Electroplating Leaves - Breck School Science

advertisement

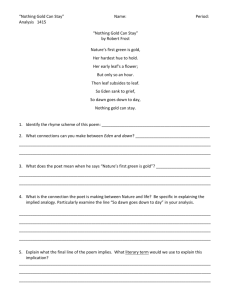

Electroplating Leaves 2001 In my research proejct, I electroplated leaves with copper. This was an unique experience that transformed an ordinary leaf into a bright, shiny, copper plated leaf. I tested how time affected the amount of copper that was electroplated and whether or not the aquarium bubbler also made a difference in the amount plated. To do this, it was necessary to get a clear understanding of what electroplating really is and what it is used for. After learning as much as I could, I was able to successfully do the lab and understand my results. Electroplating is used to make jewelry and utilizes some of the basic properties of chemistry. It is the process of covering something with metal permanently (Newman 12). Stone, metal, plastic and fabric can be covered by almost any type of metal. In my research experiment, I electroplated dried leaves with copper. It is a beautiful process to watch an ordinary leaf turn to vibrant copper. In electroplating, there are anodes and cathodes. For copper plating, the anodes are copper slabs submerged in the copper sulfate solution. They are also where oxidation takes place. The cathode is the object which is plated. In my experiment, the leaf is the cathode. It is also where reduction takes place (Metcalfe 543). For better understanding, it should be known that oxidation is the process of losing electrons and reduction is when electrons are gained (Fruen 252). In the set up for electroplating there is also a power supply and an ammeter. The ammeter measures the current and the flow of the electrons. The power supply gives off the electricity necessary to electroplate. Copper is reduced from the anode to copper ions. This process helps to maintain the concentration of copper ions in the electrolyte solution, which is basically a copper sulfate solution. The electrons then flow to the positive electrode of the power supply through a copper wire. The electrons leave the power supply through the negative electrode and flow to the positive electrode of the ammeter. From the negative electrode, they flow to the cathode, which is the leaf, and plate. However, the leaf itself is not conductive. Therefore, the leaf is painted with a silver conducting paint (Newman 17). In my research project, I tested three variables. I researched whether the use of the aquarium bubbler, stirring the solution, was vital to increasing the amount of copper that is electroplated. Another factor I determined was how the amount of time affected the amount of copper plated. I tested different plating times and actually broke each set of time into smaller intervals. Through my research, I gained a better understanding of copper electroplating leaves. Purpose: The purpose of my research experiment was to see how time affects the amount of copper electroplated onto a leaf. I also determined whether breaking the amount of time into intervals affected the amount. I also tested to see if more copper electroplated with the aquarium bubbler or without. Procedure 1: Continuous Time 1 I picked out six leaves, both ginkgo and maple. Around the first leaf, I wrapped a 18-gauge wire. I then painted the entire leaf with silver conducting paint under the fume hood, being sure to paint both sides. Then, I found the mass. wire #26 o r 28 bare s ilver painted leaf wire #18 o r 16 wire bare I filled the electroplating bath with a copper sulfate solution that had been made from 750 grams of CuSO4 (H20)5, 80 mL of 0.1M hydrochloric acid, and 280 mL of 6M sulfuric acid. To the solution was also added 25 mL of brighter that can be added whenever needed at 5 mL intervals. I then attached an alligator clip to the leaf and connected the leaf with a copper wire to the positive outlet of the ammeter. Two wires connected the copper plates from the electroplating bath to the positive outlet of the power supply. The negative outlet of the power supply was connected to the negative outlet of the ammeter. I poured the copper sulfate solution into the electroplating bath so that it covered the entire leaf. The aquarium bubbler was turned on and placed in the bath. I set the ammeter at a range of 1.0 and 1.5 amperes. I turned on the electroplating bath and left the leaf in there for twenty minutes. I repeated steps #1-#8 for different leaves increasing the amount of time by twenty minutes until the amount of time spent in the bath is 80 minutes. Every time