OLED Update - LEDs Magazine

OLED Update – May 2005

May 2005

OLED Update

A monthly review of developments in the field of

Organic Light Emitting Diodes

OLED Update is published each month by LEDs Magazine (www.ledsmagazine.com)

PRODUCT DEVELOPMENTS

Samsung Electronics develops 40-inch OLED for ultra-slim TVs

Samsung Electronics has developed the world's first single-sheet, 40-inch active matrix (AM) OLED panel for emissive flat panel TV applications. The development could pave the wave for large-size

OLED TVs with a total thickness of only 3cm or less.

The high-definition(HD)-compatible OLED prototype has a wide screen pixel format of 1280x800

(WXGA) driven by an amorphous silicon (a-Si) AM backplane to permit faster video response times with low power consumption.

Samsung's 40-inch OLED panel was demonstrated for the first time at the Society for

Information Display (SID) 2005 International

Symposium in Boston on May 24- 27.

To date, AM OLED prototypes have used costly polysilicon approaches, which have limited production sizes. The new OLED prototype was manufactured on Samsung's fourth generation (4G) production line with a mother-glass size of 730mm x

920mm. It combines all of the traditional features of emissive OLED technology - including wide viewing angle, thin package size, no color filter and no backlight - with the enormous production infrastructure advantages of standard a-Si techniques.

The 40-inch prototype offers a maximum screen brightness of 600 nits; a black-and-white contrast ratio of 5000:1; and, a color gamut of 80 percent.

Motion pictures with ultra-high quality images can be reproduced by utilizing the rapid video response capabilities of OLED technology for image processing of HD-class resolution.

Samsung’s 40-inch OLED panel

Samsung launched its OLED development initiative in 2001, and unveiled a 14.1-inch WXGA

(1280x768) OLED panel in 2004, followed by the world's first 21-inch HD-class (1920x1080) OLED panel in January 2005.

“Our development of a 40-inch OLED will provide a firm basis from which we can become the unassailable market leader in the flat-panel display market of the future,” said Dr Kyuha Chung, vice president of Samsung Electronics LCD R&D Center .

Copyright © 2005 Cabot Media Ltd and IOP Publishing Ltd. - 1 -

“We're taking an early leadership position in the next-generation display market, building on Samsung

Electronics' success in the TFT-LCD market.”

The latest round of development has been conducted as part of the project, “Development of

Solution-Based AM OLED for Low-Cost 4G HDTVs using a-Si” which is part of the Next-Generation

Growth Engine Industries Initiative funded by

Korea's Ministry of Commerce, Industry & Energy

(MOCIE).

• www.samsung.com

TMD showcases 3.46- inch QVGA OLED

Toshiba Matsushita Display Technology Co., Ltd. exhibited a 3.46-inch QVGA prototype OLED display at SID 2005.

The display demonstrated the high quality images made possible with temperature polysilicon (LTPS),

TMD's core technology. This type of OLED is expected to find use in such applications as portable video and/or media players where excellent image quality is desired.

OLED displays driven by LTPS offer several advantages over today's conventional LCD technologies, including self-emission; thinner, lighter weight displays (because no backlight is required); ultra-fast response time and ultra-wide viewing angles; and high color chromaticity.

TMD recently announced an investment of $500 million to build a new LTPS fabrication facility in

Ishikawa Prefecture in Japan. The new fab is scheduled to begin production in April 2006, with a capacity of 5.5 million 2.2-inch equivalent pieces per month, using fourth-generation 730mm x 920mm x

0.5mm thick glass.

The new fab will be dedicated to the production of small- and medium-sized cell phone and automotive displays, incorporating system on glass

(SOG) and/or OCB technologies, further establishing

TMD as the worldwide leader in the production of

LTPS displays, in small-, medium-, and large-sizes.

• www.tmdisplay.com/tm_dsp/index.htm

OLED Update – May 2005

eMagin showcases nearto-eye virtual imaging technology

eMagin Corporation demonstrated its new Z800

3D Visor and other innovations in OLED microdisplay applications at the 2005 Society for

Information Display (SID) symposium. eMagin provides OLED microdisplays and modules for more than 30 available systems so far, with many more under development.

