Gunnebo Classic

Omslag classic ny 04-03-30 16.13 Sida 1

Gunnebo Lifting

Gunnebo Classic

The wide range of lifting products gives full flexibility for any situation

Gunnebo Industrier AB

P.O. Box 44

SE-730 60 Ramnäs, Sweden

Tel: +46 (0)220 384 00

Fax: +46 (0)220 384 98

E-mail: export@gunnebolifting.com

www.gunnebolifting.com

A company within the Gunnebo Group

You can´t beat the original

Think Gunnebo Lifting when selecting lifting chain and components .

- Lifting is our business . As a result of over 200 years experience

Gunnebo Lifting has become known for quality, superior design and innovative product development, down to the smallest component .

The pride and confidence we have in our products are underlined by our rigorous quality system and the efforts put in to continually improve our processes as well as our products .

The link to the past is the future in lifting

Gunnebo Lifting today proudly carries the heritage of the innovative skills from the Swedish chain and lifting industry . Over the years a large number of Gunnebo Lifting innovations have broken new ground in the lifting gear industry . We promise and assures you that the development will continue to match your highest demands and specific needs .

Feel confident in every situation

We know how important it is to feel confident in every situation - we ensure that by having full control of the process from raw material to finished product . The close co-operation we have with our steel suppliers ensures that the raw material meets our stringent specification . We have our own chain factory as well as forging plants and machine shop for components and master links .

Safety is our highest priority

We are known as the No 1 quality manufacturer in the world, and the systematic quality control in every manufacturing stage from raw material to the finished product guarantees a high level of safety and long service life .

Quality Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

Safe use and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Connection systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Chain & Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

WARNING:

Failure to read, understand and comply with following instructions, working load limits and specifications in this publication could result in serious injury or damage to property .

Gunnebo Lifting – your partner in safe lifting

Chain and components are made from special quenched and tempered alloy steel, a guarantee for very high strength, low weight, high wear resistance and long life . All Lifting components are uniformly marked with equivalent chain size, grade, manufacturer’s designation and name for positive identification .

It’s easy to see the difference between a Gunnebo Lifting original component and copies, see the picture below for the characteristics of Gunnebo Lifting Components

Remember that it’s not only the yellow color that symbolises a quality product . Be sure to get the original – be sure that you get a Gunnebo Lifting product!

The Classic system from Gunnebo Lifting is more than just another chain sling system . It is a total lifting concept for heavy lifting .

Our chain and components are designed to give more flexibility, more options to meet any lifting situation involving slings – whether it is chain, steel wire rope or soft slings .

Latest news in our BK range is the recessed trigger, available from 6 mm up to 20 mm.

Traceability code

Flat section for connection to BL

Recessed trigger

Manufacturer name

Manufacturer identification ( 32)

Component size

Component designation, size and grade

Photo: Unloading in the harbour of

Karlshamn, Sweden

Feel confident in every situation

Photo: Courtesy of the National ScienceFoundation, USA

Quality control

Type testing

In order to prove the design, material, heat treatment and method of manufacture, each size of component and chain has been type tested in the finished condition in order to demonstrate that the component and chain have the required mechanical properties .

The following testing procedures are particularly relevant:

- Test for deformation

The Manufacturing Proof Force (MPF) for the relevant size

of the component is applied and removed . The dimensions

after proof loading shall not alter from the original

dimensions within the tolerances prescribed in our

specifications and in the international standards.

- Static tensile test

The Breaking Force (BF) for each component and size is

verified. The verified value shall be at least equal to the

Minimum Breaking Force (MBF) value . The MBF value is

equal to the Working Load Limit (WLL) multiplied by the

safety factor .

- Fatigue test

By fatigue testing in pulsator testing machines the toughest

condition of service is simulated .

Stress/elongation diagram

Chain grade 8, type KL

% of min . Breaking Force

Manufacturing testing

During manufacture continuous process tests are carried out according to the requirements in our specifications and in the latest international standards . The following testing procedures are particularly relevant .

- Proof force

Each individual component and chain link is tested to the

Manufacturing Proof Force (MPF) level before delivery .

The MPF level is 2 .5 times the WLL, equal to 62,5% of the

Minimum Breaking Force .

- Non destructive test / visual inspection

3% of every production batch of forged components are

subject to magnetic particle or dye penetrating

examination . Visual inspection is carried out on each

chain link and each forged component to detect defects .

- Static tensile test and ultimate elongation test

During manufacture, samples are tested to verify the

Minimum Breaking Force (MBF) value and the total

ultimate elongation for chain .

Bending deflection

During manufacturing, of chain and master links, samples

are taken and the minimum bend deflection is verified.

- Pin testing

100% of all load pins used in our products are tested .

Dimensions are checked, material configuration are

verified by magnetic eddy current coil.

Control System

% elongation

CDC cameras for dimensional check of load pin Every single component is proof loaded and visually inspected

Safe use and maintenance

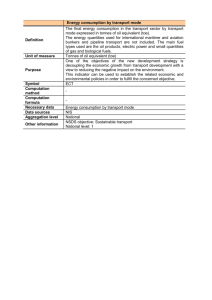

Working load limits, acc. to EN 818-:1996

1-legged

Chain dim .

(mm)

6

7

WLL

(tonnes)

1.1

1.

Master link

M/MF

6-10*

86-10*

8

10

.0

.1

86-10*

108-10*

1

16

19

.

8.0

11.

1.0

110-10*

161-10*

016-10*

0-10*

1-10

19-10

6 1.

6-10

1.

6-10 -10

*) Available with flattened section for use with BL.

2-legged

WLL (tonnes)

ß 0-45°

α 0-90°

1.6

.1

.8

.

7.

11.

16.0

1.

0.0

.0

ß 45-60°

α 90-120°

1.1

1.

.0

.1

.

8.0

11.

1.0

1.

1.

