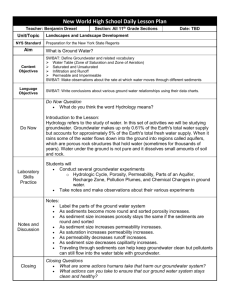

Porosity and Permeability in Sediment Mixtures

advertisement

Porosity and Permeability in Sediment Mixtures by Patrick J. Kamann1, Robert W. Ritzi2, David F. Dominic1, and Caleb M. Conrad1 Abstract Porosity in sediments that contain a mix of coarser- and finer-grained components varies as a function of the porosity and volume fraction of each component. We considered sediment mixtures representing poorly sorted sands and gravely sands. We expanded an existing fractional-packing model for porosity to represent mixtures in which finer grains approach the size of the pores that would exist among the coarser grains alone. The model well represents the porosity measured in laboratory experiments in which grain sizes and volume fractions were systematically changed within sediment mixtures. Permeability values were determined for these sediment mixtures using a model based on grain-size statistics and the expanded fractional-packing porosity model. The permeability model well represents permeability measured in laboratory experiments using air- and water-based permeametry on the model sediment mixtures. Introduction Grain size, shape, and packing are key parameters affecting porosity and permeability in unconsolidated clastic sediment. Our interest is in poorly sorted sands and gravely sands. In idealized sediment comprising uniform spheres with uniform packing, porosity is not a function of grain diameter, but permeability is a function of the square of grain diameter (Hubbert 1940). However, in mixtures of finer and coarser grains, both porosity and permeability are related to grain diameters, volume fractions, and packing arrangements of the components. We begin with a focus on porosity. In the following section, we review prior work, including the fractionalpacking model for porosity in binary sediment mixtures of Koltermann and Gorelick (1995). This empirical model represents mixtures in which finer grains are much smaller than the pore spaces between coarser grains, as might be true in sandy gravels. We derive the model from first principles, and thereby make clear the physical meaning of certain parameters and the underlying assumptions. 1Department of Earth and Environmental Sciences, Wright State University, Dayton, OH 45435 2Corresponding author: Department of Earth and Environmental Sciences, Wright State University, Dayton, OH 45435; (937) 775-3455; robert.ritzi@wright.edu Received October 2006, accepted January 2007. Copyright ª 2007 The Author(s) Journal compilation ª 2007 National Ground Water Association. doi: 10.1111/j.1745-6584.2007.00313.x With that understanding, we extend the Koltermann and Gorelick model to represent mixtures in which the finer grains are similar in size to the spaces between coarser grains, as in poorly sorted sands. We then present the results of laboratory experiments in which porosity was determined in model sediments representing poorly sorted sands and gravely sands, and compare porosity computed with the modified fractional-packing model to the experimental results. Shifting the focus to permeability, we follow the approach of Koltermann and Gorelick (1995) of determining permeability for sediment mixtures by using grainsize statistics, our fractional-packing model for porosity, and a modification of the Kozeny-Carmen equation. We compare permeability computed using this approach to measurements we made with water-based and air-based permeameters. The results collectively illustrate relationships among porosity, permeability, and fractional-packing parameters. Furthermore, the positive comparisions between the models and the experimental data help build further confidence in these approaches for modeling porosity and permeability in sediment mixtures. Sediment Mixtures and Fractional-Packing Models for Porosity Particle-packing studies, as summarized by Koltermann and Gorelick (1995), have led to the following Vol. 45, No. 4—GROUND WATER—July–August 2007 (pages 429–438) 429 knowledge about porosity in sediment mixtures: (1) the porosity of a sediment mixture of two components is determined by the size ratio and the percentage of each component; (2) the porosity of a sediment mixture is less than a linear combination of the porosity of the mixture components; (3) the average grain diameter does not determine porosity; (4) a porosity minimum occurs when the volume of the finer-grained component equals the pore volume of the coarser-grained component and the finer grains completely fill the pore space between the coarser, supporting grains; and (5) porosity values decrease when mixtures of sediments are compacted (see also Paxton et al. 2002). Koltermann and Gorelick (1995) considered the case in which the finer-grained component has a diameter much smaller than the spaces among the coarser-grained component, as illustrated in Figure 1. In this case, Clarke (1979) identified two types of ideal packing. In ideal coarse packing, the percentage of finer grains is less than the porosity of the coarser grains taken alone and groups of finer grains reside within the pore spaces among the self-supported, coarser grains. Thus, the volume of the mixture is equal to the volume of the coarser-grained