"We have developed cutting edge active matrix

OLED displays and prism optics which provide

OEMs with the most ultra-portable and powerefficient format available," said Susan Jones, executive VP, eMagin Corporation. "We've also developed near-to-the-eye virtual imaging engines and system solutions to help reduce the entry barrier for customers to enable access to high performance simulation and virtual imaging,"

Among the products were eMagin's new Z800 3D

Visor, which combines 3D full-color stereovision with hi-fi stereo sound to begin to deliver on the promise of virtual imaging. Visitors to eMagin's booth at SID had the opportunity to try a number of popular games, such as Half-Life 2 and America's

Army, on 3D-capable PCs. eMagin’s Z800 3D Visor

The Z800 3D Visor combines eMagin's novel

OLED-on-silicon technology with new wide-view lenses, state-of-the-art high-speed head-tracking capability, flicker-free 3D stereovision capability, built-in noise-canceling microphone, hi-fi stereo sound, and low-power USB compatibility. The effect

Copyright © 2005 Cabot Media Ltd and IOP Publishing Ltd. - 2 -

is equivalent to viewing a 105-inch screen at 12 feet, but with an image that moves as the head moves to effectively completely surround the viewer with screens. eMagin is now taking orders for this product.

Other products on display included:

- a 40-degree field of view optic with large eyebox and eye relief, available for sale as standalone or mounted to eMagin's SVGA OLED displays to create near-to-eye virtual imaging engines

- UXGA microdisplays: applying its fiber-optic taper technology, eMagin effectively tiles

OLED Update – May 2005 microdisplays to create UXGA (over 5.7 million individually controlled picture elements, each with high speed 256-gray level capability per color) and larger displays.

- see-through display: the Liteye 500 is a new

OEM customer's product employing eMagin OLED microdisplays, illustrates the flexibility of virtual imaging systems, offering both augmented reality and an occluded mode for standard near-eye applications.

• www.emagin.com

• www.3dvisor.com

RESEARCH & DEVELOPMENT

Philips, Novaled push white OLED efficacy to

25 lm/W

Philips and Novaled have announced white OLEDs operating at a brightness of 1000 cd/m in Electronics Weekly.

2 and a recordbreaking efficacy of 25 lm/W, according to a report

Universal Display achieves 200 dpi transparent OLED

Universal Display has developed the world's first high-resolution, active-matrix, transparent OLED

(AM-TOLED) display, according to a joint paper with Kyung Hee University, Korea, presented May

26 at the Society for Information Display (SID) symposium in Boston.

At its SID booth, Universal Display demonstrated a 120 x 160 (QQVGA), 200 dots-per-inch (dpi) monochrome AM-TOLED, developed using the company's PHOLED (phosphorescent OLED) and

TOLED transparent OLED technologies along with

Copyright © 2005 Cabot Media Ltd and IOP Publishing Ltd.

Device technology developed at Philips' Lighting and Research divisions was combined with proprietary doping technology developed by

Novaled, based in Dresden, Germany.

The results of the research are likely to be used in the recently started European OLLA (Organic LEDs for Lighting Applications) project.

• www.hitech-projects.com/euprojects/olla amorphous silicon (a-Si) backplane technology developed by Professor Jin Jang at Kyung Hee

University.

This high-resolution transparent OLED display is a next step toward thin, low power, full-motion video displays that provide transparency when turned off.

These could be required in a variety of applications where preserving partial visibility or bi-directionality is important, such as architectural vision glass, entertainment, medical and industrial products, helmet shields for military, Homeland Security, fire and rescue applications, and other applications as yet unimagined.

"This advance leverages the high-efficiency of our phosphorescent OLED technology, adding further support for the viable integration of OLEDs

- 3 -

OLED Update – May 2005 on amorphous silicon (a-Si) TFT backplanes in a variety of OLED displays," stated Steven Abramson, president and COO of Universal Display. "Working with talented researchers at Kyung Hee University's

Advanced Display Research Center, led by Professor

Jin Jang, we have achieved an exciting milestone in demonstrating the world's highest resolution, activematrix transparent OLED display."

• www.universaldisplay.com

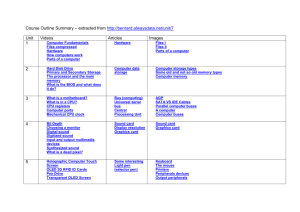

CDT achieves 100,000 hour lifetime for blue polymers

Lifetime estimates are based on accelerated testing of simple test devices at several very high initial luminance levels. These data are then used to calculate predicted lifetimes at lower brightness levels.

