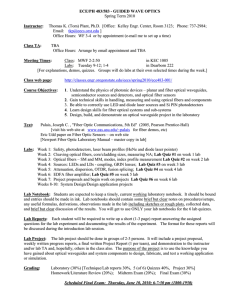

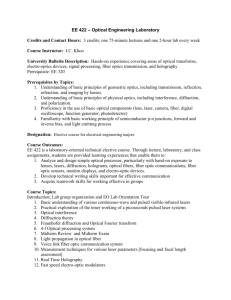

31295002835550 - Institutional Repositories

advertisement

OPTICAL FIBER EXPERIMENTS

FOR UNDERGRADUATE

ENGINEERS

by

DAVID LEO NELSON, B.S. IN E.E.

A THESIS

IN

ELECTRICAL ENGINEERING

Submitted to t h e Graduate F a c u l t y

of Texas Tech U n i v e r s i t y i n

P a r t i a l F u l f i l l m e n t of

the Requirements f o r

t h e Degree of

MASTER OF SCIENCE

IN

ELECTRICAL ENGINEERING

Approved

August 1982

C^ri^ * ^

ACKNOWLEDGEMENTS

I dedicate this work to my wife and companion Juliet Martin Nelson

for her belief in and love for me, and to my daughter Melodee Elisabeth

for providing the impetus to finish.

I would like to thank Dr. Thomas F. Krile for his guidance and interest in my education.

I also thank my colleagues in the Optical Systems

Lab — particularly, Dr. Gary K. Froehlich, Larry M. Baker and Bailey H.

Jones for many helpful conversations, and Fred Finlay and Fernando Bermudez

for important physical assistance.

Thanks are also due Telesforo Delacruz

and Lloyd Gordon who provided the technical assistance necessary for constructing the lab-built equipment.

Special thanks to Don Johnson for do-

ing the lion's share of the work for Chapter 10.

Much of the fiber used in the experiments was provided by Corning

Glass Works through the University Grant Program.

I will state here

that, in the course of these experiments, the gifts were not always

used for the purposes for which they were designed.

Any deficiencies

are, therefore, mine.

To Drs. R. H. Seacat, William M. Portnoy, and T, R, Burkes, thank

you for providing me with a strong sense of purpose and excellent examples.

With appreciation, I acknowledge Drs. John Craig, Truman Lewis

and John Walkup for serving on my committee.

Finally, thanks are due the National Science Foundation which supported the development of the projects under Grant y/SER-8001394.

11

CONTENTS

ACKNOWLEDGEMENTS

ii

ABSTRACT

iy

LIST OF TABLES

v

LIST OF FIGURES

vi

I.

II.

INTRODUCTION

1

MEASUREMENT OF NUMERICAL APERTURE

6

III. MEASUREMENT OF SPECTRAL ATTENUATION

IV.

MEASUREMENT OF FIBER LOSS. . '

19

32

V.

CHARACTERIZATION OF DETECTORS FOR OPTICAL FIBER SYSTEMS. . 45

VI.

CHARACTERIZATION OF SOURCES FOR OPTICAL FIBER SYSTEMS. . . 60

VII.

VIII.

IX.

WAVELENGTH MULTIPLEXING IN AN OPTICAL FIBER

78

OPTICAL LINK DESIGN

96

FIBER PARAMETERS BY SCATTERING MEASUREMENTS

118

X.

AN OPTICAL FIBER ACOUSTIC SENSOR

138

XI.

A HOLOGRAPHIC COUPLER FOR FIBERS

150

CONCLUSION

164

XII.

APPENDICES

I.

169

BEAM LAUNCHER

169

A LAB-BUILT GONIOMETER

172

A LAB-BUILT FIBER CLEAVER

175

A LAB-BUILT PHOTOMULTIPLIER TUBE HOUSING

178

A LAB-BUILT LASER DIODE PULSER

181

A LAB-BUILT FIBER STRETCHER

188

VII.

TRANS IMPEDANCE AMPLIFIERS

190

VIII.

A LAB-BUILT LIGHT CHOPPER

196

II.

III.

IV.

V.

VI.

BIBLIOGRAPHY

199

iii

ABSTRACT

This report describes a set of ten experiments designed to introduce undergraduate engineering students to the area of fiber optics.

The projects include measurement of pertinent parameters of optical

fibers, sources and detectors (the major components of fiber optic

systems), the construction of a simple fiber optic communication link,

the use of an optical fiber as a sensor of acoustic waves, and the making of a holographic optical element to serve as a fiber coupler.

Each

experiment is self-contained with subsections relating to theory and experimental practice. Although the experiments are expressly designed for

a project-type laboratory, it is hoped that they will prove useful in

other situations such as classroom demonstrations. A special effort has

been made to employ equipment which might be expected to be in undergraduate engineering departments.

Appendices cover the construction of

certain useful auxiliary equipment.

IV

LIST OF TABLES

Table

Page

1-1.

Comparison of Communications Cable Types,

2

5-1.

Photodetectors Compared

50

5-2.

Rise-Time Comparison

51

5-3.

Relative Responsivity

53

5-4.

Dark-Current Comparison

7-1.

Some Optical Filters in the IR

8-1.

Power and Loss Relationships

.....

54

88

,

v

9"

LIST OF FIGURES

Figure

Page

2-1. Meridional rays and skew rays in a step-index fiber. "I"

2-2

denotes an intersection with the fiber axis

15

Geometry for calculating the acceptance angle

15

2-3.

Different angles of entrance lead to different path lengths

in the fiber

2-4. Index of refraction versus wavelength. . ,

2-5.

16

16

Equipment setup: a) schematic, b) actual L, laser; C, collimator; BS, beamsplitter; R, reference detector; X, microscope objective for overfilled launch condition; M, fiber

micropositioners; MS, mode stripper; D, detector

17

2-6.

Output pattern for overfilled launch

18

2-7.

Output pattern for underfilled launch

18

3-1. Measured source spectral sensitivity

28

3-2.

Absolute spectral sensitivity of S-1 phosphor

28

3-3.

Calibrated source spectral sensitivity.

29

3-4.

Equipment setup for the measurement of spectral attenuation

CO, collimating optics; PH, pinhole; X, microscope objective;

IF," interference filter and holder; MS, mode stripper; OF

optical fiber ; PMT, photomultiplier

30

3-5.

Relative fiber spectral loss

31

4-1.

Equipment setup

43

4-2.

Loss vs. lateral misalignment

43

4-3.

Loss vs. angular misalignment

44

4-4.

Loss vs. longitudinal misalignment

44

5-1.

Equipment setup for a) rise-time measurement, b) spectral

sensitivity measurement

57

5-2.

S-1 response curve

58

5-3.

"Calibrated" tungsten-halogen source curve

58

vi

5-4.

6-1.

6-2.

Spectral sensitivity curves: a) FPT-100 phototransistor,

b) C-30808 PIN photodiode, c) C-30817 avalanche photodiode

59

Three types of input-coupling loss: a) unintercepted illumination, b) NA mismatch, and c) reflection.

72

Intensity profiles for various values of m. Circles are

drawn for values of m from 1 (Lambertian) to 30

73

6-3.

Equipment setup for measuring intensity vs. drive current. , 73

6-4.

Output current in RCA C-30808 PIN diode vs. drive current in

source. (45V back bias on PIN, 82kJ2 in series.) a) RCA

C-30123 IR-LED, b) RCA SG2001 ILD

74

6-5.

Equipment setup for measuring intensity profile

75

6-6.

Experimentally determined intensity profiles, a) RCA

C-30123 IR-LED, b) RCA SG2001 laser diode

76

Equipment setup for measuring spectral distribution of

sources

77

7-1.

Frequency- or wavelength-division multiplexing

91

7-2.

a) Spectrum of band-limited signal (modulated cosine); b)

spectrum of band-limited signal multiplied by square-pulse

of frequency oj . .'

91

7-3.

