KENTVILLE'S CENTURY OF SCIENCE

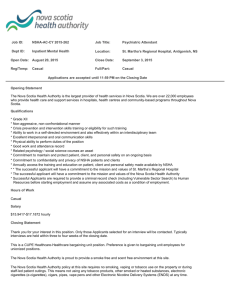

advertisement