Due to intense industry interest in lifetime figures,

CDT has made available its lifetime data for higher initial luminance levels (see Table 2).

Table 2. Lifetime vs. initial luminance

Initial luminance

(cd/m 2 )

Blue polymer lifetime (hours)

100 100,000

Cambridge Display Technology (CDT) has reached an important milestone with the development of blue polymers for light emitting devices with 100,000 hours lifetime from an initial luminance of 100 cd/m 2 . (“Lifetime” refers to the time taken for the display/pixel to fall to half its initial stated luminance.)

200 25,000

300 10,000

400 6,000

Over the past year, CDT has more than trebled the lifetime of such devices (see Table 1).

Table 1. Blue polymer lifetime polymer lifetime (hours)*

May 2004 30,000

CDT’s CEO, David Fyfe, noted that the performance of materials in an actual display system will depend on a number of factors other than simply brightness to the viewer, such as whether the devices are top-emitting or bottom-emitting, the aperture ratio, the sub-pixel aperture ratio, average pixel brightness, choice of circular polarizer and so on.

October 2004

December 2004

May 2005

70,000

80,000

100,000

"CDT intends to press for industry standards which reflect these realities and which will also allow calculations to be made of system performance at any level, enabling materials to be compared and the practical significance of quoted lifetimes to be exemplified,” said Fyfe.

* All from an initial luminance of 100 cd/m 2 .

Lifetime is one of the most important parameters governing the rate at which polymer LED technology is adopted commercially. Higher lifetimes are already available with red and green polymers, and so this increased blue lifetime will allow yet more applications to be realized using PLED technology, including full colour displays for digital cameras,

PDAs and DVD players. PLED display applications will ultimately include large flat panel televisions.

"I am delighted to be reporting these new levels of blue lifetime, levels which are consistent with our rapid yet consistent progress over the last two years.

We believe the disclosure of lifetime data at more challenging luminance levels will give additional meaning to these results and help designers and display makers to predict more accurately the performance of our technology in real life applications."

• www.cdtltd.co.uk

Copyright © 2005 Cabot Media Ltd and IOP Publishing Ltd. - 4 -

OLED Update – May 2005

BUSINESS NEWS

CDT and Sumitomo

Chemical announce P-

OLED joint venture

Cambridge Display Technology (CDT) and

Sumitomo Chemical have signed a memorandum of understanding (which is non-binding at present) to form a new joint venture company to develop and supply advanced polymer OLED (P-OLED) materials and formulated inks for use in commercial P-OLED display and lighting applications.

The new company, to be based in Tokyo, Japan, will be owned equally by the two parent companies, and will have the largest concentration of P-OLED material development expertise and intellectual property (IP) in the OLED industry. This is the first time that CDT has been directly involved in the materials supply business.

The parent companies will channel their existing

P-OLED materials R&D activities and IP into the new JV company. Sumitomo acquired the Lumation business from Dow (see below), and will make available, on an exclusive basis, the polyfluorenes technology and IP of the Lumation business to the joint venture.

The JV will have access to the strongest materials set in the polymer OLED sector, including the current best-performing full colour P-OLED materials based on polyfluorene chemistry which CDT and Dow have separately developed over the last ten years. It also has exclusive access to 'next generation' high efficiency materials based on dendrimer chemistry which CDT gained through the acquisition of Opsys in 2002. Sumitomo and CDT have been working together since 2003 on the dendrimer class of materials and have made great progress. Sumitomo became a CDT licensee in 2001 and also invested in the UK company.

The JV is expected to increase the pace of development of P-OLED materials, and in turn this is expected to accelerate the adoption of the technology in the next generation of consumer products such as mobile phones, portable DVD players and ultimately televisions.

“Sumitomo Chemical has been committed to the development of P-OLED materials since 1989 and has accumulated a substantial technology base which includes technology relating to design and product manufacture,” said Mr. Satoshi Kawachi, Executive

VP of Sumitomo Chemical. “CDT owns advanced technology regarding P-OLED devices and materials.

Combining the strengths of the two companies, along with former Dow technology, the joint venture will accelerate significantly the development of innovative materials and be able to respond to our customers' requirements.”