An envelope detector

92

7-4.

Equipment setup

92

7-5.

LED driver circuit for both analog and digital inputs. . . .

93

7-6.

Crude wavelength-division multiplexer

93

7-7.

Alternative WDM schemes: a) beamsplitter, b) wavelengthselective mirror

94

6-7.

7-8. Multiplexed output. [Red: 14mV _ , -10 Hz sinusoid; IR:

lOmV

, 120 Hz, square wave]. .^.^

94

P-P

7-9. Demultiplexed IR signal. [10 mV _ , 120 Hz, square wave], , 95

7-10.

8-1.

Transmission characteristics of Kodak Wratten filter No.

47A

Basic transmission system,

L = Loss in dB

Vll

95

HI

8-2.

Alternative formats for digital data, a) non-return-tozero (NRZ); b) return-to-zero (RZ)

2^2

8-3.

Required optical power, a) vs. bit rate for digital

system, b) vs. bandwidth for analog system with APD, and

c) vs. bandwidth for analog system with PIN detector. . . . 113

8-4.

Optical power throughput worksheet. From 12]

114

8-5.

Rise-time analysis worksheet. From I2J

115

8-6.

Electronic schematic for the system

116

8-7.

Transmitted IF signal and detected audio signal. Upper

trace — IF signal; lower trace - audio output

117

9-1.

Setup to observe backscattered light

I33

9-2.

Incident, reflected, refracted, and emergent ray paths. . . 133

9-3.

Rays incident upon fiber, traced for a single internal

reflection

Plot of $ and 6 versus 6 for a fiber of n = 1.5

o

Ray considerations to determine fiber diameter

9-4.

9-5.

9-6.

Cross section of fiber, showing paths of refracted and

reflected rays that leave the fiber at the same scattering

angle 6

-|^^,

134

135

I35

9-7.

Cross section of fiber, showing refracted ray at the angle of incidence that just grazes the core. Bounds for angles 9 and 6

are shown. Dashed ray is cladding ray which leaves at *the same

scattering angle as the core ray

136

9-8.

Composite graph of experimental and theoretical scattering

patterns, a) experimental results, b) fringe position calculated from geometric ray-tracing, and c) calculated fringe

modulation. From [4J

136

9-9.

Backscatter pattern of unclad step-index fiber

I37

9-10.

Backscatter pattern of clad graded-index fiber

137

10-1.

Homodyne acoustic sensor configuration

147

10-2.

a) fringe field at detector showing pinhole position, b)

light intensity vs. distance from pinhole, showing operating

point

'

147

viii

10-3.

Heterodyne acoustic sensor configuration, , , ,

10-4.

Fringe pattern at detector, , . ,

10-5.

Recovered acoustic signal at 1 kHz. , . , ,

I49

10-6.

Recovered signal at "transition" showing instability

149

11-1.

Setup for HOE^ recording. Plane-wave reference. L, laser;

C, collimator; Ml, M2, M3, mirrors; BS, beamsplitter; 0,

object; H, holographic plate, a) schematic, b) actual , . , , 160

11-2.

Schematic setup for HOE playback. Spherical playback, L,

laser; C, collimator; Ml, M3 mirrors; LI, converging lens

of NA equal to fiber which is to be coupled; H, hologram. , . 161

11-3.

Coordinate systems for spherical wave holography,

ing, b) playback, . . , ,

,

11-4.

I43

,,,,,,,

148

a) record161

Geometry used for calculating position of object and the

reference source given the desired positions of the playback

source and the real images, . ,

162

Virtual images of four point sources as played back from the

HOE

-

162

Real images of two of the four point sources obtained upon

playback of the HOE

163

I-l.

A typical beam launcher

171

1-2.

Bent fiber serving as a mode scrambler

171

A lab-built goniometer

174

A lab-built fiber cleaver

177

Components of the PMT housing. From left; base plate with

BNC connectors, pedestal for PMT socket, PMT and magnetic

shield, outer case and top plate with cover

180

The assembled PMT housing

180

V-1.

The discharge circuit

186

V-2.

The charging circuit

186

V-3.

The trigger circuit

187

V-4.

Waveform of the current pulse through the laser diode

(50 nsec/div)

187

11-5.

11-6.

II-l.

III-l.

IV-1.

IV-2.

IX

VI-1.

A lab-built fiber stretcher

189

VII-1.

The simplest photodiode bias circuit

193

VII-2.

Solid-state photodiode equivalent circuit when operating

into low impedance

. 193

VII-3.

The transimpedance amplifiei:

193

VII-4.

VII-5.

Poor front-end amplifier design . . . . . .

...

Better choices for front-end amplifiers using transimpedance techniques. Where two photodiodes are shown,

one of the two is shielded from all light for dark current

compensation

194

195

A lab-built light chopper

198

VIII-1.

X

CHAPTER I

INTRODUCTION

The field of fiber optics is presently experiencing a concentration

of research and application which perhaps has not been seen since the

introduction of the transistor.

The advances in silicon technology in

the electronics industry accelerated the development of low-loss optical

fibers, and communication system applications soon followed.

The elec-

tronics industry also added to the growth of the fiber optics industry

with the production of solid-state sources and detectors especially

tailored to the needs of fiber systems, and progress in fiber optic connectors promises to maintain this growth.

The advantages which optical fiber systems hold over conventional

metallic communication systems, summarized in Table 1-1, assure that

fibers will continue to see new applications [1], This, in turn, suggests that the newly-graduated electrical engineer, whatever his specialization, will inevitably encounter a design problem which is suitably

handled by a fiber system.

Any prior knowledge of such topics as the

vocabulary of fiber optics, requirements for fiber optic system design,

and relative values of parameters for the various components will be

invaluable.

With this in mind, a set of experiments is presented here to permit

undergraduate electrical engineering students to gain experience handling,

evaluating, and using optical fiber and associated sources and detectors.

The report is the fourth in a series sponsored by the National Science

Foundation for the purpose of speeding the transfer of information about

TABLE 1-1.

Characteristic

Comparison of Communications Cable Types

Twisted

Pair

Length-Bandwidth

Product (MHz-km):

1

Repeater Spacing(km) :

1-2

System Cost:

Low, slow

increase in

future

•

System Lifetime

(Years):

20-40

Crosstalk:

Noise immunity:

Electrical

input-output

insulation:

Vibration Tolerance:

Weight, size:

Cable connections:

High

Low

No

Good

High

Soldering,

standard

connectors

Coaxial

Cable

Fiber

Optics

Cable

20

1-2

Medium, slow

increase in

future

400

2-10

High, now.

steep decrease

in future

20-40

1-2, 10-40 in

future

Negligible

High

Low

Medium

No

Good

High

Soldering,

standard

connectors

Complete

Good

Low

Splicing, wellaligned

connectors

new technologies from industry to the universities [2], [3], [4]. An underlying goal in the development of these projects was to provide experiments which can be performed with relatively inexpensive equipment which

might reasonably be expected to be found in university undergraduate

laboratories.

In some cases, specialized equipment was "home-made,"

and construction details are found in the appendices.

The chapters are grouped basically by measurement and application.

Chapters II through IV deal with the measurements of fiber properties

while Chapters V and VI are concerned with the sources and detectors

which are candidates for fiber optic systems.

Chapter VII illustrates

an important property of optical fiber, namely, that many signals can

propagate through a fiber without interference.

Chapter VIII combines

knowledge obtained in the preceding chapters to construct a simple fiber

link.

Chapter IX introduces an elegant measurement technique capable of

determining an optical fiber*s dimensions and index of refraction by

observing the way in which the fiber scatters light incident on its

side.

Chapter X demonstrates the use of an optical fiber as a sensor

for acoustic waves, and Chapter XI relies on Froehlich's work [4] for

the construction of a holographic optical element which can be used as

a multi-fiber coupler.

Even with lab-built equipment, not all types of experiments are

within the reach of undergraduate students.

