military training & simulation news

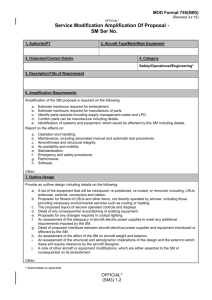

MILITARY TRAINING

&

SIMULATION NEWS

Vol. 14 Issue 6 2012

ISSN: 1366 - 2309

T raining

T raining

Maintenance Training

Maintenance Training

Many Ways to Skin a Cat

Maintenance training is on the up as new technologies are creating different training options embracing life-size aircraft system mock-ups, desk-top virtual simulation or, a combination of the two. As Trevor Nash reports, the solution that is adopted is nearly always that demanded by the customer.

M ilitary equipment of every description is becoming more complex and more expensive. Whether it be a

V-22 Osprey costing nearly USD 100 million per copy, the highly complex radars and combat operations systems in vessels such as the Royal Navy’s latest Daring Class Type 45

Destroyers or the vetronics systems that equip the most recent versions of the Bradley or Abrams armoured vehicles, the military is paying increasing attention to how it trains its maintenance technicians to keep such platforms serviceable.

Page 32.

Maintenance training for service personnel is but one issue that is currently focusing the minds of military staff officers around the globe; the other is how to recruit them in the first place. In the UK for example, the executive summary of a report commissioned for the Royal Academy of Engineering stated that,"[t]he report provides clear evidence, based on economic research, that the demand for people in Science, Engineering and

Technology (SET) occupations exceeds supply and, because the demand is pervasive to the economy, it persists even in the

MT&SN Vol. 14 Issue 6 2012

current recessionary period. As economic growth returns, demand for engineers and many other SET occupations is likely to intensify."

Although this report was looking at recruiting engineers for industry, the skills shortage also applies to the military. In the UK at least, not enough people have been channelling their efforts into approaching technical or engineering careers. As far as the military is concerned, this problem has been exacerbated by a high operational tempo leading to many qualified maintenance technicians and engineers leaving the services.

As most senior officers will acknowledge, how personnel are trained has a fundamental influence on their motivation. If the training is well thought out, planned and managed and results in the production of well-motivated and confident maintenance technicians, morale is increased. Further training also needs to be provided when for example, new equipment or upgraded equipment is introduced into service.

With this challenge as a backdrop, this feature will examine a range of maintenance training options that are open to the military. The first question that needs to be asked is how are these technicians trained?

How to Learn?

The US Military frequently uses what it refers to as a VARK assessment which looks at the learning process as either, visual

(V), auditory (A), reading and writing (R), kinesthetic (K) or a combination of all four.

The US Air Force’s Air Education and Training Command

(AETC) recently tasked the Air Force Research Laboratory

AAI Corporation is providing the F-35 Lightening II virtual maintenance training system, a key element of which is provided by DiSTI Corporation.

(Source: AAI Corporation)

(AFRL) and the Air Force Institute of Technology (AFIT), to undertake a study into how USAF groundcrew learned to maintain de-icing equipment.

After conducting a trial at the USAF Maintenance Training

Facility, Detachment 1, 345th Training Squadron in Caifornia, the report’s authors, Captain Jeremy Jordan (AFIT) and

Christopher Curtis (AFRL), reported the following:

"The performance check [on the maintenance course] is given after three days of classroom exposure to the written material; the students haven't physically worked on the vehicle at the time the test is given. The students are allowed to repair the actual vehicles with their hands the following week before the final test is given.

Interestingly, the kinesthetic learners are the lowest performers on the initial performance check and the highest performers on the final test. They start performing

Although mainly known for its flight simulation work,

CAE has provided a number of maintenance training systems for customers around the world. This device is for the Australian

Army’s S-70 utility helicopter.

(Source: CAE)

MT&SN Vol. 14 Issue 6 2012 Page 33.

The C-17 Globemaster III maintenance training programme utilises full-scale mock-ups such as the engine and nacelle shown here.