• www.cdtltd.co.uk

• www.sumitomo-chem.co.jp/english

Sumitomo Chemical acquires Lumation LEP business from Dow

Sumitomo Chemical Co., Ltd. has purchased the

Lumation light-emitting polymers (LEPs) business from The Dow Chemical Company. Financial terms were not disclosed. LEPs are the critical lightemitting material in polymeric LEDs (PLEDs), which are one class of OLEDs.

"Lumation LEPs represent an important, and potentially disruptive, advance in OLED technology," said George Biltz, Business VP, Dow Ventures and

Purchasing. "However, without a larger portfolio of offerings to the display industry, Dow does not have the market presence to rapidly advance its further development and adoption."

Sumitomo Chemical, on the other hand, has extensive experience in the flat-panel displays market and should be able to more rapidly further the development and commercialization of Lumation

LEP technology.

Sumitomo Chemical has already developed fluorescent and phosphorescent LEPs based on its long-established display material and conducting

The company's blue-color material has achieved 10,000 hours of brightness half-life, and is ideal for a printing method, a much simpler and more cost effective production process

Copyright © 2005 Cabot Media Ltd and IOP Publishing Ltd. - 5 -

for large-sized displays than the vacuum deposition method used for small-molecular OLEDs.

Sumitomo Chemical said that, as well as broadening its product line, the combination of its own proprietary technology with Lumation LEP technology would stimulate new developments. "We believe this acquisition will accelerate our R&D activities and greatly facilitate the application of our technologies not only to displays, but more broadly to solid-state lighting applications," said Satoshi

Kawachi, Executive VP of Sumitomo Chemical.

Dow had several supply agreements in place, including one dating back to February 2004 with

Osram Opto Semiconductors, under which Dow supplied Lumation LEPs for incorporation into

Osram's Pictiva PLEDs. Dow also had a similar agreement with MicroEmissive Displays (MED).

• www.sumitomo-chem.co.jp/english

• www.dow.com

Kodak licenses OLED technology to Fuji

Eastman Kodak Company has announced Fuji

Electric Holdings Co., Ltd. of Japan as the latest licensee of Kodak’s OLED technology.

OLED Update – May 2005

Fuji Electric is applying its license toward development of its own color conversion matrix

(CCM) full-color OLED display technology with the intention of offering flat-panel passive matrix (PM) displays.

The royalty-bearing license to Fuji Electric covers use of passive-matrix OLED modules in a variety of flat panel display applications and includes a crosslicense under Fuji Electric's own considerable patent portfolio in the OLED technology field. The agreement also gives Fuji Electric the opportunity to purchase Kodak's patented OLED materials for use in manufacturing displays.

Fuji Electric's CCM technology uses a production technique the company calls the "metal mask-less organic film deposition method," for dramatic improvement in manufacturing yield rate, and greater reliability in superior full-color PM displays.

Fuji Electric's research and development company, Fuji Electric Advanced Technology Co.,

Ltd., also obtained the technology to increase both luminous efficiency and longer lifetime in CCM displays.

Fuji Electric joins 15 other companies that have licensed Kodak’s OLED technology, which has been in development since the late 1980s and has generated more than 150 Kodak patents.

• www.kodak.com/go/display

CONTRACT AWARDS

Universal Display awarded $1.7 million to develop wristwatch phone

Universal Display Corporation has been awarded a two-year, $1.7 million Small Business Innovation

Research (SBIR) Phase III contract by the US

Department of Defense to continue its development of flexible OLED display technology for a nextgeneration military communications device.

Universal Display is to develop and deliver functional prototypes of a “Portable Flexible

Communication Display Device”, which will be form-fitted to a soldier's wrist and communicate wirelessly to a nearby computer, thereby enabling soldiers to see crucial video and graphics information in real time.

The device will use a full-color, active-matrix

(AM) OLED display built on metal foil. The use of metal foil substrates can lead to a rollable, retractable and rugged display with a small and lightweight form factor for use in portable communication devices.

Universal Display's FOLED® flexible OLED technology, combined with its TOLED® topemission OLED technology, enables the use of

Copyright © 2005 Cabot Media Ltd and IOP Publishing Ltd. - 6 -

flexible metal foil as a substrate material. With a 4inch diagonal screen, the 320 x 240 pixel (QVGA format) AMOLED display will also use Universal

Display's proprietary high-efficiency PHOLED™ phosphorescent OLED technology and materials.

