CE 337 Maryam Hojati

advertisement

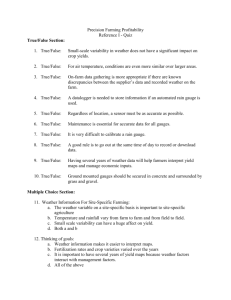

Civil and Environmental Engineering The Pennsylvania State University CE 337 Maryam Hojati Fall 2014 1/69 Introduce your self • Say your name Hello! My Name is…. • What is your year of study in Penn state!!? • Name if you have taken prerequisite courses for this lab • What do you like to learn in this course? • What is your favorite campus activity? 2/69 Break into 6 groups 3/69 CE 337: Civil Engineering Materials Lab Lectures/Labs: TH 2:30pm- 5:30pm Instructor: Maryam Hojati • mzh206@psu.edu Office Hours: • M/TH 1:30 – 2:30pm 4/63 4/69 CE 337: Civil Engineering Materials Lab Office Hours: M/TH 1:30 – 2:30pm Instructor: Maryam Hojati • mzh206@psu.edu Office Hours: • M/TH 1:30 – 2:30pm 5/63 5/69 Lab manual, and other helpful sources 6/69 Course Syllabus Regular Monday schedule Office hour: Monday/Thursday1:30-2:30 (the room above the lab) Lab Manual: Engineering Copy Center, Room 101 Engineering Unit A Attendance is absolutely mandatory. You must notify me within 24 hours of your scheduled lab that you will be absent, and the absence must have a valid excuse Do not bring food and beverages into the laboratory. Dress is to be appropriate for a laboratory. Wear long pants and closed-toed shoes. 7/69 Course Syllabus Before you leave lab Ensure that all waste is disposed properly Return every thing to its original location Team leaders must check out with TA at the end of each session by having their data sheets signed Failure to check out will result in a 10% reduction in the lab grade 8/69 Course Syllabus Weekly quizzes Student should prepare for a 10 min quiz each week Each week quizzes will be handed out at the beginning of lab. Students late to class would not make up the quiz. It is a 10 minutes closed book/note quiz The quiz will cover all of the material related to the experiment you are going to do for each class Make sure take a look at the formulations and graphs in lab manual 9/69 Course Syllabus Lab Report Each group should prepare a professional documents Refer to sample lab report in Angel and check those points Follow the lab report template in Angle ALL reports for this class should be regarded as “formal” one The word version of your lab report must be submitted online at the beginning of the following week In order to make your report more closely resemble an actual formal report and research paper, a lab report template is uploaded in Angel. There will be a 10% deduction for each day a lab report is late. 10/69 Course Syllabus Full-Length Lab Report • • • • • • • • • • • ABSTRACT TABLE OF CONTENTS LIST OF TABLES LIST OF FIGURES INTRODUCTION THEORETICAL BACKGROUND METHODS AND MATERIALS RESULTS AND DISCUSSION CONCLUSIONS AND RECOMMENDATIONS REFERENCES APPENDIX A: RAW DATA 11/69 Course Syllabus Mini Lab Report • • • • • • • • • ABSTRACT TABLE OF CONTENTS LIST OF TABLES LIST OF FIGURES INTRODUCTION RESULTS AND DISCUSSION CONCLUSIONS AND RECOMMENDATIONS REFERENCES APPENDIX A: RAW DATA 12/69 Grading: 13/69 • https://cms.psu.edu/default.asp • Login select CE 337 from “My Courses” tab • We will mostly use “Lessons” tab • Syllabus, lecture handouts, will be posted 14/69 First three exercises will be conducted on a rotating basis : 15/69 Review of Some Topics • Measurement Devices • Material Variability • Excel Skills 16/69 Measurement Devices • Dial Gage • Vernier Caliper • LVDTs • Strain Gauge • Proving Rings 17/69 Dial Gauges Small pointer Purpose: To measure deformation One rotation = 1mm Sensitivity = 0.01 mm Rotates counter clockwise 13 × 0.01 = 0.13 𝑚𝑚 Large pointer Sensitivity 18/69 The Vernier Calipers 19/69 Imperial Scale Open the jaws of the caliper and position them on both sides of the piece you are measuring. Ref: http://www.wikihow.com/Use-a-Vernier-Caliper 20/69 Imperial Scale Lock the clamp screw so that the jaws don't move Ref: http://www.wikihow.com/Use-a-Vernier-Caliper 21/69 Imperial Scale On the vernier scale is a small number 0. Look at how many inch divisions it is past on the bar scale Ref: http://www.wikihow.com/Use-a-Vernier-Caliper 22/69 Imperial Scale See how many smaller (numbered) divisions the small 0 has gone past. This represents how many tenths of an inch the workpiece is measuring in addition to the number of whole inches. Ref: http://www.wikihow.com/Use-a-Vernier-Caliper 23/69 Imperial Scale How many smaller divisions has the small 0 gone past the last numbered division, this number multiplied by 25 is how many hundredths of an inch. Ref: http://www.wikihow.com/Use-a-Vernier-Caliper 24/69 Imperial Scale Determine which division line on the vernier scale best lines up with