KemForm, possibility to improve productivity of the

advertisement

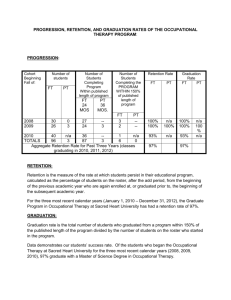

KEMFORM, POSSIBILITY TO IMPROVE PRODUCTIVITY OF THE MACHINES FOR PRINTING AND PACKAGING GRADES Matti Hietaniemi Marcus Lillandt Kemira Research Scientist Espoo, Finland Kemira Sr Research Scientist Espoo, Finland Kimmo Strengell Kemira Paper Product Line Manager Retention & Dry Strength Helsinki, Finland ABSTRACT To produce paper and paper board more costefficiently, fiber costs should be reduced. In paper making this can be achieved using chemistry promoting high filler loading. In multiply board production target can be reduction of basis weight from the layers containing expensive fiber raw materials. A narrow balance exists in attaining the desired retention and formation particularly in systems with heavier ash loads and producing paper with high speed paper machines. For paper board the challenge is to balance drainage and formation. Drainage chemistry should also improve press dryness to improve production rate and efficiency. A new generation of both cationic and anionic micropolymer technologies has been developed. These water based chemistries are free of volatile organic compound (VOC), mineral oil aliphatic compounds (MOAH) and mineral oil saturated hydrocarbon (MOSH). When these novel micropolymers are applied with linear poly-acrylamide or in conjunction with inorganic microparticle technologies, such as colloidal silica, substantial increases in drainage, fibre retention and ash retention are observed. Micropolymers also influenced on paper strength enabling higher filler content in sheet. A particular note is the drainage improvement seen with the application of the cationic micropolymers in unbleached packaging grades. INTRODUCTION During paper and board manufacture a narrow balance exists when achieving the optimal retention in the process for maximizing runnability, while obtaining the desired sheet formation. Dispersed colloids deposit onto fines and fibres to form “flocs” which are retained by filtration [1]. The adsorption of these small particles becomes a greater challenge as the furnish is exposed to increasing hydrodynamic shear stress as machine speed is increased [2,3]. Further complexity is introduced when ash containing furnishes are used and the ash constituent is elevated, intensifying the demand on retention systems. Main challenge in packaging and board grades is the drainage and press dewatering improvement without sacrificing formation. High molecular weight long chain polymers, polyacrylamides (PAM’s), are efficient for gross retention. These low charged polymers are generally linear. Although branched or structured versions are sometimes used, the linear versions are the most common chemistry applied. PAM’s generally induce the development of a large flocs via a bridging mechanism to obtain sufficient retention of fines and filler. The sheet structure created is often referred to as “hard flocced” or macro flocculated. In the presence of filler, PAM’s can agglomerate filler particles. By effectively increasing the average particle size of the filler or pigment, optical efficiency can be compromised. With the changes in filler distribution within the sheet and particle size, both opacity and formation can be adversely affected, as well as other physical properties. In addition, a substantial level of “bound” water is present within the floc often hindering the pressing efficiency of the sheet. Higher dewatering rates may be observed in the forming section of the paper machine, but the net water removal after the press section may be lower [4]. The result can be slower machine speeds or higher steam demands. Runnability can be also compromised if the bound water becomes excessive resulting in sheet crushing and picking. In manufacturing processes that utilize high efficiency presses such as an extended nip press (ENP), this loss in pressing efficiency can be very prohibitive. High charged low molecular weight polymers and inorganic coagulants allow for fixation or patch retention of fillers, fines, and detrimental substances. Although they can improve drainage in some systems through soluble charge control, they are limited in their ability to maintain retention because of the lack of floc structure. Moreover, sufficient application rates to obtain the desired drainage effect, can lead to an excessive decrease in cationic demand. This can inhibit retention of other process additives as well as the principle furnish components. MATERIALS AND METHODS Studies were made in laboratory to explore benefits of micropolymer based retention systems. In addition, a flocculant, linear cationic polymer and colloidal silica was used. Micropolymer A new generation of micropolymer technology enables a floc and subsequent sheet structure to be created that maximizes drainage in the former without compromising pressing efficiency [5]. This technology is also very efficient for retention of both calcium carbonates and kaolins. These polymers are synthesized with either cationic or anionic charge, which enables this chemistry to be reactive across the majority of wood and non-wood containing grades. The following figure illustrates how the charge and molar mass of the cationic versions of the micropolymers relates to the conventional linear cationic PAM’s and short chain high charge density coagulants. 