Dr. Kauser Jahan

advertisement

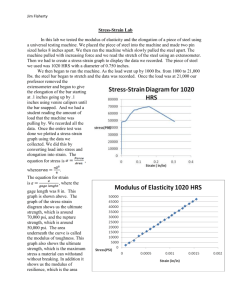

Freshman Engineering Clinic II Dr. Kauser Jahan Spring 2011 Materials Engineers use a wide variety of materials in their engineering products. Materials range from metals and alloys, ceramics and glasses, polymers, composites and semiconductors. Soil, aggregates, wood, concrete and asphalt are common materials used by civil engineers. Engineers thus need to have a fundamental understanding of material properties because material selection is the final practical decision in the engineering design process and can ultimately determine the success or failure of the design. The simplest question an engineer can ask of a material is (a) how strong is it? (b) How much deformation occurs under a certain load? The objective of this laboratory is to provide some basic understanding of mechanical properties of materials when subjected to an axial force. This force can subject the member either to tension or compression as shown in Figure 1. Tension Compression Figure 1: Tension and Compression in Axial Members Stress and Strain: Stress, is defined as the force per unit area on a material. Therefore it has the units of psi (pounds per square inches) or Pa (Pascals). Strain, , is defined as the deformation per unit length. It is dimensionless. Therefore, for a rod under applied load as indicated in Figure 2, the stress is = F/A and the strain is = x/L. All engineering materials deform under applied forces. Some materials are ductile while others are brittle. Steel and ferrous allows are ductile while ceramics and glass are brittle. The steel rod in Figure 2, subjected to an applied force F, has deflected an amount equal to x. Typically, this deflection is proportional to the applied force. 1 F x L F Cross Sectional Area A Figure 2: Steel Rod Subjected to Tension Stress-Strain Diagram Stress-strain diagrams of various materials vary widely. It is possible however to distinguish materials into brittle and ductile on the basis of the characteristics of their stress strain diagrams. A typical stress-strain diagram for ductile and brittle materials is shown in Figure 3. Rupture Fracture Yield Point Figure 3: Typical Stress-Strain Diagram for a Ductile and Brittle Material Most engineering materials are designed to undergo small deformations, involving only the straight-line portion of the corresponding stress-strain diagram. For the initial portion of the diagram, the stress is directly proportional to the strain and we can write = E 2 This is known as Hooke’s Law, after the English mathematician Robert Hooke (1635-1703). The coefficient E is known as the modulus of elasticity or the Young’s modulus, after the English scientist Thomas Young (1773-1829). Since strain is a dimensionless quantity, the modulus of elasticity E has the same units as stress. The linear portion of the stress-strain diagram is known as the elastic region as deformation is not permanent. Common values of the modulus of elasticity for various materials are shown in Table 1. Table 1: Modulus of Elasticity for Various Materials Material 1040 Carbon Steel Aluminum Borosilicate Glass Acrylic Concrete Diamond Wood E (psi) 30 x 106 10 x 106 10 x 106 0.4 x 106 2.5 x 106 170 x106 1 x 106 Steel can take high loads in tension and compression. However steel can buckle under high compressive loads. Concrete can take high compressive loads and can only take 1/10 of the same load under tension. In-Class Activity a) If a 4” steel rod subjected to a tensile force indicates a 0.25” elongation, what is the value of the applied force in lbs? b) What is the modulus of elasticity for a material whose stress strain plot is shown below: 20000 18000 16000 Stress (psi) 14000 y = 1E+07x - 2491.2 R2 = 0.9629 12000 10000 8000 6000 4000 2000 0 Strain 3 Experiment # 1: Stress and Strain In this experiment a steel and aluminum specimen will be subjected to tension. You will observe the specimen being pulled to failure. You will record data on the force being applied and the resulting elongation. Using this data you will plot (a) the stress versus strain data and (b) the linear portion of the data and obtain the equation of the best fit line. The slope of this line is the modulus of elasticity. Equipment: _________________________ Steel Cross Sectional Area _____________ Aluminum Cross Sectional Area ___________ Length of specimen ____________ Force (lbs) F ____________ Elongation (inch) x Stress F/A psi Strain x/L Experiment # 2: Rockwell Hardness Test Hardness is the property of a material that enables it to resist plastic deformation, usually by penetration. However, the term hardness may also refer to resistance to bending, scratching, abrasion or cutting. Hardness is not an intrinsic material property dictated by precise definitions in terms of fundamental units of mass, length and time. A hardness property value is the result of a defined measurement procedure. The usual method to achieve a hardness value is to measure the depth or area of an indentation left by an indenter of a specific shape, with a specific force applied for a specific time. There are three principal standard test methods for expressing the relationship between hardness and the size of the impression, these being Brinell, Vickers, and Rockwell. For practical and calibration reasons, each of these methods is divided into a range of scales, defined by a combination of applied load and indenter geometry. The Rockwell hardness test method consists of indenting the test material with a diamond cone or hardened steel ball indenter. The indenter is forced into the test material under a preliminary minor load F0 (Figure 4A) usually 10 kgf. When equilibrium has been reached, an indicating device, which follows the movements of the indenter and so responds to changes in depth of penetration of the indenter is set to a datum position. While the preliminary minor load is still applied an additional major load is applied with resulting increase in penetration (Figure 4B). When equilibrium has again been reached, the additional major load is removed but the preliminary minor load is still maintained. Removal of the additional major load allows a partial recovery, so reducing the depth of penetration (Figure 4C). The permanent increase in depth of penetration, resulting from the application and removal of the additional major load is used to calculate the Rockwell hardness number HR. HR = E - e 4 F0 = preliminary minor load in kgf F1 = additional major load in kgf F = total load in kgf e = permanent increase in depth of penetration due to major load F1 measured in units of 0.002 mm E = a constant depending on form of indenter: 100 units for diamond indenter, 130 units for steel ball indenter D = diameter of steel ball Figure 5: Rockwell Principle Team Laboratory Report Please submit a letter of transmittal along with the raw data, plots and calculations. Your results must be presented in the letter. BONUS: What is the value of E for Rubber, Human Cartilage, Human Tendon and Brass? References: 1. Shackelford, J.F. (1996) Introduction to Materials Science for Engineers, Prentice Hall, Inc. 2. Shah, Vishu (1998) Handbook of Plastics Testing Technology, Wiley Interscience. 3. http://www.gordonengland.co.uk/hardness/rockwell.htm, February 19, 2006, used verbatim in the handout. 5