component. Each group of finer grains retains the porosity of the premixed, finer-grained sediment. In the second type, ideal fine packing, finer grains are self-supported and coarser grains are suspended throughout the finergrained matrix. Here, the volume of pore space that would exist in the coarser-grained component alone is lost. Note that in either type of packing, the volume of the mixture is less than the sum of the volumes of the two components before mixing them. Here, we define parameters that are used to derive the ideal packing models from first principles, and that are further used to explore and expand the Koltermann and Gorelick (1995) model. The total volume of the mixture is VM and the total volume of voids within the mixture is VVM. The volume of the premixed coarser component is VC, and VVC and VSC are the volumes of the voids and solids, respectively, within it. The volume of the premixed finer component is VF, and VVF and VSF are the volumes of voids and solids, respectively, within it. In ideal coarse packing, VM is assumed to equal VC, corresponding to the ideal that the mixture is supported by contacts among the coarser grains and the finergrained component occurs entirely within the pore spaces created by the coarser grains. Accordingly, the composite porosity, /, is determined by how much VVC is reduced by VSF. Thus, /¼ VVM ðVVC 2 VSFÞ ¼ ; VF , VVC; VM ¼ VC VM VM ð1Þ Note that: ðVVC 2 VSFÞ VVC VF VSF ¼ 2 ; VM VC VM VF VF , VVC; VM ¼ VC ð2Þ where VVC/VC is the porosity of the premixed, coarsergrained component, /c. The coarse packing model also assumes that each group of finer grains residing within coarse pores retains the original packing arrangement and has the same internal porosity that existed in the finergrained component before mixing. Therefore, VSF/VF = 1 2 /f, where /f is the porosity of the premixed finergrained component. We define rf as VF/VM, the ratio of the premixed volume of the finer-grained component to the postmixed volume of the sediment. (We use this symbol instead of Koltermann and Gorelick’s symbol c to avoid confusion with references to the coarser component.) Using these symbols, Equation 2 can be written as: / ¼ /c 2 rf ð1 2 /f Þ; rf , /c ; VM ¼ VC Figure 1. (A) Conceptual illustration of ideal packing. In ideal coarse packing, groups of finer grains fit within pore space between coarser grains. In ideal fine packing, individual coarser grains are supported within a matrix of finer grains. (B) Variation in porosity as a function of the finergrained content. (C) Variation in permeability as a function of the finer-grained content (modified from Koltermann and Gorelick 1995). 430 P.J. Kamann et al. GROUND WATER 45, no. 4: 429–438 ð3Þ Figure 1B shows that as rf increases, / reduces toward a minimum, /min, which occurs when VF = VVC so that the finer-grained component exactly fills all pores within the coarser-grained component. Substituting VF for VVC and VC for VM in Equation 2 and rearranging gives: VF VSF /¼ 12 ð4Þ VC VF and back substitution of VVC for VF gives: /¼ VVC VVF ; VC VF VF ¼ VVC; VM ¼ VC: ð5Þ Thus, at its minimum, the composite porosity is equal to the product of the porosities of each component, /min ¼ /c /f ; rf ¼ /c ; VM ¼ VC ð6Þ In ideal fine packing, the coarser grains are dispersed and each is supported by a matrix of finer grains. Accordingly, the void spaces of the premixed coarser component are not preserved in the composite mixture and the mixed total volume is given by: VM ¼ VF 1 VSC; ð7Þ VF > VVC Because the pore spaces of the composite mixture exist only within the finer-grained component, the porosity is as follows: /¼ VVF ; ðVF 1 VSCÞ ð8Þ VF > VVC and because 1/(VF 1 VSC) = 1/VM = rf/VF: / ¼ rf / f ; rf > /c ; VM ¼ VF 1 VSC both packing types may be present, especially for rf in the middle of its range (Clarke 1979). Koltermann and Gorelick (1995) presented a fractional-packing model (Koltermann and Gorelick model hereinafter), which fits experimental data much better than the ideal model because it represents the existence of both. The model is defined piecewise over rf: / ¼ /c 2 rf yð1 2 /f Þ 1 ð1 2 yÞrf /f ; / ¼ /c ð1 2 yÞ 1 rf /f ; 0.7 rf /c ð11Þ The equations are constructed with a weighting parameter, y, such that the value of porosity for ideal coarse and fine packing are returned when y = 1. The y is empirically defined as a piecewise-linear triangle function: ymin 2 1 y ¼ rf ð12Þ 1 1; rf , /c /c ð9Þ Equations 3, 6, and 9 show how porosity varies with rf under ideal packing. Together, they can be considered the ideal packing model. The ideal packing model underpredicts porosity of sediment mixtures (Koltermann and Gorelick 1995). The greatest underprediction occurs at the porosity minimum. This is shown in results presented in Figure 2 and also in results from other experiments on sediments made of uniform spheres and of angular grains (Furnas 1929; McGeary 1961; Shakoor and Cook 1990). This underprediction results from the assumption that only one type of packing occurs at each value of rf, whereas in reality, rf , /c ð10Þ y ¼ ðrf 2 1Þ 1 2 ymin 1 1; 1 2 /c rf > /c ð13Þ which varies with rf, from 1 at each endmember (rf = 0,1) to ymin at rf = /c (corresponding to /min). The physical meaning of y will become clearer subsequently. In practice, the model is defined experimentally by determining the parameters /c, /f, /min, and then computing ymin as follows: ymin ¼ 1 1 /f 2 /min /c ð14Þ The Koltermann and Gorelick model is plotted in Figure 2. It matches the porosity data for sediment mixtures better than the ideal model. 