The most notable experi-

ments absent from this report are those dealing with the measurement of

fiber dispersion, fiber index profiling, single-mode fibers, and optical

time-domain reflectometry — all of which are important current areas of

study.

However, it is hoped that the experiments presented here will

serve to instill an appreciation for the capabilities of fiber optic

systems and to whet the students' appetite for further work.

The experiments are designed to be performed as three-week project

labs in the Electrical Engineering Department at Texas Tech University,

Typically, two students, working as partners, are given the project

assignment plus a few selected references.

They are left very much to

themselves as far as researching the material and deciding how to attack

the problem.

At the end of the three-week period, the students meet with

an appointed faculty advisor who grades them on how well their solution

meets the specifications of the problem statement.

Following this, the

students meet once more with the advisor for an oral examination in which

they are asked about the underlying principles associated with the lab

project and design and measurement details.

They receive a second grade

for this oral examination.

The experiments are adaptable to other formats, and each experiment is self-contained.

The philosophy of having the students research

the required information should, however, be left intact; i.e. this should

not be used as a "cookbook."

Students should be strongly encouraged to

read the references presented at the end of each experiment.

Sample ques-

tions after each experiment represent what might be asked at an oral examination, and may indicate ways in which the experiment might be expanded.

A bibliography is also included for general information.

Reference

[1] Wolf, H. F., editor. Handbook of Fiber Optics, Garland STPM Press,

New York, 1979, p. 8.

[2]

Peckham, L. N., M. 0. Hagler, and M. Kristiansen, "Laser Experiments for Undergraduate Electrical Engineering Students," Technical Report #1, NSF Grant GY-4761, June 1969, Texas Tech University.

[3] Molen, G. M., C. R. Parten, M. 0. Hagler, and M, Kristiansen, "Laser

Experiments for Undergraduate Electrical Engineering Students,"

Technical Report y/2, NSF Grant GY-4761, May 1971, Texas Tech University.

[4]

Froehlich, G. K., J. F. Walkup, and M. 0, Hagler, "Optical Information Processing Experiments for Undergraduate Engineers," Final

Technical Report, NSF Grant SER75-17673, January 1977, Texas Tech

University.

Copies of this report are available from the National

Technical Information Service, Springfield, VA, 22151 Caccession

No. PB 264356).

Chapter II

MEASUREMENT OF NUMERICAL APERTURE

Project Assignment

You are to measure the numerical aperture of two representative

types of optical filler using two techniques. You should take care

that the measurements you make can be repeated with good accuracy.

You may use a laser as the source.

Demonstrate how the measurement

varies with the input launch conditions.

Objectives of the Experiment

1.

To acquaint the student with the characterization of an

optical fiber by measurement of its numerical aperture.

2.

To familiarize the student with the problems of fiber

handling, inputting and extracting light, and different

types of optical fibers.

Equipment Needed

1.

Short (1 meter) length of optical fiber.

2.

Fiber cleaving tool and polishing equipment.

3.

Laser.

4.

Collimating optics.

5.

Assorted focal length lenses.

6.

Two photodetectors and power supply.

7.

Electrometer or digital voltmeter.

8.

Goniometer (see Appendix II).

9.

Simple mode-strippers.

10.

Fiber-optic micropositioners.

Theory

Introduction

The measurement of numerical aperture is probably the most

fundamental and productive measurement which can be performed on

a fiber in terms of the amount of information obtained for the

effort.

It is a first-order measure of the light-acceptance capa-

bility of the fiber, and immediately characterizes the fiber as

single-mode or multi-mode.

The measurement of numerical aperture

(or NA) is analogous to the measurement of the light-gathering

power of an optical system in lens optics [l].

The numerical aperture must be known if the system source

and detector are to be optimally matched to the fiber with respect

to coupling parameters.

It is important to choose a numerical

aperture whose value is an acceptable compromise among the normally

conflicting requirements of large bandwidth, large optical acceptance

angle, and minimum bending loss.

Basic Concepts

In optical waveguides, meridional rays

planes which also contain the waveguide axis.

enter the fiber in

If the fiber is per-

fectly straight and the rays entering are exactly parallel to the

fiber axis, the rays will propagate through the fiber with no deflection (assuming there is also no scattering).

If the fiber is

not straight, or the rays enter the fiber at an angle with respect

to the fiber axis, the rays will follow a wavelike course through

the fiber, due to reflections at (or bending near) the core-cladding

interface.

8

Skew rays describe all rays which do not pass through the fiber

axis.

Rays of this type follow continuous helical paths inside the

fiber core. Meridional rays represent the more important propagation mechanism and are easier to describe [2]. Both types are

shown in Figure 2-1.

Information carried by light in an optical fiber is constrained

to remain in the fiber by the property of total internal reflection.

At the interface of two materials of differing indices of refraction,

say n, and n„, light passing from material 1 at an angle of 6. with

respect to the normal at the interface will travel in material 2

at an angle 9^ with respect to the normal as given by Snell's law:

sin 62 = (n./n2) sin-e^

(2-1)

The maximum value of the angle of incidence 0^ for which a

ray will be totally internally reflected can be derived from Snell's

law and simple trigonometry.

With reference to Figure 2-2,

n^sin BQ = n^sin 6^ = n^cos 0^

= n^ [1 - (sin 0^)^f'^

(2-2)

At the critical acceptance angle 0^^, sin 0^^ = (n2/n^)sin 90 .

Therefore,

NA = n sin6

o

oc

r

,

/

N2n0.5

= n^ [1 - (n2/n^) J

2

2n0.5

= [n^ - nj ]

(2-3)

Notice that light entering the fiber at angles greater than the

critical angle 6^^ are "leaked" into the cladding and later lost

to the environment due to bending of the fiber and imperfections

(scratches, dust, microbends, etc.) on the cladding surface. Although the figure has been drawn for the case of a step-index fiber,

it should be obvious that there is a critical angle associated with

graded-index fibers also.

Strictly speaking, the above holds only for meridional rays

in an ideal fiber.

For this reason, the NA calculated in Equation

(2-3) is often called the nominal !^.

However, skew rays at inci-

dent angles greater than the critical acceptance angle can also be

conducted by fibers of circular cross section.

In practice, one finds that the limiting angle 6

is not as

sharply defined in real fibers as indicated by Equation (2-3).

Diffraction, striae, and irregularities at the core-cladding interface all tend to decollimate the transmitted light and, in so doing,

increase the effective NA.

There is an important connection between numerical aperture

and dispersion, both modal and material [3]. The number of internal

reflections and therefore the total length of the path which the

light travels in a given length of fiber is smaller for smaller

angles of incidence 0 , as in Figure 2-3.

Because the velocity of

light in a material is given by:

V = c/n

,

(2-4)

where n is the refractive index of the material and c is the speed

10

of light in a vacuum, monochromatic rays which are very nearly

parallel to the fiber axis will reach the output end of the fiber

faster than rays which enter the fiber at high angles of incidence.

If the range of angles at which light is allowed to enter the fiber

is very broad (i.e., if the NA is very large), and if the fiber is

very long, the puls^ of light detected at the output will be much

longer than the pulse of light injected at the input due to wavepackets arriving at different times. This is the phenomenon known

as modal dispersion.

It imposes a maximum bandwidth restriction

on the system [4].

For most materials, the refractive index is not a constant

but is a function of the wavelength of light. Hecht and Zajac [5]

have examples for several optical materials; the curves are of the

form given in Figure 2-4.

It is seen from the curves that longer-

wavelength radiation "sees" a smaller refractive index while traveling through the material than shorter-wavelength

tion.

radia-

From Equation (2-4), one infers that longer wavelengths tra-

el faster through this medium than shorter wavelengths.

This gives

another component to pulse-spreading, owing to the fact that no

sources are perfectly spectrally pure but have a spread of wavelengths

present.

This phenomenon is called material dispersion, and of

course the longer the path length, the worse will be the effect.

