Sample Engineering Brief 2

advertisement

LEAVING CERTIFICATE

EXAMINATION 2011

Engineering project

Higher level

Examination number:

1

Contents:

Introduction........................................................ 3

Analysis of Design Brief....................................... 4

Investigation of Solutions.....................................7

Criteria for Selection of Solutions..........................

Production Drawings........................................

Electronics........................................................

Testing and Evaluation......................................

2

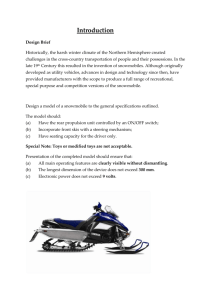

Introduction:

Historically, the harsh winter climate of the northern hemisphere created

challenges in the cross country transportation of people and their

possessions. In the late 19th Century this resulted in the invention of

snowmobiles. Although originally developed as utility vehicles, advances

in design and technology since then, have provided manufactures with

the scope to produce a full range of recreational, special purpose and

competition versions of the snow mobile.

3

Analysis of design brief:

Design a model of a snowmobile to the general specifications

outlined.

The model snowmobile should:

(a) Have the rear propulsion unit controlled by an ON/OFF switch;

(b) Incorporate front skis with a steering mechanism;

(c) Have seating capacity for the driver only.

Presentation of the completed model should ensure that:

(a)

All the main operating features are clearly visible

without dismantling.

(b)

The longest dimension of the device does not exceed

300 mm.

(c)

Electric power does not exceed 9 volts.

4

Key words and their dictionary

definitions:

Model: A miniature representation of a thing, with the several

parts in due proportion; sometimes, a facsimile of the same

size.

Snowmobile: Is a land vehicle for winter travel on snow.

Rear propulsion: Propulsion - means to push forward or drive

an object forward.

Controlled: to exercise restraint or direction over; dominate;

command.

ON/OFF Switch: a device for turning on or off

Incorporate: unite or merge with something already in

existence, have as a component.

Skis: A ski is a long, flat device worn on the foot designed to

help the wearer slide smoothly over snow, plural.

Steering Mechanism: A mechanism by which something is

steered.

Seating/the driver only: You have to have a seat for one

person.

Handle bars: Metal tube used to steer the snowmobile.

5

What is a Snowmobile?

• A snowmobile, also known in some places as a snow

machine, sled, or skimobile, is a land vehicle for winter

travel on snow.

• Designed to be operated on snow and ice, they require no

road or trail.

• Design variations enable some machines to operate in deep

snow or forests; most are used on open terrain, including

lakes or driven on paths or trails.

• Usually built to accommodate a driver and perhaps one adult

passenger, their use is much like motorcycles and All-terrain

vehicles (ATVs) intended for winter use on snow-covered

ground and frozen ponds and waterways.

• They have no enclosure other than a windshield and its

engine normally drives a continuous track or tracks at the

rear; skis at the front provide directional control.

6

Investigation of solutions:

Here are some images of Snow mobile designs that I found,

which heavily affected my design process.

7

8

There are various designs for Snowmobiles. They are all based around the

same design principles as given in the design brief.

Here, I will talk about detailed analyses of the basic existing designs:

Basic Design of Snow Mobiles:

Tracks and Steering:

Snow mobile tracks are made of a light material for mobility

and speed, while a handlebar/ski mechanism steers

snowmobiles.

Tracks succeed where wheels often fail; they spread the vehicle

weight over a greater surface area, allowing it to move on soft,

slippery or unstable terrain where wheeled vehicles are unable

to gain traction. Tracks keep a heavy snowmobile from sinking

in soft snow, just as long, flat skis and wide, flat snowshoes

spread a person's weight over a larger area.

Snowmobile tracks also provide traction on slippery surfaces

like snow and ice, where regular wheels would slip and slide.