0.6 Fractional Packing Model Porosity 0.5 Deriving the Koltermann and Gorelick Model from First Principles and Extending It 0.4 0.3 Ideal Packing Model 0.2 0.1 0 0 0.2 0.4 0.6 0.8 1.0 Clay Content by Weight Figure 2. Comparison of porosities computed with the Koltermann and Gorelick and the ideal packing models to experimental data. The fraction of the finer-grained component, in this case clay, was quantified by weight instead of by volume. Clay content by weight can be related to rf via Equations 2a and 2b in Koltermann and Gorelick (1995). The dashed curves represent porosity computed with the ideal packing model. The ideal model captures some of the features of the data, such as the porosity minimum. However, it systematically underpredicts porosities. The solid curves represent porosity computed with the Koltermann and Gorelick model. Source: Koltermann and Gorelick (1995). The empirical Koltermann and Gorelick model is based on the premise that a mixture contains both regions with coarse packing (type A regions) and regions with fine packing (type B regions). Equations 10 and 11 of the model can be derived by carefully defining all the components of volume within these regions of such a mixture, writing the exact equation for the mixture, and then examining what approximations and corresponding assumptions are needed to derive Equations 10 and 11 from the exact equation. Doing so allows us to clarify the physical meaning of certain parameters in the Koltermann and Gorelick model, to identify underlying assumptions, and, importantly, to extend the model. The total volume of type A regions is VA. Within type A regions, the total volume of the coarser-grained component is VCA, and this component has a volume of voids (before consideration of finer grains occupying them) of VVCA. Furthermore, within type A regions, the total volume of the finer-grained component is VFA, and this component has a volume of voids of VVFA and P.J. Kamann et al. GROUND WATER 45, no. 4: 429–438 431 a volume of solids of VSFA. The total volume of type B regions is VB. Within type B regions, the total volume of the finer-grained component is VFB, the total volume of voids of the finer-grained component is VVFB, and the volume of solid coarser grains is VSCB. Because type B regions have fine packing with each coarser grain individually supported in a finer-grained matrix, VB = VFB 1 VSCB. For mixtures with both types of regions, the porosity is exactly given by: /¼ VVCA 2 VSFA VA VVFB VB 1 ð15Þ VA VM VFB 1 VSCB VM Equation 10, applicable when rf < /c, can be derived from Equation 15. This is done by expanding Equation 15 as three terms: VVCA VA VSFA VA /¼ 2 VA VM VA VM VVFB VFB 1 VSCB 1 ð16Þ VFB 1 VSCB VM and then making assumptions to achieve equivalency between each of these terms and each of the three respective terms of Equation 10. The first term of Equation 10 is derived by assuming that though region B exists, its volume is small enough so that VA/VM ’ 1. The first term in Equation 16 then becomes VVCA/VA, which equals VVCA/VCA because all fines are within pores of the coarser component, which, in turn, is /c. The second term of Equation 10 is derived by rewriting the second term of Equation 16 in the following steps: VSFA VA VFA VVFA VFA VA ¼ 2 VA VM VFA VFA VA VM ¼ ð1 2 /f Þ VF VFA ¼ ð1 2 /f Þrf y VM VF ð17Þ It is clear that y represents VFA/VF, the volume fraction of the finer-grained component that exists within region A, when rf < /c. The third term in Equation 10 is derived by assuming that VSCB is very small and therefore can be neglected. In that case, the third term of Equation 16 can be rewritten as follows: VVFB VFB VFB VF ¼ /f ¼ /f ð1 2 yÞrf VFB VM VF VM ð18Þ Thus, to derive Equation 10 from exact considerations of volume, it must be assumed that VA/VM ’ 1 and VSCB ’ 0. When rf > /c, the Koltermann and Gorelick model is given by Equation 11, which has two terms. Each of these terms is an approximation of each of the respective two terms of Equation 15. The first term of Equation 15 is approximated as follows: VVCA 2 VSFA VA VVC ’ ð1 2 yÞ VA VM VC ð19Þ and the second term is approximated as follows: 432 P.J. Kamann et al. GROUND WATER 45, no. 4: 429–438 VVFB VB VF VVF ’ ¼ rf / f VFB 1 VSCB VM VM VF ð20Þ Making these approximations requires assuming that VSFA and VSCB are both negligible, that VA = VC, that VB = VF and accordingly VFB = VF, and that VM = VF 1 VC, as is true when the components are unmixed. It also requires that y represent a different physical attribute over rf > /c in Equation 11 than it represents over rf < /c in Equation 10. It is apparent through these comparisons that in Equation 11, y is equal to 1 2 VA/VM, which is equal to VB/VM, which, under these approximations, is equal to VF/VM, which is, in turn, equal to rf. Thus, in Equation 11, rf and y are the same, and the rf and (1 2 y) terms are weights that add to unity (which are not