The Design, Construction, Operation & Maintenance of an

advertisement

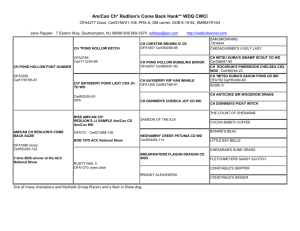

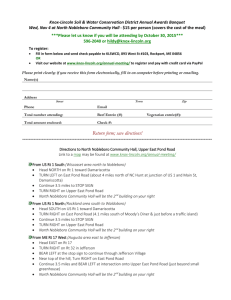

The Design, Construction, Operation & Maintenance Chinn et al The Design, Construction, Operation & Maintenance of an Experimental Magnesium Chloride Solar Pond A. Chinn, A. Akbarzadeh and C. Dixon School of Aerospace, Mechanical and Manufacturing Engineering RMIT University PO Box 71 Bundoora Victoria 3083 AUSTRALIA E–mail: audrey.chinn@mm.rmit.edu.au Abstract The two salts that have been used to establish salinity gradients in solar ponds are sodium chloride (NaCl) and magnesium chloride (MgCl2). Sodium chloride is the more common salt used in solar ponds. However, the disadvantage of using sodium chloride is its cost as it is a com mercial product. Magnesium chloride (bittern) offers a more economical alternative to sodium chloride as it is a low cost waste product. Bittern also produces a very stable salinity gradient when operating at high 2 temperatures. An experimental 15 m solar pond was designed and built for the purpose of investigating the performance of a magnesium chloride based solar pond and its role in salinity mitigation. Pond construction was completed in June 2002 and pond operation commenced in August 2002. A technique for maintaining the level of interfaces within the pond was developed. This paper describes pond features, pond gradient establishment, and pond maintenance procedures and discusses pond performance data. INTRODUCTION A solar pond is a body of water measuring several metres deep with a salt concentration that increases with depth. The salinity gradient within the solar pond enables heat to be stored more efficiently compared to a body of water the same size. As shown in Figure 1, there are three main layers in a solar pond: Upper Convective Zone (UCZ), Non Convective Zone (NCZ) and a Lower Convective Zone (LCZ). The solar radiation that penetrates through the vertical profile of the pond is stored as thermal energy in the LCZ. The normal tendency for convection to occur is suppressed by maintaining the salinity, and hence density gradient in the pond. The pond’s high density inhibits the natural buoyancy rising effect that occurs with high temperatures, therefore enabling the NCZ to act as an insulating layer in the pond. Energy from the solar pond may be extracted for use as process heat in industry or to generate electrical power. Salinity is a major environmental, social and financial issue in Australia. Tree clearing and agricultural practices contribute to changes in the water balance resulting in what is known as dryland salinity. Figure 2 shows some of the more obvious impacts of dryland salinity in Australia. Dryland salinity is the rise of the groundwater table thereby causing the mobilisation of salts previously stored in Australia’s soils. Figures from the Australian Dryland Salinity Assessment (2000) show that he estimated area affected by salinity in Australia is 5.7 million hectares with an approximate cost of $600M per year in lost production. Strategic measures such as revegetation, groundwater pumping and changed agricultural practices are some of the salinity mitigation practices that are currently being implemented in Australia. In the groundwater pumping mitigation scheme, groundwater is pumped from the ground to prevent the water table from rising to the surface. Groundwater is pumped to evaporation basins, where the water is left to evaporate leaving concentrated brine. This may then be extracted and processed in a salt processing plant producing commercial grade sodium chloride. A waste product of this process is known as bittern, which consists predominantly of magnesium chloride. Magnesium chloride is 10% denser than sodium chloride; thus has the potential for enabling a stronger salinity gradient to be developed. It is also a cheaper alternative to sodium chloride and is therefore considered to be a potentially suitable salt source that may be used to establish and maintain a solar pond. Destination Renewables - ANZSES 2003 Reviewed as full paper 329 © copyright 26 to 29 November The Design, Construction, Operation & Maintenance Chinn et al 0.001m LCZ 