Funded through the U.S. Army's Communication

Electronics Research and Development Engineering

Center (CERDEC), in Ft. Monmouth , N.J. , this

SBIR Phase III contract builds on Universal Display's successful work funded through its current Phase II contract and two other ongoing programs with the

EQUIPMENT & MATERIALS

Litrex ships large inkjet production systems

Litrex Corporation has shipped the two M-Series large-format inkjet printers to a leading display maker in Asia. The printers can be used to print displays using polymer OLEDs, and can also deposit such materials as nano-metals.

Inkjet printing is increasingly becoming recognized as the premier scaleable technology for fabrication of small, medium and large OLED displays on large substrates. It allows highly accurate pixel printing for high-resolution displays, while the ability to utilize large substrates is essential to the cost competitiveness of all flat-panel display technologies. The M-Series tools are designed to print on glass substrates upwards of Gen 4 (730 x 920 mm). This ability is expected to enable the production of P-OLED based televisions.

Cambridge Display Technology (CDT) owns

50% of Litrex, with the remaining share owned by

Ulvac Inc. of Japan, a leader in vacuum deposition for displays. Litrex in located in Pleasanton,

California

David Orgill, president and CEO of Litrex, said:

"Inkjet is quickly being recognized as offering significant cost savings over traditional deposition processes such as bulk deposition, lithography, and etching, as well as being the sole manufacturing method for making large flat-panel organic displays."

• www.litrex.com

OLED Update – May 2005

U.S. Army Research Laboratory and the U.S. Air

Force Research Laboratory.

In Phase III SBIR program's, previouslydemonstrated prototypes are further developed into commercial prototypes and subsequent products for sale in the military and/or private sector, so a Phase

III award is a strong endorsement of a technology's potential for military applications.

• www.universaldisplay.com

Vitex Systems receives system order from

Korean OLED maker

Vitex Systems Inc., a provider of encapsulation films used in the production of OLED displays and organic semiconductors, has received a major order from a leading Korean OLED display manufacturer. The order is for Vitex's Guardian thin-film encapsulation system, which is slated for shipment this August.

Malcolm Thompson, CEO of Vitex, said that the two companies are "disrupting the industry's current manufacturing norm" by working to integrate thinfilm encapsulation in-situ with OLED device fabrication.

OLEDs are extremely sensitive to moisture and oxygen. Enabled through the Guardian tool, Vitex applies a thin-film barrier encapsulation (Barix) directly on top of an OLED display, eliminating the bulky mechanical packaging components (protective sheet of glass/metal can, desiccant, glue, etc.) commonly associated with traditional display manufacturing, while at the same time providing the stringent moisture and oxygen protection required by an OLED display. As a result, displays leveraging

Vitex's Barix technology are 50-to-90-percent thinner and lighter in weight, extremely robust and significantly lower in cost.

Vitex has also established a wholly owned subsidiary, Vitex Systems Korea, Co., Ltd.

• www.vitexsys.com

Copyright © 2005 Cabot Media Ltd and IOP Publishing Ltd. - 7 -

Universal Display acquires Tokki deposition equipment for flexible OLED displays

Universal Display Corporation has announced the successful installation and start-up of a novel fullcolor OLED deposition system at its technology development center in Ewing, New Jersey. Designed and built by Tokki Corporation and sold through

Hitachi High-Technologies Corporation, and using novel features designed by Tokki and Universal

Display, the ELVES020C OLED Deposition System can produce OLED displays on both rigid glass and flexible substrates (e.g. metallic foil, and plastic).

OLED Update – May 2005

“This novel Tokki system greatly expands our capacity for prototyping a variety of full-color OLED displays and is particularly important in the pursuit of our flexible display initiative,” said Steven

Abramson, president and COO of Universal Display.

The multi-chamber, semi-automatic deposition system is designed to deposit a variety of organic and metallic films using vacuum sublimation and evaporative techniques with high-resolution patterning capabilities and an entirely new design for handling substrates including plastic, metallic foil and glass, whether they are transparent, opaque, rigid or flexible.

• www.universaldisplay.com

FINANCIAL RESULTS eMagin

eMagin Corporation reported revenue for the three months ended March 31, 2005 of $0.7 million, an increase of 28 percent from $0.5 million in the first quarter of 2004.

