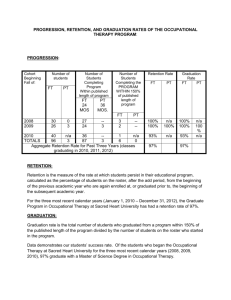

Retention

advertisement

Retention What is retention? Retention mechanisms Retention aids Retention What is retention? Retention mechanisms y Retention aid systems 1 What is retention? − The efficiency by which components of paper making are retained in a web of paper as it is being formed − “The proportion of a component in a mixture which is found in the mixture in a later process stage” − Can be specified for different components • fiber retention • fines retention • filler retention Total retention •(additive retention) Retention − Retention of a substance in a system is the ability of the system to retain the substance within the system limits − Retention parameters can be defined around different process systems (the whole paper machine, the wire part or a single dewatering element) − First-pass retention (Wire retention), ms/m0 − Machine retention, mm/(m0-m1) − System retention, mp/mf 2 First pass retention (Wire retention) − Most widely used retention parameter, equation (1) R= chb ∗ Qhb − cww ∗ Qww ∗100 % chb ∗ Qhb (1) R Fi Firstt pass reterntion t ti chb consistency of the head box furnish Qhb volume flow of the furnish from head box cww consistency of the white water Qww volume flow of the white water − The volume flows can be assumed to be equal resulting the equation ti (2) R = (1 − cww ) ∗100 % chb (2) First pass retention (FPR) − Important for the effective use of functional chemicals − Fines and fillers have large specific surface area adsorption of additives on surface f off fines fi and d fill fillers − Poor first pass retention additives into the circulation water − Loss of effectiveness of additives in water circulation system (for example hydrolysis of ASA) − Precipitates − Unretained additives act as nutriment for microbes − FPR depends p on the filtering g capacity p y of the formed fiber mat 3 First pass retention − Not constant through the whole wire section − At the beginning of wire section Initial retention (colloidal retention) − tturbulent b l t circumstances, i t nott fiber fib mat formed yet − Low retention of fine particles − Web forming during even water removal (laboratory sheet mold) − Forms fiber mat, which retains fine particles (filtration) − Good retention of fine particles − Web forming during pulsative water removal (wire section of paper machine) − Breaking down of the fiber mat − Poorer retention of fine particles − Depends on the wire section type (fourdrinier, hybrid former, gap former, cylinder former) Machine retention − Important for quality of circulation water − Dilution of pulp from stock preparation − Circulation water used in showers − Depends on efficiency of different separation units − Disc filter − Flotation > Save all and solid returning to the process − Unretained U t i d additives dditi and d fifine particles ti l can cause problems bl − Depositions in long circulation − Unretained fines retained to refining Loss of strength properties Harmful for dewatering 4 Total retention − Mass balance − ratio of p product amount to the amount of used raw materials (product/raw materials fed into the process) − Economical use of the raw materials − Greatest sources of material losses − Rejects of cleaning plants − Dissolved and colloidal substances in water discharged from the p process − Depends on first pass and machine retention − Need of circulation water treatment − Need of waste water treatment Process factors affecting retention Raw materials TTechnical h i l solutions Chemistry 5 Retention of different components Dimensions of papermaking components Fibers Fines Fillers Length 1 – 5 mm < 1 mm 0.2 – 3 μm length/thickness-ratio 50 varying 1-5 Specific surface area 1 – 2 m2/g 3 – 6 m2/g 6 – 15 m2/g Source: Zhmud, B., Retention and formation in papermaking http://www.sveacon.se/lectures/retention.pdf Retention of different components – Fibers − Fiber retention depends on fiber length − Forming fiber net net-work work > mechanical retention − Easy to achieve high retention, even over 90 % − Formed net-work can also retain fines and fillers Rettention, % KnowPap Fiber length, mm 6 Retention of different components – Fines and fillers − Mechanical retention of fibers − Even over half of the solids in headbox consists of fillers and fines − Very small particle size no mechanical retention > Conditions for retaining of fines and fillers Forming of aggregates of particles or Particle attachment on fibers in head-box or on wire-section − Forming of aggregates or attaching on the fibres is prevented, why? − Fines and fillers are usually negatively charged as also fibers > Repelling each others > Additives are needed to form aggregates > Control of wet end chemistry important - - - - - --- - - - - - -- -- - - - Importance of retention – Effects of poor retention − Effects on product properties − − − − Two sideness Sizing degree Dry and wet strength Filler content − Effects on process − Additives adsorb preferably on fines and fillers High chemical consumption − Process water quality − Grammage variation on machine direction − Decreased dewatering − Web breaks − Waste water quality − Enrichment of components in circulation water − Removal with waste water − More efficient waste water handling is needed 7 Importance of retention – Advantages gained with retention optimization − Runnability of paper machine − Economical use of raw materials − dewatering – producton rate − dewatering – drying costs − Less precipitations and cleaner water circulation − Minimizing g the loss of fibers − Minimizing the loss of fillers − Effective use of additives − Environmental aspects − Product properties − Lower waste water load − Cleaner circulation water B Possibilities to close water circuits B decrased use of fresh water − Decreased two-sideness − Less filler loss − Efficient use of additives − Sizing degree − Dry and wet strength Retention and dewatering − Dewatering (drainage) − Rate, by which water removes from fiber mat − Amount of water (consistency) − Machine speed − Machine structure − Structure of wire − Coarce wire better drainage, poor retention − Pressure difference between upper and lower side − Even pressure difference − Pressure pulses retention slow drainage, good retention formed fiber mat decomposes better drainage, poorer − twin wire machines: intensive pulsating water removal retention good drainage, poor 8 Retention and formation − Formation (paper property) − Affecting factors − − − − Consistency Shear forces in head box Pulsative water removal Formation of flocs F Formation = small scale basis weight variation in the paper (=wavelength of the scattering is 0100 mm) − Depends D d on − Floc size, amount of flocs and distribution of the flocs in the sheet − Have effect on − Physical and optical properties of the sheet Retention system A Retention system B Retention, % Formation scale in the figure: higher value, better formation Retention and drainage/formation − Objective: − Even quality (formation) − Production P d ti speed d (d (drainage) i ) − Economy (retention) − High first pass retention is desired Compromise with formation and/or drainage − Without chemicals − Good formation (few flocs) − Poor retention − Slow dewtering g ((high g amount of fine p particles)) − Retention / dewatering aids are additives which enhance the retaining of fillers and fines into the paper web 9 Cases of retention of fines and fillers − Flocculation of filler particles Large g filler aggregates gg g Decreased light scattering − Ideal case − No flocculation of fibers − Maximum attachment of fines and filler particles on the surface of fibers Retention What is retention? Retention mechanisms y Retention aid systems 10 Retention mechanisms Coagulation Flocculation Network flocculation Mechanisms of chemical retention systems − Coagulation − Charge g neutralization − patch model − Heterocoagulation − Flocculation − Bridging − Applications − Adsorption + bridging − Enhancing the flocculation flocc lation by b adding electrolyte electrol te − Complex formation flocculation (two component systems) − Network flocculation 11 Chemical retention systems − Coagulation and/or flocculation is a base for − Fines retention − Filler retention − Retention of additives − Hydrophobic sizes − Dry strength additives − Wet strength additives − Fixing of pitch and other detrimental substances − Importance of charged particles − Electrostatic interactions − Attractive forces Forming of electronic douple layer − Surface in water will be charged − F For example l − Fiber in water − Negatively charged surface − σ0 depends on the pH of water and quality of fiber − Negatively charged surface − Attracts positively charged ions 12 Coagulation - Charge neutralization − − − − Adding of counter ions, which adsorb on the Stern layer − aluminium compounds (alum) − polyelectrolyter with quite low molecular mass Surface potential unchanged Oppositevely charges in Stern layer Stern – potential decreases Diffuce potential decreases Repulsive forces diappear V deer Van d W l forces Waals f (attractive) The length of van der Waals forces quite short − Difficult to coagulate when high shear forces are present − Not enough for retention of fine particle during web forming Coagulation - Charge neutralization − Risk of over dosing − Reversal of charge to positive stabilization bili i (repulsion ( l i between b particles) 13 Coagulation – Patch model (mosaic model) − Adsorption of the positevy charged polyelectrolyte on the surface − Positivelyy charged g ”patches” p on the surface of negatively g y charged particle − Reach over the diffuce layer Enevenly distributed charge on the surface − Attraction between opposively charged parts on the surface coagulation − Charge neutralization is not reguired − Cationic polyelectrolytes − High charge − Low nmolecular mass Coagulation - Patch model − Compact, small flocs (soft flocs) − Strong bonds between particles − Not elastic bonds − Weak against shear forces − Reversible coagulation − Microcoagulation during the web forming − Increased porosity of the wet web − Better drainage − Effect of electrolytes (salt) − Small amount of electrolyte decreases the thickeness of douple layer − patces reach better over the douple layer − increased coagulation − High amount of electrolytes causes desorption of polyelectrolyte and decreased coagulation 14 Heterocoagulation − Oppositely charge particle adsorbs on the surface of fiber of filler − Electrostatic ((cationic)) stabilized size dispersiond p and emulsions − Cationized filler – fiber − Cationized disperged fillers − Electrostatic interactions - + - Flocculation mechanisms - Bridging − High molecular weight polymer (lonc chain) − Adsorbs on two or several surfaces on the same time (forming loops and tails) >bridging particles together flocculation − Large, loose flocs − Elastic bonds between particles − Quite well resistance against strong shear forces hard flocs 15 Flocculation mechanisms - Bridging − Irreversible − Breaking g of bridges, g reconfirmation Reflocculation by patch model − High retention − Over flocculation − Over dosagew − worsed formation Flocculation mechanisms - Network flocculation − Two component system − Components p forum