1.0m T3 – 0.75m T4 – 0m (at pond bottom) T5 – 0m (under pond, on top Polyethylene Tank Foam Insulation 0.15m 1.0m NCZ Foam Insulation Polyethylene Tank Polyethylene Tank Foam Insulation 1.0m 0.1m T2 – 1.8m UCZ 0.1m 0.75m Ground Surface T1 – 2.0m of insulation) T6 – 0.1m (under insulation) 4.4m Figure 1 – Schematic of a Solar Pond 0.15m Flushing Water System Diffuser Sampling Pole Figure 2 – Impacts of salinity on land and vegetation in North West Victoria Overflow System Figure 3 – RMIT MgCl2 solar pond POND DESCRIPTION An experimental magnesium chloride (MgCl2, commonly known as bittern) solar pond was constructed in June 2002 in the Renewable Energy Laboratory in the School of Aerospace, Mechanical & Manufacturing Engineering at RMIT University in Melbourne, Victoria, Australia. The pond is a circular polyethylene tank with a diameter of 4.4 m, a height of 2.0 m, wall thickness of 0.008 m and area of 15 m 2. The pond sits 1 m beneath the surface of the ground. As depicted in Figure 1, the base and walls of the MgCl2 pond are insulated. The pond base is insulated with polystyrene insulation sheets –1 0 measuring 0.1 m thick with a thermal conductivity of 0.0410 W.mK at 25 C and the pond walls are –1 insulated with 0.15 m polyurethane insulation with a thermal conductivity of 0.018 W.mK . Destination Renewables - ANZSES 2003 Reviewed as full paper 330 © copyright 26 to 29 November The Design, Construction, Operation & Maintenance Chinn et al Figure 3 illustrates other features of the pond such as the sampling pole, the overflow system, the diffuser and the flushing water system. The sampling pole is used for collecting samples for monitoring pond temperature, density and turbidity. The diffuser is used for esta blishing the pond’s salinity gradient and also for bittern injection when salt replenishment is required. The overflow system has three adjustable heights – 1.85m, 1.90m and 1.95m. The water level is kept fixed at 1.85m. GRADIENT ESTABLISHMENT The bittern, a waste product from a commercial salt production company in Pyramid Hill called Pyramid Salt, is the salt used for setting up the salinity gradient in the RMIT University MgCl2 solar pond. The bittern was delivered in a tanker from Pyramid Hill to Melbourne. The density of bittern was –3 0 measured to be 1,303 kg.m at 19 C. This was the basis for calculating the total mass of bittern required for establishing the solar pond. The mass of bittern required for a depth of 0.75 m in the LCZ was calculated to be 15 tonnes. Assuming a linear density profile, this results in a gradient decrease at –3 a rate of 30 kg.m for every 0.1 m rise from the LCZ. On this basis, the average density in the NCZ –3 was calculated to be 1150 kg.m . The calculated mass of bittern and water required for the NCZ was 17.5 tonnes. The mass of water required in the NCZ was 7.6 tonnes with the density of water at –3 1,000 kg.m . Therefore the mass of bittern required to establish the solar pond was 24.9 tonnes or 3 19.1 m , which equates to a height of 1.25 m when measured from the bottom of the pond. Assuming –1 the upward movement of salt in the pond is 0.05 m.year as stated by Hull (1989), the calculated 3 –1 volume of bittern required to replenish the bittern loss via salt diffusion is 0.76 m .year or 1tonne. Therefore the total amount of bittern required to establish and maintain a solar pond is 26 tonnes. The extra bittern is stored in a 1,000 L feeder tank situated 10 m from the pond as this enables easy access for bittern injection for salt replenishment when required. The RMIT MgCl2 solar pond gradient was established using the renowned Zangrando’s method (Zangrando, 1980). Figure 4a is a diagram of the diffuser and its dimensions and Figure 4b is a photo of the diffuser that was used to set up the gradient profile. The diffuser inlet was connected to the water mains where fresh water flowed through its outlet. Prior to gradient establishment, the diffuser was placed in an experimental tank filled with bittern to observe its fresh water jet flow patterns in bittern. The jet observed from the diffuser was a horizontal semi circle fan like flow, which rose above the diffuser as expected. Also, as stated by Zangrando (1991), the