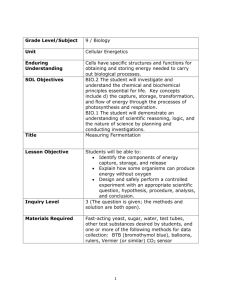

Section 3 - The Alcoholic Fermentation Lesson 8

advertisement