Hardness Laboratory - Engineering

advertisement

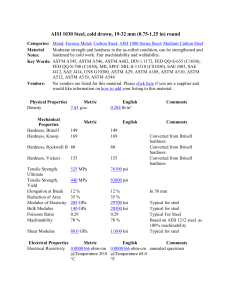

Hardness Laboratory Laboratory Performed on September 23, 2008 by the Late Tuesday Lab Group: Ryan Carmichael, Rachel Cohen, Zach Eichenwald, Anne Krikorian, Jing Ng, Meghan Whalen Report by Ryan Carmichael and Anne Krikorian E59 Laboratory Report – Submitted October 7, 2008 Department of Engineering, Swarthmore College 1 Abstract: In this lab, Rockwell hardness tests were performed on two unknown steel specimens and one unknown brass specimen, with the intent of identifying the metals. The results of our experiment, shown in Table 1 below, correlated to several possible compositions for the unknown steel specimens and one likely composition for the brass specimen. These results suggest that the Rockwell hardness test is a poor test to determine composition of specimens, although, in practice, hardness tests are useful for other purposes. Possible Materials Tested Brass ~HRB 18.6 Cartridge brass, 70% UNS C26000 annealed Steel 1 ~HRB 89.2 Carbon steel 1042 cold drawn Carbon steel 1042 normalized, cold drawn Carbon steel 1043 cold drawn Carbon steel 1045 cold drawn Carbon steel 1046 annealed, cold drawn Carbon steel 1049 hot rolled Carbon steel 1050 hot rolled Carbon steel 1137 hot rolled Steel 2 ~HRB 87.2 Carbon steel 1040 cold drawn Carbon steel 1045 annealed, cold drawn Carbon steel 1046 hot rolled Carbon steel 1140 cold drawn Carbon steel 1145 hot rolled Carbon steel 1146 hot rolled Austenitic stainless steel 201 annealed Table 1: Possible Specimen Compositions Theory: Hardness is a material quality with many definitions and applications. In this lab, we define hardness as resistance to indentation under an applied load, which corresponds with deformation of the material under a load. Other definitions of hardness include resistance to scratching, resistance to abrasion, resistance to cutting or drilling, or energy absorption under impact loads. Definitions of hardness are essentially arbitrary, and different hardness tests reflect this, measuring a variety of different qualities. 2 Hardness is related to ductility, tensile strength, and many other material properties, but does not have a defined relationship with any of them. As such, the hardness test is by and large used to compare the hardness values of different materials and not in calculations to determine other properties. Still, there are multiple applications of hardness tests. Hardness test results can sometimes differentiate between materials, and materials may be graded according to hardness. Hardness can also be used to roughly predict material properties, but only roughly. In production, hardness tests may be performed to check for consistency or the effects of a hardening treatment. This is the most common use of hardness tests. Many different hardness tests exist; for the purpose of this lab, we will focus on indentation hardness tests, but not exclusively. The main tests used are the Brinell, Rockwell, Knoop, Monotron, and Shore scleroscope tests. All of these tests use an indenter, whether a ball, cone, or pyramid made out of a hard substance such as hard steel, diamond, or, more modernly, tungsten carbide. All but the Shore scleroscope test are static tests, meaning that the load is applied gradually- it is the depth of indentation achieved by applying a steady load to the indenter that is of interest. The Shore scleroscope, meanwhile, applies a load by dropping it or propelling it with a spring, and the height of rebound of the indenter is the concern (this test measures energy absorption more than resistance to indentation). In most hardness tests, variations in the size or shape of the specimen tested can cause large variations in the results of the tests, even if they are made of the same material. As a result, care needs to be taken that the thickness of each specimen is within a testable range, and that the surface area being tested is large enough for the proximity of the edges to the indention to not affect results. Each hardness test has its own limitations. The Brinell test uses a hard ball as an indenter and applies relatively large loads, with 3000 kg common. The Rockwell test (tester shown in 3 Figure 1) is similar, but uses various types of indenters and various loads, both smaller than those used in the Brinell test. The Knoop indenter is made of diamond and shaped to produce a diamondshaped indention, and is often used for the testing of very small specimens and requires microscopic examination of the sample. The Monotron test measures the load required to achieve a standard indentation depth, and uses a diamond-tipped cone indenter with Figure 1: Rockwell Tester (formerly Troxell figure 12.7) the load applied by a hand lever. The Shore scleroscope, ass mentioned before, measures the rebound hardness of a material, and depends on the resilience of the hammer for consistent results. In the United States, the two most commonly used tests are the Brinell and Rockwell tests: we will use the Rockwell test method. The Rockwell test is particularly quick and convenient, leading to its popularity in production and manufacturing uses. The test makes use fifteen different scales, according to the hardness range of the material being tested and determined by the type of indenter and the load applied. It can, as a result, be used to find 4 hardness values that fall outside of other test method’s scales, for instance those higher than the Brinell scale reaches. In the lab, we use the two most common Rockwell scales: B and C. In general, hardness results can be converted from one scale to another, so long as the test is examining the same type of hardness. These conversions can be complicated, though, due to the inherent differences in the tests themselves. Even within the Rockwell testing methods, results fall outside of the expected range for a certain scale cannot be converted to a more appropriate scale with high accuracy. Procedure: (Adapted from Troxell) Figure 2: Procedural Diagrams (originally Troxell 12.8) 5 • As shown in Figure 2, we first examined the Rockwell hardness tester, insuring that the