jet displayed some buoyancy properties and mixing occurring above the diffuser. The type of jet flow emanating from the diffuser may be determined by Froude Number, which will be discussed later in this section. Fresh water inlet Diffuser placed at pond wall to minimise agitation effects 0.002m 0.35m Figure 4a – Side view of diffuser showing dimensions and plan view of diffuser Destination Renewables - ANZSES 2003 Reviewed as full paper 331 © copyright 26 to 29 November The Design, Construction, Operation & Maintenance Chinn et al Figure 4b – Photo of diffuser Figure 5 – Flushing water system The pond was initially filled with 1.25 m of concentrated liquid bittern then the diffuser was placed at 0.75 m (as measured from the base of the pond), as this is where the NCZ it to begin. Previous experimental work conducted by Zangrando (1980) has shown that injection intervals of 0.05 m worked well. The first injection period commences when fresh water is injected through the diffuser. When the pond surface level has increased by 0.05 m, the diffuser height is raised by 0.1 m for the next injection period. This method will ensure that the bittern above the diffuser will be progressively diluted, while the diffuser, as well as the pond surface level, rises. This is repeated until the pond is filled. This procedure is consistent with Zangrando’s method (1980) where, the rate of the diffuser’s height is increased by twice the rate at which the pond’s surface level is rising. To establish a successful salinity gradient, a certain type of flow is required so that mixing occurs at and above, but not below the diffuser. Whether this type of flow occurs may be determined by Froude Number, which is measured as the ratio of inertia to buoyancy forces of a jet. Froude Number is defined as: Fr = v ρ e − ρi gd ρ i (1) where v g d ρe ρi = = = = = outlet velocity of fluid (m.s –1) –2 gravitational acceleration (m.s ) diffuser slit width (m) –3 density of fluid environment (kg.m ) –3 density of injected fluid (kg.m ) Following Equation 1, depending on the jet velocity, the diffuser slit width and the density difference between the two fluids, mixing will occur either above the diffuser level, at the diffuser level, below the diffuser level or above and below the diffuser level. Experimental work conducted by Zangrando (1991) has shown that for mixing to occur at and/or above the diffuser level the Froude Number should be maintained at 15 during gradient establishment. However as noted in later solar pond work, this figure does still cause some mixing to occur below the diffuser centerline (Kishore, 1996). Since the diffuser slit width was fixed, the only parameter that could be varied was the jet velocity. This was achievable as the diffuser was attached directly to the mains water where its flow rate may be measured and varied. This was the method in which the flow rate was controlled in an attempt to maintain the Froude Number at 15. However, there was some difficulty in keeping the Froude Number at 15 as the range of the flow rate from the water mains was limited. The flow rate available from the –5 3 –1 –4 3 –1 –1 –1 water mains ranged from 3.33 x 10 m .s to 5 x 10 m .s (2 L.min to 30 L.min ) whereas the flow rate required to maintain the Froude Number at 15 was calculated to be in the range from –5 3 –1 –3 3 –1 –1 –1 3.33 x 10 m .s to 1.11 x 10 m .s (2 L.min to 67 L.min ) as shown in Table 1. As shown in Destination Renewables - ANZSES 2003 Reviewed as full paper 332 © copyright 26 to 29 November The Design, Construction, Operation & Maintenance Chinn et al Table 1, this does not correspond at all depths and associated densities to the available flow rates from the water mains. Froude Number for the flow rate available from the water mains was calculated, and the flow rate adjusted accordingly to ensure that the Froude Number does not exceed 20. Experimental laboratory work conducted at the RMIT University Lab showed that as long as the Froude Number does not exceed 20, a salinity gradient may be successfully established despite some mixing occurring below the diffuser. Figure 6 shows the calculated gradient profile along with the progression of the gradient profile during gradient