Because of this, high NA fibers, with the associated longer path

lengths can have larger material dispersion effects than lower M

fibers of the same material.

11

Experimental Procedure and Results

Two techniques are typically used to measure a fiber's numerical

aperture.

The first method specifies overfilling the fiber's input

and uses a white card to allow the spot size to be viewed at the output.

A fiber is said to be "overfilled" when the launching numerical

aperture is larger Chan that of the fiber. This spot size represents

approximately the width of the 90% intensity points. Thus the human

eye is the measuring instrument.

The radius of the spot divided by

the distance of the spot from the end of the fiber will be the tangent of the acceptance-cone half angle.

The second method utilizes the lab-built goniometer (Appendix II).

A PIN detector mounted in an L-shaped bracket is swept around the

fiber's endface in increments of two degrees.

In both methods, the angular extent of the cone of radiation

exiting the fiber is assumed to be the same as the acceptance cone.

The equipment configuration of Figure 2-5 is used. A laser source is

used because of the narrow spectral line width which places less

stringent requirements on the optics. If a broadband source, such as

a tungsten source, were used, special (and expensive) achromatic

optics would be required to ensure that all wavelengths were brought

to a focus at the same place on the fiber endface.

With the fiber overfilled, the curve of Figure 2-6 was obtained.

Narrowing the angle of incident radiation at the fiber output results

in a narrowing of the cone of the detected radiation at the output

and a subsequent lower measurement for numerical aperture, as indicated

in Figure 2-7.

12

Special Problems

It is imperative that some form of mode-stripping be used

to normalize the input launch conditions.

The fiber may be passed

through a pair of large black rubber stoppers with several drops

of glycerin which provides an index-match with the cladding and

strips away light which is present in the cladding.

Alternatively,

the fiber may be pressed between layers of glycerin-soaked black

velvet.

An important phenomenon to observe while performing this

experiment is the dependence of the measurement on the input launch

conditions.

It was specified that the fiber be overfilled, but

what if it is not?

Assuming appropriate mode-stripping, a narrowing

of the input cone of light entering the fiber should result in a

narrowing of the output cone and hence a smaller measured value for

fiber NA.

If mode-stripping is not done, the

high-angle

light modes propagating in the cladding may lead to an erroneous

measurement.

If a beamsplitter setup is not used to simultaneously monitor

the output power of the laser source, power fluctuations in the

source may also obscure the effect.

If a single detector is used,

the intensity readings taken from the photodiode at the output must

be averaged at each angular position to minimize the effects of

power fluctuations.

If the statistics of the laser power fluctua-

tion are known, the readings may be subjected to a weighted averaging

method.

If, for example, the source power fluctuation is known to

be Gaussian, simple averaging is sufficient.

Another problem may appear when the MA of a very long fiber is

13

measured.

If there is a strong tendency for mode coupling in the

fiber, i.e., a tendency for "low-angle" rays to be coupled into

"high-angle" rays by scattering mechanisms or microbending, the

measured NA may be larger than the true value.

In addition, the

output cone may not be noticeably narrower for a corresponding

narrowing of the input excitation angle.

Sample Questions

1.

A phenomenon called "NA-dependent loss" is often referred

to in the literature.

2.

To what does this refer?

How would you automate this measurement for a company

which manufactures optical fibers?

3.

A thin pencil of light of diameter much smaller than the

diameter of the fiber is incident on a fiber endface.

What do you predict will be the output pattern of radiation?

4.

It has been mentioned that some skew rays with angles of

incidence greater than that of the critical acceptance

angle can be transmitted.

This suggests a second critical

acceptance angle for skew rays.

What is the equation for

this angle in terms of the relevant fiber parameters?

References

[l] Smith, Warren J.,"Image Formation:

Geometrical and Physical

Optics", Handbook of Optics, Walter G. Driscoll, Ed., McGrawHill, New York, 1978, p. 2.5.

[2] Wolf, Helmut F.,"Optical Waveguides", Handbook of Fiber Optics.

H. F. Wolf, Ed., Garland STPM Press, New York, 1979, pp. 5^-57.

[3]

Ibid., pp. 59 and 61.

14

[4] Wolf, Helmut F.,"System Aspects", Handbook of Fiber Optics,

H. F. Wolf, Ed., Garland STPM Press, New York, New York, 1979,

pp. 385-386.

r5] Hecht, Eugene and Alfred Zajac, Optics, Addison-Wesley,

Reading, Massachusetts, p. 42.

15

Core

Cladding

Figure 2-1. Meridional (M) and skew (S) rays in a stepindex fiber, "i" denotes an intersection

with the fiber axis.

Figure 2-2. Geometry for calculating the acceptance angle.

16

Figure 2-3. Different angles of entrance lead to

different path lengths in the fiber.

Dense Flint

Glass

1.7

c

o

a

CO

Light Flint

Glass

1.6

u

0)

u

Crystal Quartz

Crown Glass

1.5

Vitreous

Quartz

l."*

20 0

'+00

600

3 00

1000

Wavelength X (nm)

Fi<yure 2-4. Index of refraction versus wavelength.

17

s a

\

CO

/

ia

/

en

1/ S

D

s

CO

A

X

en

pa

ij.

18

100

^s

^1

80

<»

l»

•

CO

c

>

60

1

t

0)

•H

4J

3

40

'

15.4J

3

O

>

u

20

rt

0

1

-10

-8

-6

-4

-2

0

+2

+4

Degrees off-axis

+6

+8

+10

Figure 2-6. Output pattern for overfilled launch.

100

^s

•H

CO

C

QJ

<

80

•= .

60

4-1

<1

a

40

8 4'

4J

<»

o

>

•H

(•

('

-

<

20

yi

4J

rt

0

-10

-8

-6

-4

-2

0

+2

+4

Degrees off-axis

+6

+8

+10

Figure 2-7. Output pattern for underfilled launch,

Chapter III

MEASUREMENT OF SPECTRAL ATTENUATION

Project Assignment

You are to measure the spectral attenuation of an optical fiber

utilizing a photomultiplier tube as your detector. Plot the attenuation in dB/km as a function of optical wavelength.

Be prepared to

discuss the various components of spectral loss.

Objectives of the Experiment

1.

To acquaint the student with loss in optical fibers,

particularly, spectral loss,

2.

To familiarize the student with the experimental procedure for measuring fiber attenuation.

3.

To provide the student with experience in using a

photomultiplier tube.

Equipment Needed

1.

Tungsten-halogen or other "white-light" source.

2.

A set of narrowband interference filters or a monochroma tor .

3.

A long length (approx. 100 meter) of optical fiber.

4.

Photomultiplier tube with an S-1.phosphor and high

negative voltage power supply.

(RCA 7102)

5.

Assorted optical lenses.

6.

Pinhole.

7.

Second photodetector of any type (for reference).

8.

Fiber cutter (see Appendix III).

19

20

9.

Beam splitter.

10.

Two micropositioners.

Theory

Introduction

If optical fibers attenuated light uniformly at all wavelengths,

the need to characterize spectral attenuation would not exist.

How-

ever, fibers do exhibit different losses for light of different wavelengths.

The spectral loss curve will typically show regions of

relatively lower attenuation (measured in dB/km) than others.

For

maximum efficiency, it is desirable to transmit information in the

region of lowest attenuation.

This has not been possible until

relatively recently when diode sources (both laser and LED) were

designed to emit radiation in the far infrared where many fibers

have attenuation minima.

Important also is the consideration that sources do not emit

radiation of one pure wavelength, but in fact, emit radiation in

a region about a central wavelength.

If fiber attenuation is not

uniform for the region of emitted radiation, unnecessary power

losses occur.

