Development of production strategy with focus on flexibility

advertisement

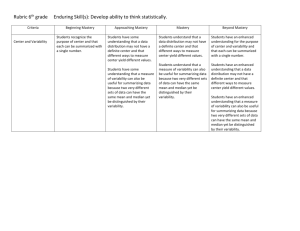

Development of production strategy with focus on flexibility Marco Semini, SINTEF 1 Production strategy Business environment Complementors Technology Business strategy Cost Quality Availability Features/innovativeness Environmental performance Production strategy Vertical Integration Process technology Capacity Facilities Sourcing Business processes Supply chain coordination Information technology Organisational capabilities (Beckman and Rosenfield 2008) Business environment Competitors Products Customers Suppliers Production system 2 Product-process matrix Product Low Volume High High Variety Low Project Process Jobbing Batch Mass Continuous (Hayes and Wheelwright 1979) 3 Internal and external variability Business environment Complementors Technology Supply variability Business strategy Cost Quality Availability Features/innovativeness Environmental performance Production strategy Vertical Integration Process technology Capacity Facilities Sourcing Business processes Supply chain coordination Information technology Organisational capabilities (Beckman and Rosenfield 2008) Business environment Competitors Product variability Products Demand variability Customers Suppliers Process Production system Workforce and equipment variability 4 variability How to respond to variability Reduce variability itself Buffer against variability Develop flexible operations 5 How to respond to variability Business environment Complementors Technology Supply variability Business strategy Cost Quality Availability Features/innovativeness Environmental performance Production strategy Vertical Integration Process technology Capacity Facilities Sourcing Business processes Supply chain coordination Information technology Organisational capabilities (Beckman and Rosenfield 2008) Business environment Competitors Product variability Products Demand variability Customers Suppliers Process Production system Workforce and equipment variability 6 variability Flexibility in manufacturing Capability to be responsive or readily-adjustable to changing conditions Product flexibility Ability to introduce new or modified products Mix flexibility Ability to produce a wide range or mix of products Volume flexibility Ability to change the level of output Delivery flexibility Ability to change the delivery dates 7 (Slack 2010) How to develop flexible operations • • • • • • • • • Flexible process type Flexible process technology, such as FMS Short setup and cycle times Postponement (Upstream position of the CODP) Extra capacity Flat organizational structure, with high level of autonomy and individual responsibility, team work Cross-trained workforce Accounting and information systems Appropriate supplier and customer relationships 8 Mass customization Quick response manufacturing Fisher's (1997) responsiveness Agility Lean Total quality management Product-process matrix Product Low Volume High High Variety Low Project Process Jobbing Batch Mass Continuous (Hayes and Wheelwright 1979) 9 How to develop flexible operations • • • • • • • • • Flexible process type Flexible process technology, such as FMS Short setup and cycle times Postponement (Upstream position of the CODP) Extra capacity Flat organizational structure, with high level of autonomy and individual responsibility, team work Cross-trained workforce Accounting and information systems Appropriate supplier and customer relationships 10 Mass customization Quick response manufacturing Fisher's (1997) responsiveness Agility Lean Total quality management How to develop flexible operations • • • • • • • • • Flexible process type Flexible process technology, such as FMS Short setup and cycle times Postponement (Upstream position of the CODP) Extra capacity Flat organizational structure, with high level of autonomy and individual responsibility, team work Cross-trained workforce Accounting and information systems Appropriate supplier and customer relationships 11 Mass customization Quick response manufacturing Fisher's (1997) responsiveness Agility Lean Total quality management How to develop flexible operations • • • • • • • • • Flexible process type Flexible process technology, such as FMS Short setup and cycle times Postponement (Upstream position of the CODP) Extra capacity Flat organizational structure, with high level of autonomy and individual responsibility, team work Cross-trained workforce Accounting and information systems Appropriate supplier and customer relationships 12 Mass customization Quick response manufacturing Fisher's (1997) responsiveness Agility Lean Total quality management How to respond to variability 5S Supplier development Flow and takttime Supermarkets Reduce variability itself LEAN Buffer against variability SMED Lead time reduction Quality circles Supplier integration Develop flexible operations 13 Flexibility: Why, what and how? WHY WHAT HOW Variability Flexibility types Flexible production strategy Demand variability Product flexibility Supply variability Mix flexibility Product variability Volume flexibility Process variability Delivery flexibility Equipment and workforce variability 14 Flexible process type Flexible process technology Short lead times Postponement Extra capacity Flat organization and team work Cross-trained work force Activity-based costing Effective use of IT Appropriate supplier and customer relationships Company Type(s) of flexibility (what) Volume flexibility Case studies Volvo Response mechanisms (how) Employee contracting Flexible, problem-solving work force Glen Dimplex Volume flexibility Mix flexibility Team organization Flexible lines Process and lead time control Benteler (spare parts business) Mix flexibility Delivery flexibility Lead-time reductions Focus Cost control Market understanding Ulstein Volume flexibility Product flexibility Modularization and standardization Reduce investments in fixed assets Reduced planning efforts Individual and team responsibility Enter new segments Tine Volume flexibility (demand and supply) Mix flexibility Product flexibility Lead time flexibility Differentiated production planning Assessment of uncertainty 15