Workplace Design for Manual Assembly Tasks: Effect of Spatial

advertisement

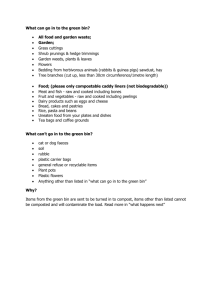

INTERNATIONAL JOURNAL OF OCCUPATIONAL SAFETY AND ERGONOMICS 1995, V O L 1, NO. 2, 136-143 Workplace Design for Manual Assembly Tasks: Effect of Spatial Arrangement on Work-Cycle Time Kamal P. Kothiyal Berman Kayis The University of N ew South Wales T his article reports th e results of an ex p e rim e n ta l study undertaken to investig ate th e effect of spatial a rra n g e m e n t o f assem b ly board and parts bin in th e norm al w o rk area on w ork-cycle tim e in m anu al assem b ly tasks. O p e ra to r p erfo rm an ce w a s m easured in term s of averag e w ork-cycle tim e taken to co m p lete a lab o rato ry -s im u la ted m anu al assem b ly task. Results sh o w ed th at both location and distance factors had sig nifican t effects on w ork-cycle tim e . Effect of th e size of parts w a s also investig ated in th e study. A v erag e o bserved w ork-cycle tim es w e re co m p ared w ith th e m e th o d s -tim e m e as u re­ m e n t (M T M ) values. R epetitive m anual assem b ly tasks are co m m o n in industry and are th o u g h t to lead to m usculoskeletal disorders. The results of this research are im p o rtan t fo r erg o n o m ic design of th e w o rkp la ce fo r assem b ly tasks, w hich w o u ld help to en ­ hance o perato rs' efficiency. erg o n o m ic design assem b ly tasks m anu al handling w o rkp lace design 1. INTRODUCTION D espite trends toward autom ation of manual work, manual assembly tasks still form a signifi­ cant proportion of activities in the production environment. In industry, workplace for assem­ bly jobs is usually arranged on the basis of predeterm ined motion time system (PMTS; Barnes, 1968). Work-cycle time for an assembly job is determ ined by first dividing each task into its com ponent motions and then adding up the predeterm ined times for these m otions to give the time for the whole task and job. An im portant limitation of the PMTS is that it does not take into consideration the effects of postures adopted by operators during work on work-cycle times (Chaffin & Andersson, 1991). Thus, PMTS-based workplace design can lead to operators being forced to adopt unnatural postures, which in turn may result in actual work-cycle times significantly different than com puted by PMTS. M anual assembly tasks generally involve repetitive movements of the shoulder-arm -hand complex. Work-cycle time of assembly jobs depends on a variety of factors such as weights of parts, direction and distance of m ovement of forearm -hand complex, individual work capacity, training, and so forth. In order to perform assembly tasks with ease and efficiency, it is essential that materials, supplies, and working (assembly) board are arranged on the table within the zone of convenient reach (ZCR; Pheasant, 1986). Many different arrangem ents of assembly board, parts bin, materials, and supplies are possible with the ZCR. Some spatial arrangem ents may generate shorter work-cycle times than others. From the point of view of production, shortest work-cycle time is preferred. However, the possibility exists that the workplace design with the shortest work-cycle time may, in the long term , lead to m usculoskeletal disorders. Thus, there is need to identify optimal positions of assembly board and parts bin so that C orrespondence and requests for reprints should be sent to Kam al P. K othiyal, D epartm ent o f Safety S cience, The U niversity o f N ew South W ales Sydney, N ew South W ales 2052, Australia. 136 WORKPLACE DESIGN FOR MANUAL ASSEMBLY TASKS 137 workplace can be designed to achieve minimum work-cycle time for the given assembly job without causing health disorders in the long term. In order to get an optimal workplace arrangem ent, knowledge of the effect of m ovem ent direction and distance on work-cycle time is necessary. Sanders and McCormick (1987) re­ ported on the relationship between the distance of m ovem ent and precision of the action. The distance of the parts bin from the operator can affect the work-cycle time of the assembly in two ways. First, the time taken by the operator to move parts over a distance increases with the distance. Second, the precision of movem ent decreases with