operating lever was in the position closest to the operator and that the correct major load was in position to be applied. • We then inserted the proper indenter into the testing machine and placed the test specimen on the anvil. • Next, we turned the elevating screw, raising the specimen into contact with the indenter. We continued to elevate the specimen until the initial load was fully applied, determined by the pointer being within 5 scale divisions of its upper vertical position. We then turned the bezel of the gage so that the B 30 mark, distinguishable by a red arrow, was directly above the pointer. • After checking that the specimen was held firmly in place by the initial load, we released the operating lever with a smooth motion. Allowing the handle to move without interference until the major load was applied, we waited until the handle and pointer came to a rest. • We then returned the operating load to its original position with a smooth, gentle motion. • Finally, we recorded the result of the test off of the appropriate dial. • We repeated this test for a total of five tests on each specimen. Results: In order to identify the composition of each specimen, we calculated the mean of the five tests and compared these results to standard hardnesses for steels and brasses, respectively, published by ASM (Appendices A and B). In order to make a direct comparison, we need to convert our result in Rockwell B hardness to Brinell hardness. For the steel specimens we converted via the formula HB = 7300 / (130 – HRB) found in ASM Handbook Vol. 8 Mechanical Testing and Evaluation. For the brass specimen, we converted to Rockwell F hardness by using a conversion graph (Appendix C). The results obtained are presented below in Tables 1 and 2. 6 Possible Materials Tested Brass ~HRB 18.6 Cartridge brass, 70% UNS C26000 annealed Steel 1 ~HRB 89.2 Carbon steel 1042 cold drawn Carbon steel 1042 normalized, cold drawn Carbon steel 1043 cold drawn Carbon steel 1045 cold drawn Carbon steel 1046 annealed, cold drawn Carbon steel 1049 hot rolled Carbon steel 1050 hot rolled Carbon steel 1137 hot rolled Steel 2 ~HRB 87.2 Carbon steel 1040 cold drawn Carbon steel 1045 annealed, cold drawn Carbon steel 1046 hot rolled Carbon steel 1140 cold drawn Carbon steel 1145 hot rolled Carbon steel 1146 hot rolled Austenitic stainless steel 201 annealed Table 1: Possible Specimen Compositions Hardness Test Results Unknown Brass Rockwell Test Result 1 B 18 2 B 19 3 B 18 4 B 17 5 B 21 Mean Standard Dev. Rockwell F equiv. B 18.6 B 1.517 F 70 Unknown Steel 1 Rockwell Test Result 1 B 88 2 B 89 3 B 90 4 B 90 5 B 89 Mean Standard Dev. Brinell Equiv. B 89.2 B 0.837 HB 178.9 Unknown Steel 2 Rockwell Test Result 1 B 84 2 B 78 3 B 90 4 B 92 5 B 92 Mean Standard Dev. Brinell Equiv. B 87.2 B 6.010 HB 170.6 Table 2: Test Results Discussion: Our results yield a number of possible materials that the unknown samples could have been composed of. For both of the steel samples, we found a range of steels that matched our results: for steel 1, carbon steel 1042-1046 cold drawn or 1049, 1050, or 1137 hot-rolled; and for steel 2, 1040, 1045, or 1140 cold drawn, 1046, 1145, or 1146 hot-rolled, or austenitic stainless steel 201 annealed. The confidence we have in these possibilities varies, as the raw data for the unknown steel 2 has the largest standard deviation while unknown steel 1 has the lowest. For the 7 unknown brass sample, we found one particular material that we considered likely. While we initially could not find a material with matching properties due to conversion problems, we later found a graph detailing the conversion between the scales for aluminum alloys and brasses, which gave more reasonable results than the formulas we found elsewhere. With the new conversion, we found that Cartridge brass, 70% UNS C26000, annealed is the most likely material, although the hardness numbers do not match precisely (HRF 70 compared to HRF 72). In this lab, error came from many sources above and beyond human error. The Rockwell hardness test is easily influenced by the cleanliness and consistency of the machine and the specimen. Dirt or dust build-up on the anvil can result in incorrect results, as can grime or oxidation on the specimen. Also, while a single specimen can be tested many times if the size is sufficient, proximity to previous indentations and to the edges of the sample can affect results. Impurities or inconsistent shape in the indenter, particularly for the steel-ball indenter, will yield incorrect values, too. Beyond material factors, the value determined for the brass specimen is inaccurate because of the scale used: we used scale B when scale F would have been more appropriate, and so our results were too small to accurately convert to the proper scale. Conclusion: Overall, we found in this lab that using the hardness number or rating of a material was a poor method of identifying the material tested. Discrepancies between different testing methods and scale conversions, along with the indistinctive nature of the hardness values, prevent hardness form being a distinguishing property. However, we did determine the likely identities of the unknown samples we tested. In order to obtain more specific results, more testing would have to be preformed. 8 References: “Aluminum Alloys and Brasses – Hardness Conversions.” Hardness Conversion Charts. Granta Design. 6 Oct 2008. < http://www.grantadesign.com/images/hardness.al1.gif> ASM Handbook, Volume 20, Materials Selection and Design. Materials Park, OH: ASM International, c1990-. ASM Handbook, Volume 8, Mechanical Testing and Evaluation. Materials Park, OH: ASM International, c1990-. ASTM E18-03: Standard Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials. West Conshohocken, PA : ASTM International, 2004. Davis, Harmer Elmer, G. Hauck, and G. Troxell. The Testing of Engineering Materials. Boston: Mcgraw-Hill College, 1982. Siddiqui, Faruq. “Mechanics of Solids: Hardness Test.” Swarthmore College, 2008. 9 Appendix A: Steel Composition and Property Chart 10 11 12 Appendix B: Brass Composition and Property Chart 13 Appendix C: Rockwell Hardness Conversion Graph 14