Basic Concepts

Spectral loss measurements are useful for showing wavelengthdependent attenuation in optical fibers due to absorption and

scattering.

phenomena:

Spectral loss is known [l] to be composed of three

(1) fundamental material scattering (Rayleigh scatter-

ing), (2) fundamental material absorption by the glass due to elec-

21

tronic transitions (in the UV region) and vibrational energy transitions (in the IR), and (3) impurity absorption due to overtones of

impurity atom vibrations.

Rayleigh scattering (named for Lord Rayleigh, who observed the

scattered flux density to be inversely proportional to the fourth

power of the wavelength) occurs when light scatters from particles

which are small in comparison to the wavelength of the light being

scattered.

In glass, Rayleigh scattering can arise from two separate

effects, density and composition fluctuations, and it tends to dominate the shape of the loss curve.

All transparent matter scatters

light due to fluctuations in the density (and hence, the refractive

index) which result

from fluctuations in temperature.

Glass differs

in that these fluctuations are "frozen-in" when the glass is cooled

in the annealing process.

The attenuation coefficient (base e)

which characterizes the scattering loss is called the turbidity [2].

A second major source of loss is material absorption.

The in-

dividual atoms of the optical material are held together by chemical

bonds and thermal energy maintains them in a state of random motion

or stretching vibration.

I^en an electromagnetic wave impinges on

an atom or a molecule, it interacts with the bound electron cloud,

imparting energy to the material; i.e., some of the light is absorbed

The oscillatory frequency of the electron cloud is equal to the

driving frequency, that is, the frequency of the electric field of

the light.

The amplitude of the oscillation will be large only

when the frequency is near the resonant frequency of the atom.

At

frequencies above or below resonance, the electrons vibrating with

respect to the nucleus can be regarded as oscillating electric di-

22

poles, and as such, they will reradiate energy at a frequency which

coincides with that of the incident light.

In addition to these

electron-oscillators which generally have resonances in the ultraviolet, there are atomic oscillators which correspond to the vibration of the constituent atoms within a molecule.

Because of the

large atomic masses, these oscillators have resonances in the infrared.

A primary contributor to this type

of loss is contamination

due to the OH- ion.

Losses due to impurity absorption arise predominantly from

transition-metal ion contamination such as iron, cobalt, and chromium.

The reason for these absorptions is that the impurities have incompletely filled inner electron shells.

Transitions between levels

of unfilled shells give rise to the characteristic absorptions.

The most widely used method for transmission loss measurement,

of which spectral loss is one type, is the "cut-back method" [3]

although other methods have been developed [4],[5].

A calorimetric

method is presented by Midwinter [6]. A fiber of length L is excited

by a suitable broadband

source (see Appendix I) such as a xenon-

arc or tungsten-halogen lamp.

The detector, located at a position

X = L measures the intensity output of the fiber I(L).

Without dis-

turbing the input launch conditions on the fiber, the fiber is cut

to a length m, where m is much less than L, and the detector at

position X = m again measures the intensity output I(m). The loss

for the fiber length, L - m, is given approximately by

A = I(m)/I(L) , or,

a = 10 Log [l(m)/I(L)] measured in dB.

(3-1)

(3-2)

23

Experimental Procedure and Results

In this experiment the fiber will be characterized by a loss

curve:

attenuation of transmitted light versus wavelength.

A

broadband ("white-light") source will be needed for excitation and

a sensitive, broadband detector, such as the RCA type 7102 photomultiplier tube, is needed at the output.

If a single broadband

detector is not available, two solid-state detectors may be used

if the respective responses cover the range of interest.

A long (>100 meter) fiber is needed:

the fiber must be long

enough that losses will be measurable on the equipment available,

yet short enough so that the signal will still be detectable.

Strictly speaking, absolute intensity measurements are not necessary

because a spectral curve will be generated for each of two fiber

lengths:

the resulting ratio of intensities at each wavelength

gives the spectral loss.

However, the method of calibrating the

spectral output of the source is included as it would have to be

for absolute loss measurements.

The subject of absolute loss mea-

surement is covered in Chapter IV.

For true losses to be measured, the source would properly need

to be calibrated spectrophotometrically, but for the purposes of

this experiment, the source can be calibrated to the spectral curve

of the phosphor of the photomultiplier tube as supplied by the manufacturer.

If the curve is not supplied, it may easily be obtained

from The Handbook of Optics [7]. There is an implicit assumption

that the curve is representative of all phosphors of this type, and

this is not a bad one for this application.

24

A curve of output intensity versus wavelength is generated for

the source using the narrow-band interference filters and PMT, as

in Figure 3-1.

This curve is divided point-by-point by the "known"

curve of the PMT phosphor. Figure 3-2, to get the calibrated source

curve shown in Figure 3-3.

The calibrated spectral output of the

white-light source"is then used to correct the loss curve of the

fiber.

As mentioned above, this is not strictly necessary.

For

example, consider the measured intensity exiting from a long length

of fiber:

^n,l ^h^ = hn,l ^h^h,l

where I.

(H>'^d(^l>

"-3)

/> is the actual optical power input into the long fiber,

L- p is the fiber loss factor for the long length, and G, is the

wavelength-sensitive gain of the detector for this particular wavelength X^ .

This expression will be divided by the measured inten-

sity exiting from a short length of fiber:

I

(X.) = I.

(X,)L. ^ (X.)G (X )

m , s l

in,s

1 f,s

1 d 1

(3-4)

where I

is the optical power launched into the short fiber, G,

in,s

"

is the same value defined above, and L-^

is the fiber loss factor

I, s

for the short length.

If the launching conditions are not disturbed,

I

« = I.

, and therefore:

in,-c

in,s

It is seen that the spectral output of the source at each wavelength

is not relevant to the measurement.

However, once again, if abso-

lute power measurements are to be made, it will be necessary to

25

know the absolute power supplied by the source at each wavelength

of interest.

Now referring to Figure 3-4, a beam launcher of the type described in Appendix I is used to excite the fiber with a tungstenhalogen lamp as the source.

Narrow-band interference filters select

the wavelength of the excitation for each data point.

Mode stripping

(see Chapter II) is used at both the input and output ends of the

fiber for standardization of the measurement.

A photomultiplier tube with S-1 panchromatic phosphor is utilized as the detector, and the fiber output is butted to the tube

glass.

Standard precautions for use of photomultiplier tubes are

followed, e.g. when measurements are not being taken, all light to

the PMT input is blocked to reduce dark current effects.

If necessary,

neutral density filters are inserted in the optical path to guard

against overexciting the PMT.

Since the cut-back method is a destructive one, planning is required if a number of measurements are to be made at once.

All

power measurements are recorded for the long length of fiber while

the source power is simultaneously monitored with the reference detector.

After the data are taken for the discrete wavelengths re-

presented by the interference filters, the fiber is cleaved at a

point near the input end.

Data are again taken at this nearer point

at all wavelengths of interest together with the power in the reference detector.

For the system described, the loss curve shown in Figure 3-5

was obtained.

Notice the characteristic Rayleigh-scattering shape

and the OH- peak.

26

Special Problems

On a practical note, care must be taken to limit the amount

of light reaching the PMT. Because of the large avalanche gain,

the last djmode in the chain is in danger of burning out for too

great an excitation.

This is not a serious limitation because neu-

tral density filters may be added in the input optics section for the

short fiber measurement. Appendix IV contains a detailed description of a lab-built housing for the PMT.

If narrow-band interference filters are used, it must be ascertained that they are placed only in collimated light beams. Their

performance is uncertain in other situations.

When the detector is moved from one position to another in the

fiber optics system, it is desirable to have the same area of the

detector illuminated for the measurement because variations may

exist over the sensitive surface of the detector.

With any measurement of transmission loss, much importance is

placed on controlling the launch conditions.

For this reason, both

a mode stripper and a mode scrambler (Appendix I) are recommended [8]

A reference detector is necessary to correct anomalies which are due

to intensity fluctuations of the white-light source.

Sample Questions

1.

In what ways do you expect the launch conditions to

affect the measurement of spectral attenuation?

2.

What mechanisms are responsible for fiber loss?

