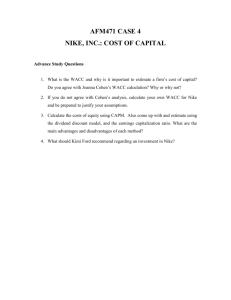

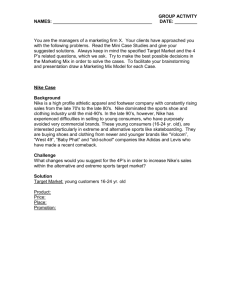

Nike & Global Labor Practices: A Case Study

advertisement