establishment. It took three days for the salinity gradient to be established. Samples were taken at the end of each day, and the density of each sample was measured to determine the profile of the pond. As depicted in Figure 6, the developing density profile sits below the calculated desired profile. This may be due to some mixing occurring below the diffuser centerline during gradient establishment as the Froude Number was kept at less than 20 instead of 15. As shown in Figure 6, even with some mixing occurring, the density gradient was successfully established. X Table 1. Gradient establishment calculations H L / min L / min Fr Calculated Distance diffuser is from pond base (m) 0.75 0.85 0.95 1.05 1.15 1.25 1.35 1.45 1.55 1.65 1.75 Distance water surface is from pond base (m) 1.25 1.30 1.35 1.40 1.45 1.50 1.55 1.00 1.65 1.70 1.75 Calculated flow rate Available flow rate from water mains Calculated Froude Number 67.33 50.64 37.04 26.66 19.03 13.52 9.58 6.78 4.80 3.39 2.40 30 30 30 30 30 30 12 12 6 6 2 7 9 12 17 9 13 19 13 19 13 19 POND MAINTENANCE Gradient maintenance is an important aspect to the overall performance of a solar pond. The two main requirements for gradient maintenance are: salt replenishment in the LCZ and surface washing in the UCZ. Salt movement through the pond is driven by two main factors: molecular diffusion from the concentration gradient, and heat diffusion from the temperature gradient. Various solar ponds have different rates of salt flux depending on these influencing factors. Generally, as stated by Tabor and –2 –1 Weinberger (1981), the estimated salt flux for NaCl solar ponds is between 20 and 30 kg.m .year . –2 –1 The theoretical average annual rate of salt flux for this MgCl2 pond is calculated to be 9.2kg.m .year –2 –1 compared to the actual observed figure of 11 kg.m .year across a NCZ thickness of 1m with a –3 –3 concentration of 415 kg.m in the LCZ and 2kg.m in the UCZ, measured from July 2002 to June 2003. This higher observed salt flux may be due to external influences such as molecular movement due to wind agitation, thermal mixing and daily temperature variations (Alagao, 1994). Regular salt replenishment and monitoring will enable detection and correction of instabilities that may occur within the pond. This is important to the overall operation of the pond, since the stratified layers within the pond suppress the natural convection process as well as acting as insulation for the LCZ. The same diffuser used for gradient establishment, shown in Figures 4a and 4b, was also used for injecting bittern to replace the salt lost in the LCZ. Following the rising pond theory (Hull, 1989) the –1 upward velocity for this solar pond was estimated to be 0.05 m . year . Based on this estimation, an average of 0.1 m 3 of bittern is injected quarterly (every 3 months) into the LCZ of the pond to replenish the salt lost through the system. Destination Renewables - ANZSES 2003 Reviewed as full paper 333 © copyright 26 to 29 November The Design, Construction, Operation & Maintenance Chinn et al The thickness of the UCZ has a marked effect on the performance of the pond (Akbarzadeh and Wang, 1983). Previous work has shown that the ideal UCZ thickness ranges from 0.1 m to 0.5 m. A flushing water system is installed to ensure the thickness and salinity of this layer is kept to a minimum and also to compensate for evaporation losses. The flushing water system uses fresh water from the –6 3 –1 –1 water mains. The flushing water flow rate is 2 x 10 m .s (0.12 L.min ), which is equivalent to twice –3 –1 the yearly average evaporation rate of 5.7 x 10 m.day (Bureau of Meteorology). As seen in Figure 5, it is a drip system. The system was designed as such for two reasons: to allow for in situ flow rate measurement, and to allow for a quick visual inspection without physically handling or disrupting the system. POND MONITORING AND INSTRUMENTATION The performance of a solar pond is strongly dependent on the following factors: § Salinity distribution § Temperature distribution § Pond clarity § Weather conditions such as wind speed, air temperature, evaporation rate, rainfall and solar radiation § Heat losses § Rate of heat extraction from the pond The