MOR - bei der IG VPE Swiss

advertisement

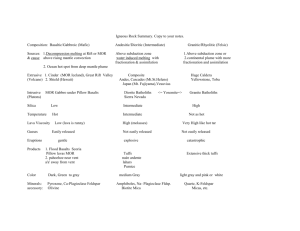

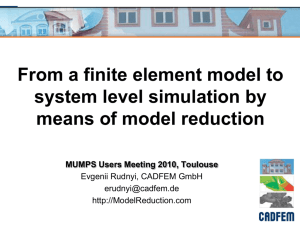

Mechatronik mit ANSYS Multiphysics Verknüpfung von 3D FEM mit 1D System Simulation (MOR und Co-simulation) Joël Grognuz, CADFEM (Suisse) AG Dynamic analyses overview in ANSYS Time saving mathematical methods: FEM 2D,3D 1. Transient with MSUP, Rigid Body Dynamics 2. Component Mode synthesis (CMS, Superelements) Circuit or PID 1D Elements embeded in the same FEM model 4. Simplorer with State space matrices obtained by Model Order Reduction (MOR for ANSYS, SPMWRITE in ANSYS Mechanical) 5. Cosimulation between Simplorer and rigid body dynamics (RBD) 3. FEM 2D,3D +1D -3- MOR and Co-Simulation: -4- Model Order Reduction Model order Reduction Mx Ex Kx Bu y Cx Model Order Reduktion (MOR): Get small dimensional Linear State-Space Model (MSUP or Krylov subspace) ax cx bu y cx Limitation: „weak“ Nonlinearities! TPH1 1. Small Amplitudes only 2. Contact status unchanged Linearization at nonlin status possible (large deformation, pre-stress, contact status frozen , …) Electronic component modeling and controller design may be fully nonlinear! -6- Multidomain Model Order Reduction (MOR) Mechanical (acoustic) Thermal Electrical -8- Validation: MOR quality: Mechanical example: hard disk drive head 3352 elements 7344 nodes 21227 equation FEM: 400 frequencies takes about 12 min MOR takes only 3 s Comparison for head ANSYS 21k DOF MOR 30 DOF MOR 80 DOF -9- Validation: IGBT power module 12 inputs and outputs have been defined DoFs: ANSYS full model > 900 000. Reduced model: 15 DoFs per input = 15*12 = 180. The reduced model covers all heat sources and thermal cross talk at once. - 10 - Validation: Comparison ANSYS Full MOR Red line – ANSYS, green line – reduced model. Difference is close to the line thickness. For such accuracy, one needs 15 DoFs per input. 1% Relative error - 11 - Validation: Comparison with Measurements Temperatures on IGBTs - 12 - Temperatures under IGBTs Validation: MOR quality: Shaker with mounting suspension 13 347 elements 11 765 nodes 55 481 equations to solve 200 frequencies take about 20 min with MOR same result takes 8 second - 14 - Validation: Efficient Simulation of Acoustic FSI with MOR - 15 - MOR Example: Machine tool with mechatronic control Joël Grognuz, CADFEM (Suisse) AG - 16 - Goal Study the dynamic interaction between : 1) Control unit 2) Machine body 3) spindle 4) Piece to machine - 17 - Machine tool geometry The structure between base and tool will be transfered to simplorer as a reduced order model the drive chain between control motor and moving base is replaced by a block called „motor“: The remainder of the structure was negleted in this workshop for simplicity but should indeed be kept in order to obtain accurate results; the focus of this workshop is on modelling techniques, not on accuracy! - 18 - Motor and transmission Block - 19 - Bushing between machine and spindle In Simplorer - 20 - Motor and transmission Block Electrical domain Coupling between rotation Translational and domain translation (thread) Rotational velocity domain Torsional Inertia gear box with rigidity & efficiency wheel friction coef. - 22 - Translational mass rigidity & friction Machine control study MOR & Verification: WB transient versus Simplorer Transient FE-Analysis in WB: ca. 1h Reduced model in Simplorer: 4 seconds Machine control study Position Control with simple PID: too slow! Tsettling = 8,3 s Machine control study Position Control with cascaded speed controller: Optimized Tsettling = 2 s Tsettling = 0,75 s Co-simulation Simplorer-RBD Co-Simulation Rigid Body Simulation: Nonlinear large scale motion and