Master link

M/MF

86-10*

108-10*

108-10*

110-10*

161-10*

016-10*

0-10*

6-10

6-10

6-10

3-legged & 4-legged

WLL (tonnes)

ß 0-45°

α 0-90°

.6

.1

.

6.7

11.

17.0

.6

1.

.0

67.0

ß 45-60°

α 90-120°

1.7

.

.0

.7

8.0

11.8

17.0

.

1.

7.

Master link

MT/MTC

6-10*

8-10*

8-10*

10-10*

1-10*

16-10*

0-10*

-10

6-10

-10

Choked endless sling

WLL (tonnes)

1.8

.

.1

.0

8.

1.

18.0

.6

.

0.0

Extreme temperature conditions

The in service temperature effects the WLL as follows .

Temp . of sling (°C)

-40 to 200

+200 to 300

+300 to 400

Reduction of WLL

None

10%

25%

Upon return to normal temperature, the sling reverts to it’s full capacity within the above temperature range . Chain slings should not be used above or below these temperatures .

Surface treatment

Note!

Hot-dip galvanizing or plating is not allowed outside the control of the manufacturer .

Asymmetric loading conditions

For unequally loaded chain legs we recommend that the

WLL are determined as follows

• 2-leg slings calculated as the corresponding 1-leg sling

• 3 and 4-leg slings calculated as the corresponding 1-leg

sling . (If it is certain that 2-legs are equally carrying the

major part of the load, it can be calculated as the

corresponding 2-leg sling)

Severe environment

Chain and components must not be used in alkaline

(>pH10) or acidic conditions (<pH6) .

Comprehensive and regular examination must be carried out when used in severe or corrosive inducing environments .

In uncertain situations consult your Gunnebo Lifting dealer .

General advice

• Ensure that the sling is precisely as ordered .

• Ensure that the manufacturers certificate is in order .

• Ensure that the identification and the WLL on the ID-tag

correspond to the information on the certificate .

(The following ID-tag information is compulsory: WLL,

Number of chain legs, nominal size (mm), individual ID

mark, manufacturer, CE marking and year of

manufacturing) .

• Ensure that all details of the chain sling are recorded .

• Ensure that the staff using the chain sling has received

the appropriate information and training .

Protect yourself and others

• Before each use the chain sling should be checked for

obvious damage or deterioration .

• Know the weight of the load, the centre of gravity and

ensure it is ready to move and no obstacles will obstruct

the lift .

• Check the conformity of the load with the WLL of the ID

tag for the specific working configuration . Never use a

sling without a legible valid ID tag!

• Prepare the landing site .

• Never overload a sling and avoid shock loading .

• Never use an improper sling configuration .

• Never use a worn out or damaged sling .

• Never ride on the load .

• Never go under a suspended load .

• Take into consideration that the load may swing or rotate .

• Watch your feet and fingers while loading / unloading .

Safe use and maintenance

6

Method of connection

A chain sling is usually attached to the load and the crane by means of terminal fittings such as hooks, links etc .

Chain should be without twists or knots, if the chain leg needs length adjustment use a shortening device . The lifting point should be seated well down in the terminal fitting, never on the point or wedged in the opening . The terminal fitting should be free to incline in any direction .

The chain may be passed under or through the load to form a choke hitch or basket hitch . The chain should be allowed to assume it’s natural angle and should not be hammered down .

Where choke hitch is employed the

WLL of the chain sling should be reduced by 20% (unless the LK choker hook is used)

Endless chain slings shall be rated in the same way as a

2-legged sling .

Sharp edges

Use edge protectors to prevent sharp edges from damaging the chain . If lifting over sharp edges reduce the working load with the following reduction factor .

Edge load

Reduction factor

R >2 x chain Ø R > chain Ø R < chain Ø

1.0

0.7

0.5

• The angle of the edge must not be below 90o .

• Chain links shall be protected from being bent or deformed

and from receiving cuts or gouges .

• Chain sling WLL is to be reduced when chain is rigged

over an edge radius R less than two (2) x chain diameter (d) .

• Reduced WLL equals chain sling WLL from identification tag

x reduction factor .

• Slings shall be padded or protected from edges of their

loads when the edge radius is less than 0,5 of the chain

diameter(d) .

• Slings shall be rigged to prevent chain from sliding over a

load edge radius while lifting .

• Slings used in basket hitch shall have the loads balanced to

prevent slipping .

When lifting with chain directly on lugs the lug diameter > 3x the pitch of the chain, otherwise the WLL must be reduced by

50% .

Assembly:

G-link assembly:

1 . Join the link halves .

2 . Place the retaining bush between them .

3 . Insert the load pin and ensure that the load pin .

snaps into place .

BL-link / Clevis assembly:

1 . Assemble the component, chain and load pin .

2 . Fit the retaining pins .

3 . Make sure that the load pin are properly

secured by the retaining pins .

Maintenance

Periodic thorough examination must be carried out at least every 12 months or more frequently according to statutory regulations, type of use and past experience .

1 . Overloaded chain slings must be taken out of service .

2 . Chain and components incl . load pins which has been

damaged, deformed, elongated, bent or showing signs of

cracks or gauges shall be replaced . Grind of small

sharp cuts and burrs . Additional testing by magnetic

particle inspection and/or proof loading at max . 2 x WLL

may be carried out .

3 . Check the function of latches, triggers and retaining pins /

bushes, replace when necessary . Always use Gunnebo

Lifting original spare parts .

4 . Max . clearance between hook and latch .

Note: For a Griplatch hook measure the difference between

measure A with unloaded spring and measure A when

the latch is pressed against the hook . Clearance B not

applicable .

A

B

A

Size

6

7/8

10

13

16

18/20

22

26

28

Max . A (mm) .

2,2

2,7

3

3,3

4

5,5

6

6,5

7

Max . B (mm) .