(Source: AAI Corporation) well after they have spent hands-on time with the vehicle. The kinesthetic learners are the only group who (sic) showed any significant variation between the performance check and the final test. This shows the necessity of allowing the students to spend a lot of time working on the actual vehicle. Finding other ways to reach the students with other learning preferences could also boost final test scores. These findings support the notion that matching instruction to learning preference increases student performance as discussed earlier in the methods section."

The question that this report raises is can the kinesthetic learners be seduced by desk-top learning using high-fidelity, dynamic 3D graphics? The growth of such systems has flourished tremendously over recent years.

As part of the AETC study, AFRL did use a synthetic training system of which, the report says:

"The fabricators of the enhanced software programme [the synthetic training programme] claim benefits such as increased

Page 34.

learning and heightened knowledge of the maintenance required on the vehicle. Interestingly, test scores and independent performance evaluations paint a different picture…The new computerised learning tool doesn’t appear to have any effect on student performance indicating that more traditional methods of instruction may be just as effective in certain areas of education. Thus, there is no reason to replace traditional instruction methods (i.e. paper schematics). If the new tool is being used in the field as a job aide, it may; however, be beneficial to learn the tool while in school to allow easy transition to the field. Finally, there may be other benefits not examined in this paper that warrant the implementation of the tool."

The clear question that this aspect of the study raises is how proficient was the ‘enhanced software programme’ or ‘tool’? Previous studies, notably one carried out by Boeing in 2008 that centred on the

Phalanx anti-missile ship defence system, concluded that using a dynamic desk-top synthetic training solution could reduce training time by around 30% whilst improving the quality of training compared to conventional hardware-based approaches.

Despite the length of time that desk-top virtual trainers have been available, there is still a belief in some quarters that training on the real equipment or replications of the real equipment is the only way to train maintenance technicians. There are some merits to this argument which will be examined later. One example of using synthetic training equipment combined with the real aircraft is in the

USAF’s approach to C-17 Globemaster training.

Maintenance training for this aircraft is provided using synthetic training devices manufactured by

AAI Corporation in a conventional schoolhouse environment (see sidebar).

In essence then, maintenance training options examined so far include training on the real equipment, training on simulated, full-scale 3D replications of the aircraft or parts of the aircraft and using desk-top virtual simulators. These options are not of course, mutually exclusive and training organisations frequently mix-and-match solutions.

MT&SN canvassed some views on each approach.

Blended Learning

"The cost of using real equipment is really too cost-prohibitive, especially in the case of an aircraft," explains Gerry Fabian,

Business Development Manager for Export at Selex Systems

Integration. "It’s not only the cost of taking the aircraft out of service when it could be undertaking its prime role, but also the cost of rectifying any damage done by the students and the cost of preparing the aircraft for flight after it has had a number of unqualified maintenance students climbing all over it in the hangar for a day."

Neil Wiles, a Training Solutions Analyst, also from Selex

Systems Integration, says that, "the real aim of the maintenance training system should be to download training from the aircraft.

This is not only because of the cost but also because the real platform is not designed as a training tool. A purpose-designed training system allows the instructor to insert a range of faults which the student has to deal with and then record the student’s

MT&SN Vol. 14 Issue 6 2012

Indian Air Force Undertakes Maintenance Training with USAF at Charleston AFB

The Indian air force has begun sending the first of 100 airmen to Charleston AFB in South Carolina to undergo C-17

Globemaster III maintenance training from the 373rd Training

Squadron Detachment 5. India has ordered 10 C-17s with the first expected to enter service in 2013 at Hindon air force station located close to Ghaziabad, in Uttar Pradesh. The IAF expects to receive their C-17s in June 2013. India paid $4.1 billion for the aircraft, which is expected to replace their IL-76 fleet.

Indian Air Force students are undertaking training using a variety of C-17 full-scale mock-ups during their courses at

Charleston AFB.