the distance moved, thus requiring m ore parts handling time. Studies have also been done to find out efficient directions of movements in the horizontal plane of the forearm -hand complex. Schmidtke and Stier (1960; quoted in Grandjean, 1988, p. 118) showed that the speed of m ovem ents for the right hand in the horizontal plane is greatest in a direction of 45° to the right m easured from the sagittal plane in front of the body. Bouisset and M onod (1962) and Bouisset, Laville, and M onod (1964) investigated manual movements using oxygen consum ption (energy expendi­ ture) as the criterion for most efficient m ovement direction. Their studies involved participants moving weights up to 1 kg and at a frequency of 24/min. They obtained the lowest oxygen consum ption for the movem ent direction of 60° from the front. Spatial arrangem ent of parts bin and assembly board with respect to the operator is also im­ portant from the point of view of workload experienced by operators. Spatial arrangem ent will determ ine the relative involvement of the various muscles of the shoulder-arm -hand complex as well as that of the neck and lower back. In turn, this will determ ine the physiological cost of the movements. Hence different spatial arrangem ents of the workplace will lead to different physi­ ological costs. Strasser, Keller, Niuller, and Ernst (1989) pointed out that the differential in the physiological cost of movements could affect the perform ance by as much as four times. The relationship between workload and musculoskeletal disorders has been intensely inves­ tigated (K roem er, 1989; Putz-Anderson, 1988; Silverstein, Fine, & Arm strong, 1986). Although, at present, it is difficult to prove a causal relationship between workload and cumulative traum a disorders (CTDs), it seems certain that as the workload in repetitive movements increases, the probability of cumulative traum a disorders or repetitive strain injuries also increases. Thus, to prevent CTD in repetitive manual assembly jobs, it is im portant to design the workplace in such a way that the spatial arrangem ent of parts bin, assembly board, materials, and supplies imposes minimum workload on the operator. The objective of this study was to investigate the effects of spatial factors such as the location of parts bin relative to the body midline of the operator and its distance from the operator on work-cycle time for manual assembly tasks. The effect of the size of parts on work-cycle time was also studied. 2. MATERIALS A ND METHODS Ten male university students participated in the study on a voluntary basis. A t the start of the experiments, the purpose and procedures of the study were fully explained to the subjects and their verbal consent to participate in the experim ents was obtained. All subjects showed a high degree of willingness and motivation to participate in the study. Using a professional anthropom eter (Model “T T M ” M artin’s Body M easuring Kit, UK) various anthropom etric characteristics of the 10 subjects were recorded. The anthropom etric data of the subjects are given in Table 1. All subjects were healthy male students. They were asked if they had any previous history of musculoskeletal disorders or pain; if they had experienced any such problems, they were excluded from the study. However, no formal medical exam ination was conducted on the subjects. The average age of the subjects was 27.3 years (SD = 2.3 years). The average stature, forearm length, and forward grip of the subjects were 1,748 mm (SD = 37 mm), 482 mm (SD = 26 mm), and 785 mm (SD = 34.7 mm), respectively. Eight subjects were right-handed and 2 were left-handed. Using the anthropom etric data obtained, a workplace was created in the ergonomics labo­ ratory to carry out assembly tasks. Subjects worked in a seated posture at a workstation that 138 K. P. KOTHIYAL AND B. KAYIS TABLE 1. Subject 1 2 3 4 5 6 7 8 9 10 M SD Anthropom etric Characteristics of th e Subjects Stature (mm) Forearm length (mm) Forward Age (years) grip (mm) Preferred hand 26 28 26 30 30 26 29 30 23 25 27.3 2.3 1720 1700 1740 1720 1780 1700 1800 1780 1800 1740 1748 37 460 480 460 460 500 450 520 510 520 460 482 26.3 760 780 760 740 810 750 840 810 830 770 785 34.7 Left Left Right Right Right Right Right Right Right