3,5

4,5

6

7

9

10

11

12

13 d

1

+ d

2

2

0,9d n

A

5 . The wear of the chain and component shall in no place

exceed 10% of the original dimensions . The chain link

wear - max . 10% - is defined as the reduction of the

mean diameter measured in two directions .

dn = nominal diameter

G-coupling links

Gunnebo Lifting’s G-links are universal . They can be used together with chain, master links, hooks and other lifting components as well as with steel wire ropes .

The G-links have a smooth surface to avoid snagging . The heavy duty retaining bush with its well protected stainless, square-sectioned spring ensures high reliability and safety .

Gunnebo Lifting G-links are available up to a WLL of 32 tonnes .

Connection systems

Direct coupling to clevis-type fittings

Gunnebo Lifting’s clevis fittings are designed to facilitate direct connection to chains without any intermediate coupling-links .

There are clevis fittings up to a WLL of 12.5 tonnes.

Berglok

Berglok chain couplings are foolproof, since they are designed to only match with the correct chain and components . The design prevents the coupling from snagging .

Berglok couplings are available up to a WLL of 11 .5 tonnes .

The SK system

A range of specialised Grade 8 alloy steel components for safe and easy assembly of lifting slings based on chain, steel wire rope, webbing and roundslings . A system that easy make a combination between synthetic slings and chain .

The SK-system is available up to a WLL of 12 .5 tonnes .

8

Chain & Components

Master link, M

Master link, MF

Code

M-6-10

M-86-10

M-108-10

M-13-10

M-1310-10

M-1613-10

M-19-10

M-2016-10

M-2220-10

M-2622-10

M-32-10

M-3226-10

M-3632-10

M-4536-10

M-90T-10

M-100T-10

M-125T-10**

WLL (tonnes)

EN1677-4

ß 0–45°*

ASTM A962

SF 5:1

28

33

43

10

12

17

25

1 .25

2 .5

4

5 .4

7 .5

56

70

90

100

125

13 .6

16

20 .6

30 .9

32

38 .6

46 .6

1 .5

3 .2

5 .2

5 .6

8

65

72 .7

100

100

125

L

190

200

240

250

250

300

300

100

120

140

150

160

350

375

450

450

450

Dim . in mm

B

110

120

140

150

150

180

200

60

70

80

90

95

200

210

250

260

260

D

40

45

50

25

30

34

38

11

14

17

19

22

55

60

70

80

80

Weight appr . kgs

8

12

15

2 .3

3 .5

5 .3

7

0 .2

0 .4

0 .8

1 .0

1 .5

21

26

43

57

57

Code

MF-6-10 ***

MF-86-10 ***

MF-108-10 ***

MF-1310-10 ***

MF-1613-10 ***

MF-2016-10 ***

MF-2220-10 ***

WLL (tonnes)

EN1677-4

ß 0–45°*

ASTM A962

SF 5:1

1 .25

2 .5

4

7 .5

10

17

25

1 .5

3 .2

5 .2

8 .0

13 .6

20 .6

30 .9

L

100

120

140

160

190

240

250

Dim . in mm

B

60

70

80

95

110

140

150

D

11

14

17

22

25

34

38

Weight appr . kgs

0 .2

0 .4

0 .7

1 .5

2 .2

5 .2

7

Master link, MT

Code

MT-6-10 ***

MT-8-10 ***

MT-9-10

MT-10-10 ***

MT-13-10 ***

MT-16-10 ***

MT-20-10 ***

MT-22-10

MT-26-10

MT-32-10

EN1677-4

ß 0–45°*

WLL (tonnes)

ASTM A952

SF 5:1

3 .5

5 .2

6 .9

11 .5

17

28

35

53

70

90

5

35

50

75

8

9 .7

16

26

100

125

L 1 L

Dim . in mm

B D

270 150 90

300 160 95

340 190 110

360 200 120

450 250 150

500 300 200

550 300 200

610 350 200

730 450 250

750 450 260

19

50

55

60

22

25

30

40

70

80 l b

120 70

140

150

80

90

160 95

200 120

200 120

250 150

260 140

280 160

280 160 d

14

32

38

45

17

19

22

30

50

55

Weight appr . kgs

1 .8

23

33

46

3 .0

4 .3

6 .5

15

71

91

Master link, MTC

Code

MTC-6-10***

MTC-8-10 ***

MTC-10-10 ***

MTC-13-10 ***

MTC-16-10 ***

WLL (tonnes)

EN1677-4

ß 0–45°*

ASTM A952

SF 5:1

3 .15

5 .2

8 .4

14 .1

21 .0

-

-

-

-

L 1

210

L

150

B

90

230 160 95

290 200 120

380 240 140

420 250 150

Dim . in mm

D

19

22

30

34

40 l b

60 38

70

90

46

60

140 65

170 100

* If used for chain, check for correspondling WLL values in the WLL table acc EN818-4 .

