joint strength - The Johns Hopkins University Applied Physics

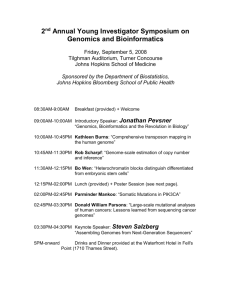

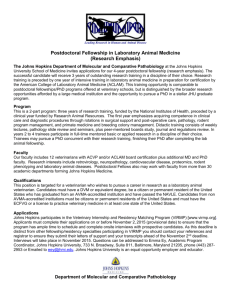

advertisement