(d) major projects executed - Tarek Nasser Al Akeel Co . ltd

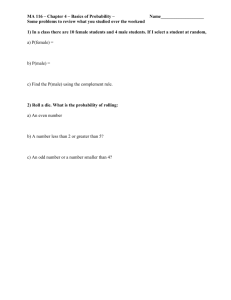

advertisement

INDEX 1. Chairman’s Message. 2. Introduction. 3. Company Registration Documents. 4. Product Sales Division. a. Messer Eutectic Castolin, Switzerland b. Dillinger Middle East, D u b a i c. Metrode Products Ltd, UK d. Rywal- RHC 5. Contracting Division a. Project Manager’s Profile b. Work Portfolio c. Clientele d. Major Projects Executed 6. Central Warehouse 7. Workshop 8. Field Services 9. Key Contacts 10. CDP Manufacturing, Dubai CHAIRMAN’S MESSAGE We adhere strictly to human values and professional principles. We are enhancing our area of operations to ensure a consistent and positive experience for our customers, principals, suppliers and employees. As a business group we remain committed to corporate and social responsibility and we strive to ensure that all economic, environmental and social factors are taken care of. This approach of respect, rigour and involvement makes us more responsible and acceptable. Our vision is to be the best organization in our chosen field of operation. Dr. Tarek Nasser Al Akeel Chairman / C.E.O Tarek Nasser Al-Akeel Co. Ltd is a leading Saudi owned company operating in Kingdom of Saudi Arabia, the largest oil producing country in the world and also the largest Arab country in the Middle East. We are in operation since 1982 with a vision to provide technical innovation and engineering skills to contribute to the growth of the nation. The company has very good reputation in its chosen field, built on a philosophy of providing performance with quality and service from the initial enquiry to execution of the assignment. We are flexible in terms of understanding and responding to the client needs, our entire work portfolio is quite unique which gives us a competitive edge; we give careful attention to the client needs and strive hard with continuous improvements in our performance in terms of quality and competitiveness. Our growth has been achieved through long lasting business relations with our esteemed clients, support from Principals and commitment of “employees and management”. We plan our future growth through deeper understanding of clients and focus on a fruitful relation through innovative, quality services and delivering promised services. We are equipped with adequate resources and knowhow for the timely delivery of our products as well projects completion to the entire satisfaction of our clients. PROJECT MANAGEMENT Our basic principle is to provide utmost customer satisfaction through delivery of prompt services expected by the clients. From the point of contract award, we ensure the involvement of the company’s well-experienced staff to provide a professional service to the client’s satisfaction. We focus on Process Industries, fully understanding the importance of schedule, quality and reliability of the services rendered. We strive to provide the most reasonable standards of engineering and workmanship, which are achieved by constant monitoring of every stage of work and by utilizing the latest available technology and tools We have a balanced team with experience and energy, experienced in large Industrial Projects such as Cement Plants and Steel Plants as well as infrastructure projects such as Dubai Motor City and Dubai Maritime City. LABOUR POLICY Understanding the fact that the Human Resources is the heart of the service industry, we employ a mixture of Qualified, trained, experienced and enthusiastic work force and have an excellent record in labour Relations. We possess a positive attitude in ensuring quality and safety while being strict on implementation of the procedures. HEALTH AND SAFETY Throughout the execution of a project, we maintain a strong commitment to safety at site, aiming at zero accidents, wellbeing of the workers and totally discouraging unsafe or unhealthy work practices. 2. 3. 4. RYWAL-RHC Plasma cutter FanCut 41 WELDING GENERATOR MOST 220S FANMIG 404GP SYNERGY Plasma torch for FANCUT 41 MOST MOST 300SE FANMIG 1701 PONTE 3.2 MOST Dryer PD 0-20 MOST MMA ELECTRODES WIRE PONTIG 1880 HF MIG TORCH MIG/TIG GRINDING WHEEL CUTTING WHEEL RME Middle East –FZCO distribute the professional beveling, drilling, welding and cutting products of Promotech Company. Promotech is the main manufacturer of professional power tool and industrial equipment. Each product from Most, Gold, Eckert, Promotech family has been chosen after detail selection process, starting from market research design, distribution, pricing and finally marketing. It is the respond to customers who look for complex offer, good quality and reasonable prices that is why we find it was a perfect tool and guide through the whole welding and cutting assortment. (B) WORK PORTFOLIO Tarek Nasser Al-Akeel Co.to remain flexible on the