true for Equation 10). The piecewise-linear function Koltermann and Gorelick used for y over rf < /c in Equation 12, representing VFA/VF, cannot be defined from first principles following the aforementioned methods because there is no basis for defining what volume fraction of the finer-grained component should reside in type A or type B regions. However, the function explains the results in Figure 2 fairly well and thus serves as a good empirical model. To summarize, the Koltermann and Gorelick model is conceptually based on the idea that different types of packing (type A and type B regions) can occur within a sediment mixture. It contains empirically structured equations. To define the model for a specific sediment mixture, one must know the porosity of each of the premixed components and the minimum porosity that would occur among possible rf. Considering Poorly Sorted Sands The ideal packing model and the Koltermann and Gorelick model both assume that the diameter of the finer grains, df, is much smaller than the size of pore spaces between the coarser grains, dcp, and thus that in type A regions, many finer grains are able to fit within each pore space between coarser grains. This assumption cannot be made for many natural sediments. For example, spheres with a diameter, d, of 0.385 mm (equivalent to medium sand used below) in perfect cubic packing can contain a spherical grain as large as 0.414d, or 0.159 mm in diameter (Kamann 2004). Let dcp represent the size of the largest such sphere to fit within the pore space between coarser grains. If fine sand spheres with a diameter greater than 0.159 mm are mixed with this medium sand, a single fine sand grain could not fit within an undisturbed pore between medium sand grains. Clearly an aggregate of fine sand grains, with their original pore space intact, could not fit within such a pore space either. We noticed in some early work that the Koltermann and Gorelick model did not represent mixtures very well if the diameter of the finer grains, df, was as large as or larger than dcp. Furthermore, the minimum porosity in such mixtures did not occur where rf = /c (as shown in Figure 3). Equation 10 is a function of rf and y, and Equation 12 shows rf is also a function of y. When Equation 12 is substituted in Equation 10, it is clear that porosity is a parabolic function of rf. The first and second derivatives of the parabolic function show it will have a minimum at 21 rf ¼ 0:5/c ð/f 2 1Þð/f 2/min /21 c Þ . As shown in Figure 3, if this minimum occurs at rf < /c, the polynomial can swing down to a spurious minimum, below what is specified for /min in Equation 14. Thus, we sought a fractional-packing model that better represented these mixtures and that did not have a parabolic formulation. Our approach to developing an alternate fractionalpacking model is still conceptually based on the idea that multiple types of packing can occur within a sediment mixture. When rf < /c and df > dcp, then ideal coarse packing cannot occur because each finer grain mixed into the coarser component causes separation of the surrounding coarser grains. The packing of coarser grains will be disturbed. In this case, and also when df ’ dcp, the void space of the premixed finer-grained component is largely lost. We will refer to such cases as disturbed coarse packing. We allow that there may be a number of region types possible in a mixture: regions with (1) ideal coarse packing or (2) disturbed coarse packing, and regions with (3) ideal fine packing, (4) coarser grains only, and (5) finer grains only. There is no way to define the relative volumes of each region type a priori from physical first principles. However, it again seems reasonable to assume, as Koltermann and Gorelick did, that the most significant departure from ideal packing porosity will occur when rf has intermediate values, and the least departure will be at extreme values of rf, where the sediment is virtually of one component. A triangle function is used as in the Koltermann and Gorelick model, as follows. First, n is defined as the premixed volume of finer grains per premixed volume of sediment, VF/(VC 1 VF). If the components were combined but not mixed (so that regions of finer and coarser grains were entirely segregated), then rf = n. If the sediment is stirred, then regions of types (1) to (3) can occur and, consequently, the volume of the mixture reduces and rf becomes greater than n. We define rv as a ratio rv ¼ rvmax 2 1 rv ¼ n 1 1; n/min rv ¼ Modified Model /c 2 /min rf / ¼ /c 2 ; n/min rv Porosity n¼ 0.4 ð23Þ where n/min is the premixed volume fraction of fines at which /min occurs. A piecewise-linear fractional-packing model for porosity is then posed as follows: 0.3 0.2 n n/min ð22Þ rf 21 ; rv n n/min n n/min ð24Þ ð25Þ To define the model for a specific sediment mixture, one must experimentally know /c, /f, and /min, just as in the Koltermann and Gorelick model. The rvmax is computed from the VC, VF, and VM at which /min occurs. When df ’ dcp and /c ’ /f, then /min occurs where n ’ /c, rather than at rf ’ /c as in the Koltermann and Gorelick model. We can understand this from physical first principles starting with: Mean Porosity 0 n n/min rvmax 2 1 ð1 2 nÞ 1 1; 1 2 n/min / 2 /min / ¼ /f 1 f 1 2 n/min K&G Model ð21Þ To relate this expression to the triangle weighting function, y, in the Koltermann and Gorelick model, recall that y equals unity under ideal coarse packing. The amount that y departs below unity represents the degree of nonideal packing. The greatest departure below unity is at ymin. In a similar vein, under ideal coarse packing, rv will equal (VF 1 VC)/VC, which is at a maximum when VF = VVC (Equation 5). The amount that rv actually departs below this value represents the degree of nonideal packing. The greatest departure below this value is at rvmax. Accordingly, we define the following triangle function for rv: 0.4 rf VC 1 VF ¼ VM n 0.6 0.8 1 rf Figure 3. Comparison of fractional-packing models to porosities of mixtures of fine and medium sand. The mean porosity determined in the laboratory among replicate mixtures is plotted with bars representing 62 standard deviations. The parameters used in the models are the mean values from the experiments, with /c = 0.407, /f = 0.411, /min = 0.328 at rf = 0.407 in the Koltermann and Gorelick (K&G) model, and /min = 0.328 at n = 0.410 in the modified model. VF VVF 1 VSF ¼ VF 1 VC VF 1 VC ð26Þ Consider the case where each pore among coarser grains is large enough to accommodate approximately one finer grain. Therefore, /min should occur when a finer grain obstructs every pore among coarser grains (VSF ’ VVC). Thus: n¼ VVF 1 VVC VVF VF VVC VC ¼ 1 VF 1 VC VF VF 1 VC VC VF 1 VC ð27Þ P.J. Kamann et al. GROUND WATER 45, no. 4: 429–438 433 Furthermore, if /c ’ /f, Equation 27 can be rewritten as follows: n¼ VVC VF VVC VC 1 VC VF 1 VC VC VF 1 VC ð28Þ Thus, VVC VF VC 1 n¼ ¼ /c VC VF 1 VC VF 1 VC ð29Þ Experiments Measuring Porosity in Sediment Mixtures We combined grains from two different size categories (pairing from among four categories: fine sand, medium sand, coarse sand, and pebbles) to create binary sediment mixtures as simple models for poorly sorted sands and sandy gravels. So that grains were fairly uniform and spherical in each size category, glass sandblasting beads were used for the sand-sized components and marbles were used for the pebble-sized component. The sand blasting beads were obtained as presorted fine, medium, and coarse sand. These beads were further sorted in the laboratory with sieves. Our model fine sand was restricted to those grains retained between sieves with 0.148 and 0.177 mm openings, medium sand between sieves with 0.350 and 0.420 mm openings, and coarse sand between sieves with 0.590 and 0.710 mm openings. The marbles representing the pebble size category were already uniform in size with a diameter of 10 mm. Table 1a compares the grain diameters to the approximate ‘‘spherical’’ pore sizes under cubic packing (largest pore sizes) for the sediments used. In the mixtures with only sands, df is approximately equal to dcp. Thus, disturbed coarse packing will occur. Samples were created for each endmember category and for mixtures of two categories. The categories can be paired in six combinations (Table 1b). Samples were created for each mixture combination with n differing by 10% increments, spanning the range between 0% and 100%. Additional mixtures were created with n at 25% and 75%, and with n = /c. Each sample was created with 100 mL of premixed sediment (VF 1 VC). To create a sample, the appropriate volume of each component was measured in graduated cylinders. These components were added together in a larger container and stirred with a rod 15 cm long and 0.05 cm in diameter until they were thoroughly mixed (see Conrad [2006] for experiments on mixing time required to achieve a homogenous mixure). After the sediments were mixed, they were then poured into a graduated cylinder and VM was recorded. To measure /, water was added to the mixture within a graduated cylinder. To avoid trapped air bubbles, the graduated cylinders were tilted as water was slowly poured in. This allowed the water to flow down one side of the glass to the bottom of the graduated cylinder and force out air in pore space above it. The volume required to saturate the sediment mixture was recorded as the volume of void space within the sediment, and / was computed as VV/VM. This procedure for creating a sample and measuring / was repeated three times for each n. Additional detail on the procedure and results of these experiments is given in Kamann (2004). The average / was 41.1% for fine sand, 40.7% for medium sand, 39.0% for coarse sand, and 40.7% for pebbles. Each value is plotted in Figure 4 as endmembers, with bars indicating two standard deviations. Note that all four grain categories had / that were close among repeated measures, close among categories, and closer to the theoretical / for spherical grains in cubic packing (47.65%), than in rhombohedral packing (25.95%). The mean of the percent volume reductions from VC 1 VF to VM in each sediment mixture is given in Kamann (2004). The pebble mixtures had the greatest reductions, typically 10% to 30%. The greatest volume reduction generally occurred at the /min. In Figure 4, the / measurements are plotted with the modified fractional-packing porosity model given in Equations 24 through 25. The average measured /min for mixtures containing