3.

What is responsible for the attenuation peak at

approximately 950 nm?

27

4.

What relative weights do you attach to the various

components of spectral loss; i.e., which factors."

are relatively strong and which are relatively weak?

References

[l]

Sandbank, C. P> , Editor, Optical Fibre Communication Systems,

John Wiley and Sons, Chichester, 1980, pp. 44-46.

[2] Maurer, Robert D., "Glass Fibers for Optical Communications,"

Proceedings of the IEEE, vol 61, April 1973, p. 454.

[3] Marcuse, D., Principles of Optical Fiber Measurements, Academic

Press, New York, 1981, pp. 226-230.

[4] Technical Staff of CSELT [Centro Studio e Laboratorio Telecomunicazioni]. Optical Fibre Communication, McGraw-Hill,

New York, 1981, pp. 160-ff.

[5] Miller, Stewart E., and Alan G. Chynoweth, editors. Optical

Fiber Telecommunications, Academic Press, New York, 1979,

p. 355.

[6] Midwinter, John E., Optical Fibers for Transmission, John

Wiley and Sons, New York, 1979, pp. 197-204.

[7] Driscoll, Walter G., Handbook of Optics, McGraw-Hill, New York,

1978, Section 4, p. 23.

[8] Marcuse, op. cit., p. 197 and p. 201..

28

100

/ ^

rJ

80

6

3

E

\

N

k-

/

\

/

\

»6 0

6

/

\

O

CO

c §40

CO

/

o

u

V

\

/

(U

0L,

/

20

\

•

\

/

i+OO

<,

600

500

700

800

900

1000

1100

Wavelength (nm)

Figure 3-1.

Measured source spectral sensitivity.

£. » >3

•

?. 2.0

1

/

\

"s

•

/

\

>>

/

\

\

r

•H

U

/

\

CO

c

/

\

CO 1 . 0

•u

\

/

3

.

/

0

\

CO 0 . 5

V

<

\ ^

'^.

t+00

500

600

700

800

Wavelength (nm)

900

1000

1100

Figure 3-2. Absolute spectral sensitivity of S-L phosphor.

29

100

/

/

80

/

e

X u

rt -H

60

\

\

\

/

f

e >

•H

/

O -H

CO

•u C

C (U

(U CO

a

;^

(U

04

/

1*0

\

/

^

20

t+00

500

600

700

800

900

1000

Wavelength (nm)

Figure 3-3. Calibrated source spectral sensitivity,

30

r

MS

FKQ

X

TungstenHalogen

Source

CO

IF

PH

Stabilized

Power

Supply

OF

V

MS

Electrometer

Figure 3-4.

Equipment setup for the measurement of spectral

attenuation. CO, collimating optics; PH, pinhole; X, microscope objective; IF, interference

filter and holder; MS, mode stripper; OF, optical

fiber; PMT, photomultiplier.

31

en

n

o

it)

-i

m

CO

u

u

o

o.

CO

u ^.

12

10

••

\

•\

^

.a -a -8

0) P3

•H »-'

t4-t

-6

>

_?

0

i+O0

500

60 0

7 00

800

900

Wavelength (nm)

Figure 3-5.

Relative fiber spectral loss.

1000

CHAPTER IV

MEASUREMENT OF FIBER LOSS

Project Assignment

You are to measure the fiber loss (in dB/km) for a length of multimode optical fiber.

Repeatability of the measurement should be emphasized

and demonstrated.

Construct a short 2-meter fiber link.

Cleave the fiber carefully in

the middle and measure the loss for the butt joint. Plot the effects of

lateral and angular misalignment as well as the effects of longitudinal

displacement of the fibers at the joint.

Objectives of the Experiment

1.

To acquaint the student with the various factors contributing to

power loss of signal in optical fibers.

2.

To develop an intuitive feeling for the relative sizes of these

losses.

3.

To give students an appreciation for how fiber coupling affects

loss.

4.

To give students experience in handling optical fibers.

Equipment Needed

1.

Long (glass: >100 meters; plastic: >10 meters) of step- or gradedindex optical fiber.

2.

Fiber cleaver (Ap'pendix III).

3.

Avalanche photodiode (APD) and bias supply.

4. Oscilloscope.

5.

Index-matching fluid (glycerin).

6.

Mode-strippers (Appendix I).

32

33

7. Micropositioners (3 needed),

8.

Optical source and launching optics (Appendix I).

9.

Narrow-band interference filter (800 to 900 nm).

10.

Light chopper (Appendix VIII).

11.

Goniometer (Appendix II),

Theory

Introduction

There are many ways to measure fiber loss, but not all of them are

suitable for a laboratory program for undergraduates.

Possible methods

are the cutback method, which is still probably the most widely used in

industry, and the integrating-sphere method.

For either of these methods,

it is necessary for the input end of the fiber to remain fixed, overfilled, and undisturbed.

Mode stripping, as discussed in Appendix I, at

both the input and output is necessary to remove extraneous light in the

cladding which would lead to a measurement error.

The cutback method begins with a relatively long fiber. With the

input overfilled, the intensity of the output light is measured by a

detector butted to the output of the fiber. Overfilling the input refers

to the mismatch between source numerical aperture, or NA, and fiber numerical aperture; the source NA is larger than the fiber NA, and hence some

light is launched into the fiber at angles larger than the acceptance angle

of the fiber.

This light will ultimately leak into the cladding and be

lost, and it may seem wasteful to overfill the input. However, this method

guarantees that as many modes as possible will be launched into the fiber.

34

Without disturbing the launch end of the fiber, the fiber is carefully cleaved two meters away from the input, and an intensity measurement is again made with the same detector butted to the new shorter length.

If the input has remained undisturbed during the measurements, the ratio

of the two powers (intensities) may be converted to a power dB loss per

kilometer II].

The integrating-sphere method takes a slightly different approach.

A silicon photodetector is mounted in the wall of the sphere while the

optical fiber being measured passes through the sphere along a diameter,

A narrow interior baffle is used to block direct light from the fiber

from reaching the photodetector.

The detector measures the average

amount of light escaping from the fiber over a length equal to the diameter of the sphere.

per kilometer.

This loss can be converted into a power dB loss

However, this measurement of loss ignores the loss due

to absorption centers in the material because it is only concerned with

light that is escaping from the cladding, the scattering loss.

A prob-

lem arises here due to the large amount of light lost by absorption at

the inner surface of the sphere.

The integrating sphere is primarily

passive, relying on the wall of the sphere to perfectly reflect light

to the one photosensitive element.

Tynes [2] describes an integrating-

cube method where all of the inner area of the cube is photosensitive.

A third, calorimetric, method exists which measures the amount of

light power absorbed in the fiber per unit length I3J,

The sum of the

losses measured by the integrating-sphere method and the calorimetric

method should be the total loss number measured by the cutback method.

Unfortunately, the calorimetric method requires the construction or

35

purchase of a rather sophisticated device to measure the heat gain of a

fiber directly attributable to the light passing through it, a subtle

effect.

Basic Concepts

It should be noted that there is a tendency in the literature for

the words "mode" and "ray" to be used interchangeably. Marcuse provides a good explanation of the difference 14],

However, for our pur-

poses, we can think of low-order modes as families of rays traveling

through the fiber which strike the core-cladding boundary at small angles

of incidence.

High-order modes would then be families of rays which

travel at relatively higher angles. The high-order modes are most susceptible to loss by being leaked into the cladding and ultimately out of

the fiber (by Snell's law; see Chapter II),

Because each mode is subject

to a different loss, the distribution of modes will affect the loss measured.

Except in rare instances, communications engineers are not particularly interested in isolating the various losses contributing to total

loss:

the single total loss number is good enough. For purposes of

developing better fibers, it would of course be necessary to be able

to evaluate each type of loss independently.

Thus stated, only the-measurement of total loss will be discussed.

Conceptually, the measurement of total fiber "insertion loss" is one of

the easiest to grasp.