Right consisted of a fully adjustable chair and table. The table height was initially adjusted to the subjects’ sitting elbow height. However, subjects were allowed to m ake m inor adjustm ents to the seat and/or table height so that they were com fortable at work. On the worktable, the limits of normal and m anual work area were drawn for each subject (see Figure 1) by using the values of forearm length and forward grip from Table 1. The assembly job consisted of inserting parts into an appropriately shaped receptacle made on a wooden assembly board (see Figure 1). The receptacle was designed for easy and smooth insertion of parts. For the purpose of the experiments, assembly parts were m ade of light wooden m aterial weighing 10 to 50 g. All parts were cylindrical in shape. The parts bin was made of a transparent plastic material. A typical assembly job was sim ulated for the experi­ ments. A lthough assembly jobs in industry are very variable in term s of work-cycle times, a short work-cycle time job was selected for this study. The simulated assembly job required the subject to pick up 10 parts by the preferred hand, 1 by 1, and insert them into the assembly board. Time taken by subjects from grasping to the insertion of 10 parts was defined as the work-cycle time. Subjects were asked to move parts in a sm ooth and continuous manner. Because the subjects did not have any previous experience with manual assembly tasks, they were allowed to perform the tasks several times in order to become completely familiar with the experim ents and achieve a continuous and smooth m ovem ent pattern. Work-cycle time was m easured by a stopwatch. Figure 1. W orkplace layout used for the experim ents WORKPLACE DESIGN FOR MANUAL ASSEMBLY TASKS 139 Subjects picked up (grasped) parts from the parts bin and moved (transported) them to the assembly board, oriented the parts to bring them in line with the axis of the receptacle, and then inserted them into the receptacles. To avoid bias in handling the last part, extra parts were put in the parts bin. For each experim ent 15 parts were put in the parts bin. Each subject com pleted 30 work cycles for each experiment. Subjects were allowed to set their own pace, and the sequence of experim ents was randomized. To investigate the effect of the location of the parts bin on the work-cycle time, two locations were considered. In the first location (L I), the parts bin was kept directly in front of the subject, that is, on the body midline. In the second location (L2) the parts bin was kept 30° from the body midline and towards the preferred hand side. (In 8 of the 10 subjects, the right hand was the preferred side.) The effect of the distance of the parts bin from the subject on work-cycle time was deter­ mined by considering three distances (D l, D2, and D3; see Figure 1). These distances were equal to 100%, 75%, and 25% of the forearm length of the subject. In all experiments, the assembly board was kept at a distance equal to 50% of the forearm length. The effect of the size of parts was also investigated in this study. Three parts sizes were used in the experiments. The parts sizes varied both in diam eter and length. The dimensions of parts were: SI, 70 X 25 mm; S2, 70 X 14 mm; and S3, 50 X 14 mm. These dimensions were chosen somewhat arbitrarily but parts were neither too small nor too large to handle by hand. 3. RESULTS Table 2 presents the observed work-cycle times for the 10 subjects for the two parts bin locations. The values shown in Table 2 are the averages of 30 work cycles. A work cycle was defined as the time taken by the subject for inserting 10 parts in the assembly board. Table 3 shows the effect of the distance between the subject and the parts bin on work-cycle time. A n analysis of variance (ANOVA; Miller & Miller, 1988) was perform ed on the data presented in Table 3 to determ ine w hether the effect of the distance of the parts bin from the operator was significant; the results are provided in Table 4. The effect of part size on work-cycle time is summarized in Table 5. Parts of three sizes were selected for the experiments. The largest size was 70 X 50 mm and the smallest was 50 X 14 mm. A n ANOVA was perform ed to check the statistical significance of the data; the results are presented