“Good shoes are made in good facto-ries

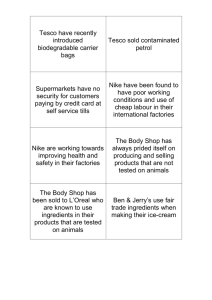

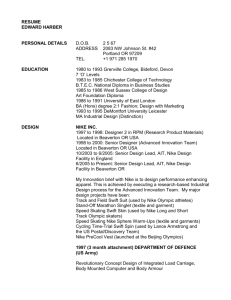

advertisement

NIKE in Southeast Asia SOURCE: This case study was written by William H. Heuer and Ilkka A. Ronkainen. The contribution of André Gamrasni is appreciated. For more information, see http://www.nike.com/faq/ for the Nike point of view, and http://www.caa.org.au/campaigns/nike/index.html for an example of the criticism. “G ood shoes are made in good facto-ries. Good factories have good labor relations.” These are the words from Nike’s chairman and CEO Phillip Knight responding to an attack on the company’s labor relations. Over the past few years, Nike has had to answer a number of charges regarding its labor practices in its Southeast Asian plants. Nike celebrated its 25th anniversary during the summer of 1997. Since its inception from the back of chairman and CEO Philip Knight’s car, Nike has grown into one of the most successful companies in the sports apparel industry. In 1972, the company began with seven models of shoes and collected $3 million in sales that first year. Sales of Nike athletic shoes have continued to grow over the past 25 years. Shoe sales reached $2.2 billion in 1990 and $9.2 billion at the end of 1997. Nike’s amazing growth is the result of an effective international marketing and promotion strategy. The company’s sponsorship of Michael Jordan, Tiger Woods, and other top athletes helped Nike become associated with high-performance athletics. In addition, the company’s motto “Just Do It!”is one of the most recognizable in the world and has become a part of popular culture. These are just a few examples of the shrewd moves that helped fuel Nike’s rapid growth. Another essential factor of Nike’s success is its ability to limit labor expenses. Since its inception the company has attempted to find the least expensive labor to manufacture its shoes, often finding Southeast Asia to offer the most attractive labor setting. Nike subcontracts production to a number of independent facilities throughout Asia for manufacturing of its shoes and its sportswear and concentrates itself in the design, marketing, and technology of footwear and apparel. Traditionally, the company located in markets where labor unions were not very strong or were illegal. With the support of the governments in these countries, Nike limits its exposure to labor problems and keeps costs low. These facilities allow Nike to assemble and ship shoes for a cost of $22.50, then sell them in the United States for $90 (see Figure 1). In some cases, such as South Korea and Taiwan, Nike even moved production facilities after workers gained significant individual rights and labor costs began to rise. While these moves may have helped Nike’s profitability, it opened the company up to increased criticism for creating sweatshop conditions in these plants. Nike began to face increased allegations of worker mistreatment in the early 1990s, forcing the company to develop some guidelines for its subcontractors to follow. In 1992, Nike introduced its first Code of Conduct document. The Code was designed to illustrate the company’s commitment to improving workers’ rights in all respects. (A summary of the code’s provisions are provided in Table 1.) In addition, the Code requires that management respect individual workers’ right to form a union and forbids management from harassing, abusing, or punishing employees. Although the guidelines are in place, many subcontractor plants still do not follow the code. Even after the Nike Code of Conduct was adopted, the company faced continued criticism concerning its labor relations. Nike defended itself by saying that employing 500,000 people worldwide in contract manufacturing makes it very difficult to enforce the code, especially when Nike does not own the factories. Many people, however, doubted Nike’s desire to enforce its own Code of Conduct. Critics believed that strict enforcement of the Code would raise production costs for the company. In September 1997, Nike terminated its contract with four subcontractors in Indonesia. The company stated that the four factories did not comply with Nike standards in three important areas: overtime requirements, physical work environment, and meeting minimum wage requirements. According to the company, the move represented an effort by Nike to improve the labor conditions in the subcontracted facilities. Nike did not name the factories, although the company did state that they were not shoe manufacturers. By not mentioning the production facilities, Nike kept open the option that it would use the factories once they were able to meet Nike standards. While Nike acknowledged the move in Indonesia as a positive move, many critics felt that the company was just attempting to counter recent criticism over its labor practices in Asia. In either case, Nike has become the most visible target for exploitation of labor by large multinational corporations. The company realizes the damage that these allegations cause to its reputation and its business; however, the company does not seem to have the answer to ending the problem. QUESTIONS FOR DISCUSSION 1. What recommendations would you offer Nike for dealing with the allegations of labor exploitation in Asia? 2. What value does the Code of Conduct offer to Nike? How can the company ensure proper adherence to the Code? 3. Should Nike cancel contracts with these facilities if they do not meet Nike’s requirements? What about the company’s responsibility to the workers employed in these facilities? Does Nike have better options besides termination of the production contract? 4. Are there differences between Nike’s responsibility to its shareholders and its responsibility to its stakeholders? 5. Do you think Nike should be responsible for the labor practices in subcontracted facilities? What should be its level of responsibility? FIGURE 1 Cost of a Pair of Nike Shoes TABLE 1 Excerpts from the Nike Code of Conduct NIKE designs, manufactures and markets products for sports and fitness consumers. At every step in that process, we are driven to do not only what is required, but what is expected of a leader. We expect our business partners to do the same. Specifically, NIKE seeks partners that share our commitment to the promotion of best practices and continuous improvement in: 1) Occupational health and safety, compensation, hours of work and benefits. 2) Minimizing our impact on the environment. 3) Management practices that recognize the dignity of the individual, the rights of free association and collective bargaining, and the right to a workplace free of harassment, abuse or corporal punishment. 4) The principle that decisions on hiring, salary, benefits, advancement, termination or retirement are based solely on the ability of an individual to do the job. Wherever NIKE operates around the globe, we are guided by this Code of Conduct. We bind our business partners to these principles. While these principles establish the spirit of our partnerships, we also bind these partners to specific standards of conduct. These are set forth below: Forced Labor (Contractor) certifies that it does not use any forced labor—prison, indentured, bonded or otherwise. Child Labor (Contractor) certifies it does not employ any person under the minimum age established by local law, or the age at which compulsory schooling has ended, whichever is greater, but in no case under the age of 14. Compensation (Contractor) certifies that it pays at least the minimum total compensation required by local law, including all mandated wages, allowances and benefits. Benefits (Contractor) certifies that it complies with all provisions for legally mandated benefits, including but not limited to housing; meals; transportation and other allowances; health care; child care; sick leave; emergency leave; pregnancy and menstrual leave; vacation, religious, bereavement and holiday leave; and contributions for social security, life, health, worker’s compensation and other insurance. Hours of Work/Overtime (Contractor) certifies that it complies with legally mandated work hours; uses overtime only when employees are fully compensated according to local law; informs the employee at the time of hiring if mandatory overtime is a condition of employment; and, on a regularly scheduled basis, provides one day off in seven, and requires no more than 60 hours of work per week, or complies with local limits if they are lower. Health and Safety (Contractor) certifies that it has written health and safety guidelines, including those applying to employee residential facilities, where applicable; and that it has agreed in writing to comply with NIKE’s factory/vendor health and safety standards. Environment (Contractor) certifies that it complies with applicable country environmental regulations; and that it has agreed in writing to comply with NIKE’s specific vendor/factory environmental policies and procedures, which are based on the concept of continuous improvement in processes and programs to reduce the impact on the environment.