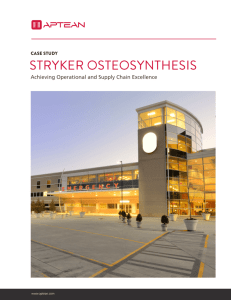

Stryker - Case Study

advertisement

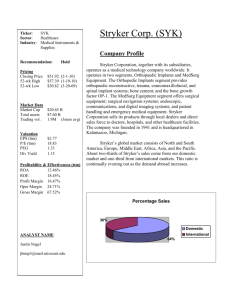

Stryker - Case Study Stryker - Case Study THE CUSTOMER: Stryker Corporation Stryker Corporation, together with its subsidiaries, operates as a medical technology company worldwide. It operates in two segments, orthopaedic implants and medical surgical equipment. The orthopaedic implants segment provides orthopaedic reconstructive, trauma, craniomaxillofacial, and spinal implant systems; bone cement; and the bone growth factor OP-1. THE PROJECT: Trauma Theatre Trolleys Stryker manufactures orthopaedic implants for trauma. The volume of implants designed for the human body is vast, which includes size variations based on the dimensions of individual patients. Surgeons would traditionally have pre-ordered parts for operations based on individual requirements. This did not allow for on the spot changes in requirements or to fix unforeseen problems. Stryker wanted a system so surgeons could access the full suite of parts required for an operation allowing them to choose the parts on location and to change or request new parts without delays. This system would mean changes could be made during surgery and would require surgical nurses to leave the OR to obtain the new part. The parts would need to be clearly labelled and easy to find. Achieving this goal would increase operation efficiency to help patient recovery, and surgeons could make better decisions on what was required. It would also allow Stryker to increase sales and for hospitals to reduce costs as they would only be billed for what was used. THE SOLUTION: Flight Cases with Welded Plastic Internals Traditional flight cases can be manufactured in many shapes and sizes. CP Cases manufacture a range of cases under the name ProCase. ProCases are made using the finest Finnish birch plywood. Each case is carefully designed, the plywood is laminated with tough but washable PVC and fitted with aluminium extrusions and heavy duty knuckle ball joints. CP Cases carefully compiled the subcomponents of each trolley and took measurements of each of the surgical parts. CP Cases’ expert design team set about creating solutions which housed all of these parts in a case that was transportable in and out of theatre but also allowed every part to be visible and easily found. Left: Design view of component layout with drawers. Right: Photo of finished case. DRILLS 3 x 300mm 3 x 300mm GUIDE PINS 4.2 x 130mm 4.2 x 180mm 4.2 x 230mm 4.2 x 300mm 4.2 x 130mm 4.2 x 180mm 4.2 x 230mm 4.2 x 300mm Gamma 3 Long Nail Left Gamma 3 Long Nail Right 11 x 280 x 120 11 x 280 x 125 11 x 280 x 130 11 x 280 x 120 11 x 280 x 125 11 x 280 x 130 11 x 300 x 120 11 x 300 x 125 11 x 300 x 130 11 x 300 x 120 11 x 300 x 125 11 x 300 x 130 11 x 320 x 120 11 x 320 x 125 11 x 320 x 130 11 x 320 x 120 11 x 320 x 125 11 x 320 x 130 11 x 340 x 120 11 x 340 x 125 11 x 340 x 130 11 x 340 x 120 11 x 340 x 125 11 x 340 x 130 11 x 360 x 120 11 x 360 x 125 11 x 360 x 130 11 x 360 x 120 11 x 360 x 125 11 x 360 x 130 11 x 380 x 120 11 x 380 x 125 11 x 380 x 130 11 x 380 x 120 11 x 380 x 125 11 x 380 x 130 11 x 400 x 130 11 x 400 x 120 11 x 400 x 125 11 x 400 x 130 11 x 400 x 120 11 x 400 x 125 11 x 420 x 120 11 x 420 x 125 11 x 420 x 130 11 x 420 x 120 11 x 420 x 125 11 x 420 x 130 11 x 440 x 120 11 x 440 x 125 11 x 440 x 130 11 x 440 x 120 11 x 440 x 125 11 x 440 x 130 11 x 460 x 120 11 x 460 x 125 11 x 460 x 130 11 x 460 x 120 11 x 460 x 125 11 x 460 x 130 1 Stryker - Case Study Stryker - Case Study A suite of cases was designed and submitted to Stryker. Over the course of our meetings alterations were made to improve the efficiency of each case to optimise it for use in surgery. The internals of many of the cases were designed with a complex plastic frame using 3mm High Density Polypropylene. The internal frame is hard wearing and rigid enough to support the heavy items. The HDPE frame is welded in place and then fitted into each case. Every case required a combination of drawer systems, plastic welded dividers and CNC routed foam partitions. Stryker had a clear advantage working with CP Cases: our ability to supply a range of products and design services under one roof. CP Cases can manufacture complex flight cases out of plywood and can draw on experience from nearly 40 years of shaping plastic, metal fabrication and foam routing. 9 x 240mm 9 x 240mm 12 x 260 mm 11 x 280 mm 12 x 280 mm 9 x 300 mm 10 x 300 mm 11 x 300 mm 12 x 300 mm 12 x 320 mm 9 x 320mm 10 x 320mm 11 x 320 mm 9 x 340 mm 10 x 340 mm 11 x 340 mm 12 x 340 mm 9x 360 mm 11 x 260 mm 9 x 340 mm 10 x 260 mm 10 x 280 mm 9 x 320mm 9x 260 mm 9 x 280 mm 9 x 300 mm 12 x 240mm 9 x 280 mm 11 x 240mm 9x 260 mm 10 x 240mm 9x 360 mm 10 x 360 mm 11 x 360 mm 12 x 360 mm 9 x 380 mm 9 x 380 mm 10 x 380 mm 11 x 380 mm 12 x 380 mm 9 x 400 mm 9 x 400 mm 10 x 400 mm 11 x 400 mm 12 x 400 mm 9 x 420 mm 9 x 420 mm 10 x 420 mm 11 x 420 mm 12 x 420 mm 9 x 440 mm 9 x 440 mm 10 x 440 mm 11 x 440 mm 12 x 440 mm 9 x 460 mm 9 x 460 mm 10 x 460 mm 11 x 460 mm 12 x 460 mm 9 x 480 mm 9 x 480 mm 10 x 480 mm 11 x 480 mm 12 x 480 mm 15 x 440 mm 14 x 440 mm 14 x 460 mm 15 x 460 mm 14 x 480 mm 15 x 400 mm 15 x 420 mm 14 x 460 mm 13 x 480 mm 14 x 400 mm 14 x 420 mm 14 x 440 mm 13 x 460 mm 15 x 360 mm 15 x 380 mm 14 x 420 mm 13 x 440 mm 14 x 360 mm 14 x 380 mm 14 x 400 mm 13 x 400 mm 13 x 420 mm 15 x 340 mm 14 x 380 mm 13 x 380 mm 15 x 320mm 14 x 340 mm 14 x 360 mm 13 x 360 mm 14 x 320mm 14 x 340 mm 13 x 340 mm 15 x 280 mm 15 x 300 mm 14 x 300 mm 14 x 320mm 13 x 320mm 14 x 280 mm 14 x 300 mm 13 x 300 mm 15 x 240mm 15 x 260 mm 14 x 260 mm 14 x 280 mm 13 x 280 mm 14 x 240mm 14 x 260 mm 13 x 260 mm 14 x 240mm 13 x 240mm 14 x 480 mm 15 x 480 mm Left: Design view of component layout with drawers. Right: Photo of finished case. 2