monitoring of these factors will provide adequate information on the pond’s operation to determine when and if maintenance or corrective measures are required. The salinity, temperature and turbidity are m onitored fortnightly at sample intervals of 0.05m. Salinity Distribution A density meter, based on the U–tube principle, is used for measuring the density of liquids where the effect of oscillation frequency is measured and converted to density. The density meter also has a temperature sensor, where the meter gives a reading of the sample density at its sample temperature. This allows for the measured density to be corrected to pond temperature thus reflecting the “true” density profile in the pond. Equation 2 is the density equation used for calculating density corrections which is a function of both temperature and concentration (National Research Council, 1928). The density constants a and b are derived empirically from data obtained in the International Critical Tables (National Research Council, 1928). ( ? (S,T ) = 0.99987 + 0.008652 S + 1.626 x10 −5 S 2 + 4 .877 x10 −7 S 3 − a T + b T 2 ) (2) where: ρ(S,T) = density of MgCl2 solution as a function of temperature and concentration (x 10–3 kg.m –3) S T = concentration grams of solute per 1 kg of solution (weight %) 0 = temperature of MgCl2 solution ( C) a = density constant as a function of concentration (x 10–6 kg.m –3.0C–1) 1 1 2 −1 3 a = –9.9970 x10 + 4.5947 x 10 S–4.9072 S + 4.5486 x10 + 6.3663 x10 −4 S 5 –6.5215 x10 −6 S 6 b –^ S –2.4128 x10 −2 S 4 –3 0 –1 = density constant as a function of concentration (x 10 kg.m . C ) b = 8.3769 –9.9102 x10 −1 S + 1.3005 x10 −1 S 2 –1.3099 x 10−2 S 3 + 7.0857 x10 −4 S 4 –1.8687 x10 −5 S 5 + 1.9021 x10 −7 S 6 Destination Renewables - ANZSES 2003 Reviewed as full paper 334 © copyright 26 to 29 November The Design, Construction, Operation & Maintenance Chinn et al The salinity and concentration profile may be calculated using the corrected density profile. Samples were withdrawn at 0.05m intervals using a siphon sampling tube from the vertical profile of the pond. The temperature at that same point is also measured. Temperature Distribution The temperature profile of the pond is obtained by using a digital thermometer, where one end of the probe is attached to the sampling tube at its sampling point. When withdrawing a sample at a sample point, the temperature at that same sample point is also measured, thus generating a temperature profile for the pond. The pond’s temperature profile is an indication of the pond’s thermal performance and it is also essential for calculating sample density corrections. Pond Clarity Water clarity in the pond is very important to the overall thermal performance of the pond. Poor water clarity is usually an indication of suspended solids present in the body of water, which can interfere with solar transmittance and penetration through the pond. It is important for the UCZ to have good water clarity as this allows a higher percentage of solar a r diation to penetrate through the lower layers of the pond, thus enabling more heat to be stored in the LCZ. Water clarity is measured using a turbidity meter, where the instrument passes a beam of infrared light and detects the amount of light scattered by the suspended solids present in the sample. Weather Hull had stated that expensive airport quality weather instruments are not necessary for pond monitoring purposes (1989). Therefore, a commercial, moderately priced weather station is used for this pond. As recommended by Hull (1989), the more important items to monitor are solar radiation, wind speed and dry bulb temperature. These measurements are averaged over the hour and logged. Continuous Monitoring T–type thermocouples were installed at various points within the solar pond. The positions of these thermocouples as shown in Figure 1 are: § § § § § § T1 – 2.00 m from the bottom of the pond T2 – 1.80m from the bottom of the pond (UCZ) T3 – 0.75m from the bottom of the pond (LCZ and UCZ interface) T4 – 0m at pond bottom T5 – 0m under pond bottom and on top of insulation T6 – 0.10m under insulation Six thermocouples, each measuring 30 m, were laid from the pond, along the site’s fence line and