Safety factor 4:1

** Dimensions L and B not acc . to EN1677-4

*** With flattened section for use with BL d

13

16

19

25

32

Weight appr . kgs

1 .4

2 .1

4 .7

9

15

Chain & Components

Chain KLB

Code

KLB-6-8E

KLB-7-8E

KLB-8-8E

KLB-10-8E

KLB-13-8E

KLB-16-8E

KLB-19-8E

KLB-22-8E

KLB-26-8E

KLB-32-8E

WLL tonnes*

1 .12

1 .5

2 .0

3 .15

5 .3

8 .0

11 .2

15 .0

21 .2

31 .5

D

22

26

32

10

13

16

19

6

7

8

Dim . in mm

P

66

78

96

30

39

48

57

18

21

24

W

1

8 .5

10

11

30

35

43

14

18

22

26

Weight appr . kgs/m

0 .8

1 .1

1 .4

2 .2

3 .7

5 .8

7 .8

11 .0

14 .3

23 .0

Coupling link G

Code

G-6-8

G-7/8-8

G-10-8

G-13-8

G-16-8

G-18/20-8

G-22-8

G-26-8

G-32-8

WLL tonnes*

1 .12

2 .0

3 .2

5 .4

8 .0

12 .5

15 .5

21 .6

32 .0

For chain size mm

6

7, 8

10

13

16

19

22

26

32

L

44

56

68

89

105

125

152

160

200

B

29

36

43

50

58

70

15

18

25

Dim . in mm

G

15

19

22

24

29

38

8

9

12

E

33

40

47

59

61

78

16

22

26

Weight appr . kgs

0 .1

0 .2

0 .3

0 .7

1 .2

1 .9

3 .0

4 .6

8 .6

Berglok chain coupler BL

Code

BL-6-8

BL-7/8-8

BL-10-8

BL-13-8

BL-16-8

BL-19-8

WLL tonnes*

1 .12

2 .0

3 .2

5 .4

8 .0

11 .5

For chain size mm

6

7, 8

10

13

16

19

L

27

35

45

56

68

80

B

Dim . in mm

G

20

25

32

40

50

58

9

11

14

17

22

25

H

14

18

22

28

35

41

Weight appr . kgs

0 .1

0 .2

0 .4

1 .0

1 .4

2 .3

Safety hook OBK with grip latch

Code

OBK-6-10

OBK-7/8-10

OBK-10-10

OBK-13-10

OBK-16-10

OBK-18/20-8

OBK-22-8

WLL tonnes*

1 .5

2 .5

4 .0

6 .7

10 .0

12 .5

15 .5

For chain size mm

6

7, 8

10

13

16

19

22

L

103

139

170

206

251

293

335

B

26

37

47

53

67

73

87

Dim . in mm

E

22

28

34

44

56

60

70

F

9

10

13

15

19

22

24

G

14

20

22

28

29

37

40

H

17

22

29

37

45

48

57

Weight appr . kgs

0 .4

0 .8

1 .3

2 .6

4 .4

7 .5

10 .0

*Safety factor 4:1

9

Chain & Components

Safety hook GBK with grip latch

Code

GBK-7/8-8

GBK-10-8

GBK-13-8

GBK-16-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

For chain size mm

7, 8

10

13

16

L

119

151

172

204

B

37

47

54

68

Dim . in mm

G

20

22

27

29

H

22

29

35

43

Weight appr . kgs

0 .8

1 .4

2 .3

4 .0

Safety hook BK

Code

WLL tonnes*

For chain size mm

BK-6-10

BK-7/8-10

BK-10-10

BK-13-10

BK-16-10

BK-18/20-10

BK-22-8

BK-26-8

BK-28-8

1 .5

2 .5

4 .0

6 .7

10 .0

16 .0

15 .5

21 .6

25 .0

Size 6 - 18/20 with recessed trigger .

6

7, 8

10

13

16

19

22

26

32

L

109

137

168

207

253

290

320

345

400

B

29

37

45

54

62

68

80

100

120

Dim . in mm

E F

22

28

34

44

56

60

70

80

90

10

11

13

16

20

22

24

25

27

G

15

17

21

30

37

44

47

50

62

H

21

25

30

39

49

64

62

68

81

Weight appr . kgs

0 .5

0 .9

1 .5

2 .8

5 .6

8 .3

11 .2

14 .5

22 .0

Safety hook BKG

Code

WLL tonnes*

For chain size mm

BKG-7/8-8

BKG-10-8

BKG-13-8

BKG-16-8

BKG-19/20-8

2 .0

3 .2

5 .4

8 .0

12 .5

Size 6 - 18/20 with recessed trigger .

7, 8

10

13

16

19

L

120

149

187

226

240

B

Dim . in mm

G

37

45

54

62

70

17

21

30

37

46

H

26

30

39

49

63

Weight appr . kgs

0 .9

1 .5

2 .8

5 .1

8 .3

Shank safety hook BKT

Code

WLL tonnes* L B L 1

Dim . in mm

D

BKT-6-10

BKT-7/8-10

BKT-10-10

BKT-13-10

BKT-16-10

1 .5

2 .5

4 .0

6 .7

10 .0

90

111

133

170

202

29

37

45

54

62

36

47

51

65

76 dmin = the smallest shank dimension after matching

Note! After matching of the shank, proof loading must be carried out .

Size 6 - 18/20 with recessed trigger .

20

24

29

34

37 d min

11

13

16

20

25

G

15

17

21

30

37

H

21

25

30

39

49

Weight appr . kgs

0 .5

0 .9

1 .5

2 .8

5 .4

10

*Safety factor 4:1

Chain & Components

Swivel safety hook BKL

Code

BKL-6-10

BKL-7/8-10

BKL-10-10

BKL-13-10

BKL-16-10

BKL-18/20-10

WLL tonnes*

1 .5

2 .5

4 .0

6 .7

10 .0

16 .0

For chain size mm

6

7, 8

10

13

16

19

L

149

183

218

280

343

367

Size 6 - 18/20 with recessed trigger .

B

29

37

45

54

62

69

C

23

27

36

47

57

70

Dim . in mm

E

33

38

42

48

61

74

F

11

12

15

19

22

26

G

15

17

21

30

37

44

H

21

25

30

39

49

64

Weight appr . kgs

0 .7

1 .2

2 .0

3 .8

7 .1

11 .1

Swivel safety hook with ball bearing BKLK

Code

BKLK-6-10

BKLK-7/8-10

BKLK-10-10

BKLK-13-10

BKLK-16-10

BKLK-18/20-10

BKLK-26-8

WLL tonnes*

1 .5

2 .5

4 .0

6 .7

10 .0

16 .0

21 .6

Size 6 - 18/20 with recessed trigger .