type of work that the company undertakes and is prepared to enter new markets and work with clients on new concepts. Our recent portfolio falls into the following areas: Steel Constructions:- Fabrication and erection of structures, Pipes, Process ducts etc. Total solutions to Process Industry. We undertake debottlenecking, avoidance of repeated failures, enhancement of life/ reliability, productivity improvement etc. Erection of rotary and static equipment. Maintenance Support Jobs in Process industry. Execution of projects, minor/ major. Execution of major Repairs to Rotary Kilns, mills, Preheaters, grate coolers etc. Replacement/ modification of Ball Mill internals. Repair and reconditioning of components. Emergency repairs to heavy components such as Kiln Tyre, Supporting roller, Roller press rolls, VRM Rollers etc. Thermal spray coating for corrosion protection, wear protection etc. (C) CLIENTELE. S. No. Name of the Company Country 01. Saudi Arabian Oil Company (Saudi Aramco) K.S.A 02. Saudi Basic Industries Corporation (Sabic) K.S.A 03. Saudi Electricity Company K.S.A 04. Saline Water Conversion Corporation (SWCC) K.S.A 05. Arabian Cement Company K.S.A 06. Yanbu Cement Company K.S.A 07. Southern Province Cement Company K.S.A 08. Tabuk Cement Company K.S.A 09. Qassim Cement Company K.S.A 10. Saudi Cement Company K.S.A 11. Eastern Province Cement Company K.S.A 12. City Cement Company K.S.A 13. Yamama Saudi Cement Company K.S.A 14. Riyadh Cement Company K.S.A 15. MMG K.S.A 16. M. S. Al-Suwaidi K.S.A 17. Nasser Al Hajri Corporation K.S.A 18. Al Rushaid K.S.A 19. CCC (All Projects) K.S.A 20. Al Zamil Steel Heavy Industries K.S.A (D) MAJOR PROJECTS EXECUTED S. No. Job Description 1 Client Replacement of Front Mill table, repairs to the foundation by chipping of and re- HADEED grouting with EPOXY. 2 Replacement of Down Coiler 1 and 2 Aprons and repairs to the down coiler. HADEED Replacement of buckets and belts of 3 Belt bucket elevators, 108m. height and CCC 42m. height. 4 5 Replacement of Chains and buckets of 2 Nos. Raw Mill elevators. Major repairs to Lime stone stacker and reclaimer Harrow, chain etc. CCC SCC Modification of 5 Nos. belt conveyors 6 take up structure and Major repairs to SCC Apron feeder. Replacement of damaged bags, 7 straightening and reinforcing tube sheets of kiln bag house. NCC Replacement of Raw Mill # 1 & 2 8 partition walls (Drying diaphragm) with YCC new structure fabricated from CDP. Complete major repair of grate cooler, including replacement of compact swing elements, cross beams, removal of all 9 compact swing elements and re-aligning NCC the entire moving grates- 2 sets, replacement of cooler plates, modification to bull nose cooling etc. Complete overhauling of Apron feeder below Limestone silo, including 10. modification to inlet chute, fabrication SCC and replacement of pingates with modified one. 11 Replacement of dip tube deflection plates of 8 cyclones of VRM 1 & 2. SCC Modification to IKN cooler (Clinker 12 cooler) of Kiln # 8, including extension of grates, installation of modified plates in KIDS. SCC Dismantling, shifting, Modifying and re13 installation of bins and feeders for SCC feeding limestone to CM 9 & 10. 14 15 Supply and installation of various water piping, storing and pumping systems. Fabrication and supply of solid waste cyclones lined with CDP 112. SCC CRISTAL. Kiln supporting roller assembly 16. replacement, Kiln tyre re-positioning, NCC aligning and chair pads replacement. TA Duct expansion joint replacement, 17. Repairs to plate work of Kiln hood, TA Duct and Preheater duct, cyclones, inlet NCC chamber. 18. Final alignment and spring plate welding of kiln # 7 girth gear. SCC. Replacement of cooler vent duct (5m. dia.x 22m. long at a height of 30m.) 19. from cooler outlet to EP, including design and preparation of modified drawings. YCC Kiln # 6 inlet and outlet shells (4.4m. dia., 4.8m. long, 40mm. thick) replacement with tip castings and SCC modified sealing arrangements. 20. 21. Gas pipeline replacement 12” dia. 300m. Rehabilitation of burnt out limestone conveyor over Hofuf highway. SCC SCC Replacement of ducts from Cement mill 22. outlet to bag filter (1.8m. dia. x 20m. YCC long)- 2 Nos. Replacement of system fan outlet ducts 23. in Raw Mills. (2.6m. dia. x 15m. long at YCC +32m. elevation)- 2 Nos. 24. Kiln # 6 -Cooler ESP, electrodes and GD Screen replacement. SCC Cement Mill and drive alignment 25. checking, slide shoe bearings replacement and support services for YCC tyre (Slide Ring) grinding, 26. Upper bearing replacement for Rotary stacker for Lime stone. Very special job. ACC Replacement of mill outlet duct elbow, cyclones and cyclone outlet ducts for 27. Losche Make VRM. (150 Tons of dismantling and re-erection in a ACC constrained space, ie. Building with roof, in 19 days) Re-conditioning worn out Raw Mill 28. classifier fan impeller and dynamic YCC balancing. Inspection, repair, heat treatment and 29. Ultrasonic testing of Kiln support Roller- NCC. INSITU. Dismantling of Clay drier complete with support rollers, girth gear & drive station, chutes and ducts and storage. 