rBruch r0 1.25r0 r0 The (tensile) strength of an ionic bonded solid should be ~ 1/8 of the elastic modulus. Ceramics: Bond Energy and Properties, Chap 3 32 Material Science I The Theoretic Strength of Solids - more sophisticated approximation generalized form of the potential – distance function with n > m and max » Fmax/(r0)2 E typical values for n and m, in case of ionic bonds (n = 9, m = 1) leads to max E 15 The (tensile) strength of an ionic bonded solid should be ~ 1/15 of the elastic modulus. Ceramics: Bond Energy and Properties, Chap 3 33 Material Science I The Theoretic Strength of Solids simple approximation: more sophisticated approximation: Examples: Al2O3: bend = 330 MPa, E = 300 GPa (/ 910) (http://www.accuratus.com/) SiC: bend = 550 MPa, E = 410 GPa (/ 745) BN: bend = 75.8 MPa, E = 46.9 GPa (/ 620) • The tensile strength of ionic bonded solids should be about ~ 1/10 of the elastic modulus E. • However, we find experimentally that the strength of these materials is about 1/100 to 1/1000 x E. That is much less than our approach using the potential well predicts !!! • There must be other issues determining the low strength than the potential well! Ceramics: Bond Energy and Properties, Chap 3 34 Material Science I Summary 1.) the bond energy / force determines 2.) the deeper the potential well covalency in ionic bonds 3.) the thermal expansion deeper potential well loose packed structures many physical properties of a solid, i.e. melting temperature Tm thermal expansion a elastic modulus E theoretical strength the stronger the bonds the higher the melting temperature. stabilizes discrete structure elements lowers melting temperature lower. anharmonic potential well. smaller thermal expansion. smaller thermal expansion. 4.) stiffness / elastic modulus proportional to the curvature of the potential Solids with stronger bonds are stiffer than solids with weaker bonds. 5.) theoretical strength should be ~1/10 of the elastic modulus E. However, experimentally measured strength values are about 1/100 to 1/1000 of this value. Ceramics: Bond Energy and Properties, Chap 3 35 Material Science I Additional Slides Ceramics: Bond Energy and Properties, Chap 3 36 Material Science I Ratio of the Bond Energy of Al2O3 to MgO Ebond z1 z2 e2 1 1 4 0 r0 n Al2O3 Al2O3 Ebond MgO Ebond z1 z2 r 0 MgO 1.64 z1 z2 r 0 Al2O3: r0 = 193.5 pm, n = 7 MgO: r0 = 212 pm, n = 7 Ceramics: Bond Energy and Properties, Chap 3 37 Material Science I Ratio of the Lattice Energy of Al2O3 to MgO z1 z2 e N Av 4 0 r0 2 ELattice Al2O3 Lattice MgO Lattice E E N Av E N Av E Al2O3 Ebond 1.64 MgO Ebond Ceramics: Bond Energy and Properties, Chap 3 Al2O3 bond MgO bond Al2O3: MgO: 1 1 a n a 23.54 MgO a Al2O3 aAl2O3 = 25.0312 aMgO = 1.7475 38 Material Science I Determination of „B“ (Born Constant) and „n“ Born Exponent • at equilibrium Elattice 0 r r r0 r0 can be measured N Av z1 z2 e 2 a n B n 1 0 2 4 0 r0 r0 N Av z1 z2 e 2 a r0 n 1 B 2 4 0 r0 n N Av z1 z2 e 2 a r0 n 2 B 4 0 n • n is still unknown! • To find n, we need to move away from equilibrium, i.e. compress the solid and measure its compressibility Ceramics: Bond Energy and Properties, Chap 3 39 Material Science I Compressibility • compressiblity is measured • then we can calculate n 1 V V0 P T 4 4 18 r 0 0 2 a e n 1 • Examples: NaCl 4.18 x 10-11 1/Pa -> n = 7.7 Ceramics: Bond Energy and Properties, Chap 3 40 Material Science I Sample calculation for NaCl = 8.854×10-12 SI units e = 1.602×10–19 coulombs a = 1.74756 (NaCl structure) d = 5.628×10-10 m giving r0 = 2.814×10–10 m = 4.18×10–11 SI n is found by This compares to 769.4 kJ/mole experimental (2.4% error) Ceramics: Bond Energy and Properties, Chap 3 41