For chain size mm

6

7, 8

10

13

16

19

26

L B C

Dim . in mm

E

150

184

218

29

37

45

24

27

35

33

38

42

281

339

54

62

45

63

48

61

367 69 59 74

467 100 100 102

F

19

22

26

35

11

12

15

G

30

37

44

50

15

17

21

H

39

49

64

68

21

25

30

Weight appr . kgs

0 .7

1 .1

1 .9

3 .8

7 .2

11 .3

22 .8

Clevis swivel safety hook with ball bearing BKH

Code

BKH-6-8

BKH-7/8-8

WLL tonnes*

1 .12

2 .0

For chain size mm

6

7, 8

L

145

181

B

28

37

Dim . in mm

K

6 .8

8 .8

G

15

17

Size 6 - 7/8 with recessed trigger .

H

21

23

Weight appr . kgs

0 .7

1 .2

Sling hook EKN with latch

Code

EKN-6-10

EKN-7/8-10

EKN-10-10

EKN-13-10

EKN-16-10

EKN-18/20-8

EKN-22-8

EKN-26-8

EKN-32-8

WLL tonnes*

1 .5

2 .5

4 .0

6 .7

10 .0

12 .5

15 .5

21 .6

32 .0

For chain size mm

19

22

26

32

6

7, 8

10

13

16

L

229

269

301

333

94

108

134

166

203

B

60

77

81

93

24

28

37

42

50

Dim . in mm

E F

60

64

66

76

22

28

34

44

56

26

31

32

38

10

13

15

19

24

G

41

42

51

61

17

17

23

28

36

H

51

67

75

80

20

23

30

38

45

Weight appr . kgs

5 .5

8 .9

12 .6

18 .3

0 .4

0 .6

1 .0

2 .1

4 .0

*Safety factor 4:1

11

Chain & Components

Sling hook EK

Code

EK-6-10

EK-7/8-10

EK-10-10

EK-13-10

EK-16-10

EK-18/20-8

EK-22-8

EK-26-8

EK-32-8

WLL tonnes*

1 .5

2 .5

4 .0

6 .7

10 .0

12 .5

15 .5

21 .6

32 .0

For chain size mm

6

7, 8

10

13

16

19

22

26

32

L

94

108

134

166

203

229

267

301

333

B

29

32

42

49

60

69

83

95

105

Dim . in mm

E

44

56

60

64

66

76

22

28

34

F

19

24

26

31

32

38

10

13

15

G

28

36

41

42

51

61

17

17

23

H

38

45

51

67

75

80

20

23

30

Weight appr . kgs

0 .3

0 .5

1 .0

2 .0

3 .8

5 .3

8 .9

12 .1

17 .7

Sling hook EGKN with latch

Code

EGKN-7/8-8

EGKN-10-8

EGKN-13-8

EGKN-16-8

EGKN-19/20-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

12 .5

For chain size mm

7, 8

10

13

16

19

L

95

121

147

170

212

B

Dim . in mm

G

29

37

42

49

60

17

19

27

34

43

H

22

29

36

44

51

Weight appr . kgs

0 .5

0 .9

2 .0

3 .6

6 .0

Sling hook EGK

Code

EGK-7/8-8

EGK-10-8

EGK-13-8

EGK-16-8

EGK-19/20-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

12 .5

For chain size mm

7, 8

10

13

16

19

L

95

121

147

170

212

B

Dim . in mm

G

33

42

48

56

73

17

19

27

34

43

H

22

29

36

44

51

Weight appr . kgs

0 .5

0 .9

1 .9

3 .4

5 .8

Foundry hook OKE

Code

OKE-7/8-10

OKE-10-10

OKE-13-10

OKE-16-10

OKE-18/20-8

OKE-26-8

OKE-32-8

WLL tonnes*

2 .5

4 .0

6 .7

10 .0

12 .5

21 .6

32 .0

For chain size mm

7, 8

10

13

16

19

26

32

L

123

151

184

217

247

300

384

B

63

76

90

102

114

113

145

Dim . in mm

E

60

66

80

28

34

44

56

F

11 .5

15

19

23

27

38

48

G

46

64

77

20

26

33

40

H

60

73

94

26

29

39

45

Weight appr . kgs

0 .7

1 .3

2 .8

4 .9

7 .1

16 .4

35

1

*Safety factor 4:1

Chain & Components

Swivel latch hook LKN

Code

LKN-7/8-8

LKN-10-8

LKN-13-8

LKN-16-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

For chain size mm

7, 8

10

13

16

L

155

192

238

295

B

29

36

40

53

C

28

37

47

62

Dim . in mm

E

36

42

48

61

F

12

15

19

22

G

18

23

28

33

H

23 .5

30

35

44

Weight appr . kgs

0 .9

1 .5

3 .0

5 .1

Swivel latch hook with ball bearing LKNK

Code

LKNK-7/8-8

LKNK-10-8

LKNK-13-8

LKNK-16-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

For chain size mm

7, 8

10

13

16

L

156

191

238

295

B

29

35

40

53

C

28

35

47

59

Dim . in mm

E

35

42

48

61

F

12

15

19

22

G

18

23

28

33

H

21

30

35

43

Weight appr . kgs

0 .9

1 .6

3 .1

5 .3

Clevis swivel hook LKNG

Code

LKNG-16-8

WLL tonnes*

8 .0

For chain size mm

16

L

252

B

53

C

30

Dim . in mm

F

28

G

33

H

43

M

27

Weight appr . kgs

5 .5

Grab hook OG

Not for use with Berglok .

No reduction of working load limit, thanks to supporting lugs on either side of hook to prevent chain link deformation .

Code

OG-7/8-8

OG-10-8

OG-13-8

OG-16-8

OG-19/20-8

OG-22-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

12 .5

15 .5

For chain size mm

7, 8

10

13

16

19

22

L

65

85

104

130

156

180

B

Dim . in mm

E

10

12

15

19

22 .5

25 .5

16

20

25

28

36

42

F

10

12

16

19

23

26

Weight appr . kgs

0 .3

0 .6

1 .2

2 .4

4 .6

6 .2

Grab hook GG

No reduction of working load limit, thanks to supporting lugs which prevents chain link deformation .

