15th PEWS booklet_2014 FINAL WEB

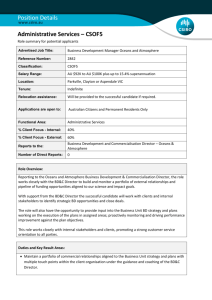

advertisement