30. Dismantling of lime stone drier complete YCC with rollers, drive station, chutes, hoppers etc., shifting and re-erection at clay drier location and commissioning. Fabrication, supply and replacement of 31. the grit funnel of LOESCHE Mill with double side cladded CDP plate. ACC. Fabrication and supply of 3 Nos. 32. Seperator Cyclone complete with wear YCC. resistant liners. Fabrication and supply of Lower Cone 33. and Furnace Middle Cone with 25 thk. GSS Indl. Services. CDP Plate, for HADEED. Fabrication, supply and erection of 34. complete, including bend Airlift discharge Pipes from ground to Pre- ACC. heater top with CDP. Total length 180m. 35. 36. 37. Fabrication and supply of Pipe Bends, 24 nos. for HADEED. Repair of Lamellae of 2000 wide Apron Conveyor, 60 nos. Repair of cracked Kiln tyre. Repair of cracked Kiln tyre. Middle Tyre, 38. multiple cracks, one of them through crack. 39. Repair of Cracked Trunnion and Mill head. GSS Indl. Services. YCC. YCC. SPCC. Bisha Plant YCC (A) PROJECT MANAGER’S PROFILE. Name: BalachandraKumar.P.P PROFESSIONAL SYNOPSIS An Engineer with more than 25 years’ experience in Operations & Maintenance, Project Management, Maintenance Audit, Major Repairs, Erection & Commissioning in Cement Plants in India (ACC) and UAE (Sharjah Cement). Possess a rare combination of experience, viz. Operation and maintenance, Major Repairs, Projects and Contracting. Expertise in various types of alignment jobs, identifying and implementing improvement projects, trouble shooting and eliminating root cause in problem areas and providing cost effective solutions. Thorough knowledge of EPs (Electro Static Precipitators), Rotary Kilns. An effective communicator with polished leadership, relationship management, planning, coordination and analytical skills. Experience of working under cross-cultural, multinational and multi-lingual environments. KNOWLEDGE PURVIEW Maintenance & Major repairs of the following equipment: Complete cement plant equipment like Kiln / Clinker Cooler / Pre-Heater / Ball Mills / Vertical Mills / Crushers / Stackers, Reclaimers, various types of conveyors, Utilities (Hydraulic Systems, Compressors, Blowers, Water Pumps, Cooling Towers) & other related cement industry equipment. Erection & commissioning of the following: Kilns, mills, Bag Houses, ESPs, Conveyors, Compressors, Structures, Rails & Piping. Well conversant with survey equipment like Theodolite, Auto Levels, Digital Total Stations etc. and its usage for various alignment work of Mechanical equipment and structures, Rails etc. Kiln Alignment, Kiln Drive installation, Kiln Shell Replacement, Girth Gear Reversal, Ball Mills Maintenance & Major Repairs, Shell Liner & Diaphragm Replacement, Planetary Gearbox Overhauling, Cyclo drives overhauling etc. CORE COMPETENCIES Operations & Maintenance Management Oversee the functioning of Engineers, Experienced supervisors and a large workforce. Impart training to Engineers, Supervisors and Technicians. Reporting progress on a regular basis to the client management and taking necessary steps to make up for any variances in the achieved against the actual targets. Identifying bottlenecks and carry out de-bottlenecking. Project Planning and Execution Planning, describing scope, estimation, tracking & implementation of project plans within preset estimate. Major Repairs. Well conversant with analyzing the needs, planning and executing major repairs. Erection & Commissioning Managing Ensuring installation & commissioning of equipment to highest quality standard. completion of assignment with effective resource utilization to maximize the output. We offer In Situ Thermal Spray Coating services for external & internal coatings of Process equipment, offshore structures, pipelines. Etc. Before Coating After Coating Name of Person Dr. Tarek N. Al Akeel Mr. Mohammed Abdul Moid Khan Mr. Balachandra Kumar Designation Chairman & CEO General Manager Mobile No. +966 50 9391417 E-Mail : moid.khan@talakeel.com Project Manager Mobile No. +966 54 8196141 E-mail: bala@talakeel.com Address for Communication Head Office. Post Box – 9906, Jeddah – 21423, Kingdom of Saudi Arabia Telephone No’s: +966 12 690 1230 /1232 Fax No: +966 12 690 1231 E-Mail : tabco@talakeel.com Web site: www.talakeel.com Eastern Region Branch. Al-Oleyaa Center – Al Khobar, Al- Akrbeya Dist., Makkah St. 1st Floor, Office No. 109. Tel: +966 13 8652474/ 8895131. Fax: +966 13 8895134. Workshop 3279, Dallah Industrial Area, P.O. Box: 34542, Dammam 31478, Saudi Arabia. Tel: +966 13 818 0814 Fax: +966 13 818 0814