20 18 Pure PEI Charge Density (meq/g) 16 14 DMA-Epichlorohydrin 12 Modified PEI Hydrophobe 10 Figure 3. Schematic of association of hydrophobic monomers. 8 NEW Micropolymers (Cationic) 6 4 These associations or interactions build a very highly structured polymer, creating a three dimensional micronetwork that is estimated to be 50 nanometres (nm) in size as determined by Zimm analysis. Because the structure is created without truly cross-linking the polymer constituents, the charge of the polymer is very accessible, increasing reactivity. Recent work has shown that this structure is preferred for retention of clays and carbonates [6]. Data suggests that there is selectivity for ash. The structure is illustrated in Figure 4. p-DADMAC 2 CATIONIC PAM'S 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 Molecular Weight (MM) Figure 1. Charge density versus molecular weight for various cationic polymers. The illustration shows the unique combination of molecular weight and charge density of the cationic micropolymers. In addition to these properties, they possess a unique structure and composition. Micropolymers appear as 3 dimensional in a weak water solution. The structure in weak water solution enable charges to migrate over longer time in flocculation. Micropolymer conserve charges over longer time compared to linear flocculant. This gives certain benefits in a papermaking retention application. These polymers are synthesized using a controlled molecular weight cationic polyacrylamide polymerized within a coagulant matrix. The end result is a system of high charge density low molar mass polymers and higher molecular weight medium cationic polymers. This system is depicted in the following illustration (figure 2). Figure 4. Micropolymer structure. Although the charge is highly accessible, a considerable portion is buried in the network and requires some shear to expose it. This is referred to as the ionic regain. Consequently, it should be noted that the charge density data for this chemistry is determined by streaming potential and does not represent the total charge available within the micropolymer structure. This combination of charge and structure allows the polymer to control anionic trash through fixation while retaining fibres and fillers. The control of detrimental substances is necessary in many systems in order to maintain efficiency of process additives such as starch and sizing agents [7]. The floc structure created is not only efficient for retention, but it also improves sheet dewatering through the former and press. Fines and fillers are flocculated along the long fibres as small discrete flocs, which minimizes the level of bound water. This structure reduces the blocking of inter-fibre pores. A greater level of water can be removed from the former and this dewatering can continue through the press section. Pictures comparing the floc structures created with a conventional long chain linear polymer versus the micropolymer is shown in figure 5. Figure 2. Characteristics: SEM-cryo picture. This chemistry can also be produced using an anionic system of anionic acrylamide, which allows for the development of anionic charged polymers. The micropolymers are highly structured polymers demonstrating very little linearity. This is largely due to the inclusion of hydrophobic associative groups in the synthesis. These groups increase the number inter and intra molecular interactions as shown in the figure 3. 2 Linear polymer Fennopol K 3500R was used as polymer in the retention system. Fennopol K3500R is linear polyacrylamide based premium retention polymer that is delivered as a dry product. It has a 10 mol-% cationic charge and a medium molecular weight of 7 million g/mol (Figure 7). (a) (b) Figure 5. Light microscopy pictures from flocculated fiber and filler particles. (a) with linear polymer flocculant. (b) with micropolymer flocculant. An additional advantage of the floc structure depicted by Figure 5b is the improved fines and ash distribution due to the flocculation along fibre surfaces. This can bring about increases in strength and improved optical properties. Kemform® is a retention and drainage system comprising linear polymers, microparticle silica/bentonite and micropolymer. Fennosil E TM and Fennosil ESTM product families have anionic and cationic micropolymers having charge from -40 to +40 mol-%. The FennosilTM products are water in water dispersions in salt solution (ES) or in coagulant solution (E). Finally, this micropolymer technology is made without oil. They are not emulsions, and as such, do not contain volatile organic compounds (VOC’s) or alkyphenol ethoxylate. The micropolymer selected for the laboratory experiments is Fennosil