any leaf was taken out of the bath, it was rinsed in water and acetone and dried on paper towel and then weighed. Procedure 2: Time Interval Follow the set up of the electroplating bath from procedure 1, steps 1-5. I took one leaf and placed it in the bath. I then removed the leaf after twenty minutes and repeated the last step in the previous procedure. I then placed the same leaf in the bath for another twenty minutes. Working my way up by twenty minute intervals until the leaf total time in the bath was eighty minutes. I compared the weight of this leaf and the amount of copper electroplated to the leaves in procedure 1 who remained in the bath for continuous times. Procedure 3: Aquarium Bubbler I set up the electroplating bath and the leaf the same way as in the previous procedure. The leaf was placed in the electroplating bath for twenty minutes with the aquarium bubbler on. I took the leaf out, rinsed it with water and acetone and weighed. I prepared a second leaf with the wire and paint and put it in the bath for twenty minutes without the aquarium bubbler on. Results The first graph shows the effects of time and the second graph shows the effects of the aquarium bubbler on the amount of copper electroplated. The graph on the mass of copper electroplated compared to time shows that breaking the amount of time the leaf is electroplated does not affect the amount of time electroplated. The first leaf was put into the bath for eighty minutes, broken up by twenty minute intervals. After the first twenty minutes, the amount of copper plated was 0.700g. After plating for another twenty minutes, for a total of forty minutes, the amount of copper plated was 1.36 g, or 0.660 g for the second twenty minutes interval. Leaf #2 was placed in the bath for exactly 40 minutes. The amount of copper plated was then 1.22 g. Compared to the leaf #1, they differed only 0.14 g. That is a fairly insignificant number that can be blamed on human error. I continued to electroplate leaf #1 for another twenty minutes, for a total of 60 minutes. The amount of copper was 2.00 g. Leaf #3 was electroplated for 60 minutes and the copper plated was 1.81g. This varied from leaf #1, with a difference of 0.19 g. At this point in the lab, I noticed that the leaf that was electroplated continuously plated less copper than the leaf that had been broken into twenty minute intervals. Leaf #4 was plated for 80 minutes and had 2.45 g plated. The interval leaf plated 2.63 g. This showed that my assumption was correct that the interval leaf plated more than the continuos leaf in each case. The graph on the aquarium bubbler shows that the leaf plated with the bubbler ended up with more copper than the leaf plated without the bubbler. Leaf #5 had no bubbler and plated 0.26 g. Leaf #6 had the bubbler and plated 0.68 g. This difference of 0.42 g is significant enough to assume that the bubbler affects the amount of copper plated. this can be attributed to the fact that the bubbler stirs the copper sulfate solution, keeping the ion distribution equal. We only tested this once, and to achieve a better result and conclusion we could test more leaves and at different time intervals. However, I would go into those labs with the hypothesis that the leaves with the bubbler will plate more than the leaves without. In conclusion, I was able to determine that that how the time was administered did not make a significant difference in the amount of copper electroplated. As the graph shows, all four leaves head generally in the same direction. The fact that they vary slightly could be because of human error or problems with my apparatus. It was determined that the aquarium bubbler did make a difference, though not a very large one. The bubbler serves an important function of stirring the solution which results in a greater equal distribution of copper ions. This lab taught me about different ways to investigate a problem in the laboratory. Electroplating is a difficult process where many intervals could be introduced. WORKS CITED Fruen, Lois. The Real World of Chemistry. 4th ed. Dubuque: Kendall/ Hunt Publishing Company, 2000. Metcalfe, Clark H., John E. Williams and Joseph F. Castka. Modern Chemistry. New York: Holt, Rinehart and Winston Publisers, 1998. Newman, Lee Scott and Jay Hartley Newman. Electroplating and Electroforming for Artists and Craftsman. New York: Crown Publishers, Inc., 1999. Warburton, L. Electroplating for the Amateur. Hertfordshire: Model and Allied Publications, 1998.