Code

GG-7/8-8

GG-10-8

GG-13-8

GG-16-8

GG-19/20-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

12 .5

For chain size mm

7, 8

10

13

16

19

L

58

77

97

124

145

Dim . in mm

B

10

12

15

19

22 .5

Weight appr .

kgs

0 .4

0 .8

1 .5

2 .8

4 .8

*Safety factor 4:1

1

Chain & Components

Shortening clutch GKL

Can be supplied without safety latch .

Code

WLL tonnes*

For chain size mm

GKL-6-8

GKL-7-8

GKL-8-8

GKL-10-8

GKL-13-8

GKL-16-8

1 .12

1 .5

2 .0

3 .2

5 .4

8 .0

6

10

13

7

8

16

A

75

93

93

120

151

179

B

34

42

42

55

66

79

Dim . in mm

C

38

42

42

58

74

90

D

15

20

20

25

32

40

L

53

66

65

84

103

122

Weight appr . kgs

0 .3

0 .5

0 .5

1 .0

2 .4

3 .4

Choker hook LK

For use with Berglok as end component .

Code

LK-7/8-8

LK-10-8

LK-13-8

WLL tonnes*

2 .0

3 .2

5 .4

For chain size mm

7, 8

10

13

L

96

120

150

Dim . in mm

B

19

21

26

E

32

42

52

Weight appr . kgs

0 .3

0 .8

1 .8

Shackle SA

Code

SA-7/8-8

SA-10-8

SA-13-8

SA-16-8

SA-19-8

SA-22-8

SA-26-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

11 .5

15 .5

21 .6

For chain size mm

7, 8

10

13

16

19

22

26

L

30

52

65

72

86

94

116

B

15

24

28

30

36

40

48

Dim . in mm

D

8

13

16

18

22

25

32

G

20

35

42

46

55

62

75

M

10

16

20

22

27

30

39

Weight appr . kgs

0 .1

0 .4

0 .7

1 .0

1 .8

2 .5

5 .2

Clevis shackle GSA

Code

GSA-7/8-8

GSA-10-8

GSA-13-8

GSA-16-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

For chain size mm

7, 8

10

13

16

A

36

48

65

70

B

32

34

50

60

Dim . in mm

C G

79

93

118

141

34

40

44

54

L

60

80

98

114

M

16

20

22

27

Weight appr . kgs

0 .5

0 .9

1 .7

3 .0

Clevis egglink CEL

Code

CEL-7/8-8

CEL-10-8

CEL-13-8

CEL-16-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

For chain size mm

7, 8

10

13

16

A

80

100

130

157

B

40

50

65

78

Dim . in mm

G

14

18

23

28

H

15

19

25

30

L

100

126

162

197

Weight appr . kgs

0 .4

0 .7

1 .5

2 .6

Ø B

1

*Safety factor 4:1

Chain & Components

Container hook CH-

Code

CH-3

CH-3 Turned 45° left

CH-3 Turned 45° right

WLL tonnes*

12 .5

12 .5

12 .5

L

192

B

70

Dim . in mm

H F

46 25

G

47

E

75

Weight appr . kgs

4 .0

Container hook BKGC

Code

WLL tonnes*

For chain size mm

BKGC-13-8

BKGC-16-8

5 .4

8 .0

13

16

(Spare part: RDOBK-16 to both sizes)

L

164

160

B

Dim . in mm

G

55

55

27

27

H

43

43

Weight appr . kgs

3 .2

3 .4

Master link D

Code

WLL tonnes** B

D-14-8

D-17-8

D-22-8

2 .5

4 .0

8 .0

55

64

76

** The loadbearing width must be at least 0 .5 X B

14

17

22

D

Dim . in mm

L

65

62

90

R

24

29

33

Weight appr . kgs

0 .3

0 .5

1 .0

Universal weld-on hook UKN

Code

WLL tonnes**

B C G

Dim . in mm

H K L S

Weight appr . kgs

UKN-0,75***

UKN-1***

UKN-2***

UKN-3

UKN-4

UKN-5

UKN-8

UKN-10

UKN-15

0 .75

1 .0

2 .0

3 .0

4 .0

5 .0

8 .0

10 .0

15 .0

20

20

26

30

29

34

34

47

53

56

72

86

105

114

131

133

170

188

13

17

20

23

29

30

40

43

50

20

25

30

32

38

47

51

58

67

19

25

30

35

42

45

50

55

60

81 .5

95

114

132

140

165

172

220

240

5

6

8

10

11

12

13

14

15

If welding on to an excavator or it's accessories we recommend that the working load limit is reduced, where necessary, to meet any appropriate legislative requirements . Please contact your distributor for further information .

*** Welding plate slightly curved

** Safety factor 5:1

0 .3

0 .6

1 .0

1 .3

1 .9

2 .9

3 .5

6 .4

8 .8

Weldable lifting point WLP

Can be supplied with or without spring for stay up function .