One starts with a long length of fiber and meas-

ures the optical power exiting the fiber.

The fiber is then cut to a

shorter length, and a power measurement is again made.

The change in

36

optical power detected (assuming the input has remained unchanged, and

the detector is illuminated over the same area) must be the amount of power

"lost" in the removed section (for whatever reasons), and is defined to

be

^=^°^°^>(^long/^hort> ^^-

^^-1>

The loss per kilometer will be L divided by the length of the section

removed.

The technique works well for high-loss fibers: say, fibers

with losses around 100 dB/km,

The results are easily repeatable, too.

However, when extremely low-loss fibers (1 dB/km) are to be measured,

the problem becomes much more difficult. To compound the problem,

fibers are often supplied in lengths no greater than 1 km, meaning that

the measurement technique must be capable of greater precision. At these

levels, the condition of the endfaces of the fiber becomes important.

One other annoyance is that there is still no agreement as to what

one number constitutes the loss figure for a multi-mode fiber.

This is

due primarily to the fact that it is not clear how the fiber should be

excited.

Should all modes be excited or just the low-order modes?

should some happy medium be reached?

Or

The consensus now appears to be

to measure the fiber loss for the steady-state modal distribution in

the fiber; i.e., the distribution of light among the various modes which

is most likely to occur after the light has' propagated through a very

long section of the fiber.

If it is assumed that this is the most

desirable distribution (overfilling the fiber now would be wasteful),

steps must be taken to launch a distribution in the fiber which approximates the steady-state distribution. Various techniques have been sug-

37

gested:

sending the light first through a long section of dummy fiber,

using a mode scrambler (see Appendix I), or sending the light first

through a section which consists of step-graded-step-index fibers

spliced together.

Some fibers show a tendency to couple energy from one group of modes

to other groups:

this is the phenomenon referred to as mode coupling.

By no means do all fibers exhibit this.

Fibers which show a large degree

of mode coupling will tend to rapidly establish a steady-state modal

distribution.

Fibers which show no significant coupling of energy

between modes even after several kilometers may not be characterizable

by a single number for the loss figure.

With all of this uncertainty about what fiber loss really means,

manufacturers have taken to specifying an "at worst" attenuation which

provides an upper bound for the loss.

experiment.

This is the approach taken in the

Exciting only the low-order modes would be overly optimistic;

launching a steady-state distribution would require that the distribution

be known a priori.

Therefore, the loss will be measured for the case of

an overfilled input, which is to say that more modes will be launched

than can be guided by the fiber.

Simply put, the source numerical aper-

ture will be larger than the fiber numerical aperture.

Experimental Procedure and Results

The experiment proceeds much the same as the experiment of Chapter

III, with careful attention paid to the order in which different measurements are performed,

A long length of type 1504 silica graded-

index 63 ym core fiber was unwound from a spool donated by Corning.

38

The longest length which could be obtained before a break was encountered

was 142.5 m.

Two persons were needed to perform the unrolling;

one un^

wound the fiber from the stock spool while the other took it up on a

spare spool. The new spool was marked with the length and dated and

signed.

The long length of fiber was placed in the experimental setup

of Figure 4-1 with 2 meters unwound and marked with tape at the input

end to permit easy cleaving of the 2-meter length later. An avalanche

photodiode was utilized as the detector due to the anticipated small intensity at the output end of the long fiber. For illustrative purposes,

the loss was measured not at a single wavelength but, instead, for the

total light input into the fiber from a broad-band tungsten-halogen

source.

The addition of the narrow-band interference filter in the in-

put optics resulted in an intensity too low to be detected,

The light

chopper of Appendix YIII was also used to permit the signal to be seen

above the relatively high dark voltage of the APD load resistor.

Careful movement of the micromanipulators at the input and output

ends of the fiber resulted in signal maximization at the detector. After

this, the input optical alignment was not disturbed. Mode stripping

was accomplished by placing the fiber and a drop of index-matching

fluid (glycerin) between two large black rubber stoppers. With the

long-length measurement having been made, the fiber was cleaved 2 meters

from the input end. Another measurement was taken. The total length

of the section which was removed was 142.5 - 2 = 140,5 m.

obtained was

The loss

39

L = 10 log (V /V ) = 10 log (17m'V/5QmV)

= -4.7 dB/140.5 km

= -33.4 dB/km.

The fiber is rated at -16 dB/km at 900 nm, and for the crude setup

used, and the broad-band launch, the value obtained is certainly within

expectation.

At this point, the 2-meter length was cleaved as closely as possible in half.

The ends were butted together after mounting each in a

micropositioner and these ends and the end at the detector were adjusted

until once again a maximum signal was received at the detector. The

reading of 25 mV across the detector load was used with the previously

obtained value of 50 mV for no joint in the 2-meter section to obtain

the loss of the dry joint which was

L. = 10 log (25mV/50mV)

= -3 dB,

a reasonable value for a dry joint.

With the break now made in the 2-meter section, it is a straightforward problem to obtain curves of loss versus the three types of misalignment:

lateral, angular and longitudinal. To obtain the sensitivity

necessary to move one fiber a fraction of a micron laterally with respect to the other, a modification was made to one of the micromanipulators as discussed in the section Special Problems.

The goniometer of

Appendix II was used to position one fiber at an obtuse angle

with respect to the other.

The goniometer yielded a resolution of

40

1/2 degree. For the longitudinal misalignment, the fibers were

butted, the signal was maximized, and the fibers were then gradually separated with the help of a micrometer on the goniometer.

The micrometer had a resolution of 0.001".

Figures 4-2, 4-3, and

4-4 show both the geometries used and the loss vs. misalignment

curves for the three cases. The input optics were still unmoved

from the measurement of the long length of fiber. The mode

strippers of Figure 4-1 were used at the input and output only not at the joint.

Special Problems

The use of the avalanche photodiode is recommended due to

the likelihood of very small signals.

There was a problem in getting enough resolution in the

lateral misalignment experiment.

This was solved by noting that

one turn of the screw on the micromanipulator resulted in a

displacement of 0.013".

By mounting a 360° protractor (incre-

mented by degrees) onto this screw and adding a pointer, a

precision of 0.013"/360 was obtained.

Although the narrow-band interference filter resulted in

a signal which was too small to be detected over the long length

of fiber, it should be noted that the long length represented

a loss of over 33 dB. This suggests that the long length could

have been made much shorter with no danger of being unable to

measure a loss.

This would allow the fiber loss to be measured

41

at 850 nm which is a popular wavelength for specification.

It is believed by us that an integrating-sphere or an integrating-cube experiment would be instructive for those desiring to expand

upon this project. A suggested starting point for the sphere would be

a ping-pong ball coated on the inside with Eastman 6080 White Reflectance Coating.

Or a Christmas tree ornament with no coating?

Sample Questions

1.

Loss in dB is calculated from Equation (4-1) as L = 10 log

P

/P. , Why then was the loss calculated as L = 10 log

out in

"^

V

out

/v. , instead of the standard L = 20 log V ^/V. which

m'

out in

you learned in introductory electrical engineering?

2.

What is optical time-domain reflectometry?

Describe the funda-

mentals of the theory.

3.

For conventional copper telephone systems in your area, how

closely are repeaters spaced?

How closely are microwave re-

peaters spaced for cross-country runs?

4.

With regard to the spectral sensitivity curve measured in

Chapter III, what does the loss measured in Chapter IV represent?

References

[1] Marcuse, D., Principles of_ Optical Fiber Measurements, Academic

Press, New York, 1981, pp. 226-230.

12]

Tynes, A, R,, "Integrating Cube Detector," Applied Optics, vol. 9,

1970, p. 2706.

42

[3] Stone, F, T., W, B, Gardner, and C, R, Lovelace, "Calorimetric

measurement of absorption losses in optical fibers," Optics Letters,

vol. 2, 1978, p. 48.