pebbles is close to the ideal packing model. The greatest departure from the ideal model occurred in the medium and coarse sand mixture where average measured /min is 36.2% and the ideal /min is 15.9%. The model compares well to laboratory porosity measurements. However, the model deviates from measurements in mixtures of fine sand and pebbles and medium sand and pebbles. Here, the model tends to overpredict measured porosity when rf > /c just as the Koltermann and Gorelick model does in Figure 2. The linear interpolations in Equations 12 through 13 (Koltermann and Gorelick model) and Equations 22 Table 1a Table 1b Sizes of Grains and ‘‘Spherical’’ Pore Spaces Under Cubic Packing Median Grain Diameter (mm) Pebbles Coarse sand Medium sand Fine sand 434 10 0.650 0.385 0.163 df/dcp for Various Mixtures Coarser Component dcp (mm) 4.142 0.269 0.159 0.068 P.J. Kamann et al. GROUND WATER 45, no. 4: 429–438 Finer Component Fine sand Medium sand Coarse sand Medium Sand Coarse Sand 1.025 — — 0.606 1.431 — Pebbles 0.039 0.093 0.157 Figure 4. Comparison of porosities computed with the expanded fractional-packing model to experimentally determined porosities. For the experimental data, the mean is plotted with bars representing two standard deviations. through 23 (new model) do not capture all aspects of fractional packing when df dcp . Permeability in Sediment Mixtures k¼ Method Based on Grain-Size Statistics Hubbert (1940) showed that for spherical grains of uniform diameter, permeability is proportional to the square of grain diameter: k ¼ vd 2 ð30Þ where v is a proportionality coefficient (dimensionless). Kozeny (1927) and Carman (1937) related v to porosity and took median grain size, dm, as representative in sediments with nonuniform grains giving: k¼ 2 dm /3 180 ð12/Þ2 and Gorelick (1995) modified the Kozeny-Carman equation to consider the fractional packing of grains in sediment mixtures: ð31Þ The use of dm works best in sediment that is well sorted. To better represent sediment mixtures, Koltermann 2 3 dfp /fp 180ð12/fp Þ2 ð32Þ where dfp is the representative grain diameter, dependent on fractional packing, and /fp is the porosity of the sediment mixture calculated with the fractional-packing model. Koltermann and Gorelick (1995) found that in sediment mixtures with rf < /c, the geometric mean of grain diameter works well for dfp; with rf > /c, the geometric mean causes overprediction of k, but the harmonic mean of grain diameter works well for dfp. Figure 1C illustrates how k predicted by the Koltermann and Gorelick model changes with change in the percentage of finer grains. As rf increases from 0 toward that at which a porosity minimum occurs, k decreases slightly from that of the coarser-grained component, kc. As rf nears that of the porosity minimum, k sharply decreases toward kmin. As rf increases past that of the P.J. Kamann et al. GROUND WATER 45, no. 4: 429–438 435 porosity minimum, k gradually increases to that of finer grains, kf, at rf = 1. Using Equation 32, k was computed for each of the six sediment mixtures with rf ranging from 0 to 1. For these computations, /fp was computed with Equations 24 and 25. Based on the findings of Koltermann and Gorelick (1995), for pebble mixtures, the geometric mean of median grain diameters for each component (Table 1a) was used to calculate dfp when rf < /c, and the harmonic mean of grain diameters was used when rf /c. For mixtures without pebbles, the geometric mean of the median grain diameters was used to calculate dfp when n < /c, and the harmonic mean of grain diameters was used when n /c. The computed k for each grain mixture is plotted against rf in Figure 5. Experimental Determination of Permeability Permeability was measured using both air- and waterbased methods. Samples were loaded into a constant-head permeameter tube 31.3 cm long and 8.3 cm in diameter with two manometer tubes spaced 15.3 cm apart along its axis. Air permeameter measurements were collected as the constant-head permeameter tube was filled. This was done by closing one end with a cap and glass-wool filter packing, securing the tube with the long axis vertical and capped end on bottom, and filling it with premixed sediment at 5 cm increments for a total of six increments. At each increment, an air permeameter measurement, a, was made at three locations on the sediment surface, and at each location, three measurements were taken. The air permeameter tip seal had an inside diameter of 4 mm and an outside diameter of 26 mm. More details on the compressed-air permeameter instrument and a model used to correct for non-Darcian flow and other effects are given in Conrad (2006). After the measurements were completed on an increment, the next increment of sediment was added and the process was repeated until the tube was filled. This resulted in a total of 54 measurements with the air permeameter on the entire column of sediment. The geometric mean of the nine measurements for each increment was computed. To determine the average k of the entire sediment column, the harmonic mean of the geometric means from each increment was calculated giving Æaæ, the air-based measure for a column of sediment. Figure 5. Comparison of permeability computed with the expanded fractional-packing model (Equations 24, 25, and 32) to air- and water-based experimental measurements. Note that the scales of the ordinate axes for (A) to (C) differ from those for (D) to (F). There are three x and Æaæ values plotted at each rf. This cannot be discerned in all the plots because, in most cases, the three values varied only slightly. 