network ((like fish net)) − While moving in the liquid liikkuessaan collects fine material − Effective also in systems containing high amounts of detrimental substances (anionic trash) − Rarely used − expensive 16 Properties of polyelectrolytes affecting flocculation mechanisms − Functional groups − Molecular weight − Charge and charge density Roperties of polyelectrolytes – Functional groups Anionic − − − sulphonic acid group Ph Phosphoric h i acid id groups Carboxylic acid grouos Cationic − − − Sulphonium group Phosphorium grup Ammonium groupryhmä - quaternary ammonium - tertiary ammonium O O ള ള - P – O- S – Oള M+ ള M+ O O Sulphonic acid Phosphoric acid group group R ള – S+ – R XSulphoniu p m group R ള – P+ – R XPhosphoni p um group CH3 R– N+ –CH3 CH3 Kvartäärinen ammoniumioni O ԡ - C – OM+ Carboxylic group R ള – N+ – R XAmmonium group CH3 – N+ – H CH3 Tertiäärinen amiini 17 Properties of polyelectrolys – Molecular weight − Increasing of molecular weight − Increased chain length g and extent − Better retention effect by bridging − Extent is also dependent on the branching of the polymer molecule − extent − Ability to charge neutralization on the surface − Vinyl polymers − linear − Moleculas weight in the calibre of 106 − Condensation polymers − Molecular weight 50 000 – 200 000 − branched Properties of polyelectrolytes – Charge density − Charged groups in the monomer units − Share of charged groups 1 – 40 % − Charge density − Condensation polymers > vinylpolymers or starch base − Important because of the adsorption − Interaction forces between surface and polymer − Polymer P l conformation f ti on the th surface f 18 Polyelectrolyte adsorption − Adsorption of the polyelectrolyte on the fiber surface 1) Adsorption on the surface with one or several areas 1) 2) Confformation change (flatter conformation) on the surface 3) Polyelectrolyte diffusion into the porous surface f off the th surface f ( l in (only i case off porous surfaces) Decreased charge on the surface Important because of the effective dosing point 2) 3) Polyelectrolyte adsorption − Dosing of retention aids a few seconds before head bos − Adsorption rate − Rate of conformation change − Collision frequency of particles 19 Polyelectrolyte adsorption − The amount of adsorbed polyelectrolyte increases with time Polyelectrolyte adsorption (charge density) − Charge density of polyelectrolyte affect − Adsorption p rate − rate of change of conformation − Polylectrolyte conformation in solution depends on − Mobility of polmer chain − Interactions between liquid and polymer − Repulsion between charged segments in the polymer chain 20 Polyelectrolyte adsorption (charge density) − Conformation have effect on how the polyelectrolyte adsorbs on the charges surfaces − L Low charge h d density it – weakk interactions i t ti − Middle charge density – moderate interactions − High charge density – strong interactions + + -+ - - -- + -- - + - + + + + + - + - - --- - High charge density of the polyelectrolyte, strong interaction - - --- - Moderate charge density of the PE, weaker interaction Low charge density, weak interaction Polyelectrolyte adsorption (charge of the surface) − The charge of fiber depends on the carboxylic groups on the fiber (surface charge) − Low surface charge – weak interaction − Moderate surface charge – moderate interaction − High surface charge – strong interaction + + - - + + + Low surface charge, weak interaction + + - + - -Moderate surface charge, weaker interaction + + - - -- + -- - + - + High surface charge, strong interaction 21 Polyelectrolyte adsorption (molecular weight) − Linear depence betweem the adsorbing amount of polyelectrolyte and carboxylic groups on the fiber (surface − Depends on the molecular weight of the polyelectrolyte − 3. stage – dissusion of the polyelectrolyte molecul into the pores of fiber − High M less adsorption − Surface charge caused by the polyelectrolyte adsoprtion − High M all three stages − Low M no change of conformation (flatt adsorption) − Change of charge as a function of time Retention What is retention? Retention mechanisms Retention aids 22 Retention aids − Ipolynorganic − coagulation − Alum, polyaluminiumchloride (PAC) − In two component systems (microparticles) − Bentonite, silicate − Natural based − starch − Synthetic water soluble organic polymers/electrolytes − Usually charged (anionic/cationic) − Function by different mechanisms − Coagulants (charge neutralization/patch mechanism) − For example polyamine, poly-DADMAC, PEI, PAC − Flocculants − For example polyakcrylamide (PAM), PEO, (poly-DADMAC) Polymers/polyelectrolytes used as retention aids − Cationic starches − − Part of hydroxyl groups of starch are replaced by side chain containing cationic group Usual kvaternar ammonium group − Vinyl polymers − − − polyacrylamides linear Molecular mass in scale of 106 − Condensation polymers − − Molecular weight 50 000 – 200 000, even higher branched molecules − The higher M, the more branced Charge density : condensation polymers > vinyl polymers − PEO − − − Uncharged Used together with for example phenol rosin (network formation) Molecualr weight 10-15 * 106 23 Retention aid systems − Alum − Single chemical systems (polyelectrolytes) − Patch P t h model d l − bridging − Dual systems (two polyelectrolytes) − At least one component acts by bridging − Used because of lack of effectiveness of single chemicals in some cames (high shear forces, high amount of disturbing substances) − Network formation − Microparticle systems − Polyelectrolyte + microparticle − Use of three components − Coagulatn + flocculat + microparticle 24