(Source: AAI Corporation)

"The Indian air force purchased the C-17s and they need the training because these Indian airmen are going to be the ones standing up the initial C-17 unit and we were nominated to be the schoolhouse that teaches them," said Technical Sergeant

Paul Higgins, and electrical environment instructor with the

373rd TRS Detachment 5.

The 373rd TRS Detachment 5's mission is to provide aircraft maintenance to the Department of Defense and its allies.

"We are learning the basics of the aircraft as well as the technical manual, which is quite helpful in learning the part numbers and

Indian Air Force students in the classroom at Charleston AFB.

Note the desk-top computers for CBT.

(Source: US Air Force) other technical aspects of the C-17," explained Indian air force

Junior Warrant Officer Prakash Chand.

Each specialty-specific class has four students. The length of the course varies by specialty, but usually lasts about four to six weeks.

"We teach across the board" said Higgins. "Every specialty we have on the C-17, we are teaching here. We have electrical environmental, communication, navigation and general crew chief functions, just to name a few."

The training includes classroom time as well as hands-on work where the new maintainers apply the skills they learned in the classroom on aircraft maintenance simulators.

"What we're learning here is going to help us to be able to maintain the C-17 aircraft in India," said IAF Junior Warrant

Officer Ranbir Singh Rana. "We have very good and experienced instructors and very good communication with them. We are catching on very quickly and when we have questions, they are able to clear up things quickly."

(With thanks to the US Air Force News Service)

MT&SN Vol. 14 Issue 6 2012 Page 35.

The Australian Army’s S-70 maintenance trainer features a blended learning approach including a full-scale cockpit and virtul classroom learning.

(Source: CAE) actions, data from which is used in a properly managed debriefing process."

The question is though, what is meant by a purpose designed training system? Although today’s virtual desk-top systems have tremendous graphical realism, they do not represent the physical form, fit and function of the real equipment. Fabian agrees but says that does not and should not drive the customer to train on the real platform.

"When designing the platform, we must be clear what the customer wants to achieve with it in terms of his training outcomes," says Fabian. "For example, some years ago, the

Royal Air Force wanted an aircraft propulsion systems trainer that featured desk-top training which was both instructor-led and also allowed students to conduct free-play exercises, but also with the ability to network to a full-scale mock-up of the aircraft to enable students to undertake start-up and shut-down procedures as a team as they would do for real on the flight line."

The company is shortly to deliver a similar system to an undisclosed customer that will be used for avionics training. This device features a generic life-size cockpit that is networked to a number of desk-top training systems in the classroom.

DiSTI has been involved in virtual maintenance training systems for a number of years and its latest system for

ROV support has been developed in conjunction with RRC Robotica in

Brazil. DiSTI tools used in the development include GL Studio and Replic8.

(Source: RRC Robotica)

As Neil Wiles has stated, the aim is to download training from the real platform, but also have students as well prepared as possible before they leave the classroom and either move on to 3D replicated equipment or undertake maintenance tasks for real for the very first time on the actual platform.

The question of the cost of training on the real equipment was also raised by NGRAIN, a company that has had considerable success over the years with its Virtual Task Trainer product line. The company’s Josie Sutcliffe, VP Marketing says that, "the leading problem for our customers has been either lack of access to equipment, or the cost associated with using equipment for training." Interestingly, NGRAIN is seeing a trend where some customers are relying on the totally virtual route for maintenance training.

"One of the earliest applications of our virtual task training solutions was to supplement student hands-on time with equipment –used either in addition to or in replacement of hard trainers - or mock ups," says Sutcliffe. "Used largely to support procedural training – allowing students to practice procedures virtually – the virtual task training solutions were also used as instructional aids, helping instructors train on theory and system orientation.

"More recently, in response partly to the proven training results achieved by virtual training, and partly to continuing downward driving economic pressures, we’ve seen an increasing move towards an entirely virtual approach to training. Simulation provides a significant opportunity here for cost savings – while also allowing unlimited, real-time access to training materials."

