Aspen Fired Heater

Maximize process throughput through more efficient design and operation

of your fired heaters

Aspen Fired Heater is the latest generation of thermal design software for the simulation and rating of

process fired heaters. Fired heaters are found on almost every process unit in a petroleum refinery

and are widely used in petrochemical and bulk chemical production. Correct design and operation of

heaters is vital for achieving overall plant operational objectives in terms of efficiency and

achievement of desired product slate.

The Challenge: Reduce Risk, Gain More Control of Fired Heaters

Ninety percent of the energy consumed in a typical refinery is associated with fuel burned in fired heaters. Heaters are vital to

the operation of distillation and conversion units. These devices are highly complex heat transfer units involving combustion,

radiation, and convective heat transfer, often interacting with several streams in a process. Changes in feedstock or crude

composition must be considered carefully in terms of the local process conditions within a heater. Without careful control,

heaters can suffer from excessive coking and even tube failure, with serious consequences to safety and plant availability.

The AspenTech Solution: Flexible Modeling to Adapt to Changing Conditions

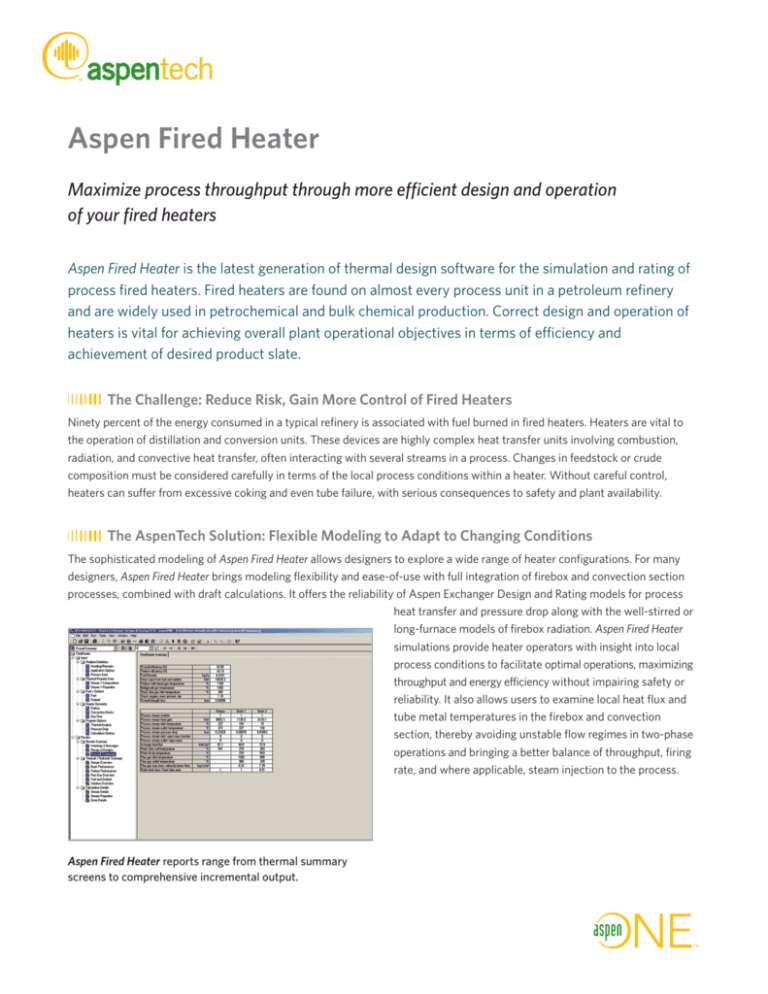

The sophisticated modeling of Aspen Fired Heater allows designers to explore a wide range of heater configurations. For many

designers, Aspen Fired Heater brings modeling flexibility and ease-of-use with full integration of firebox and convection section

processes, combined with draft calculations. It offers the reliability of Aspen Exchanger Design and Rating models for process

heat transfer and pressure drop along with the well-stirred or

long-furnace models of firebox radiation. Aspen Fired Heater

simulations provide heater operators with insight into local

process conditions to facilitate optimal operations, maximizing

throughput and energy efficiency without impairing safety or

reliability. It also allows users to examine local heat flux and

tube metal temperatures in the firebox and convection

section, thereby avoiding unstable flow regimes in two-phase

operations and bringing a better balance of throughput, firing

rate, and where applicable, steam injection to the process.

Aspen Fired Heater reports range from thermal summary

screens to comprehensive incremental output.

Aspen Fired Heater

Wide Range of Applications

Aspen Fired Heater: Key Technical Features

• Combined modeling of firebox and

convection section

• Up to 10 process streams in a single heater

• Handles cylindrical and cabin fireboxes

• Firebox well-stirred and long-furnace

radiation models

• Firebox wall tubes (vertical horizontal and

helical coil)

• Central tubes and cell-type fireboxes

• Up to 9 process convection section tube

banks and processes

• Tubes can be plain or finned

• Convection section tubes with high round fins,

serrated fins, circular fins, and rectangular fins

• Flexible, easy-to-use user interface

• Full process thermal and hydraulic calculations

using Exchanger Design and Rating methods

• Combustion calculations for up to 4 fuels

in the firebox

• Fuels can be selected from a standard set of 5

common fuels or specified by gaseous

composition or for liquid fuels by ultimate

analysis

• Outputs include the heater overall

thermal performance in addition to many

detailed reports

• Evaluation of local process conditions,

temperatures, and pressures

Fired heater design involves balancing the thermal and hydraulic

requirements for the main process stream and the subsidiary

streams in the unit, while avoiding excessive capital cost. The

complexity of the interactions and the wide range of possible

configurations necessitate the use of a powerful tool like

Aspen Fired Heater. Its detailed modeling capabilities provide

an accurate assessment of local metal temperatures, allowing

users to select the most appropriate tube materials.