a division on the bar scale. This is how many thousandths of an inch Ref: http://www.wikihow.com/Use-a-Vernier-Caliper 25/69 Imperial Scale 26/69 Examples: 27/69 Examples: 28/69 Metric Scale: A = 18mm Diameter = 18 + 0.44 = 18.44mm 29/69 Examples 30/69 Examples 31/69 Examples 32/69 LVDTs LVDTs: Linear Variable Differential Transformers/Transducers - An electronic device Used to measure small deformation There are different forms Parts: - Core (attached to a rod) - One Primary Coil - Two Secondary Coils - The relationship between the core position and the output voltage is linear. - the displacement can be determined by measuring the output voltage 33/69 LVDTs Application: An example for the application of LVDTs to measure the vertical deformation of Asphalt Concrete Samples under uniaxial loading in the laboratory. Two LVDTs attached in vertical direction 34/69 Strain Gauges Purpose: To measure Small Deformations within a certain gauge length There are different types of strain gauges but those of the most frequent uses are electrical gauges. Device parts: A foil or wire bonded to a thin base plastic or paper. Measurement basis: When the gauge undergoes strain its electrical resistance changes proportionally. Ranges: A gauge length of 5 mm to 15 mm, but larger gauges may be made for specific applications. 35/69 Proving Rings Purpose: To measure force Device parts: A steel ring with a dial gauge attached to the ring Measurement basis: Apply force to ring Ring Deforms The applied force would be determined Dial gauge measures the deformation Force-Deformation Relationship is known for the Proving ring 36/69 Proving Rings An example for the application of proving rings to measure the stability of Asphalt Concrete Samples in Marshall test Proving Ring 37/69 Material Variability • Engineering materials are inherently variable: • Steel properties (chemical composition and method of manufacturing) • Concrete properties (type and amount of cement, type of aggregate, air content, slump, method of curing, etc.) • Asphalt properties (the type and the amount of binder, aggregate properties and its gradation, amount of compaction, and age.) • Wood properties (the tree species, method of cut, and moisture content) 38/69 Material Variability • The observed variability is the cumulative effect of 3 types of variance: • Inherent variability of the material, • Variance caused by the sampling method, • Variance associated with test method, • The goal is to minimize sampling and testing variance so the true statistical features of the material can be identified. 39/69 Material Variability • Fundamental concepts to the understanding of variability • Precision refers to the variability of repeated measurements under carefully controlled conditions. • Accuracy is the conformity of results to the true value or the absence of bias. • Bias is a tendency of an estimate to deviate in one direction from the true value. 40/69 Material Variability 41/69 Sampling Samples are selected randomly, • All elements of the population have an equal chance for selection. • The sample must be representative of the entire lot. • Statistical parameters describe the material properties: • Mean • Standard deviation • The standard deviation is an inverse measure of precision 42/69 Normal Distribution • A symmetrical function around the mean. • The area under the curve between any two values represents the probability of occurrence of an event of interest. 43/69 Excel Skills 44/69 Plotting a graph 45/69 Insert, scatter, scatter with smooth lines 46/69 Right click, select data 47/69 Write the curve name (for legend), Select x and y values 48/69 49/69 Chart tools, Design (select the graph) 50/69 Showing Data Points: click on the figure, chart tools, change chart type 51/69 Select scatter with smooth lines and markers 52/69 Edit the format of data series: right click on curve, format data series 53/69 Marker options, built-in, change the size and type 54/69 In marker fill , you can changed the color 55/69 Write titles for x and y axes 56/69 Edit the axes: click on the axis, right click, format axis 57/69 Change the maximum, minimum, major unit, minor unit 58/69 59/69 Change the decimals for axes: click on axis, right click, format axis, numbers, change the decimals 60/69 Changing the legend: right click on the curve, select data, 61/69 Select the curve name, edit 62/69 Change the name 63/69 64/69 Change to log scale: right click, format axis 65/69 Select the log scale 66/69 Edit the figure: change the vertical axis crosses position 67/69 Again right click on axis, insert the desirable value 68/69 Deflection versus logarithmic time graph 69/69