The large surface area and the roughness of the treads create

friction between the snowmobile and the surface, giving the

snowmobile a better grip. Most snowmobiles add sharp studs to

their tracks; these act like cleats on athletic shoes and sink a

short distance into the ice or hard snow, gouging small holes

9

that enable the tracks to grip the ice even tighter on

particularly slippery terrain.

Handlebars:

You steer a snowmobile by turning the handlebars, in much the

same way as you steer a bicycle or motorcycle. The handlebars

connect to a stem mounted near the front of the snowmobile,

which in turn connects to skis mounted on a bracket at the

bottom of the snowmobile. Turning the handlebars turns the

skis in the same direction.

10

Skis:

Snowmobile skis come in varying widths and sizes for different

terrain, as well as single or double-ski models. Wider skis

displace the snowmobile's weight over a larger area, enabling it

to "float" higher over the snow, while narrower skis allow for

sharper turns.

Shock absorbers play a large part in providing a comfortable

and stable ride. Springs and dampers are used in a manner

similar to mountain bikes, enabling the rider to pilot their

vehicle with the mobility of skis, but the stability of a tracked

vehicle.

11

Engine:

Heavier touring models tend to use the four-stroke engine,

while the lighter, sportier models use the two-stroke.

A snowmobile engine links to a track drive, which rotates the

tracks. The wheels on a snowmobile are essentially large gears

with teeth spaced evenly with holes in the tracks. Every

rotation of the gears powers the tracks and drives the

snowmobile forward. The faster the engine, the faster the

gears rotate, and the faster the tracks move.

Snowmobiles also have a clutch system that is a type of pulleybased CVT (Continuously Variable Transmission). This system

consists of two pulleys, or clutches, connected by a drive belt.

The primary clutch sits on the engine crankshaft. A pressure

spring holds the primary's two halves apart when the engine

rpm is low. As the engine begins to accelerate, the clutch

weights generate enough centrifugal force to close the clutch,

allowing the belt to move freely and transmit power.

12

13

The secondary clutch connects to the track drive, which turns

the wheels and powers the tracks. A spring in the secondary

clutch operates the cams, which are sensitive to torque. As the

engine's RPM increases and the primary transmits power, these

cams squeeze together and tighten the belt. The process

continues as the snowmobile accelerates. Once it reaches its

top speed, the primary clutch closes, moving the belt into a

higher "gear." Because the snowmobile needs less power to

accelerate than it did to get going, the secondary clutch opens.

Criteria for selection of solution

Possible Designs:

I chose two possible designs, A and B. I chose idea B because

over all its was a simplier, cost effective and a more sufficient

design. I only have a certain amount of time to complete this

project, so the simpliest design would be a logical choice. It

only involved the use of 8 sprockets and 4 chains, rather than

Design A that involved the use of 12 sprockets and 6 chains,

which just caused unecassary complication of the rear

propulsion system, making it awkward and cumbersome!

The chains and gears are also very expensive, costing E9.99

for a set of 670mm chain and E4.99 for the sprockets varing on

sizes, so this was also an important factor to take into account.

After my research on the designs of Snow mobiles I found one

similarity which was a basic frame, I began my project by

producing a frame made of aluminium, this was to hold

14

everything into place, so it was vital! Aluminium is a light

weight but yet strong material, perfect for my design. As I talk

about in the ‘Manufactoring Processes’ pg. 16, I drilled holes

into the side of the frame at varies sizes, this was an

imporovement form design A, as they are both aluminum

frames, this is a small improvement on its design, but has a

great effect on the performance of the vehicle.

I could have used aluminium as the body of my frame, but i

wanted to make the vehicle as light as possible, so it can travel

fast. I decided to use a polymer frame instead. Not only does it

look better, but its a lighter material.

Finally, I will talk about the steering system I incorporated into

my design, the Pantograph system, this involved the use of 5

small rectangular pieces of aluminium, of size {..}. If they are

placed into the right position and the centre leg pivited as you

can see in my drawings, they demonstrate the basic

pantograph system.

