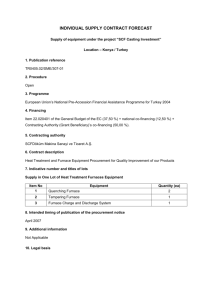

Elmelin Solutions for the Metal melting Industry

advertisement

Vapourshield Plus Elmelin Solutions for the Metal melting Industry Why Vapourshield ? Many foundries would like to save money by making use of some galvanized scrap in their melts. They are often prevented from doing this by the possibility that zinc vapour could condense onto the induction coil, causing interturn shorting. Other metals such as lead, tin and cadmium can cause similar problems. About Vapourshield Vapourshield has been developed for customers who have already encountered problems caused by metal vapour deposition and also for customers who would like to increase the galvanised content of their scrap. The Type 2 version is particularly designed for use in mains and medium frequency induction furnaces, where appropriate. With respect to suitability, reference should be made to the relevant Vapour shield Suitability Guides, prior to use. The Plus Three additional enhancements. 1. Metal Penetration Alarm. Vapourshield plus, with its stainless steel core, can be attached to the earth-leakage system of an induction furnace. Were the melt to penetrate the crucible and come in contact with the earthed Vapour shield core, an alarm can be triggered and the furnace made to shut down. In this way a major Health and Safety gain can be achieved. 2. Metal Penetration Barrier. Depending on the temperature of the melt, Vapourshield Plus can be an effective, if temporary, barrier to metal penetration to the coil grout and beyond to the coil. In this way Vapour shield may be able to prevent catastrophic damage to the coil from occurring. 3. Improved Push-out Characteristics. One of the many benefits of using mica based slip-plane materials in the lining of coreless induction furnaces, is the improved push-out performance that they provide. It has been shown that the addition of the internal stainless steel layer within Vapour shield Plus, has significantly added to the performance of our standard slip-plane materials, in this regard. Versuchsbericht / Test report Vapourshield test October 2011.doc 9 -rc ABP Induction Systems GmbH, Kanalstr. 25, D-44147 Dortmund, http://www.abpinduction.com Von/From ABP/DA1 Robin Chakrabarti Telefon/Phone + 49 231 997 2278 Fax 2431 An/To G. Ulrich 1/11 Datum/Date 2011-11-11 Firma / Company Schütte, Meyer & Co. Gusstechnik GmbH Teilnehmer / Participants Stephen Weiss (Elmelin), Andrejs Umbrasko, Stefan Martini, Robin Chakrabarti (ABP) Besuchsdatum / Visiting Date 12. – 13.10.2011 Melting equipment: FS10 (1t) / 750kW / 500Hz / IGBT Test aim: To establish, to what extent, the electromagnetic field of a medium frequency induction furnace, would couple with the stainless steel foil of the Elmelin Vapourshield material. Vapourshield is a laminate of flexible phlogopite mica paper and stainless steel foil. It is designed to prevent the carbon and metal vapours, which are generated by the melt, from condensing onto the induction coils of the furnace. Test set-up: The old crucible is pushed out. 2 lengths of Vapourshield (1150mm long x 960mm wide), are sufficient to cover the furnace wall. In total, approx. 2m² of. The Vapourshield was installed, with 50mm of overlap Avoiding an electrical circuit. For this trial, an additional strip of conventional mica foil was inserted between the 2 sheets of Vapourshield, at the overlap points, to rule out any possibility of an electrical circuit being formed. The upper ends of the Vapourshield foil were slit, to permit the foil to be easily formed over the top lip of the furnace. The slits in the spout area extend lower down into (the magnetic field of) the furnace. Where possible, slits should not extend into the vertical wall area of the furnace, because of their potential to create local hot-spots, and gaps in the vapour barrier. Temperature monitoring. Two prefabricated thermocouple panels were installed – one at the point of overlap, and the other in the middle of a sheet. Each panel contained 3 thermocouples which were set at different heights. The thermocouples were attached to temperature displays. The furnace, which was empty and had not been given its refractory lining, was then switched on and allowed to run at full power. The maximum temperature recorded on the upper thermocouple was approx. 330°C, in the middle it was100°C and at the bottom it was 200°C. These maximum measurements were obtained at the overlap points, where there is a double thickness of foil and 2 vertical edges. The middles of the sheets were much cooler – at typically approx. 100°C The furnace control panel, when running at full power. The maximum voltage that could be obtained with an empty furnace, was approximately 2,210V at 409 Hz and 273kW. Red glowing spots, at the end of the slits in the Vapourshield, in the spout area. These result from the intrusion of the slits into an area of dense electromagnetic field, caused by the current path. (see note on P. 3) In order to supplement the temperature readings from the six thermocouples, the Vapourshield was painted matt black, so that measurements could be taken with a thermal imaging camera General view of the temperature distribution of a full sheet of Vapourshield, with the furnace running at full power. The electrical power readings taken on the Control Panel of the furnace, were checked and confirmed by measurements taken at the rectifier input. Cutting away the slit material, in the area of the spout, prevented the formation of a glowing hot spot - see also photos pages 3 & 4. In theory, larger sheets should get hotter than smaller sheets. Tests were carried out on 140mm, 280mm and 400mm wide strips of Vapourshield, in order to confirm this. Temperature distribution of a 140mm wide layer. Temperature distribution of a 280mm wide layer . Temperature distribution of a 400mm wide layer. Overall it was concluded that the best in service results, would be achieved using full width Vaporshield sheets. Results: When the furnace was running at full power, the induced power in the approximate 2m² of installed Vapourshield foil, was 8kW or 2.93% of the total. (Dr. Umbrasko had predicted this result, from his theoretical calculations.) This means that the Vapourshield was absorbing about 4kW/m² of induced power. The vertical edges of the foil tended to generate the hottest spots, because of the dense electromagnetic fields caused by the current paths. The vertical edges of the wider sheets of Vapourshield, tended to be hotter than those of the narrower sheets. Generally, it can be said, that this 2 day trial has demonstrated that the installation of Vapourshield foil, in middle frequency crucible induction furnaces, should not adversely affect the performance of the furnace or its lining. For this always to be the case, the parameters of every furnace where Vapourshield is going to be installed, (power, frequency, size etc.) and the precise method of installation, should be discussed with Elmelin, prior to its use. This was a very demanding trial for Vapourshield, because in service, the foil would be covered by a massive refractory lining on one side, and on the other side would be the water cooled coil grout. These two factors would substantially dissipate any local hot spots in the low mass foil.