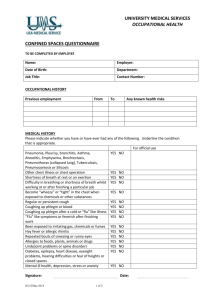

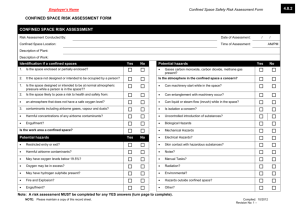

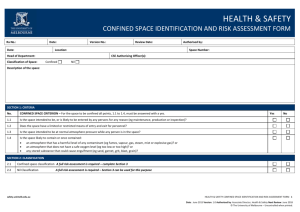

for Working in Confined Spaces

advertisement