ES 325™ - a high molecular weight cationic micropolymer. Figure 7. Illustrative picture of cationic polymers like Fennopol K3500R. Colloidal silica Fennosil 515 is microparticle colloidal silica. It’s particle size is 5 nm and specific surface area 500 m2/g. Primary use of microparticle silica is to improve drainage at the wire and especially at the wet pressing. Microparticle silica retains efficiently starch, fines, internal size AKD or ASA and fillers – primary (fresh) or secondary filler (with RCF). Use of microparticle silica typically reduce linting and improve bonding (Scott Bond) of the paper or board (Figure 8). Coagulant PAX XL60, a polyalumiunium chloride with 8 % aluminium and a basicity of 40%, was used as coagulant. Its structure is illustrated in figure 6. This is a coagulant that has fast reaction to colloidal particles. It enhances flocculation when used together with polyacrylamide flocculants and microparticle colloidal silica in Kemform® system. Use of PAX XL 60 typically lowers COD, reduce deposition tendency and improve papermachine cleanliness. Figure 8. Schematic particle and surface chemistry of microparticle silica. Pulp Studies were conducted on recycled fiber (RCF) furnish collected from a mill producing coated folding boxboard (FBB) in Europe. Test pulp was the middle ply furnish containing RCF and broke. The details of the used pulp and wire water can be seen in Table 1. The furnish used in the testing consisted of one part pulp and two parts wire water. The dilution of the pulp to the consistencies used in the testing was done with deionized water. Table 1. The characteristics of used pulp and wire water. Pulp Wire water pH 6,86 6,84 Turbidity NTU 1978 69 Conductivity of µS/cm 3170 2410 filtrate Charge µekv/l -216 -258 Zeta potential mV -9,6 n.d. Consistency g/l 31,4 2,9 Ash content % 20,4 56,2 Figure 6. PAC structure 3 Retention test With a very high amount of only Fennopol K3500R it is also possible to reach good drainage time. The drawback is though a poor formation of the sheet, which is due to the large size of the flocks. This was not studied in this evaluation, but is a known drawback of one polymer retention systems. The first pass retention (FPR) of different chemical systems was determined using Dynamic Drainage Jar (DDJ, Figure 9). The main part of the equipment is a cylindrical plastic jar. At the bottom of the jar was a stainless steel screen type 60M. The papermaking furnish (500ml, 7.7g/l) was added to the cylindrical plastic jar and agitated at 1000rpm. The chemical components were added to the furnish and 100ml of the water was taken out through the wire without stopping the stirrer. PAX XL60 was added 25 s before the dewatering started, Fennopol K3500R 20 s, Fennosil 515 10 s and Fennosil ES 352 7 s before dewatering. Based on the dry solids and the ash content of the initial furnish and the water taken out through the wire, the first pass retention and first pass ash retention was determined. Figure 10. Improved drainage was seen when Fennosil 515 and XL60 was combined with K3500R. By adding the micropolymer Fennosil ES 325 to the retention system, even better drainage performance was achieved, Figure 11. This can be seen already at quite small dosages of Fennosil ES 325 and this system can can effectively be combined with Fennosil 515. Figure 9. The Dynamic drainage jar showing the cylindric plastic jar and stirrer. Drainage test The drainage tests were performed with Dynamic Drainage Analyzer (DDA). The DDA measures drainage under vacuum. The DDA consists of a cylindrical plastic jar with stirrer similar to the DDJ and a vacuum system. The pulp was added to the jar (500ml, 4g/l), stirred at 1000 rpm while the chemicals were added to the furnish at the same times as in the retention tests. Thereafter, the stirrer was stopped and the dewatering started through a steel wire with 0,25 mm opening. When air starts to flow through the fiber mat, the vacuum decreases rapidly and this point gives the dewatering time [8]. Figure 11. The drainage is even further improved when adding Fennosil ES325 to the retention system. In this study, clear differences were also found as expected in first pass ash retention. The relationship between first pass ash retention and drainage is presented in Figure 12. At a specific retention level, the linear cationic polymer alone gives the longest drainage time. By using microparticle silica (Fennosil 515) and PAX XL60 at a specific retention level, the dewatering speed was improved with up to 10% compared to a single component system. RESULTS AND DISCUSSION Experimental work is consisting from laboratory tests and mill cases. In the laboratory tests focus was on dewatering and retention, while the mill tests focused on production and cost efficiency verification. Laboratory results Drainage and retention performance are crucial for all retention systems. Fennopol K3500R, which is a cationic polymer, gives a clear improvement in drainage, see Figure 10. The drainage can also be even further improved by adding Fennosil 515 and PAX XL60 to the furnish. 