into the laboratory and connected to a data logger. Due to cost constraints, only six thermocouples were installed. The temperatures at these six points are logged at hourly intervals and the data is downloaded regularly. This data will provide historical temperature profiles for the MgCl2 solar pond and enable detailed analysis on pond performance to be conducted. POND PERFORMANCE The thermal efficiency of the pond is very much dependent on the amount of solar radiation that penetrates through the pond’s LCZ and also the amount of heat losses from the ground and conduction within the pond. The yearly average solar radiation for Melbourne as obtained from the -2 -1 Bureau of Meteorology is 14.8 MJ.m .day . Based on Tabor’s assumption (1981), where 25 % of Destination Renewables - ANZSES 2003 Reviewed as full paper 335 © copyright 26 to 29 November The Design, Construction, Operation & Maintenance Chinn et al solar radiation penetrates through to the LCZ, the efficiency for this MgCl2 solar pond is calculated to be 9.3%. This includes calculated heat losses from the ground and via conduction at 5.4% and 10.4% respectively. Figure 7 shows the quarterly density gradient profile for the pond. Between July 2002 and November 3 2002, 0.07 m of bittern was injected into the pond. As reflected in the profiles in Figure 7, the salt flux –2 –1 3 for this period is 10 kg.m .year . Between November 2002 and March 2003, 0.4 m of bittern was –2 –1 injected into the pond and the salt flux for this period had increased to 29 kg.m .year . Between 3 March 2003 and June 2003, 0.1 m of bittern was injected into the pond. The salt flux for this period is –2 –1 12.5 kg.m .year . These observations show that the salt flux increases significantly over the summer period, where pond temperatures are higher. The quarterly temperature profiles are shown in Figure 8. As reflected in the profiles, the highest temperatures are observed in the summer months. This is also reflected in Figure 10 where the peak temperature is observed in the summer period. Figures 9 and 10 are also used as a management tool for determining whether pond maintenance is required. The maximum density line in Figure 9 is monitored for trends indicating when bittern injection or surface water flushing is required. As observed in Figure 9, immediately after bittern has been injected into the LCZ, the graph shows an increase in the maximum density trendline. When the trend for this line appears to decreasing, it is an indication that more bittern is required to maintain the profile of the pond. The same principle is applied for the flushing water system. The minimum density trendline is monitored for any increase in the trend line. When the minimum density line appears to be increasing, the flushing water flow rate is increased to keep the density (which is directly related to the salt concentration) at its minimum. Figure 10 shows the historical maximum and minimum temperatures for the MgCl2 pond. The highest º th temperature recorded in the LCZ was 78.5 C on 18 January 2003 during the summer period and the º rd lowest temperature recorded was 35 C on 3 September 2002. This was when the pond was in its º th second month of operation. The lowest temperature recorded in the UCZ was 6.5 C on 8 September º rd 2002 and the highest was 36.3 C on 23 November 2002. As depicted in Figure 10, the temperature in the LCZ is now declining as the colder months approaches. The last recorded temperature for the th º º pond was on the 10 June 2003 with a LCZ temperature of 41.6 C, UCZ te mperature of 13.9 C and º an ambient air temperature of 13.1 C. As observed, even during the colder months, the MgCl2 pond is º still able to maintain a temperature difference of more than 25 C, thus showing the possibility of solar heat being available during the colder months. Zone boundaries (or interfaces) are depicted historically in Figure 11. This shows that during the summer period, the LCZ had decreased whilst the UCZ started increasing. This coincides with observations made in Figures 7 and 9, where the salt flux had increased during the hotter periods thus increasing the salt concentration (consequently increasing the density) in the UCZ. Thickness