Cost Allocation and Activity-Based Costing

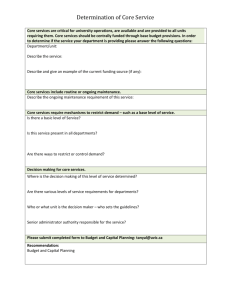

advertisement