Code

WLP-1T

WLP-3T

WLP-5T

WLL tonnes*

1 .0

3 .0

5 .0

B

50

58

64

D

14

17

22

Dim . in mm

G L

27

34

41

53

48

73

R

24

29

33

T

95

97

135

Weight appr . kgs

0 .5

0 .9

1 .7

*Safety factor 4:1

1

Chain & Components

Screw-on lifting point SLP

Code

SLP-1T

SLP-3T

SLP-5T ***

WLL tonnes*

1 .0

3 .0

5 .0

B

50

58

64

C

72

84

116

D

14

17

22

*** Can be supplied with spring for stay up function

Dim . in mm

H L

98

114

160

55

50

74

M T

M14 139

M16 144

M20 203

R

24

29

33

Weight appr . kgs

0 .9

1 .4

2 .9

Eye lifting point ELP

Code

ELP-M16-8

ELP-M20-8

ELP-M24-8

ELP-M30-8

ELP-M36-8

WLL tonnes*

1 .0**

1 .5**

2 .0**

3 .0**

4 .0**

WLL

0°**

4 .0

6 .0

8 .0

12 .0

16 .0

B

72

72

88

106

127

D

16

16

19

22

26

Dim . in mm

G H

42

42

48

60

72

55

57

70

84

100

L

24

30

36

45

54

M

M16

M20

M24

M30

M36

Weight appr . kgs

0 .4

0 .5

0 .9

1 .4

2 .3

** In case of 1-leg application where loading is limited to straight loading in the direction of thread

(no bending force) it is possible to use ELP with four times higher WLL .

Note: Threaded depths need to be at least 1xM for steel, 1,25xM for cast iron and 2xM for aluminium alloy .

16

Rotating lifting point, RLP

B

Code

D

WLL tonnes*

L M B

Dim . in mm

D

M

*Safety factor 4:1

L

G

H

RLP M8-10***

RLP M10-10***

RLP M12-10***

RLP M16-10***

RLP M20-10***

RLP M24-10

RLP M30-10

RLP M36-10

RLP M42-10

RLP M48-10

0 .3**

0 .5**

0 .75**

1 .5**

2 .5**

3 .5

6

8

14

16

15

20

19

24

32

37

49

61

65

75

M8

M10

M12

M16

M20

M24

M30

M36

M42

M48

42

42

57

57

83

83

114

114

149

149

12

12

19

19

28

28

34

34

40

40

35

34

46

44

56

53

69

65

90

86

60

60

85

85

111

111

144

144

185

185

0 .3

0 .3

0 .9

0 .9

2 .8

2 .8

7 .0

7 .3

14 .0

14 .9

Longer bolt can be supplied on special request

*** The WLL of the RLP may be double in case of 1-leg applications provided only axial loading takes place,

i .e . no bending force applied in the direction of the thread .

** Available in UNC thread; 5/16”, 3/8”, 7/16”, 5/8”, 3/4” .

Working Load Limits (tonnes)

β β

RLP- Rotating Lifting Point, Grade 10

No . of legs

β

1

0°

Load factor *)

RLP-M 8-10 0 .60

RLP-M10-10 1 .00

RLP-M12-10 1 .50

RLP-M16-10 3 .00

RLP-M20-10 5 .00

RLP-M24-10 7 .00

1

90°

1

0 .30

0 .50

0 .75

1 .50

2 .50

3 .50

2

0°

*)

1 .20

2 .00

3 .00

6 .00

10 .00

14 .00

2

90°

2

0 .60

1 .00

1 .50

3 .00

5 .00

7 .00

2 symmetric 3 and 4 symmetric

0-45° 45-60° 0-45° 45-60°

1 .4

0 .42

0 .70

1

0 .30

0 .50

2 .1

0 .63

1 .05

1 .5

0 .45

0 .75

1 .00

2 .10

3 .50

4 .90

0 .72

1 .50

2 .50

3 .50

1 .60

3 .15

5 .25

7 .35

1 .13

2 .25

3 .75

5 .25

RLP-M30-10 12 .00

RLP-M36-10 14 .00

6 .00

8 .00

24 .00

12 .00

8 .40

28 .00

16 .00

11 .20

6 .00

8 .00

12 .60

16 .80

RLP-M42-10 16 .00

14 .00

32 .00

28 .00

19 .60

14 .00

29 .40

RLP-M48-10 20 .00

16 .00

40 .00

32 .00

22 .40

16 .00

33 .60

*) Provided only axial loading takes place, i .e . no bending force applied in the direction of the thread .

9 .00

12 .00

21 .00

24 .00

G H

Weight kgs

The patented new design of the RLP makes it suitable also in applications where a conventional

Lifting point would not be fully adequate . Intended to be used as a Lifting point, Lashing point or

Towing attachment .

• Dismountable open D-ring . Enables assembly of

roundsling, master link, link or hook directly onto

the RLP .

• Hexagon-headed screw for easy assembly/

disassembly by means of an ordinary wrench .

• RLP can rotate 360° and articulate 180° .

• Forged in Grade 10 material permits higher WLL

than Grade 8 and DIN 580 eyebolts .

Chain & Components

The SK System

A range of specialised Grade 8 alloy steel components for safe and easy assembly to chain, steel wire rope, webbing and roundslings, designed to solve your below-the-hook problems .

The SK System provides:

– Universal coupling of components to chain, wire and

synthetic slings .

– Quick and simple assembly – only a hammer needed .

– Foolproof assembly – standardised dimensions within

each size range effectively eliminates the wrong assembly

of components with different safe working loads .

– Heavy hoisting with strong yet lightweight equipment –

all components are manufactured from alloy steel for use

with Grade 8 chain .

Master link (closed) SKG

Code

SKG-7/8-8

SKG-10-8

SKG-13-8

SKG-16-8

SKG-18/20-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

12 .5

For chain size mm

7, 8

10

13

16

19

L

99

127

145

175

204

Dim . in mm

B

50

66

72

82

105

G

14

18

22

25

30

Weight appr . kgs

0 .3

0 .6

1 .1

1 .7

2 .8

Master link (open) SKO

Code

SKO-7/8-8

SKO-10-8

SKO-13-8

SKO-16-8

SKO-18/20-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

12 .5

For chain size mm

7, 8

10

13

16

19

L

99

127

145

175

204

B

Dim . in mm

G

50

66

72

82

105

14

18

22

25

30

B1

15

20

25

30

36

Weight appr . kgs

0 .3

0 .6

1 .0

1 .6

2 .6

Sling hook with latch ESKN/SKN, without latch ESKH/SKH

Code

SKN-7/8-8

SKN-10-8

SKN-13-8

ESKN-16-8

ESKN-18/20-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

12 .5

For chain size mm

7, 8

10

13

16

19

L

90

115

141

181

197

B1

32

40

48

62

67

Dim . in mm

B2

27

34

42

54

59

G

18

23

28

34

41

H

21

29

36

43

51

Weight appr . kgs

0 .4

0 .9

1 .8

3 .4

5 .0

*Safety factor 4:1

17

Chain & Components

Roller-bearing swivel SKLI

Electrically insulated, lubricated, sealed rollerbearing swivel . Fully rotational even at maximum load .