In modern plant operation, profitability is highly dependent on

how well heaters are running. If feedstocks change or pre-heat

trains foul up, the appropriate firing rate is not easy to determine.

Similarly, if fuel changes are required, an accurate model is most

important. Aspen Fired Heater helps operators achieve maximum

efficiency while avoiding operating regimes that may jeopardize

the run-time of the unit (due to excess coking), or that may

even impair the integrity of heater pressure parts. By modeling

a heater in the program, operators gain insight into local

conditions, which goes far beyond that revealed by

instrumentation.

Three major physical property databases are included in Aspen

Fired Heater—Aspen HYSYS® Thermodynamics COM Interface,

the leading package in oil & gas processing, Aspen B-JAC

standard properties package, which handles many common

industrial fluids, and Aspen Properties®. These databases

provide access to more than 1,100 components and include a

range of industry-standard VLE methods and mixing rules.

Aspen Fired Heater has a utility to import process data and

stream properties from Aspen HYSYS®. This allows users to

quickly set up studies of heater performance from the Aspen

HYSYS process flowsheet.

• Flagging of conditions that exceed

expected limits

• Flagging of unstable flow regimes

• Import of process and property data from

Aspen HYSYS®

• Aspen HYSYS Thermodynamics COM

Interface and Aspen B-JAC property databanks

An extensive selection of graphics makes Aspen Fired Heater

easier to use.

Aspen Fired Heater

Thermal Output

Aspen Fired Heater uses the power and flexibility of the Microsoft® Windows environment to allow you to explore unit geometry

and performance detail. In addition, Aspen Fired Heater is designed to support “drag & drop” interfacing with Microsoft Excel, as

well as high-level communication with other software.

Thermal output includes:

• Overall heater thermal performance summary, including details of the heat load and the thermal efficiency of the unit

• Extensive warning and error reporting, alerting you to potential operational problems

• Overviews of thermal performance of each part of the heater, firebox, and tube bank

• Thermal overview of each stream in the heater

• Combustion information and fuel details, including calculated flue gas composition for individual fuels and fuel mixtures

• Comprehensive incremental output, including local temperatures, pressures, and heat flux

• Radiation information including zonal analysis

A number of program defaults helps minimize

the required user input.

Graphing is available for enhancing your visual interpretation of

output information.

Aspen Exchanger Design and Rating

Aspen Fired Heater is a part of the Aspen Exchanger Design and Rating family of products. Aspen Exchanger

Design and Rating products offer state-of-the-art heat exchanger simulation and design based on over 30

years of industry-leading research. Our aim is to enhance the value of heat transfer solutions by providing

the most integrated product offering across the widest range of technologies. This enables our customers

to use the most advanced physically-based modeling, from unit design and overall process design, through

to optimization and operational monitoring.

Worldwide Headquarters

Aspen Technology, Inc.

200 Wheeler Road

Burlington, MA 01803

phone: +1-781-221-6400

fax: +1-781-221-6410

info@aspentech.com

EMEA Headquarters

aspenONE Process Engineering

Aspen Exchanger Design and Rating family of products is a key component of aspenONE Process Engineering

for chemical, refining, and E&P companies. aspenONE Process Engineering is an integrated lifecycle solution—

from conceptual design through to plant startup and operations support—enabling our customers to build

and operate safer, competitive and more reliable process plants. Companies are able to reduce capital

and operating costs, increase engineering efficiency and quality, and accelerate time-to-market—with

payback in months instead of years.

AspenTech Ltd.

C1, Reading Int’l Business Park

Basingstoke Road

Reading UK

RG2 6DT

phone: +44-(0)-1189-226400

fax: +44-(0)-1189-226401

ATE_info@aspentech.com

About AspenTech

AspenTech is a leading provider of award-winning process optimization software and services. AspenTech’s

integrated aspenONE™ solutions enable manufacturers to reduce costs, increase capacity, and optimize

operational performance end-to-end throughout the engineering, plant operations, and supply chain

management processes.

For more information, visit www.aspentech.com.

© 2008 Aspen Technology, Inc. AspenTech®, aspenONE™, and the Aspen leaf logo are trademarks or registered

trademarks of Aspen Technology, Inc. All rights reserved.

1319-05-0808

APAC Headquarters

AspenTech - Shanghai

3rd Floor, North Wing

Zhe Da Wang Xin Building

2966 Jin Ke Road

Zhangjiang High-Tech Zone

Pudong, Shanghai

201203, China

phone: +86-21-5137-5000

fax: +86-21-5137-5100

apac_marketing@aspentech.com