436 P.J. Kamann et al. GROUND WATER 45, no. 4: 429–438 When the permeameter tube was filled, the top was packed with glass-wool and sealed with a cap. It was then clamped in place and connected to a system of hoses that provided for water flow into one end, discharge from the other end, and head measurements from the manometers. Reynold’s numbers during water flow were well within the Darcian regime (Conrad 2006). We measured head in each manometer of the permeameter to within 0.001 m, measured flow rate to within 0.001 m3/s, and measured water temperature to within 0.1C. These measurements and tables giving q and l as a function of temperature were then used to compute k with Darcy’s law, giving a water-based measurement, x. Each time the permeameter was filled, these water-based measurements were repeated three times under different gradients, giving three x values. The mean of these values was computed, giving x, the water-based measure for a column of sediment. After completing the air- and water-based measurements on a sediment column, the sediment was emptied from the tube and dried. The procedures for filling the permeameter tube and taking air- and water-based measurements were then followed again using the dried sediment, giving a total of three air-based and three waterbased determinations of k for each sediment mixture. Using these procedures, permeability was determined using sediment samples representing each of the four grain-size categories, and samples representing the six combinations of any two categories. Generally, sediment samples were created representing each combination with n varied to represent a percentage of finer grains that was below, around, and above /c (e.g., 0.25, 0.35, 0.40, 0.75). However, in combinations that include pebbles, when n < /c, the finer grains do not remain evenly dispersed in the mixture but settle to create a layer where they completely fill the pores among the coarser grains, overlain by a layer where they are mostly absent. Because it was not possible to maintain uniformity in these combinations when n < /c, they were not tested. Furthermore, the 100% pebble sediment has permeability above the measurement range of the air-based permeameter (the compressed air backpressure is not measurably different from ambient air pressure) and the water-based permeameter (a difference in head is not measurable across the manometers). Thus, the experiments were limited to gravely sands and poorly sorted sands. Different instruments would be required for the determination of the permeability of the pebbles. permeability values for the calculation. The lines in Figure 5 representing the permeability model are computed using only the median grain size of the endmembers and the expanded fractional-packing model for porosity. Thus, the model lines and the experimental permeability data presented in Figure 5 are completely independent of each other over the full range of rf. The differences between the model and the experimental results are viewed as generally small, and the model is judged to represent the permeability of the sediment well. Discussion The expanded fractional-packing model for / generally compared well to the / measurements among all sediment mixtures. The results represented cases in which df/dcp is approximately 0.04, 0.10, 0.15, 0.6, 1.0, and 1.4. The original Koltermann and Gorelick model represents only the first three of these. Use of the expanded model does not require knowledge of df/dcp and can be used in all cases. When k values are determined from the modified Kozeny-Carmen model, which uses the expanded fractional-packing model for /, they correspond closely to airand water-based k measurements among the sediment mixtures we examined. The results increase confidence in determining k using a method based on grain-size statistics. All sediments used in these experiments consisted of highly spherical glass beads, and sediment mixtures were of bimodal, nearly binary, grain sizes. These sediments provide an approximation of natural sands and gravely sands. However, grains in natural deposits have more angularity and a more complex distribution of grain sizes. Nevertheless, the sediment mixtures used in these experiments did contain complex packing arrangements, which likely included finer grains filling pores of coarser grains (ideal coarse packing), single finer grains occupying expanded space between coarser grains (disturbed coarse packing), coarser grains occupying expanded space between finer grains, and regions of only coarser grains and of only finer grains. This conceptual framework for packing arrangements seems generally applicable to angular grains that are either much smaller than or close to the size of pores within the coarser-grained component. Conclusions Results The experimentally determined permeabilities are plotted in Figure 5 together with permeability