in Table 6. TABLE 2. Average Observed Work-Cycle Times (in Seconds) for th e Two Locations of the Parts Bin Average w ork-cycle tim e Subject 1 2 3 4 5 6 7 8 9 10 M SD Location LI Location L2 15.9 15.7 15.0 15.5 15.6 15.6 15.6 15.4 15.5 15.0 15.48 0.29 15.2 15.1 15.1 15.2 15.4 15.4 15.0 15.2 15.0 15.1 15.17 0.14 140 K. P. KOTHIYAL AND B. KAYIS TABLE 3. Variation of Observed W ork-Cycle Time (in Seconds) w ith Respect to Distance of M ovem ent Average work-cycle time (Movement distance D1) Subject (Movement distance D3) 15.2 15.5 15.0 15.4 15.4 15.4 15.1 15.2 15.0 15.1 15.24 0.18 14.9 15.2 15.1 14.8 15.0 15.1 15.1 14.8 15.1 15.0 15.01 0.14 15.9 15.7 15.0 15.5 15.6 15.6 15.6 15.4 15.5 15.0 15.48 0.29 1 2 3 4 5 6 7 8 9 10 M SD TABLE 4. (Movement distance D2) ANO VA of Parts Bin Distance from th e Subject on Work-Cycle Time Source of variance Between group W ithin group Total TABLE 5. Seconds) 55 df ms 1.18 1.11 2.29 2 27 .555 .043 F 12.90 fcrit at p = .05 3.35 Effect of Size of Parts on Work-Cycle Time (in Average Work-Cycle Time Subject Part size S1 Part size S2 Part size S3 15.9 15.7 15.0 15.5 15.6 15.6 15.6 15.4 15.5 15.0 15.48 0.29 15.6 15.8 15.4 15.4 15.6 15.6 15.4 15.4 15.6 15.2 15.5 0.17 15.6 15.8 15.5 15.8 15.7 15.6 15.4 15.5 15.7 15.3 15.59 0.17 1 2 3 4 5 6 7 8 9 10 M SD TABLE 6. ANO VA of Part Size on Work-Cycle Time Source of variance Between group W ithin group Total ss df ms F F „;t at p = .05 0.065 1.245 1.31 2 27 .0325 .046 0.71 3.35 WORKPLACE DESIGN FOR MANUAL ASSEMBLY TASKS TABLE 7. M eth o d s -U m e M easurem ent (M TM ) Values for th e Assembly Tasks Experimental condition Location Location Distance Distance Distance Size S1 Size S2 Size S3 L1 L2 D1 D2 D3 *Note. TM U 141 Reach TMU Grasp TMU Apply pressure in TMU 9.6 9.6 9.6 7.0 7.0 9.6 9.6 9.6 2.0 2.0 2.0 2.0 2.0 2.0 2.0 2.0 10.6 10.6 10.6 10.6 10.6 10.6 10.6 10.6 Move TMU Position TMU Total TMU MTM (s) Observed mean work-cycle tim e (s) 12.9 12.9 12.9 8.1 8.1 12.9 12.9 12.9 5.6 5.6 5.6 5.6 S.o 5.6 5.6 5.6 40.7 40.7 40.7 33.3 33.3 40.7 40.7 40.7 14.7 14.7 14.7 12.0 12.0 14.7 14.7 14.7 15.48 15.17 15.46 15.24 15.01 15.48 15.50 15.59 = Time M easurem ent Unit, 1 TMU = 0.0006 minute. In Table 7, work-cycle times generated by the MTM system for the assembly tasks per­ form ed by subjects are provided with a view to compare these with the observed work-cycle times. 4. DISCUSSION This study was aimed at understanding the effect of workplace design factors on hum an perform ance in assembly tasks. For this purpose a workstation was created in the laboratory and assembly tasks similar to those perform ed in industrial workplaces were simulated. Ex­ perim ents were perform ed to determ ine the effect on work-cycle time of the parts bin location, distance betw een the parts bin and subject, and the size of parts. Table 3 presents the data on the effect of the parts bin location on work-cycle time. A com parison of the work-cycle times indicates that locating the parts bin to the preferred side of the subject (i.e., L2) was better because it generated a shorter work-cycle time for most (8 of 10) subjects. The difference between the mean work-cycle times of the two locations was about 0.3 s (2% ). S tudent’s t test (Miller & Miller, 1988) was perform ed on the data to determ ine if this difference was statistically significant. The test of significance revealed that the difference was significant at the .05 level. Location of the parts bin relative to the operator appears to be an im portant workplace design factor because the strain imposed on the shoulder-arm -hand complex depends on the m ovem ent direction (Strasser et al., 1989). In this study, a significant effect on work-cycle time was observed by changing the location of the parts bin. Only a limited num ber (30) of work cycles were observed in this study. In a real-life situation, however, assembly tasks are per­ formed over a long period of time. Kothiyal, Bhasin, and De (1990) showed that when assembly tasks are perform ed until the endurance limit, the difference in average work-cycle time can be as much as 13 to 25%. Thus, the duration of work in the experim ents conducted in this study was not long enough for the cumulative effect due to the location factor to manifest in work-cycle time. Thus, the small change