14] Marcuse, D., op. cit,, p." 245-249.

43

tape

marking

2-m length

APD

TungstenHalogen

Source

Micropositioner

Micropositioner

and mode stripper and mode stripper

Light

Chopper

Figure 4-1. Equipment setup.

t

1

-0 C3

-2 •u

C

-i+

v

^

no

-6 -

fl

CO

—4

E

-8 -

1—i

cC

1-1

-10 -

•u

c^

—"

.

-12 -

CO

>

X

-11+

.

0

1—1

-16 -

0.0

0.1

0.2

0.3

0.4

0.5

0.6

Figure 4-2. Loss vs. lateral misalignment.

0.7

0.8

^

/D

44

T

-5

1

r

r

+2

-2 -1

0 +1

Degrees Misaligned

T

T

T

+3

+4 +5

Figure 4-3. Loss vs. angular misalignment.

1 1 \ T

14

16

4

6

8

10

12

End separation (in mils)

T — I — I — I — I — I — I — I

0

2

r

Figure 4-4. Loss vs. longitudinal misalignment

CHAPTER V

CHARACTERIZATION OF DETECTORS FOR OPTICAL FIBER SYSTEMS

Project Assignment

In comparative measurements, you are to investigate four types of

optical detectors with respect to rise time, relative responsivity,

spectral sensitivity, and dark current.

The detectors are to include

a phototransistor, a PIN photodiode, an avalanche photodiode and a

photomultiplier tube.

Objectives of the Experiment

1.

To familiarize the student with devices presently in use for

detecting optical signals,

2.

To acquaint the student with the operation, advantages, and

disadvantages of each type.

Equipment Needed

1.

Injection laser diode (pulsed),

2.

Phototransistor (PT).

3.

PIN photodiode.

4.

Avalanche photodiode (APD).

5.

Photomultiplier tube (PMT) with S-1 phosphor (RCA 7102).

6.

High voltage negative power supply.

7.

0 - 50V power supply.

8. Monochromator or set of narrow-band interference filters.

9.

Mode stripper (see Appendix I).

10.

Tungsten-halogen or other white-light source.

11.

Oscilloscope, or digital voltmeter,

12.

Light chopper (see Appendiit VIII).

45

46

Theory

Introduction

At present, information transmitted via light through an optical

fiber must be converted to electrical energy at a receiver to be meaningful.

another:

This conversion is effected in photodetectors of one type or

which type is used depends a great deal on the characteristics

of the communication link.

With regard to suitability for fiber optics

applications, photodetectors must have:

high sensitivity (to be able

to detect weak optical signals), peak efficiency near the wavelength

of the system source, high speed, large signal-to-noise ratio, roomtemperature operation capability, and high reliability.

Present systems utilize solid-state p-n junction devices for

detection because they satisfy many of the above requirements and

typically are smaller and consume less power than nonsemiconductor detectors.

Optical detectors can be characterized by four parameters:

rise-

time (or bandwidth), spectral sensitivity, responsivity (at a given

wavelength), and dark current [1]. The first represents a limitation

on the overall system frequency response.

The second is necessary

to optimally match detector to both source and fiber.

The third and

fourth dictate the minimum detectable signal for the link for which the

detector is to be used.

These quantities aid in the proper choice of

a detector for use in a particular fiber optic communication channel.

Other detector parameters are important also.

The noise equiva-

lent power (NEP) is one typically specified by the manufacturer.

It also

47

is useful for determining the "minimum detectable signal" which defines

the amount of incident optical power necessary to generate a photocurrent equal to the photodiode noise current.

To ensure integrity of

the link, the detector is operated with a signal level above the minimum detectable signal. Unfortunately, the detector NEP measurement is

too difficult to be performed without sophisticated measurement equipment.

Basic Concepts

The response time of the photodetector is the transit time of the

generated charge carriers to the output terminals of the device.

It is

dependent on the device construction as well as the external circuitry.

It is a measure of how fast the detector can respond to changes in the

incident light intensity, and hence a measure of the bandwidth.

In lieu of measuring the detector 3-dB bandwidth directly, the

bandwidth information may be inferred from the measurement of the rise

time of the device [2]. For rise-time measurements, an optical signal

with a rise time faster than that expected for the detector is required.

This implies an optical step function or a fast-rising optical pulse.

The pulses supplied by a pulsed injection laser diode are usually adequate for this purpose.

In any cascade-connected system, the overall system rise time, t ,

is approximately

t = 1.1 (t? + t^ + ... + t5°'^

r

where t

1

2

C5-1)

m

is the total system rise time, and t. is the rise time associ-

ated with the element i of the system.

For fiber optic systems, these

f

t

48

typically include the rise time of the source, the dispersion effects

of the fiber, and the rise time of the receiver.

If the rise time of

the source is known (say, from measurement in Chapter VI), and if no

fiber is used, the rise time of the receiver can be obtained from a

measurement of the system rise time. The detector 3-dB bandwidth in

Hz is then approximately 0.35 divided by the rise time in seconds 13].

The measurement of absolute spectral sensitivity for the various

detectors requires the use of a standard source emitting many wavelengths

of light where the output intensity at each wavelength is known. Responsivity, which has units of amps/watt, is an absolute spectral sensitivity

defined for the wavelength where the response is a maximum [4].

A de-

tector with a relatively higher responsivity will be able to resolve

lower-power signals than one with relatively lower responsivity.

Standard sources are, in general, expensive and sensitive to temperature and aging effects.

In this experiment, only relative sensi-

tivity curves will be obtained and relative responsivity data will be

inferred by comparing the spectral response curves for the different

detectors.

With a tungsten-halogen broad-band source in place, a device

for individually selecting single wavelengths follows, allowing a sensitivity of the detector at each wavelength to be determined. Figure

5-lb.

The device for selecting individual wavelengths may be a mono-

chromator or a set of narrow-band interference filters.

For the purposes of comparison, it is only required that all of

the detectors be referenced to the same spectral curve. If the curve

for the tungsten-halogen source is not available, the response of each

49

detector may be compared to that of the photomultiplier tube. To do

this, the PMT is used to "calibrate" the output of the tungsten source,

and this "standard" source is measured by the other detectors.

(If

the chopper of Appendix VIII is also used for all four detectors, it

should be included as part of the "standard" source.) All spectral

responses may be compared in this fashion.

Of course, no information

is obtained for the PMT because its spectral response (obtained from

a standard phosphor curve) was tacitly assumed to be exact.

Dark current is a very simple quantity to obtain with the electrometer. With only the detector circuit operational and the detector

input blocked with opaque paper, the output current is measured.

Experimental Procedure and Results

The equipment setups of Figure 5-1 were used for all measurements.

For measurements which did not require the laser diode pulser to be the

source, an improvement in signal-to-noise ratio was achieved with the

use of a lab-built light chopper (Appendix VIII).

This allowed the

relatively larger dc bias voltage to be subtracted from the signal

by ac coupling to the oscilloscope.

The four phiotodetectors to be compared

are listed in Table 5-1 with a few of the important parameters. The

photodetectors were positioned a distance from the source as necessary

to avoid saturation.

The rise-time measurement required the use of a

source of fast-rising optical pulses. The pulsed laser diode of Chapter

VI is used for this purpose.

The 10%-90% rise time for the laser diode

as used in the pulser of Appendix V was about 8 ns. A tungsten-halogen

lamp served as the source for the spectral sensitivity measurements.

50

Table 5 - 1 .

P h o t o d e t e c t o r s Compared by Manufacturer

Area (mm )

Specifications

Spectral

Sensitivity ((? 900nm)

Fairchild FPT-100

phototransistor (PT)

not available

RCA C-30808 PIN

photodiode:

0.6 A/W

RCA C-30817

avalanche

photodiode (APD):

0,5

75 A/W

780

450 A/W

RCA 7102

photomultiplier

tube (PMT):

A set of narrow-band interference filters was required to select