Fundamental Strategy for Control of Retention and

advertisement

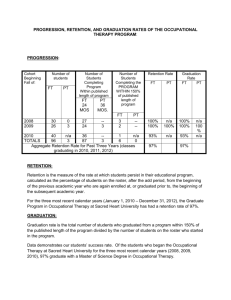

Netention and u r a i n a g m w-9 ental strategy for control ention and drainage on a rn paper machine M,Sprhger,Jefsrey S. Noe, and T.H. Wegner t and maintain control ouer contaminants in reqcled uhite uater, ment-bked retention control strategy must be deueloped. rates must be adjusted to compensate for this constantly moved the paper industry toward ever in- changing environment. To detect changes in chemical conditions at the wet end, ees of system closure and white water reuse. new on-line sensors will need to bedeveloped, and those that are available will have to be used more effectively.A recent Pete with filler and fibrous additives for survey (6) revealed that we are in our infancy in this field. The most-needed capability is a reliable way to monitor the costly cationic chemicals. state of charge of the system. Knowing the state of charge of the system is necessary, but it is not sufficient information for controlling retention and drainage. The lack of recognition of this fact is partly responsible for the poor results that have been experienced in trying to apply zeta potential sensors in the paper mill. ctivity is useful for measuring the total con- Retention and drafnage of inorganic contaminants. The concentration To adequately control retention and drainage, an instrument-based strategy must be developed(3-5,7). Such a trol of retention and drainage is accomplished strategy is illustrated in Fig. 1. For this strategy, it is combination of machine design and chemical presupposed that a good pH control program has already he best approach is first to optimize the mech- been implemented in the mill. The strategy would contors on the machine such as headbox conditions tinuously monitor the concentration of contaminants and eluding the number of foils and their key system responses and automatically adjust addition control agents appropriately. A strategy like this would likely result in substantial raw material savings and increased productivity, while including such benefits as: leaving the couch. 1. Reduced loss of high-cost materials such as titanium have been studying the effects dioxide and synthetic size s a chemical engineer for USDA Forest Laboratory, P.O. Box 5130, 2. Increased dewatering on the paper machine, leading to a lower water content in the sheet going to the press section and lower energy requirements in the dryer section 3. Potential for increased machine speeds because of an increase in drainage rate 4. Improved paper machine runnability 5. Potential for increased water reuse, which can result in energy and raw material savings. Lindstrom and coworkers (8) also have proposed a retention control strategy model. Three major generalizations can be drawn from the extensive amount of research aimed at elucidating wet-end chemistry mechanisms and fundamental knowledge (5). Serving as the basis of a first-pass retention control strategy, these three generalizations are as follows: January 1987 TapplJoumal 43 I%"* 1. The performance of most wet-end additives and components is highly dependent on the first-pass retention. 2. On medium- to high-speed paper machines, retention aid additives are necessary to achieve acceptable first-pass retention. 3. The effectiveness of cationic additives is impaired by interference from dissolved and colloidal anionic substances at the wet end. The proposed retention and drainage control strategy (Fig. 1) consists of three main control loops. The first loop measures and neutralizes the organic contaminants on the thick-stock side of the stock preparation area. Total organic carbon (TOC) measurements serve as a measure of the cationic demand of the system (9). Based on the demand measured, a cationic-charge neutralizing additive of low molecular weight and high charge density is added to counteract detrimental organic effects. This amount will be affected slightly by the concentrationof dissolved inorganics (9). In theory, as the furnish exits the stock preparation area, the total charge of the system is checked to determine if the charge of organics is sufficiently neutralized. In the second loop, the first-pass retention performance is measured, and the addition rate of the high-molecularweight retention aid is adjusted if a change in retention is needed to achieve a targeted uniform retention. A retention value that correlates with first-pass retention can be derived with the M/K and Chemtronics retention meters. The adjustment of drainage rates and couch dryness would be controlled by this additive also. Information about the mass of incoming fine solids (filler, pulp, and broke fines) from the stock preparation area is also known and fed forward to this loop. The third loop illwtrated in the diagram monitors the retention of filler in both the final sheet and in the recovery system for recyclying broke. This information is fed back to the stock preparation area to adjust the flow rates of mineral fillers such as clay and TiO2. Not illustrated in the diagram but quite necessary is a feedback loop that relays information on such properties as the optical nnd strength charaeteristicsof the paper tosome type of process control computer. This information would include measurements of opacity, brightness, ash contact, strength, etc., so that product specifications would remain acceptable. In short, a first-pass retention and drainage control strategy could be implemented with relatively few on-line sensors. However, sensors which are currently unavailable are those that measure total charge of the system, the process stream, and wet ash in the system. G future demands required in the paper machine wet end from alkaline papermaking and the increased filler loadings, higher machine speeds, lower basis weights, white water recycling, etc., the industry needs to take a stronger approach toward this type of on-line process control strategy. If the needed sensors can be developed and are sufficiently dependable, control of retention and drainage should be possible. We have begun to work on a reliable technique to monitor total charge in the papermaking system, since the industry survey ( 6 ) indicated that this was of top priority. The measurements to characterize fine solids and wet ash still need to be developed. Instruments for monitoring retention are under development,and some commercial installations exist. The sensors for monitoring sheet ash by components exist and are readily available. They are becoming part of I.Diagram of the proposed control strategy for retention and drainage. 44 Januaty 1987 TapplJournal package systems for the paper machine. ions of inorganics in the system are best t, so the main questionsto be answered ions of the measurement (9). f the instruments necessary to implement the trategy aredeveloped. What is missing are a wet sensor,a fine solids sensor, and a technique to monitor a papermaking system. and pH are compensated for. TOC is measure of the colloidal and dissolved m! A Manager's Guide to Process Simulation Designed for the manager . . . . 0 With limited background in simulation/computers Considering developing a process simulation capability 0 Wanting to improve an existing simulation group 0 . Springer, A., Noe,J., andTaggart, T., 1985Advanced Topics in Wet End Chemistry Seminar Notes, TAPPI PRESS, Atlanta, 4. Springer, A., McMahon, W., and Boylan, J., 1984 Papermakers Conference Proceedings, TAPPI PRESS, Atlanta, 1984, p. 13. . Springer, A., Boylan, J.. and McMahon, W., Southern Pulp Paper 47(3): n(1984). 6. Scott, W.E., Tappi J. 67(11): 72(1984). 7. Scott. W.E.,1983 Retention and Drainage Seminar Notes, TAPPI PRESS, Atlanta, p. 59. Lindstrom, T., Rydefalk, S., Wagberg, L., Development of an Integrated Retention Control System, New Available Techniques P"$ings from the World Pulp and Paper Week, Swedish A w i a t i o n of Pulp and Paper Engineers, April 10-13, Noe. J.S., Mechanism for Control of Retention and Drainage in ms, M.S. thesis, Miami University, After reading the 44-pageI soft cover report, the manager should understand the basics of process simulation, when to use it as a tool, what simulators are available, what resources are required for simulation, and what steps should be taken to carry out a simulation project. You will then be ready to direct a person or group to: Compare available simulators 0 Select one for your simulation project Arrange to be trained to use it Start simulating (work with knowledgeable personnel) 0 0 0 for review April 15.1986. 1985.44 pages. 8'/2 x 11 Soft Cover. Order Number: 01 01 R131 TAPPI Members: $8.00; List: $12.00 TAPPI PRESS PublicationSales Technology ParWAtlanta 0 P.O. Box loJ113 Atlanta, GA 30348 0 (404)446-1400 January 1987 TappiJournal 45