observed in 30 workcycles in this study could lead to large increases in work-cycle time in actual practice. The effect of the parts bin location on work-cycle time obtained in this study is in good agreem ent with the results of Sanders and McCormick (1987) and Schmidtke and Stier (1960; quoted in G randjean, 1988, p. 118). These authors found that m ovem ent directions away from the body midline are quicker than movements perform ed directly in front of the body. The L2 location in this study, which has the parts bin 30° away from the body midline, is biomechanically advantageous because it allows the forearm movem ent to pivot at the elbow. O n the other hand, in the LI location, where the parts bin is directly in front of the body, the forearm 142 K. P. KOTHIYAL AND B. KAYIS m ovem ent can only be perform ed by involving significant m ovem ent of the upper arm. In this situation, the upper arm is abducted, which from biomechanical point of view, is not an advantageous position. Hence longer work-cycle time results in the situation where the parts bin is directly in front and at the body midline of the subject. The results on effect of distance of the parts bin from the operator show that work-cycle time was 3% shorter for the D3 parts bin distance (25% forearm length) as com pared to D1 (100% forearm length). Even though the m ovement distance between the assembly board and parts bin was the same, it is interesting to note that the difference in work-cycle time betw een parts bin distances D2 and D3 was 1.5%. The ANOVA results indicate that the differences in work-cycle times are significant at the .05 level. The assembly task in this study was considered a precision task because the operator had to bring parts very close to, and directly over, the receptacle before insertion. Precision of m ovem ent depends not only on the distance moved but also on the direction of movement. Sanders and M cCormick (1987) pointed out that outward m otions of the forearm are m ore precise than inward motions, and that precision is proportional to the m ovem ent distance. Thus the increase in assembly time in the present study was as expected on the basis of variable m ovem ent distances. Also, when subjects moved parts by outward forearm movements, as in the case of parts bin distance D3, the resulting work-cycle time was less com pared to parts bin distance D2 when subjects had to move parts by inward motions, even though in both situ­ ations the m ovem ent distance was the same. The effect of part size on work-cycle time is shown in Table 5. The results indicate that the average work-cycle time for larger parts was less com pared to smaller parts. The ANOVA results (see Table 6), however, show that the differences in work-cycle times were not statisti­ cally significant. Also, the data in Table 5 did not show a consistent pattern of change. In these experiments, part sizes were selected on an arbitrary basis but it was m ade certain that they were neither too small nor too big to handle. It appears that part sizes were already large enough to handle and thus no significant effect of parts size on work-cycle time was noted. A lthough no attem pt was made here to determ ine the limits of part sizes that would affect work perform ance, it seems obvious that longer handling time would be required if parts were to become very small. A com parison of the mean observed work-cycle time was made with the m ethods-tim e m easurem ent (M TM ) generated time for the assembly task. Table 7 indicates that the mini­ mum m ean observed work-cycle times for the assembly task were higher than the estim ated MTM time for all experim ental conditions. The largest effect (25-29% ) was seen in the conditions when the distance between the operator and parts bin was varied. It is worth noting that although MTM times for distances D2 and D3 are the same, the observed m ean work-cycle times were significantly different. The relationship between work-cycle time and location and distance of parts bin is im por­ tant for the ergonomic design of manual assembly workstations. The results of this study suggest some guidelines for arranging the workplace: For efficient m anual assembly tasks, the parts bin should not be placed directly in front of the operator, but should be