reactions: Co-Simulation: System behavior 1:1 available in System Simulation Tool: - 29 - Simplorer-RBD cosimulation: Landing Gear Application - 30 - - 30 - Simplorer-RBD cosimulation: Landing Gear Application Hydraulic Circuit Piston Position - 31 - Simplorer - EM - CFD Cosimulation: solenoid valve - 32 - - 32 - EM 1D+2D: Synchronous motor Synchronous Machine with AC-Voltage Excitation - 33 - Source: CADFEM GmbH EM 1D+2D: Synchronous motor Synchronous Machine with PWM Control Ansoft LLC Phase Voltage / Current 4_Partial_Motor_TR_PWM 150.00 1.00 0.80 100.00 0.60 15.00 Current(PhaseA) Setup1 : Transient Current(PhaseB) Setup1 : Transient Current(PhaseC) Setup1 : Transient 10.00 0.40 ANSOFT Curve Info 50.00 0.20 0.00 0.00 -0.20 -50.00 -0.40 -0.60 -100.00 -0.80 -150.00 10.00 -1.00 15.00 Time [ms] Current [A] 5.00 0.00 -5.00 -10.00 -15.00 0.00 - 34 - 5.00 Source: CADFEM GmbH 10.00 15.00 Time [ms] 20.00 25.00 30.00 NodeVoltage(IVa) [kV] PESM_PWM -BranchCurrent(VIA) [A] Winding Currents Further System Simulation examples Multidomain conservative blocks Electrical circuits Magnetics Mechanics J Hydraulics, Thermal, ... A 11B 11C 11 B 12 M 3~ C 12 A2 M( t) B2 STF MMF C2 GND A 12 L JA + R OT1 R OT2 - F( t) m STF GND ASMS Q H Simplorer Simulation Data Bus / Simulator Coupling Technology CLK ffj INV ffj ffj ffj CLK ffj PST State-space Models (MOR) Block Diagrams State Graphs Digital/ VHDL J Q CLK Flip flop QB CLR CLK CLK INV state transition PROCESS (CLK,PST,CLR) EIN BEGIN SET: TSV1:=1 SET: TSV2:=0 SET: TSV3:=0 SET: TSV4:=1 x Ax Bu y Cx IF (PST = '0') THEN (R_LAST.I >= I_OGR) state <= '1'; ELSIF (CLR = '0') THEN AUS (R_LAST.I <= I_UGR) SET: TSV1:=0 SET: TSV2:=1 SET: TSV3:=1 SET: TSV4:=0 state <= '0'; ENDIF; ffj ffj K Battery simulation - 37 - Conservative vehicle model – Physical domains Simplorer car: Driver Gear DThr Motor_Thr DBrake Reg_brake DGear ICE_Thr Brake Gear mrv mrv mtv mtv GN Thr_ICE 100 % 2 1 FD Eng TR_ICE Eng MechAcc mrv mrv mtv mtv Shaf t Vehicle_mass IFuel CONST I Gas cooling System / CERN Geneva System design, modeling, assembly testing and commissioning System in underground LHC ATLAS underground Detector gas cooling system modeled (1D), built, tested and validated on the surface before installation and commissioning 100m underground without any prototype. ATLAS underground areas Control/ Gas renewal Distribution racks compressor Compressor unit (Lumped Parameters) - 41 - High Fidelity System Simulation Ultra High Speed Motor Unit: 〔mm〕 Fan Motor Aspects of the Motor design (1) Surface type permanent magnet synchronous motor (2) Rotor surface is covered by the inconel material for shatterproof of the magnet (3) Protection from oil infiltration (4) Concentrated winding is employed. Rated Output 5 kW Rated Voltage 200 V Rated Speed 240,000 rpm Number of Poles 2 Stator Length 40 mm High Fidelity System Simulation Experiment System FPGA DSP TMS320C6701 V/F Control Stabilization Method High Efficiency Control DO8 EPF10K30RC240-4 SNC signal Sine Wave Amp 8bit DOM Angle 8bit 16 PWM Swiching Dead Time Gate Drive Circuit AIO8 6 V dc iu iv iw Conv. PWM Inv. UHS Motor High Fidelity System Simulation Ultra High Speed Motor, Complete Model C/C++ VHDL-AMS (digital) Fan Motor VHDL-AMS VHDL-AMS (or Maxwell) Take home: Dynamic analyses overview in ANSYS Time saving mathematical methods: FEM 2D,3D 1. Transient with MSUP, Rigid Body Dynamics 2. Component Mode synthesis (CMS, Superelements) Circuit or PID 1D Elements embeded in the same FEM model 4. Simplorer with State space matrices obtained by Model Order Reduction (MOR for ANSYS, SPMWRITE in ANSYS Mechanical) 5. Cosimulation between Simplorer and rigid body dynamics (RBD) 3. FEM 2D,3D +1D - 52 -