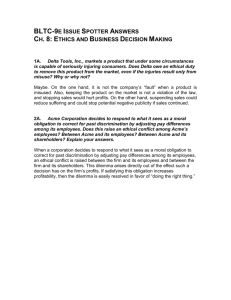

Case Study - Atlantic Paper

advertisement

Case Study Simplifying the Purchasing Process with AMI The go–to supplier for over 600 Southern New England businesses since 1948 The Problem Acme, a seasonal manufacturing company, produces 80% of its product within a five month time period. To manage inventory levels and to keep operations running smoothly during these peak months, the company employs a two-person purchasing team. Despite having a dedicated purchasing staff, the Acme plant was constantly running out of necessary products such as boxes, tape, and protective gloves. Because they purchased neither in advance nor in bulk, they frequently found themselves paying exorbitant fees for overnight shipping and emergency deliveries when they ran out of critical supplies at the last minute. This fire drill approach to their inventory earned Acme a reputation for being high maintenance among some of its suppliers - which meant the company was generally charged a “nuisance tax” in higher overall pricing quotes from suppliers factoring in last minute requests and service fees. The Solution Acme’s Purchasing Team knew they needed to take action to avoid the constant supply shortages. Though they had limited knowledge of vendor management, or Atlantic Paper's exclusive Atlantic Managed Inventory (AMI) program, they were interested in the benefits such a program could bring in terms of cost and inventory stability. To begin the managed inventory journey, the Acme team sat down with a Senior Account Manager and day-to-day Account Representative from Atlantic Paper for an in depth "discovery" session. Specifically, they discussed Acme’s inventory challenges, why they always seemed to run out of critical supplies, and how the AMI program’s practical, hands on management could correct these issues. Case Study Simplifying the Purchasing Process with AMI For the Atlantic Paper team, this initial strategy session is a critical reason their AMI customers save so much in the program. Taking the time to learn about the ins and outs of Acme’s purchase process allowed them to identify inventory gaps that were creating these expensive last-minute orders, and determine other saving opportunities. After vetting the Atlantic Paper team’s know-how, Acme decided to begin a test AMI program, with the initial management covering just those supplies Acme buys on consignment. With the tactics established, the Atlantic Paper team got to work. First, the Account Representative sat down with Acme’s purchasing team. Within days, they reviewed the company’s entire purchase history to establish seasonal inventory levels, distinguishing between peak and off-peak time periods. This meant the company knew how much stock they would need to backlog for each season, and they could avoid storing too much during the hot summer months, while continually running out in the wintertime. With the process planned, the Account Rep began to regularly track Acme’s supply. She made weekly visits to the Acme warehouse to check on the supply levels and established a delivery schedule. According to their plan, when the company entered its slow season, Acme reverted to the off-peak supply levels and Atlantic Paper moved to biweekly visits and deliveries. The Results In short order, the once high maintenance purchasing process at Acme Manufacturing became blissfully predictable. Rather than fire drills, Acme's plant managers benefit from a streamlined process of supply ordering and replenishment. Through the implementation of AMI, emergency shipments and holding costs were eliminated, and cash flow improved dramatically. The company realized the most significant savings during peak-season because there was always enough product on hand to support production and shipping. The Atlantic Paper AMI program improved Acme’s work flow, and helped to maximize production for this cyclical business, ensuring that all their manufacturing resources were dedicated to production during their critical season, rather than wasting time and money running around to back-fill essential supplies.