These small improvements can change the performanceof the

drastically.

15

Manufacturing process

Frame:

I chose to use aluminium as the material for my frame, it is a

light but strong material, which will be a great feature, as it will

have to hold the seating compartment and the electronics, but

also I need my snowmobile to be lightweight, as it may have to

travel fast on the snowy terrain. I began with a rectangular

piece of aluminium of [……] in size. I marked out my bending

lines. I drilled holes into the side of the frame, this is a positive

aesthetic point but also helps in the design of the snowmobile,

and these holes allow the snow to pass through as it travels on

the snow. The use of light weight material and drilling of the

side panel holes increases the power to weight ratio which will

beneficial to the performance of the machine. I drilled four

holes, two on each side for the axels. As I was using bevelled

gears, I had to cut out a small rectangular piece from my

frame to allow the bevelled gears to spin. I rounded the

16

corners off with a file for aesthetic appeal and safety. I then

bent the frame at 90 degrees on each side.

(PHOTO)

Axels:

The axels were very simple to design; I got two lengths of

4mm […] steel bar and threaded them with a die tool. I

threaded them with a 4mm die.

(PHOTO)

Body:

The body of my snowmobile was made from … black acrylic.

Originally, I had made a polymer body, from a thin sheet of red

polymer. I formed a mould out of clay; I designed it

aerodynamically so when it travelled there would be less drag.

After, I placed a sheet of red polymer on to the vacuum

former. It formed a great piece, with a lovely finish but

unfortunately, it would not fit on to my frame correctly, so due

to time constraints I made a simple acrylic piece. I got a

17

rectangular piece of black acrylic of size […X…] and marked out

bending lines. I also centre punched the markings for where I

would be drilling the hole for the steering columns, for the bulb

and L.E.D fittings. After completing this, I bent the acrylic

pieces into a stylish angle; I found doing this it more appealing

than a box shape.

(PHOTO)

Track:

In my design, I decided to use a similar design as a track but

using chains instead. I bought the chain and then assembled

them in the workshop, these work equally as well as the track

system, but not as expensive. The chains move by the rotation

of the gears on the rear axle spun by the motor, for this to

work, I attached bevel gears on to the end of the motor and on

to the axis. This allowed the chains to run smoothly.

(PHOTO)

Steering:

For my steering, I had thought of a couple of designs, but

eventually used the simplest and most effective design, the

Pantograph system. The Pantograph is made up of

18

Skis:

My skis were also made from black acrylic. I designed, marked

and measured out the style and size of skis I wanted on to two

rectangular pieces of acrylic using a scriber and ruler. I centre

punched the middle of each ski; this is where I would slot the

steering column connected to my Pantograph steering system.

I created a small bend at the top of my ski on the heated

bender for style and functionality.

(PHOTO)

Secondary Frame:

Initially I was not going to have a secondary frame, but I

needed to make one, as I had not taken into count where the

19

skis would be fitted. This Secondary frame allows the skis to fit

perfectly into my design without hitting off the moving chains

and sprockets. I cut a rectangular piece of aluminium of size

[….] I marked, centre punched and drilled 2 holes, these would

allow me to attach the secondary frame on to my initial frame.

I then drilled another two holes; these would allow me to fit on

the acrylic body and steering system for my snowmobile. I

marked where it was to be bent with the scriber and right

angle tool. I bent the sheet on the box pan bender.

(PHOTO)

20

Electronics

My project required:

One Key Switch.

4 chains and 8 sprockets.

21

One double poll double throw switch.

One mm28 motors (one with gearbox)

22

2 fixed L.E.D’s

23

A battery snap

2 Bevelled Gears

24

2 Bulbs

Investigation of Control

Circuits:

Circuit 1 -

25

Circuit 2 – Motor Control: DPDT

Circuit No. 3 – On / Off and Reversing

26

Evaluation

Things that I would change

Overall opinion

27

Drawings

Please see enclosed drawings from design stage.

28