growth in the UCZ is not desirable as this reduces the pond’s efficiency. Bittern injection and continuous surface flushing soon rectified this, as shown in Figure 11. Using solar pond data and presenting it in graphs such as Figures 9 and 11, is a good tool in effective solar pond management. CONCLUSIONS The experimental 15 m 2 bittern (MgCl2) commenced operation in August 2002. Pond observations and data have been collected over a period of 10 months. Data collected from this experimental MgCl2 solar pond has been shown that it is possible to establish a solar pond with bittern. The thermal performance of this pond has shown to be quite promising with a yearly average pond efficiency of 9.3% and the ability to provide a solar heat average of 240W. Bittern has also shown the ability to maintain stability at high temperatures as there has been no observed erosion within the LCZ and NCZ interface. Though sodium chloride may be the more common salt used for salinity establishment in solar ponds, magnesium chloride (bittern) is seen to be a viable alternative. The ability of magnesium chloride to generate a stronger and more stable gradient and the added bonus of it being a waste product in the salt production process in salinity stricken areas makes it a more attractive option than sodium chloride. Destination Renewables - ANZSES 2003 Reviewed as full paper 336 © copyright 26 to 29 November The Design, Construction, Operation & Maintenance Chinn et al 2.0 2.0 2002 July 31st 29th July 2002 30th July 2002 1.6 2002 Nov 11th 1.6 2003 March 21st Calculated Profile 1.2 2003 June 9th Pond Height (m) Pond Height (m) 31st July 2002 1.2 0.8 0.8 0.4 0.4 0.0 1000 1050 1100 1150 0.0 1000 1250 Density 1300 (kg/m3 ) 1200 Figure 6 – Progression of gradient profile development 1050 1100 1150 1250 Density 1300 (kg/m3 ) 1200 Figure 7 – History of quarterly density profiles 2.0 1350 2002 July 31st 2002 Nov 11th 1.6 1300 2003 March 19th Maximum Density 1250 Minimum Density Pond Height (m) Pond Height (m) 2003 June 9th 1200 1.2 Bittern Injection 1150 0.8 1100 1050 0.4 1000 0.0 950 0 10 20 30 40 60Temperature 70 ( 0C)80 50 0 Figure 8 – History of quarterly temperature profiles 100 150 200 250 Number 300of Days350 Figure 9 – History of maximum minimum densities showing bittern injection into the LCZ and 2.0 Maximum Temperature Minimum Temperature 80 50 1.8 Ambient Air Temperature 1.6 Summer Period Temperature ( C) 1.4 UCZ 0 Pond Height (m) 60 NCZ 1.2 LCZ 1.0 40 Bittern Injection 0.8 0.6 20 0.4 0.2 0 0.0 0 50 100 150 200 250 300 350 Number of Days 0 Figure 10 – History of maximum and minimum temperatures showing peak temperature in summer period Destination Renewables - ANZSES 2003 Reviewed as full paper 50 100 150 200 250 300Number350 of Days Figure 11 – History of upper and lower interfaces showing bittern injection 337 © copyright 26 to 29 November The Design, Construction, Operation & Maintenance Chinn et al REFERENCES Australian Dryland Salinity Assessment 2000. National Land and Water Resource Audit. Commonwealth of Australia. Akbarzadeh, A., MacDonald, R.W.G., and Wang Y.F. (1983). Reduction of surface mixing in solar ponds by floating rings, Solar Energy, 31 (4), 377–380. Alagao, F. (1994). Closed cycle salt–gradient solar pond, Ph.D. Thesis, Royal Melbourne Institute of Technology University, Victoria, Australia. Hull, J.R., Nielsen, C.E., and Golding, P. (1989). Salinity gradient solar ponds. CRC Press, Inc., Boca Raton, Florida, 153–158. Kishore, V.V.N. and Kumar, A. (1996). Solar pond: An exercise in development in indigenous technology at Kutch, India, Energy for Sustainable Development, 3 (1), 17–28. National Research Council, (1928). International Critical Tables, lst Edition, 3, McGraw –Hill, New York, USA. Tabor, H. and Weinberger, Zvi. (1981), Nonconvecting solar ponds, in Kreider, J.F. and Kreith, F., “Solar Energy Handbook”, Mc–Graw–Hill, Inc., USA, Chapter 10, pp. 1–28. Zangrando, F. (1980). A simple method to establish salt gradient solar ponds, Solar Energy, 25, 467– 470. Zangrando, F. (1991). On the hydrodynamics of salt gradient solar ponds, Solar Energy, 46 (6), 323– 341. Destination Renewables - ANZSES 2003 Reviewed as full paper 338 © copyright 26 to 29 November