As anticipated the results reflect limited production output as eMagin accommodates reconfiguration of its plant and processes toward monthly output of 15,000 to 20,000 microdisplays in

2005. This compares to a typical average output of

1,000 - 2,000 units per month in 2004.

Net loss was $3.5 million, or $0.04 per share as compared to a net loss of $6.6 million or $0.13 per share during the three months ended March 31, 2004.

"I'm pleased to report that we believe that we've completed the first phase of the critical step of updating our Hopewell Junction fabrication facility to accommodate the much higher output levels we anticipate this year," said Gary Jones, eMagin's CEO.

Jones also said that the company predicts initial shipping availability of its first commercial Z800 3D

Visor units (see page 2) to begin by the end of this quarter.

• www.emagin.com

Universal Display

Universal Display reported revenues of $1.5 million for the quarter ended March 31, 2005, compared with

$2.1 million for the comparable quarter in 2004.

Revenues consisted of $699,056 from government contract research, $444,757 from development and commercial chemical revenue, royalty and license fees totaling $73,255, and $250,000 in technology development revenue from business partners.

For the quarter, Universal Display reported a net loss of $4.9 million, or $0.18 per diluted share, compared with a net loss of $4.1 million, or $0.17 per diluted share for the first quarter of 2004. During the first quarter of 2005, cash used in operating activities was $1.2 million, compared to $1.9 million for the first quarter of 2004.

“The reduction in cash used in operations is important to Universal Display, as payments from customers, whether recorded as revenues, deferred revenues or deferred license fees, represent progress towards our goal of industry adoption of our OLED technologies,” said Sidney Rosenblatt, CFO.

“In addition, after the end of the quarter we signed an OLED patent license agreement with

Samsung SDI Co., Ltd., paving the way for Samsung

SDI to integrate our proprietary OLED technologies

Copyright © 2005 Cabot Media Ltd and IOP Publishing Ltd. - 8 -

OLED Update – May 2005 into Samsung SDI's active-matrix OLED display products.”

“Looking ahead, we remain strong from a cash perspective. Our balance sheet strength should serve us well as we drive the commercialization of our

OLED technologies.”

• www.universaldisplay.com

Cambridge Display

Technology

Cambridge Display Technology, which completed its initial public offering in December 2004, reported revenues of $1.6 million for the first quarter of 2005, up 19% from $1.3 million for the corresponding quarter in 2004.

The majority of revenues arose from Technology

Services and Development and included receipts from several major display producers with whom the company is currently engaged in development programs, including Kolon, Samsung Electronics and

Sumitomo Chemical.

Net loss decreased to $8.7 million for Q1 2005, from $17.7 million in Q1 2004. Cash used in operations was $5.9 million for Q1 2005, up from

$3.8 million in Q1 2004. $1.4 million of the increase was due to the settlement of liabilities relating to the company's IPO and to the acquisition of Opsys

Limited in December 2004.

CDT says that its operating results fluctuate significantly from quarter to quarter as licensing and other contract negotiations are concluded and revenues become recognizable. At March 31, 2005,

CDT had $8.6 million in current deferred revenues, which it expects to recognize as revenue during the remainder of 2005.

R&D expenses of $4.0 million were slightly higher in Q1 2005 than in Q1 2004 ($3.7 million).

These levels of expenditure underscore the company's commitment to the continued development of its technology and support for its licensees and partners.

During Q1 2005, CDT made a strategic investment of $1.0 million in cash, as well as a paidup license to certain of its intellectual property, in

Add-Vision, a US-based developer of emissive polymer technology, and loans of $1.3 million to

Litrex.

CEO David Fyfe comments: "We are pleased with the progress being made in our strategy of gaining the interest and commitment of display producers for our P-OLED technology. The display industry requires substrates larger than the current

Gen 2/2.5 prevalent for OLED manufacture (to produce larger displays and for economical reasons), and our belief that P-OLEDs represent the most scaleable OLED technology is gaining more widespread industry acceptance. We continue to expect strong revenue growth in 2005."

• www.cdtltd.co.uk

OLED Update

OLED Update is a monthly publication from LEDs

Magazine.

Visit our OLEDs channel at: www.LEDsMagazine.com/articles/features/1/4/9/1

Copyright © 2005 Cabot Media Ltd and IOP Publishing Ltd. - 9 -