located away from the body midline and towards the preferred hand side. Also, the parts bin should preferably be closer to the operator. It needs to be pointed out that the results of these experim ents were obtained using young healthy university students who had very little experience with the assembly tasks done in industrial situations. No doubt the situations on the shop floor are generally different, and hence laboratory experim ents must be validated in real-life situationd. Chaffin and A ndersson (1991) also pointed out the limitations of laboratory results for application to practical situ­ ations. Thus, these results should be interpreted with caution as far their application in indus­ try is concerned. However, the main achievements of this study are in raising ergonomic questions and showing that these can significantly affect work-cycle times. M oreover, a work­ place not designed on sound ergonomic principles can give rise to situations where workers are forced to adopt undesirable postures. For the sake of w orkers’ productivity, muscular strain imposed by undesirable postures must be avoided, which was pointed out by Strasser et al. (1989). WORKPLACE DESIGN FOR MANUAL ASSEMBLY TASKS 143 5. CONCLUSIONS This study investigated the effect of spatial arrangem ent of workplace on work-cycle time. The results show that the location and distance of the parts bin have significant effects on work-cycle time of a m anual assembly task. The location of the parts bin relative to the operator increased work-cycle time as the parts bin was moved away from the “directly in front” location to 30° away from the body midline. The increase in the distance of the parts bin resulted in an increase in work-cycle time. However, parts size did not have any significant effect on work-cycle time. This study also shows that the M TM -generated work-cycle times are, in general, underestim ates of observed times. The overall conclusion of this study is that the workplace design for m anual assembly tasks should be based not only on MTM values, but should also consider the effect of ergonomic factors so that realistic work-cycle times can be determ ined. REFERENCES Barnes, R. M. (1968). Motion and time study: Design and measurement o f work (6th ed.) New York: Wiley. Bouisset, S., Laville, A., & Monod, H. (1964). Recherches physiologiques sur l’economie des mouvements [Physiological research on the economy of motions. Proceedings of second IEA Congress). Ergonom­ ics, 7,61-67. Bouisset, S., & Monod, H. (1962). Etude d’un travail musculaire leger. I. Zone de moindre depense energetique [Studying light muscular labor: I. The area of least energy outlay]. Archives Internationale du Physiologie et Biochimie, 70, 259-272. Chaffin, D. B., & Andersson, G. (1991). Occupational biomechanics. New York: Wiley. Grandjean, E. (1988). Fitting the task to the man (4th ed.). London: Taylor & Francis. Kothiyal, K. P., Bhasin, H. V., & De, A. (1990). Precision manual assembly jobs: Biomechanical considera­ tions in workplace design. In C.M. Haslegrave, J.R. Wilson, E.N. Corlett, & I. Manenica (Eds.), Work design in practice. London: Taylor & Francis. Kroemer, K.H.E. (1989). Cumulative trauma disorders. Applied Ergonomics, 20,274-280. Miller, J. C., & Miller, J. N. (1988). Statistics for analytical chemistry (2nd ed.). Chichester, England: Ellis Horwood. Pheasant, S. (1986). Bodyspace: Anthropometry, ergonomics and design. London: Taylor & Francis. Putz-Anderson, V. (1988). Cumulative trauma disorders: A manual for musculoskeletal diseases o f the upper limbs. London: Taylor & Francis. Sanders, M., & McCormick, E. J. (1987). Human factors in engineering and design (5th ed.). New York: McGraw Hill. Schmidtke, H., & Stier, F. (1960). Der Aufbau komplexer Bewegungsablaufe aus elementarbewegungen. The development of complex movement patterns from simple motions. (Forschungsbericht des Lan­ des Nordrhein-Westfalen, No.822). Cologne: Westdeutscher Verlag. Silverstein, B., Fine, L., & Armstrong, T.(1986). Hand-wrist cumulative trauma disorders in industry. British Journal o f Industrial Medicine, 43,779-784. Strasser, H., Keller, E., Niuller, K. W., & Ernst, J. (1989). Local muscular strain dependent on the direction of horizontal arm movements. Ergonomics, 32, 899-910.