Tested to resist 1000 V . Suitable for protection of overhead cranes during welding operations on suspended loads .

Code

SKLI-7/8-8

SKLI-10-8

SKLI-13-8

SKLI-16-8

SKLI-18/20-8

SKLU-22-8**

SKLU-26-8**

**) Uninsulated

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

12 .5

15 .5

21 .6

For chain size mm

7, 8

10

13

16

19

22

26

L

75

96

120

137

159

160

207

Dim . in mm

D

48

59

75

90

104

109

135

Weight appr .

kgs

0 .7

1 .4

2 .9

4 .9

7 .2

9 .2

17 .7

Roundsling coupling SKR

Special shape for full WLL of the roundsling .

Code

SKR-7/8-8

SKR-10-8

SKR-13-8

SKR-16-8

SKR-18/20-8

SKR-22-8

SKR-26-8

WLL tonnes*

2 .0

3 .2

5 .4

8 .0

12 .5

15 .5

21 .6

L

35

42

50

62

71

111

129

Dim . in mm

B

40

47

53

67

80

125

150

K

18

24

29

35

43

50

58

Weight appr .

kgs

0 .2

0 .4

0 .7

1 .2

1 .9

5 .3

9 .0

Shank coupling SKS

Supplied unmachined as standard . Can be machined to customer requirements .

Code

WLL tonnes*

For chain size mm L

SKS-7/8-8

SKS-10-8

SKS-13-8

SKS-16-8

SKS-18/20-8

2 .0

3 .2

5 .4

8 .0

12 .5

7, 8

10

13

16

19

70

85

100

112

88 d min = The smallest shank dimension after machining .

Note! After machining of the shank, proof loading must be carried out .

27

34

43

52

55

L2

Dim . in mm

D

30

36

42

50

72 dmin

13

16

20

25

30

Weight appr . kgs

0 .5

0 .9

1 .4

2 .5

4 .7

Half link SKT

(incl . locking set) .

Code

SKT-7/8-8

SKT-10-8

SKT-13-8

SKT-16-8

SKT-18/20-8

SKT-22-8

SKT-26-8

SKT-32-8

WLL tonnes*

12 .5

15 .5

21 .6

32 .0

2 .0

3 .2

5 .4

8 .0

For chain size mm

19

22

26

32

7, 8

10

13

16

L

63

76

80

100

28

34

44

52

B

Dim . in mm

G

43

50

58

70

18

25

29

36

22

24

29

36

9

12

15

19

E

48

60

61

78

22

26

33

40

Weight appr . kgs

1 .1

1 .7

2 .6

4 .9

0 .1

0 .2

0 .4

0 .7

18

*Safety factor 4:1

Spare parts

SKA locking set for Coupling links G, consists of load pin and bush .

Size: SKA 6 -

SKA 32-8

BLA, set for Berglok and Clevis type connections . Consists of one load pin and two retaining pins

Size: BLA 6 - BLA 19

Note: Special spare part set for GKL 7

RDBK, set for BK Safety hooks consists of latch, stainless steel spring, retaining pin and assembly kit .

Size: RDBK 6 -

RDBK 28

RDOBK, set for OBK Safety hooks consists of latch, stainless steel spring, retaining pin and assembly kit .

Size: RDOBK 6-

RDOBK 22

Tool kit for replacement BK-trigger set.

Tool kit in a plastic box, suit BK and OBK hooks, sizes 6 mm-16 mm .

Spare parts

RDEKN set consists of latch, stainless steel spring and rivet .

Fits:

EKN 6 - EKN 32

LKN 7/8 - LKN 16

EGKN 6 - EGKN 19/20

RH 1 - RH 5

ESKN 16 - ESKN 18/20

RDSKN/LKN/OKN set consists of latch, stainless steel spring and rivet .

Fits:

SKN 7/8 - SKN 18/20

LKN 7/8 - LKN 16 (old)

OKN 16 - OKN 22

RDGKN/OKN set consists of latch, stainless steel spring and rivet .

Fits:

GKN 7/8 - GKN 16

OKN 7/8 - OKN 13

RDUKN msp, consists of forged latch, pin, stainless steel spring and retaining pin .

RDUKN usp, consists of pin, stainless steel spring and retaining pin .

Size: RDUKN 0 .75 – RDUKN 15

RDRLP , set consists of bolt and metal clip .

Size RDRLP M8-10 – RDRLP M48-10

RDGKL , set consists of latch, stainless steel spring and retaining pin .

Size RDGKL 6 – RDGKL 16

RDSKLI , set for roller bearing swivel SKLI, consists of spring pin, sealing, lower insulating bush, screws,labels and user instructions .

Size RDSKLI-7/8 – RDSKLI-18/20

ID-tags , in stainless steel .

19

Omslag classic ny 04-03-30 16.13 Sida 1

Gunnebo Classic

The wide range of lifting products gives full flexibility for any situation

Gunnebo Industrier AB

P.O. Box 44

GUNNEBO INDUSTRIER AB (publ)

Tel: +46 (0)220 384 00

Fax: +46 (0)220 384 98

SE-730 60 Ramnäs, Sweden

Tel: +46 220 384 00

E-mail: export@gunnebolifting .com

www .gunnebolifting .com