One company that has had a long track record of providing virtual maintenance training systems is Orlando-based DiSTI.

The company’s latest success is through the Brazilian deep sea specialists, RRC Robotica Submarina, based in Macaé who not only undertake their own exploration work but also have their own Deep Water Education Centre to train their own personnel as well as those from third-parties. As part of this training, the company specialises in training customers in how to use deep sea

Remotely Operated Vehicles (ROV). Customers include commercial operators as well as military users.

Having recently procured a number of ROV systems from

Schilling Robotics, the company turned to DiSTI to provide

Page 36.

MT&SN Vol. 14 Issue 6 2012

maintenance training systems for use by its staff. DiSTI has significant experience in this field and have developed maintenance training systems for platforms such as the

F/A-18 and F-35 as well as for military trucks built by

Oshkosh where the trainers are in service at the company’s customer training school.

DiSTI has also undertaken some internal research and development to develop virtual maintenance training courses for the F-15 and F-16. Both the F-15 and F-16 systems will be shown at this year’s I/ITSEC event in Orlando in

December.

"Some of these sophisticated ROV platforms cost up to five million dollars and any downtime costs major money as they are operated from very sophisticated ships that may only have a small window in which to complete a specific task," explains

DiSTI’s Director of Global Sales, Chris Giordano.

"RRC Robotica wanted a maintenance training system that could be used whenever the ROVs deploy onboard ship to enable maintenance technicians to train during the downtime between missions," says Giordano. "Our solution was to install the maintenance training courseware on a computer in the ROV containers that control the actual ROV mission."

In developing the ROV maintenance trainers, DiSTI used its GL

Studio and Replic8 software development tools. The key with both systems is that the customer is able to develop his own maintenance training synthetic environment.

"We’re seeing that increasing numbers of customers are asking to develop their own products and this is primarily due to security issues," explains DiSTI’s Director of Global Marketing,

Scott Ariotti. "Replic8 is an example of a product that not only reduces the workload required to create content but also means

MT&SN Vol. 14 Issue 6 2012

A US Marine Corps technician undertakes routine shipboard checks on a MV-22.

(Source: US Marine Corps) that lesson content can be created by the instructional systems designer and does not need a dedicated programmer."

As to the state of the market for maintenance training systems,

Ariotti says that, "we are seeing real growth in the maintenance training sector at the present time. Our F/A-18 SAMT product was the first of its kind in terms of content, student interaction and visual quality and we are continuing to build on that capability."

I/ITSEC will see DiSTI launching its new Lumens product which is understood to be a new native engine for GL Studio that will include a number of benefits, one of which is improved rendering.

DiSTI’s buoyant view of the maintenance training market is also supported by Selex Systems Integration.

"We’re seeing that there is a great deal of interest from emerging markets in South America, the Middle and Far East," explains

Gerry Fabian. "Our experience is showing us that these markets are full of individuals that are very ‘IT savvy’ but that they are short of instructors and so we are looking at providing and so systems are being adopted for training students and for train-thetrainer courses."

In Canada, NGRAIN has also noted that there is an increasing requirement for customers to develop their own training courseware and therefore, the provision of easy to use tool is a must. The company is about to release a new Software

Development Kit (SDK),

Page 37.

Selex Systems Integration has developed a number of different maintenance training systems including desk-top and blended systems with the latter including desk-top training integrated with 3D mock-ups.

(Source: Selex Systems Integration)

That allows developers to access the company’s core volume graphics technology to develop their own advanced applications.

Called NGRAIN Constructor, the SDK is built using NGRAIN’s volume graphics technology, which is, says the company, "based on a series of discrete points in space that can support realtime interactive data manipulation and visualization. This is particularly useful for the development of mission rehearsal scenarios and other simulations requiring on-the-fly adjustments. With this new product, we are expanding beyond the realm of equipment sustainment."