4 Table 2. Mill trial conditions for Mill case 1. Trial basic data Production: 30 t/h Grades: 3 ply board Grammages: 200 - 350 g/m2 Speed 450 m/min Table 3. Mill trial dosages for Mill case 1. Chemistry REFERENCE PVAM (g/t) Top/ Back 700 - 750 Middle 700 - 750 Figure 12. The drainage was improved also at a specific first pass ash retention. K3500R added 0g/t (FPAR approx. 5%), 250g/t (FPAR approx. 30%), 500g/t (FPAR approx. 45%) and 750g/t (FPAR approx 55%). TRIAL Fennosil ES 325+ Fennosil 515 (g/t) 600 + 1250 300+ 500 Mill case 2. White top kraftliner By using a cationic micropolymer (Fennosil ES325), we got excellent dewatering at high first pass ash retention, Figure 13. Once again, the Fennosil 515 can also be used to improve the retention system even further. Mill is producing white top krafliner board with a production rate of 310 000 ton/a. Currently board market for packaging grades is very good and the key thing is to increase output with same fixed costs. Mill runs the retention system based on cationic PAM + bentonite -system with fair amount of cationic starch. Kemira implemented Kemform® trials on this machine with very impressive results: Production rate at 38 t/h against budgeted 36 t/h Improved runnability and board characteristics Improved retention and more clean wire part and short loop Mill case 3. Specialty fine paper Mill producing uncoated fine paper from hardwood and softwood bleached kraft together with PCC had ambition to increase filler content in paper because mill is limited with fiber supply in the pulp plant. Increasing filler in paper improve profit. Kemira’s Kemform system was trimmed with Fennosil 515 microparticle technology. Anionic linear Fennopol was added as a co-mix with Fennosil 515 and anionic micropolymer Fennosil ES 210 through a mixing device after the pressure screens. Figure 13. Best drainage at a specific first pass ash retention can be achieved with a combination of Fennopol K3500R, Fennosil 515 and Fennosil ES325 Mill case 1. Folding boxboard (FBB) Mill is producing coated folding boxboard with a production rate of 250 000 ton/a. Mill wanted to improve production output and they also suffer from quality problems such as delamination. Trial set-up is expressed in tables 2-3. Mill runs polyvinylamine (PVAM) chemistry in retention. Kemira implemented Kemform® trials on this machine with solid results: Overall equipment efficiency (OEE) % was reported being 2% units higher on monthly basis after Kemira system was onstream Delamination problems disappeared. Key success factor was the realized higher dry content after the wet press Results: Response of the retention system improved in such a way that it was able to increase 2% filler in the sheet with similar dusting propensity than with standard filler content in paper. Reduced usage of bleached kraft pulp provided great savings for the mill! Mill case 4. Fine paper Mill producing specialty bulky uncoated fine paper from hardwood bleached kraft and BCTMP together with PCC had target to increase filler content and improve formation in paper. Increasing filler in paper improve gross margin % of paper production. Good formation for a specialty producer is a necessity. 5 Kemira’s Kemform® system was applied on the machine with significant machine and quality improvements. Results outlook was following: It was able to increase 2% filler in the sheet Formation improved visually and by Beta measurement by 10% Bulk is maintained despite increased filler content in paper CONCLUSIONS Kemform® comprises a retention system that consist a micropolymer, Fennosil 515 microparticle silica and traditional retention polymer. Micropolymers are polymerized in a salt solution. Micropolymers are structurated polymers in a weak water solution and therefore provide differentiated performance profile compared to traditional retention polymers In the experimental part was tested for folding box board with recycled pulp furnish. Fennosil 515 improves drainage. Drainage can further be improved by adding PAX XL 60 (PAC) and cationic micropolymer Fennosil ES 325 to the system. Reference case histories proof that in industrial scale production Kemform® can improve productivity. Dry content after wet pressing was improved which enables savings in dryer section steam consumption and enables higher production speed. On printing and writing grades Kemform can support to increase filler content in paper with similar strength and optical properties than earlier. REFERENCES 1. Klass, C.P., Sharp, A.J. and Urick, J.M., Tappi C.A. Report No. 57(55) (1975) 2. Hubbe, M.A., Tappi J. 69(8): 116-117 (1986) 3. Tam Doo, P.A., Kerekes, R.J., and Pelton, R.H., J. Pulp Paper Sci. 10(4): J80-88 4. Henderson, K., Lewis, C., Tappi 2000 Annual Meeting Proceedings, P.125 5. Lewis, C., Polverari M., Paptac 2007 Proceedings 6. Polverari, M., Lagos, D., Lewis, C., 2006 Mineral PIRA Proceedings 7. Auhorn J.W. and Melzer J, Tappi 1979 Annual Meeting Proceedings, p.49. 8. AB Akribi Kemikonsulter. www.dda.se/dda_manual.pdf 6