computed with Equation 32 and the expanded fractional-packing model. Note that there is an important difference between this figure, which compares measured and modeled permeability, and Figure 4, which compares measured and modeled porosities. The fractional-packing model for porosity required using the endmember and minimum porosities to compute porosity. However, the model for permeability (Equation 32) does not require knowing any In this research, we expanded on work by Koltermann and Gorelick (1995) and examined how porosity and permeability are related to attributes characterizing sediment mixtures. We measured porosity and permeability in model sediment mixtures, while systematically varying grain sizes and proportions of size fractions. While Koltermann and Gorelick (1995) considered mixtures in which the finer grains are much smaller than the pore spaces between coarser grains, we also considered mixtures in which the finer grains are not. Furthermore, we experimentally measured permeability using air- and P.J. Kamann et al. GROUND WATER 45, no. 4: 429–438 437 water-based methods as a basis for evaluating permeability computed using the Koltermann and Gorelick version of the Kozeny-Carmen equation (based on grain-size statistics) with our expanded fractional-packing model for porosity. The analysis of these results has led to the following significant conclusions: 1. The expanded fractional-packing model performed well in representing porosity of the sediment combinations used in these experiments. This model represents porosity in sediments where the diameter of finer grains is much smaller than the diameter of pores among coarser grains, as does the Koltermann and Gorelick (1995) fractionalpacking model. The model also represents porosity in sediments where the diameter of finer grains is approximately equal to the diameter of pores among coarser grains. 2. In sediment mixtures where the diameter of finer grains is approximately equal to the diameter of pores between coarser grains and the porosities of the two components are similar, a porosity minimum occurs when the volume fraction of finer-grained component in the premixed sediment equals the porosity of the coarser-grained component. 3. When permeability values calculated from grain-size statistics account for fractional packing, they correspond closely to experimentally determined permeability measurements among the sediment mixtures we examined. This correspondence indicates that methods based on grainsize statistics give representative results for the permeability of poorly sorted sands and gravely sands. Acknowledgments This research was partly supported by the National Science Foundation under grant NSF-EAR 00-01125. Any opinions, findings and conclusions, or recommendations expressed in this article are those of the authors and do not necessarily reflect those of the National Science Foundation. This research was also partly supported by a Wright State University Research Incentive Grant. This support is gratefully acknowledged. We 438 P.J. Kamann et al. GROUND WATER 45, no. 4: 429–438 appreciate the constructive review comments of Christine Koltermann and two anonymous reviewers. Finally, we thank David Moulton and Daniel Tartakovsky for providing the geometric factor value (via the method of Tartakovsky et al. 2000) for the air permeameter used in these experiments. References Carman, P.C. 1937. Fluid flow through granular beds. Transactions of the Institution of Chemical Engineers 15, 150. Clarke, R.H. 1979. Reservoir properties of conglomerates and conglomeratic sandstones. AAPG Bulletin 63, no. 5: 799–809. Conrad, C.M. 2006. The air-based measurement of permeability in pebbly sands. Masters thesis, Department of Earth and Environmental Sciences, Wright State University, Dayton, Ohio. Furnas, C.C. 1929. Flow of gases through beds of broken solids. United States Bureau of Mines, Bulletin 307, 144. Hubbert, M.K. 1940. The theory of groundwater motion. Journal of Geology 48, 795–944. Kamann, P.J. 2004. Porosity and permeability in sediment mixtures. Masters thesis, Department of Geological Sciences, Wright State University, Dayton, Ohio. Koltermann, C.E., and S.M. Gorelick. 1995. Fractional packing model for hydraulic conductivity derived from sediment mixtures. Water Resources Research 31, no. 12: 3283– 3297. Kozeny, J. 1927. Uber kapillare leitung des wassers in Boden, Sitzungsber. Akademie der Wissenschaften in Wien. Mathematisch-Naturwissenschaftliche Klasse 136, no. 2a: 271–306. McGeary, R.K. 1961. Mechanical packing of spherical particles. Journal of American Ceramic Society 44, no. 10: 513–522. Paxton, S.T., J.O. Szabo, J.M. Ajdukiewicz, and R.E. Klimentidis. 2002. Construction of an intergranular volume compaction curve for evaluating and predicting compaction and porosity loss in rigid-grain sandstone reservoirs. AAPG Bulletin 86, no. 12: 2047–2067. Shakoor, A., and B.D. Cook. 1990. The effect of stone content, size, and shape on the engineering properties of compacted silty clay. Bulletin of the Association of Engineering Geology 27, no. 2: 245–253. Tartakovsky, D.M., J.D. Moulton, and V.A. Zlotnik. 2000. Kinematic structure of minipermeameter flow. Water Resources Research 36, no. 9: 2433–2442.