Growing Opportunities

CAE has built a number of different maintenance training systems over the years which cover the whole gamut from desk-top devices to 3D replication of aircraft components.

MT&SN asked the company’s Senior Manager for Maintenance

Training Business Development, Denis Guimond, how the company approaches the market.

"CAE’s approach is to select the appropriate training media for optimum training effectiveness," explains Guimond. "The technical solution, whether that is a virtual system on the desktop or a life-size physical replication of the weapon system, is therefore subordinated to the training objectives. A desktop virtual maintenance trainer can be very effective to provide system knowledge, functional representation, and troubleshooting scenarios for skilled, experienced technicians. However, for a recent graduate, the basic manual skills of using maintenance or diagnostics tools, or ground support equipment, may need to be demonstrated and performed on a representative physical device for maximum training effectiveness.

"Many of CAE’s recent projects combine virtual and hardware or hands-on training media as required to meet the training objective," continues Guimond. "For instance, we have integrated desktop virtual maintenance trainers with hardware-based trainers, such as helicopter cockpits and avionics modules. We have also replicated engine part-task trainers on platforms such as the C-130J that feature virtual FADEC and test equipment.

For the US Army, CAE has designed ground combat training systems where virtual and hands-on trainers for platforms such

Page 38.

as the Abrams tank form the overall training curriculum. CAE considers that a blended approach depending on the training task is most suitable.

Sometimes that training task may mean a desktop virtual maintenance trainer is sufficient; other times a hands-on hardware trainer combined with a VMT is required to meet the training task and deliver the necessary learning environment."

Like others, CAE is seeing a growing interest in maintenance training coming from customers and potential customers around the world.

"We are seeing many militaries looking to increase the amount of training done in a synthetic environment, and there is definitely an increased interest in maintenance trainers," says Denis Guimond. "This interest is generated by a combination of factors, including fewer experienced instructors which leads to the need to have more self-paced courseware integrated with virtual trainers; the desire for suitable distance learning capabilities; reduced accessibility (or opportunities) to use operational aircraft for hands-on training; and a need to reduce time to qualify technicians, particularly the period of on-job-training.

Simulation-based maintenance training devices almost always offer a positive return on investment in terms of students throughput, proficiency, and standardisation."

From NGRAIN’s perspective, the market for maintenance training is also a growing one but as the company’s Josie

Sutcliffe says, its not only the appreciation of modern training technologies that are having an effect, but there are also demographic factors at work.

"We are seeing some key drivers at play that seem to be moving spending towards maintenance training," she says. "There is a perfect storm facing NATO militaries worldwide: a weakened economy, reduced budgets, and lots of tired iron that needs to be reset. Procurement of new equipment is down, with militaries focusing on extending the lifespan of existing systems. At the same time there is a demographic shift occurring, with experts retiring and Millennials – typically coming in with more experience using computers than wrenches – becoming a larger part of the workforce. Maintenance training will become a key focus as efficiently regenerating combat power becomes a priority.

"In relation to this, we are seeing a trend of more personnel being trained on the job, and interactive 3D equipment simulations being used to support or improve the efficiency of job performance in the field. For example, we have delivered a Virtual Damage

Assessment & Repair Tracking solution for the F-35 and F-22 aircraft to Lockheed Martin, which allows aircraft maintainers to capture damage information on a detailed 3D virtual model of the aircraft."

In summary then, maintenance training is certainly bubbling at the present time. With weapon platforms becoming ever more costly and complex, maintenance technicians need to be trained to a very high standard to keep such systems at a high state of readiness. The perennial argument is how these technicians should be trained?

The general thrust is that the use of the real platform is untenable for a variety of reasons, mainly cost, availability and safety.

Desk-top systems are clearly an excellent method of preparing students but many countries believe that there needs to be an intermediary step using physical 3D simulations.

MT&SN Vol. 14 Issue 6 2012